Shrinkproof elastic tape and a method of making same

a technology of elastic tape and elastic tape, which is applied in the field of shrinkproof elastic tape, can solve the problems of confusion in the garment industry, achieve the effects of reducing shrinkage, prolonging the service life of clothing, and ensuring the appearance of intact clothing including the tap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

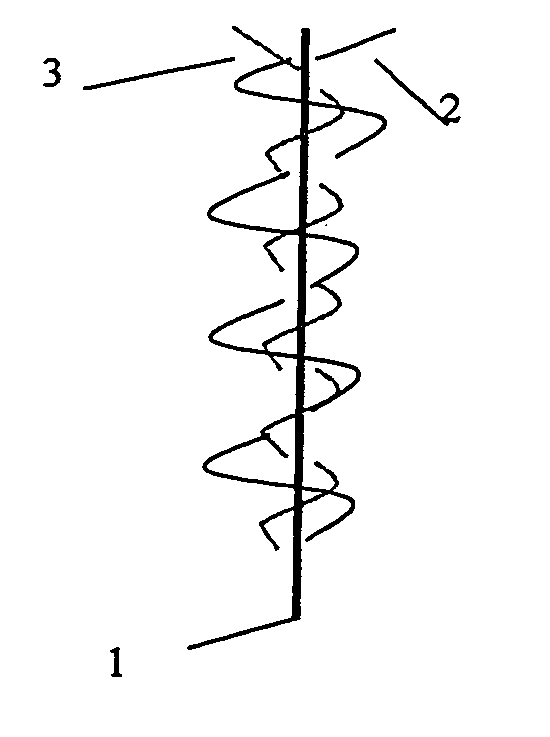

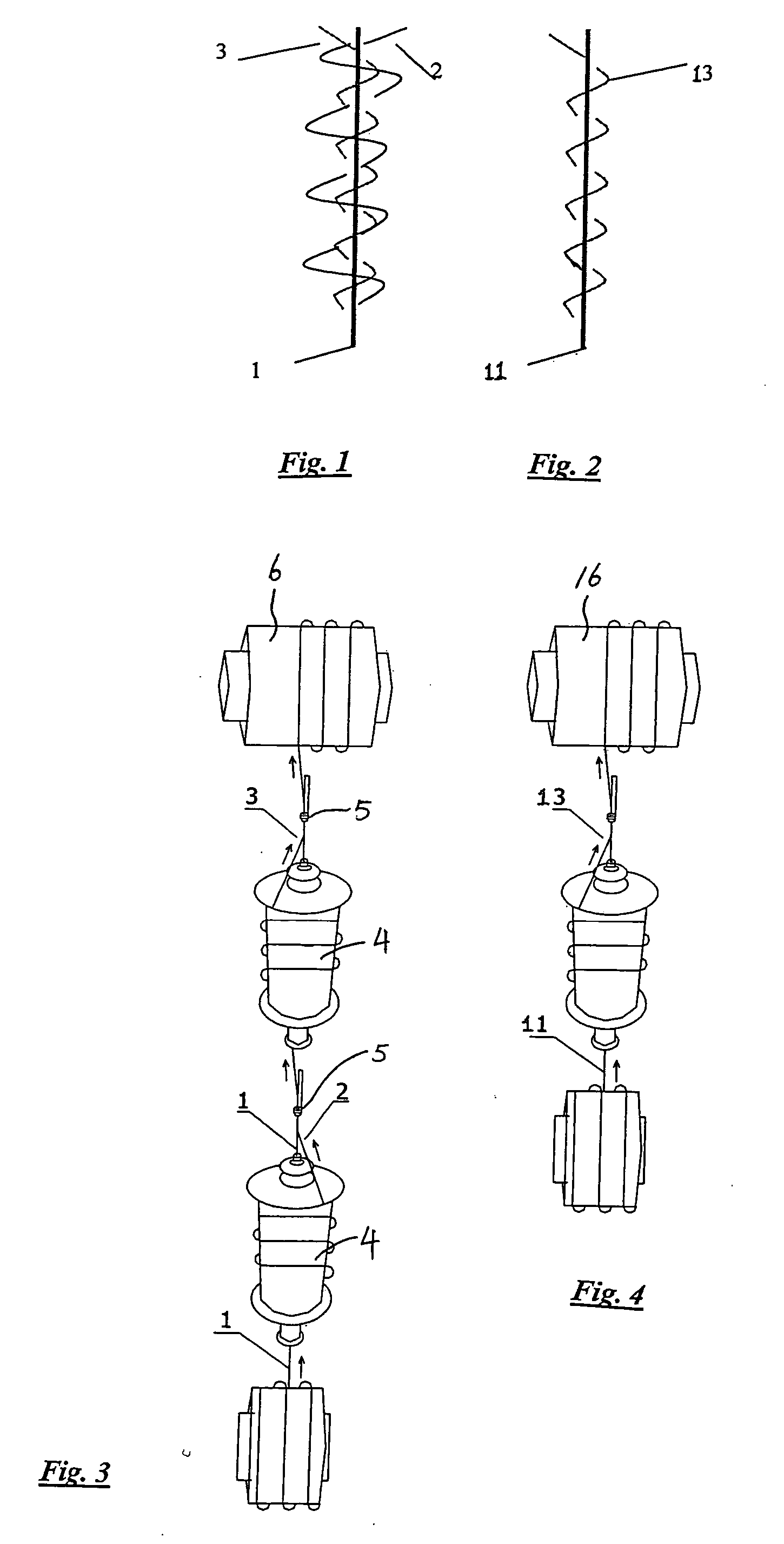

[0011] Shown in FIG. 1 are core yarns used for weaving an elastic tape according to a first preferred embodiment of the present invention. The core part of such a tape is an elastomeric yarn 1. The elastomeric core yarn 1 is wound by a non-thermo-fusible yarn 2 and a thermo-fusible yarn 3. The elastomeric yarn 1 may be polyurethane yarn or rubber yarn. The thermo-fusible yarn 3 may be made from polymers with a low melting point. During dyeing and finishing, when the temperature exceeds the low melting point, the thermo-fusible yarn 3 will melt and become adhesive, thus bonding the surrounding yarns together.

[0012] The covering process of the core yarns 1 is shown in FIG. 3, in which the elastomeric yarn 1 is driven on one or two rolls 4 and guided through the middle of a hollow spindle 5. The hollow spindle 5 carries the yarn 3 which covers the elastomeric yarn 1. The elastomeric yarn 1 is first wound or covered by a non-thermo-fusible yarn 2 and then by a thermo-fusible yarn 3, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastomeric | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com