Retractable optical fiber assembly

a technology of optical fiber and assembly, which is applied in the direction of optical elements, optical apparatus testing, instruments, etc., can solve the problems of affecting the performance of the test fiber box, the size and weight of the inability to use the conventional test fiber box as a jumper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

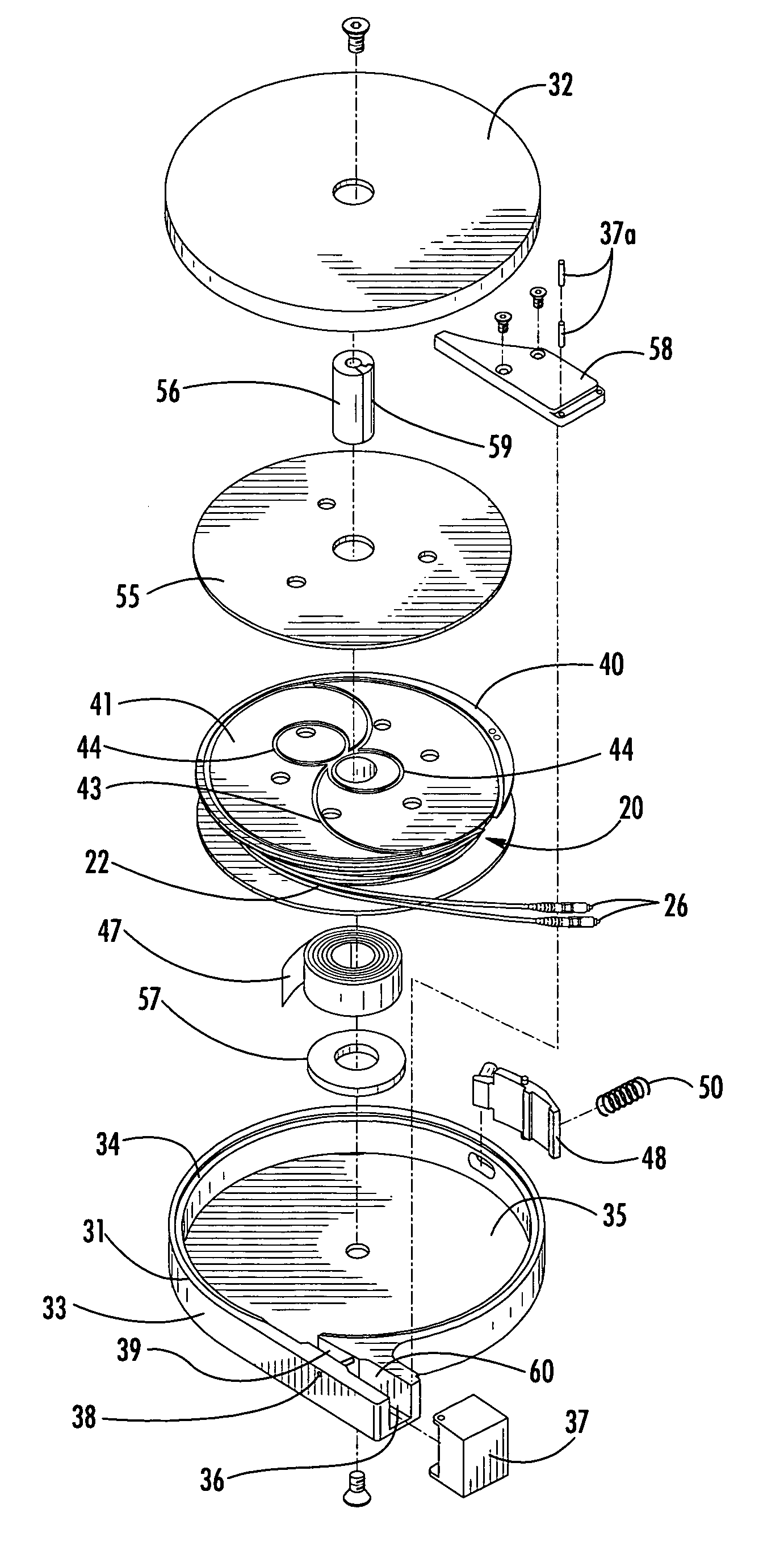

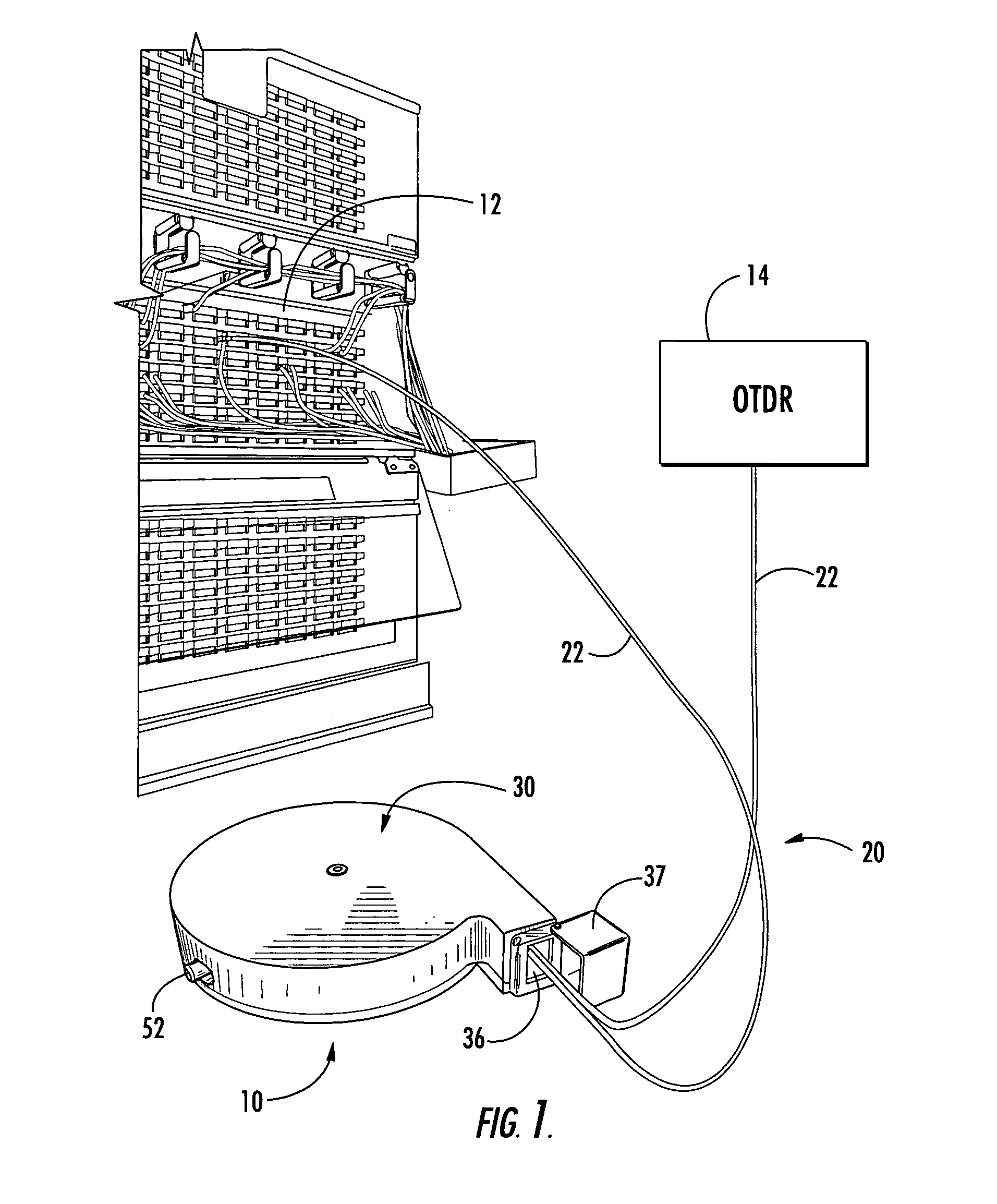

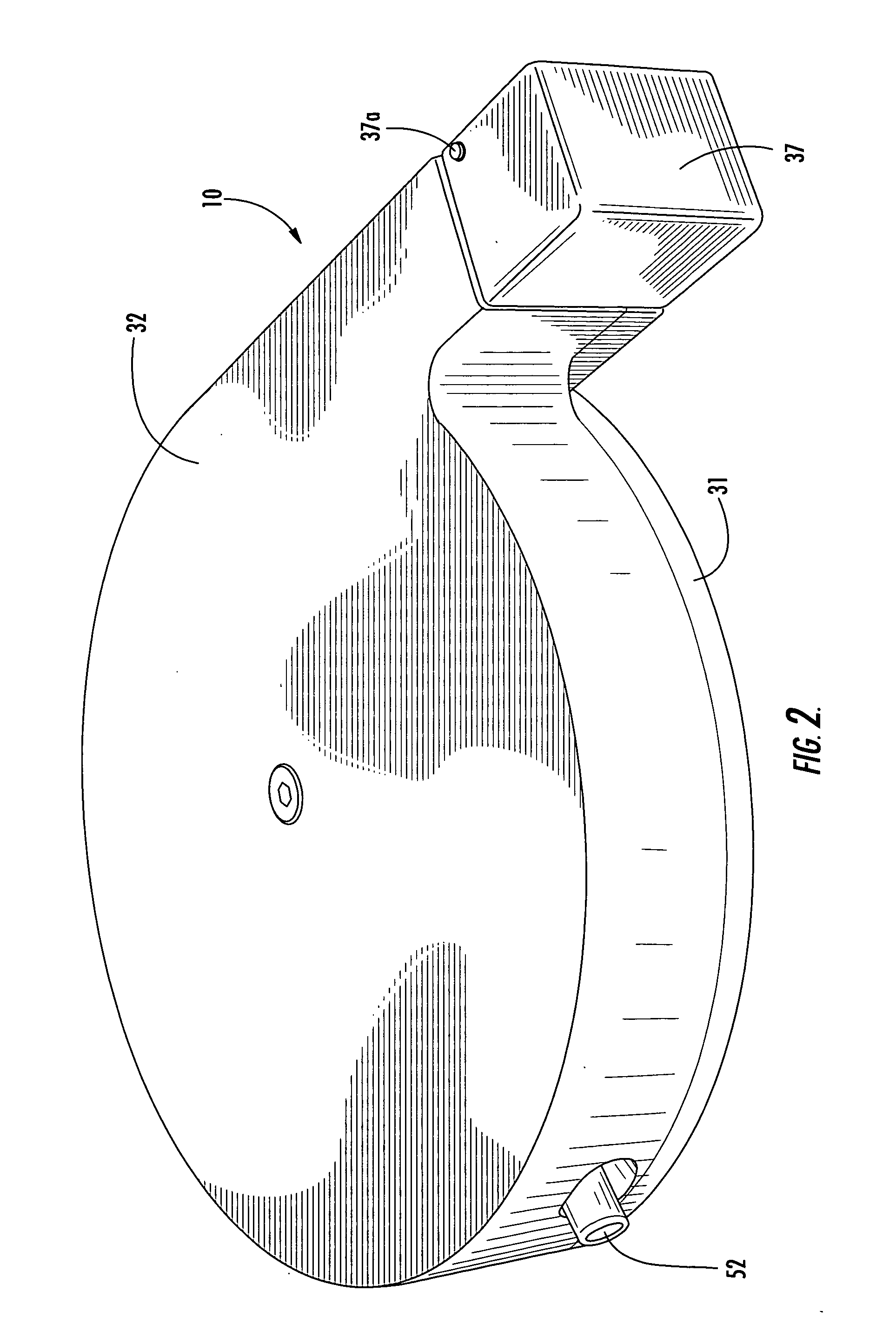

[0015] A retractable optical fiber assembly 10 in accordance with the invention is especially suited for connecting optical test equipment 14 to an optical network 12 so that the optical network can be tested, evaluated, qualified, demonstrated, calibrated, monitored or otherwise analyzed. In the exemplary embodiments shown and described herein, the retractable optical fiber assembly 10 is an improved test fiber box suitable for use in conjunction with optical test equipment 14, such as an optical time domain reflectometer (OTDR), to test the optical network 12. The test fiber box 10 contains a predetermined length of optical waveguide 20 suitable for performing the required testing in conjunction with the OTDR 14. In particular, the test fiber box 10 functions in the same manner as a conventional “test fiber box,”“launch cord,”“launch cable,”“break-out box,”“dead zone box” or “pulse suppressor” to provide from about 50 meters to about 5 kilometers length of optical waveguide to enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com