Drum assembly for washing machine

a drum and washing machine technology, applied in the field of washing machines, can solve the problems of complicated assembly process and long time for an assembler, and achieve the effects of improving the structure of the drum assembly of the washing machine, fixing the lifter to the drum quickly and easily, and improving the structure of the drum assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

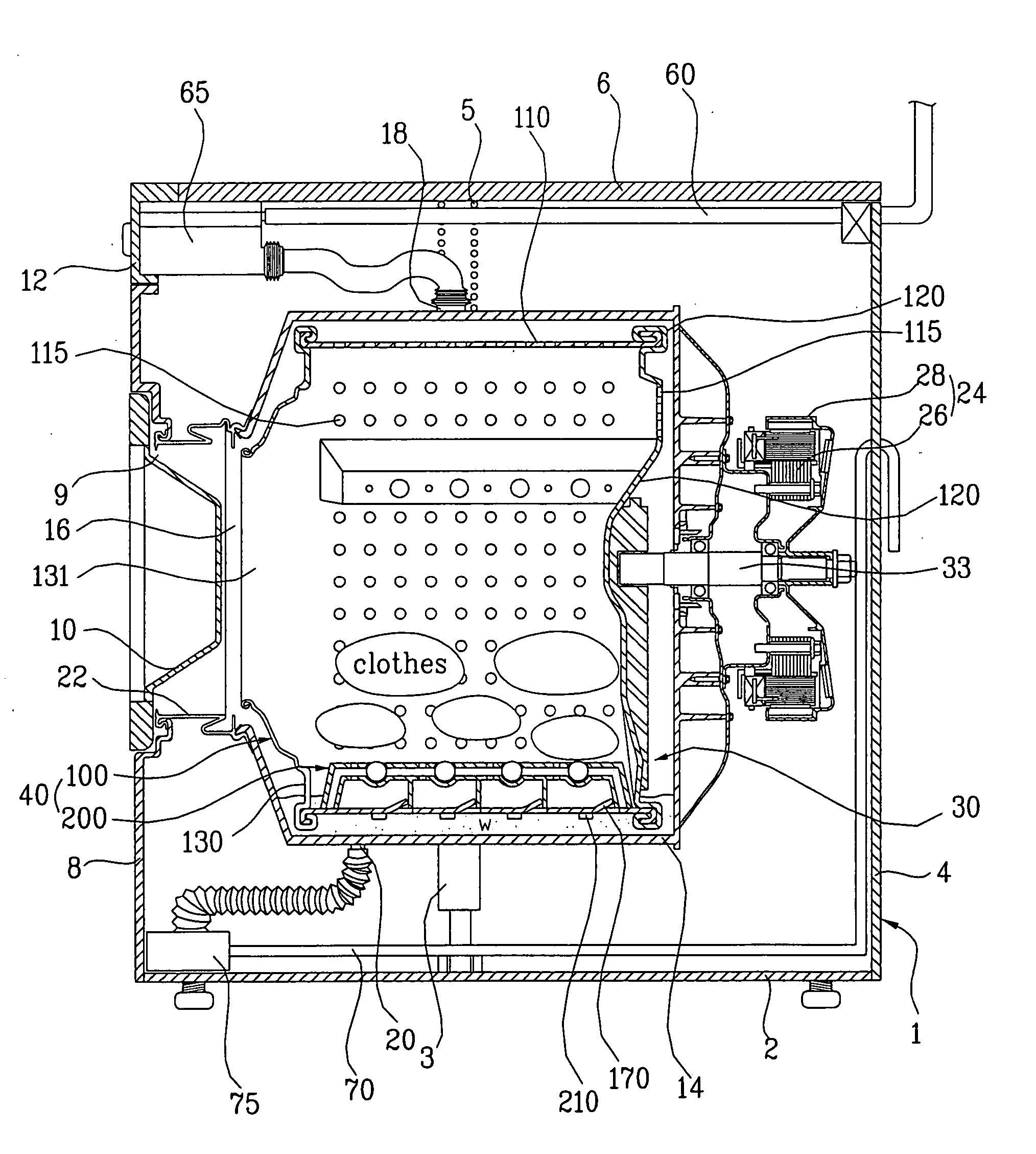

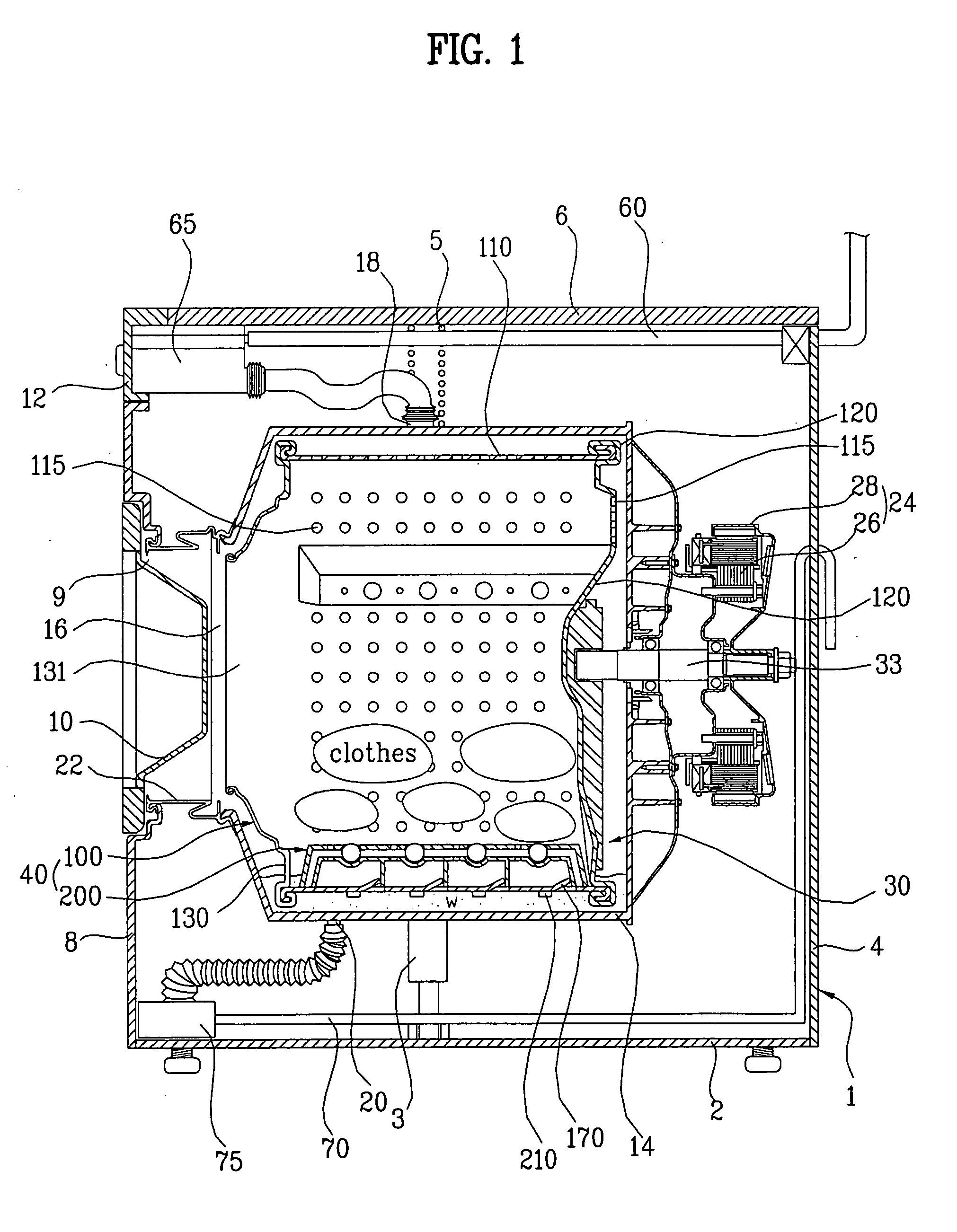

[0031] With reference to FIG. 1, a case 1 of the washing machine according to the present invention comprises a base plate 2, a wall 4, a top cover 6, and a front cover 8. The base plate 2 forms a bottom of the case 2, and the wall 4 is vertically mounted on the base plate 2, and forms a rear wall and both side walls of the washing machine according to the present invention. A top of the wall 4 is open, and a front of the wall is also open. And, the top cover 6 covers the open top of the wall 4, and the front cover 8 covers the open front of the wall 4. Further, there is a control panel 12 between a top of the front cover 8 and the top cover 6 so that the user can control the washing machine using the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com