Method and device for lubricant oil transport in an internal combustion engine

a technology of internal combustion engine and lubricant oil, which is applied in the direction of lubrication of auxiliaries, pressure lubrication with lubrication pumps, oilsumps, etc., can solve the problems of affecting the efficiency of lubricant oil supply, interrupting lubricant circulation, and cost-intensive pumps that are additionally integrated into the internal combustion engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

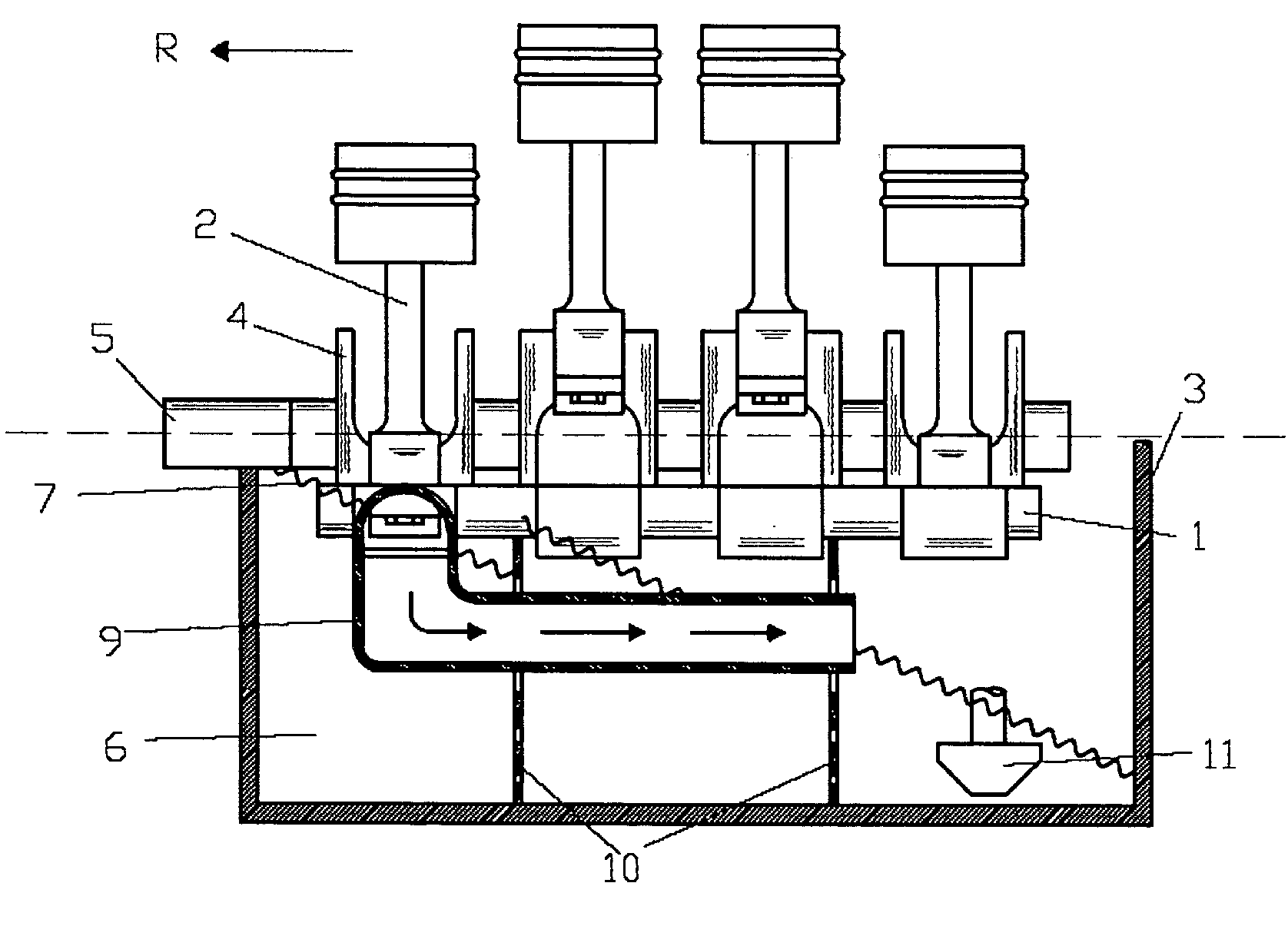

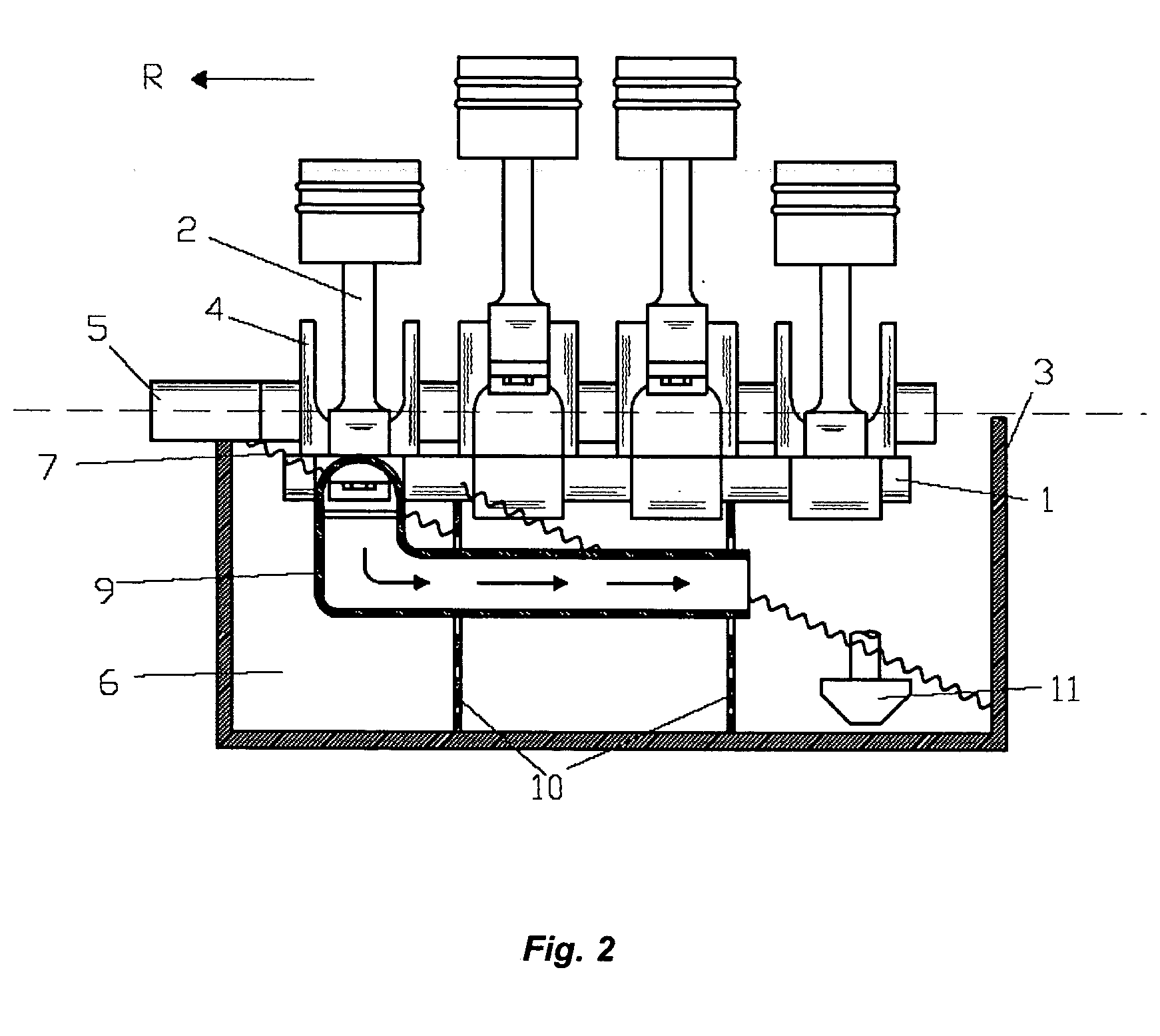

[0033] Referring now to the drawings, FIG. 2 shows an oil repulsion part 1 integrated into an internal combustion engine 3. A connecting rod 2 and crankshaft cheeks 4 are disposed on the outside in the direction of the transverse acceleration and / or inclination R. The direction of the transverse acceleration relating to the present invention means the direction of the centrifugal acceleration which is directed against the centripetal acceleration. Oil repulsion part 1 is configured, in the region of connecting rod 2 and crankshaft cheeks 4 so that a centrifugal flow, resulting from the interaction of oil repulsion part 1, connecting rod 2, and crankshaft cheeks 4 is brought about. This centrifugal flow is used for transport of the lubricant oil into the region of an oil pan 6 that lies opposite the transverse acceleration and / or inclination. A lubricant oil suction system 11 is disposed in this region of oil pan 6.

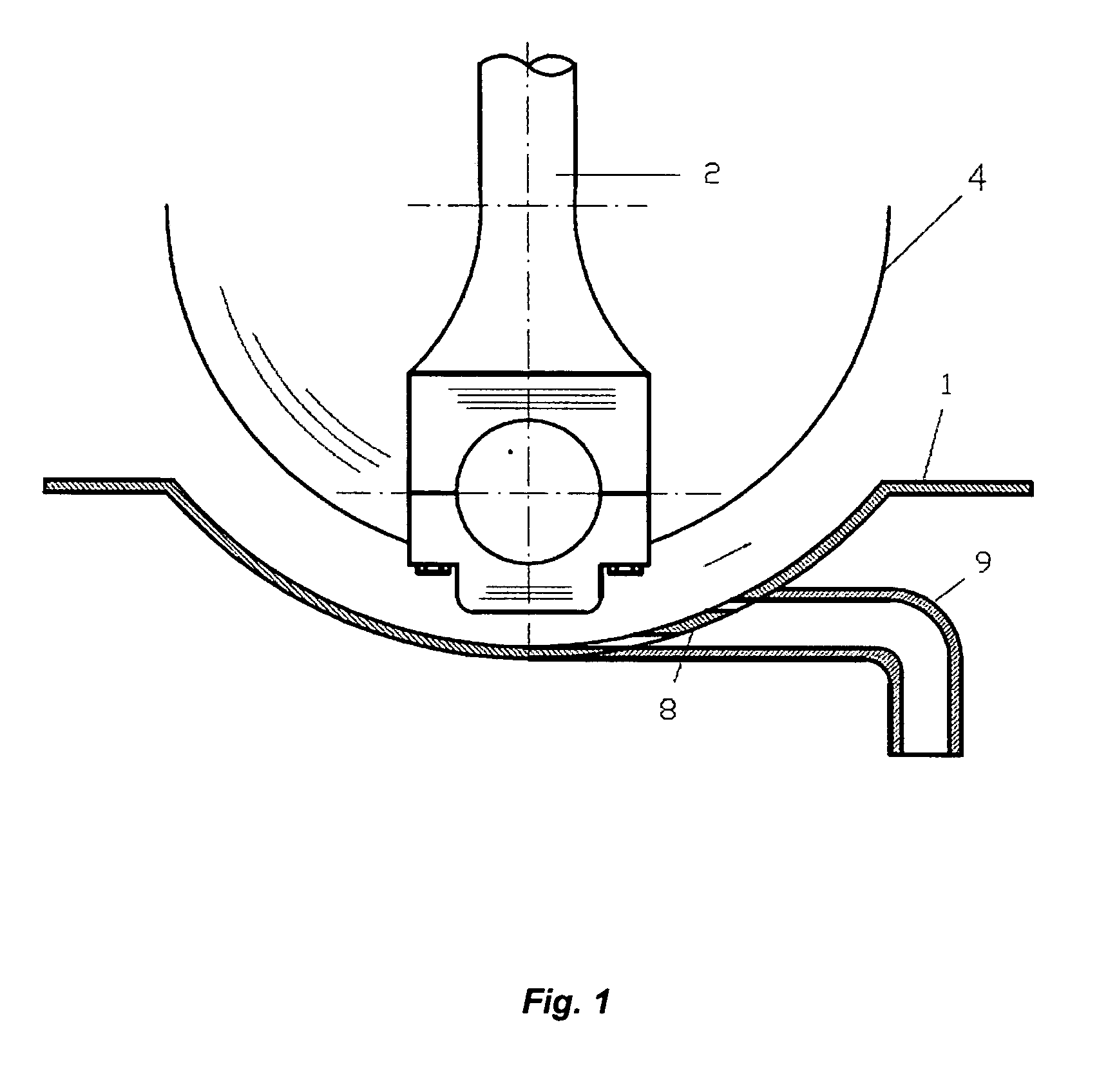

[0034] An oil repulsion part 1 of the type shown in FIGS. 1 to 4, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com