Cam-driven pump mechanism for a battery-powered grease gun

a grease gun and cam-driven technology, applied in the direction of pump components, piston pumps, positive displacement liquid engines, etc., can solve the problems of periodic need for replacement of sliding blocks, erratically operating pump mechanisms, and unreliable pump mechanisms, and achieve the effect of prolonging the life of grease guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

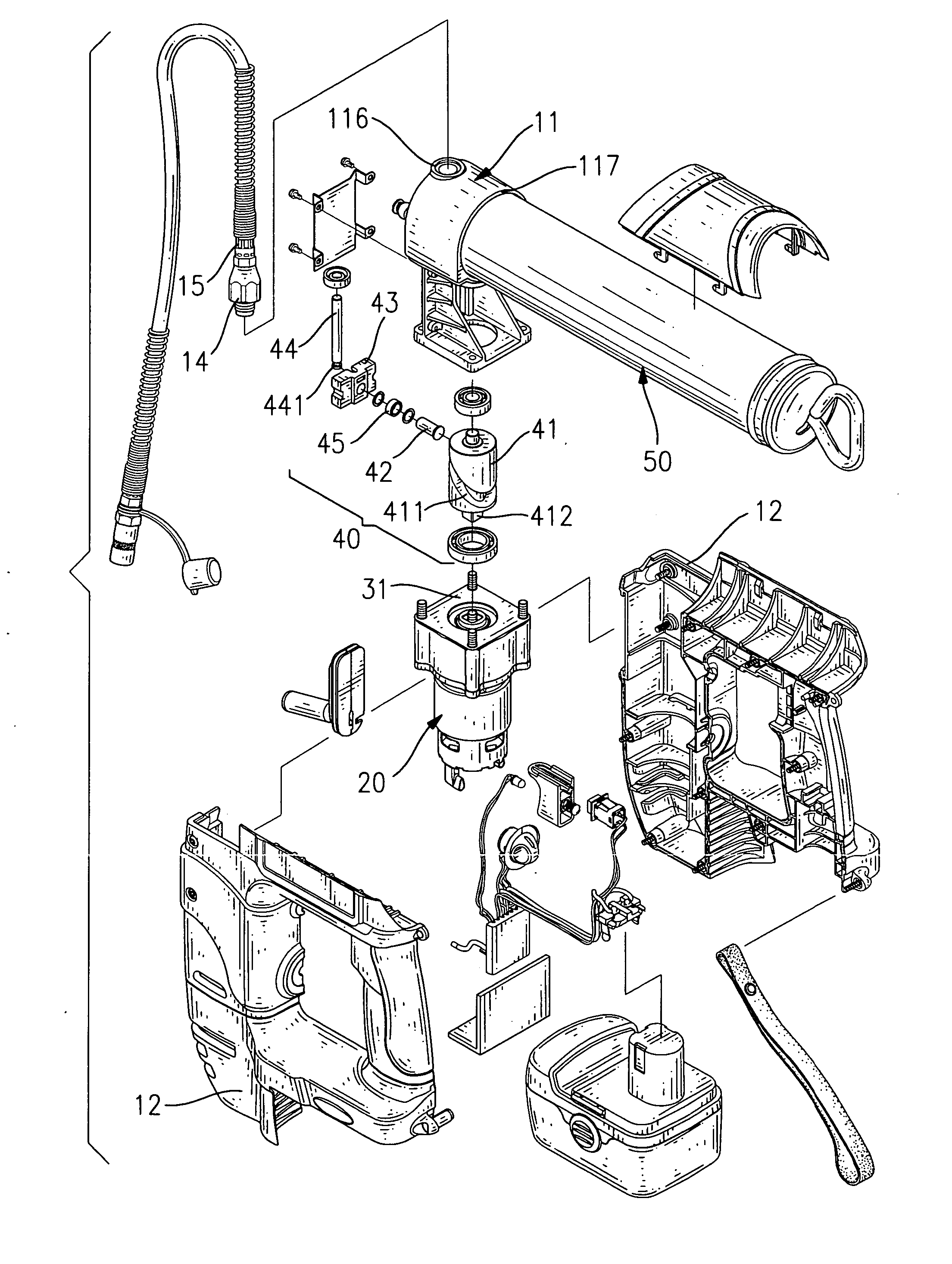

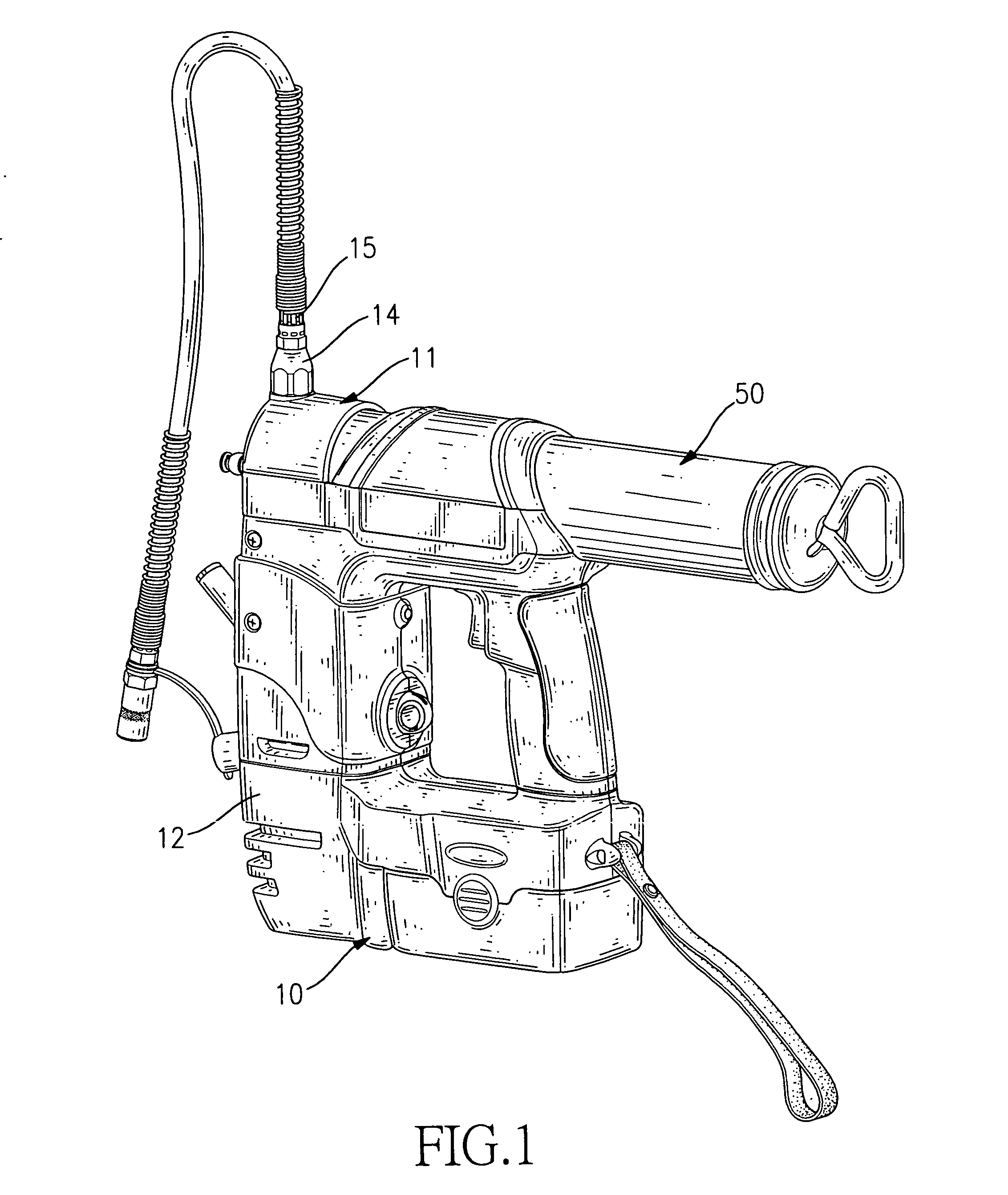

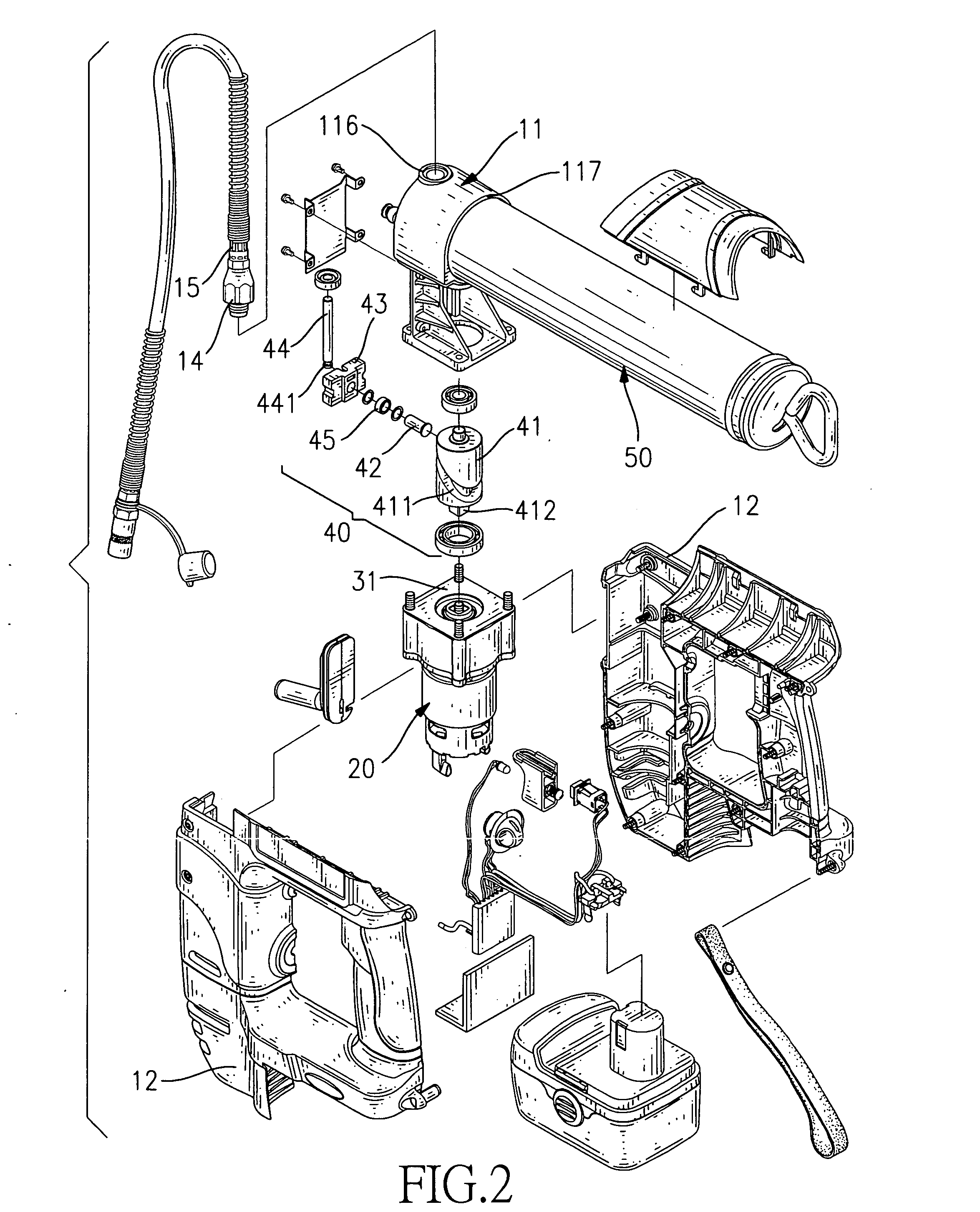

[0022] With reference to FIGS. 1 and 2, a cam-driven pump mechanism in accordance with present invention is used in a battery-powered grease gun (not numbered). The battery-powered grease gun has a body (10), a cartridge holder (50) and a cam-driven pump mechanism. The body (10) comprises a casing (12) and a discharge assembly (not numbered).

[0023] With further reference to FIG. 4, the casing (12) comprises two half shells (not numbered) and has a top (not numbered) and an inner chamber (121) formed when the half shells connect to each other.

[0024] The discharge assembly is mounted on the top of the casing (12) and comprises a transition body (11), a ball check valve (14) and a discharge adapter (15). The transition body (11) has a top (not numbered), a bottom (not numbered), an inward side (not numbered), an outward side (not numbered), a grease channel (110), a ball check valve housing (116) and a cartridge connector (117).

[0025] The grease channel (110) is formed longitudinall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com