Method and apparatus for cooling concrete during curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

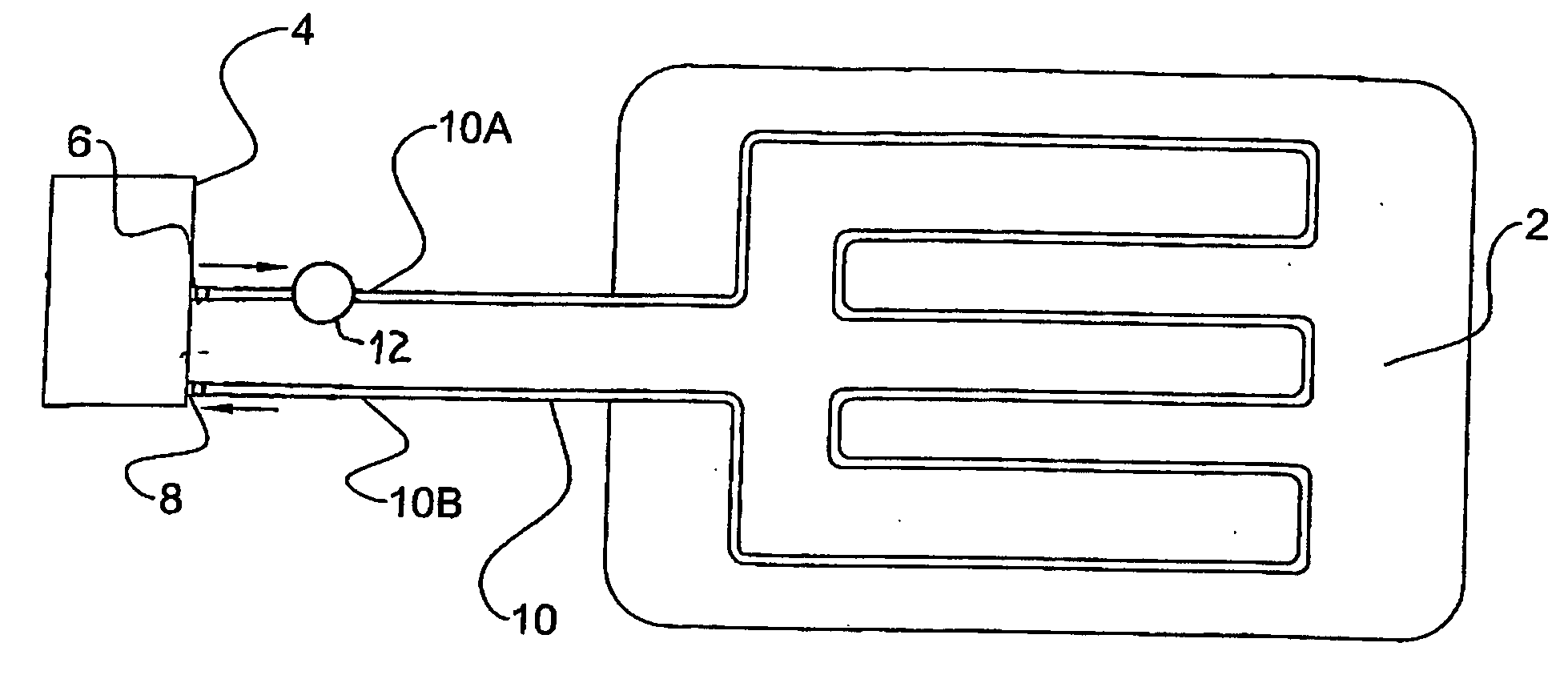

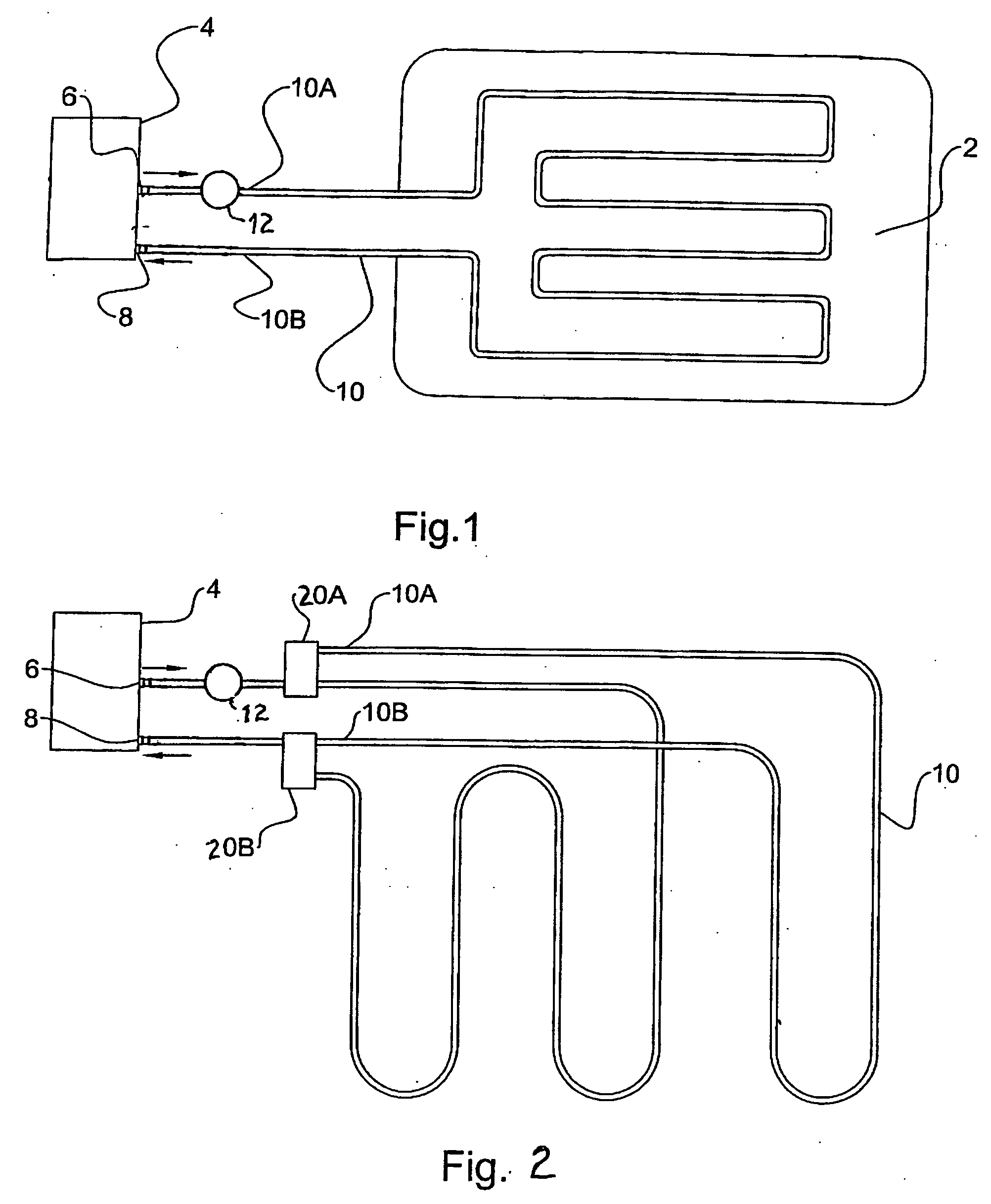

[0014]FIG. 1 schematically illustrates a system for cooling a concrete slab 2 to improve curing in hot weather. The system comprises a portable liquid cooler 4 having a supply port 6 and a return port 8. The cooler 4 is conveniently an absorption chiller that is conveniently portable and can be operated on fuel such as diesel or propane such that a significant electrical power supply is not required. The cooler 4 is operative to cool liquid entering the return port 8 such that the temperature of the liquid entering the return port 8 is greater than the temperature of liquid leaving the supply port 6.

[0015] A conduit 10 is connected to the supply and return ports 6, 8 of the liquid cooler 4 and is arranged in proximity to the concrete slab 2. In the system illustrated in FIG. 1 the conduit 10 is flexible and arranged in loops on the surface of the concrete slab 2. Alternatively the conduit 10 could be embedded in the concrete slab 2. Once the concrete has cured, the liquid cooler 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com