Furnace device for eliminating volatile organic compounds (VOCs)

a technology of volatile organic compounds and furnaces, which is applied in the direction of solid fuel combustion, lighting and heating apparatuses, and combustion types, etc., can solve the problems of volatile organic compounds, wasting space, and polluting the environment, and achieves the effect of small size and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

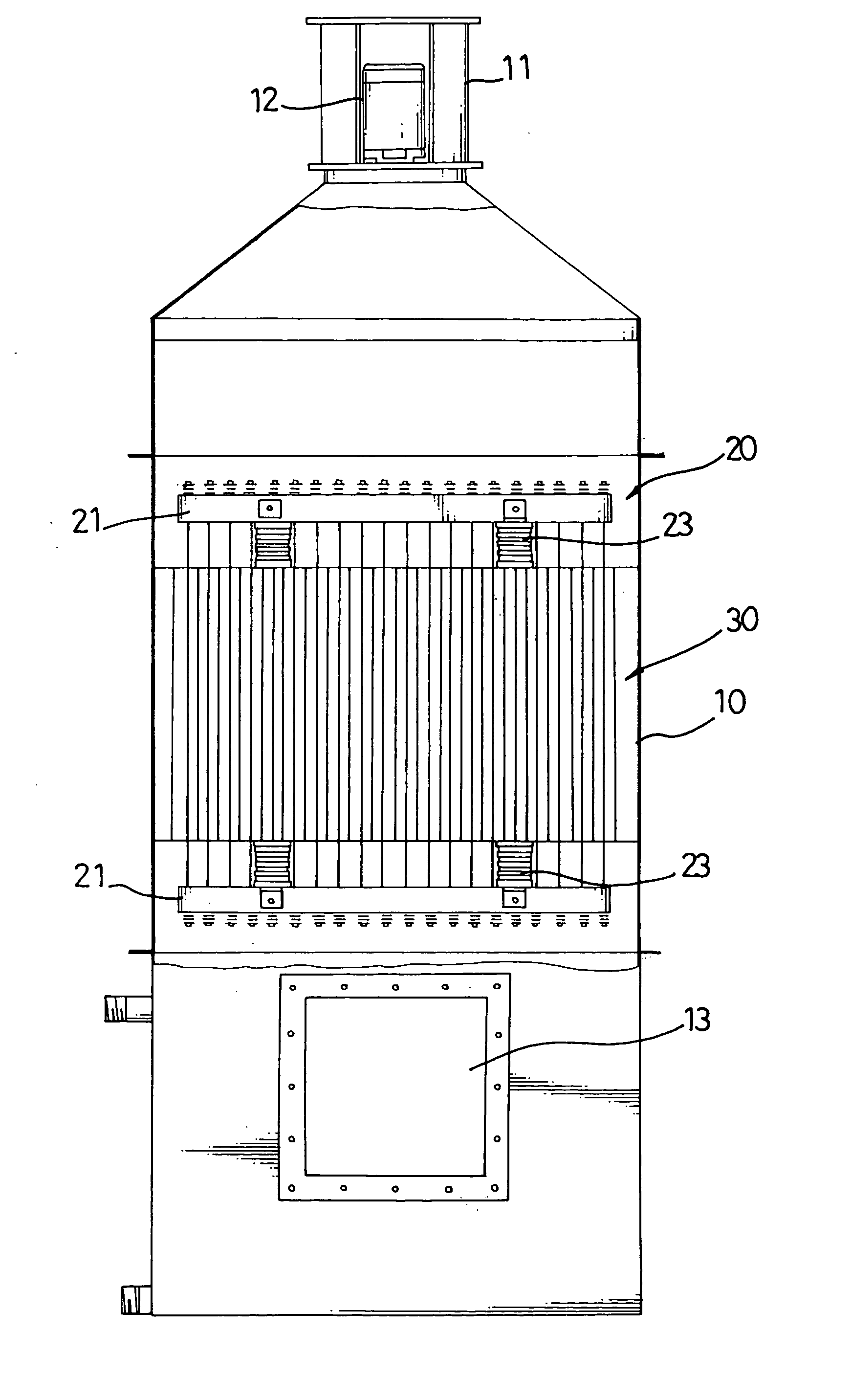

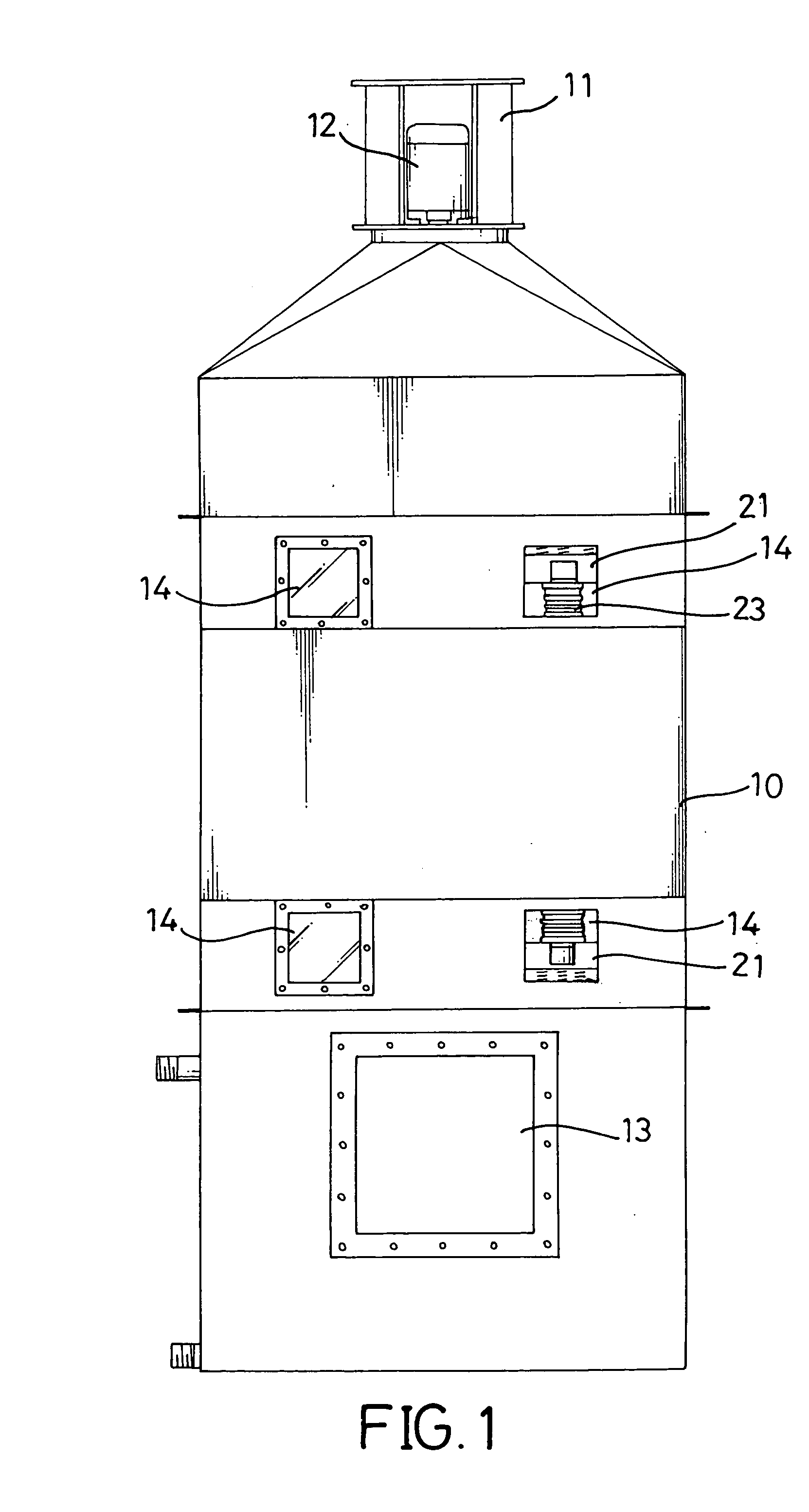

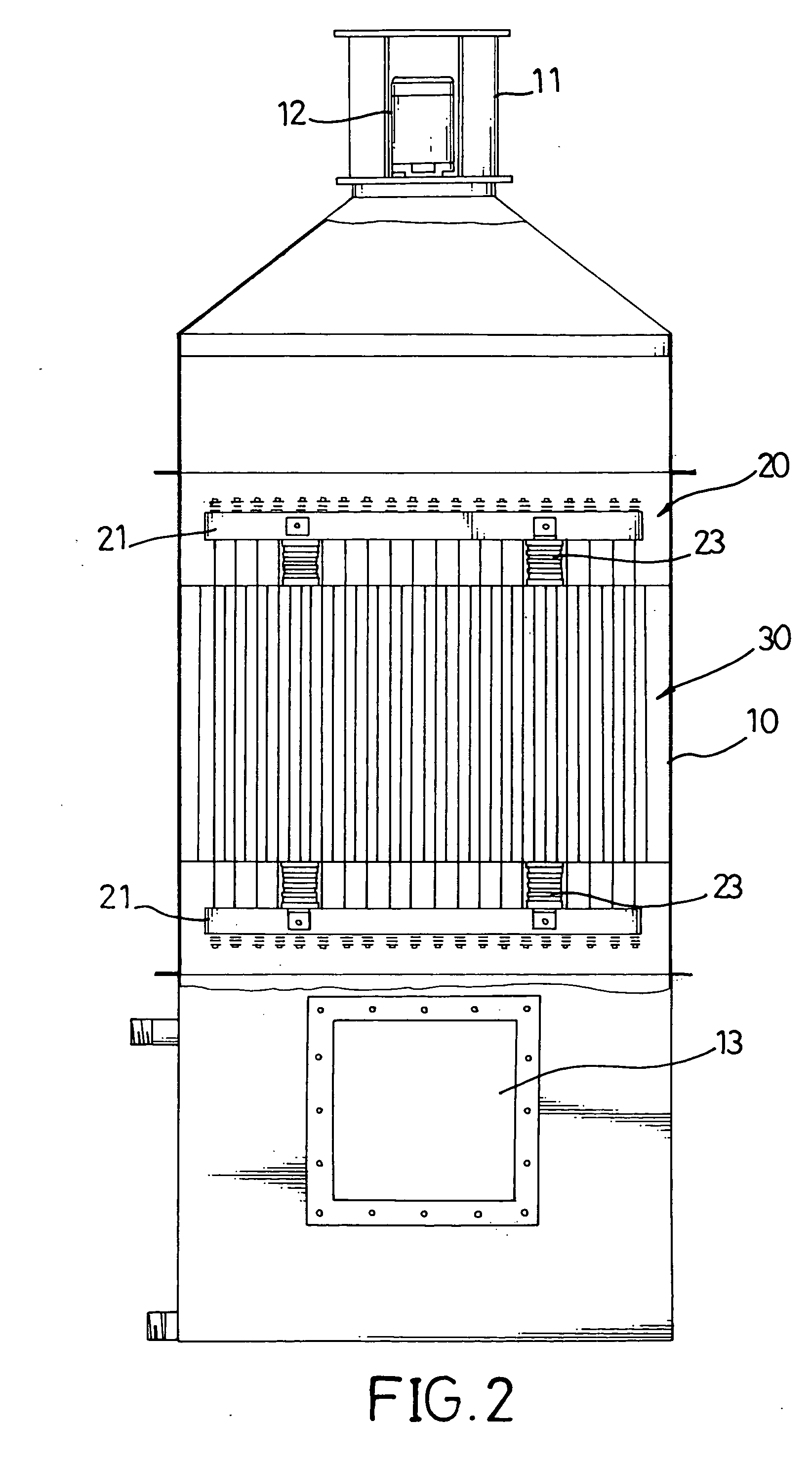

[0017] A furnace device for eliminating volatile organic compounds in exhaust gas comprises a hollow body, a gas inlet, a gas outlet, an arc generator, two positioning plates and multiple optional damping devices. The hollow body has a top and a bottom. The gas inlet is defined near the bottom of the hollow body, and the gas outlet is defined at the top of the hollow body. The arc generator is mounted between the gas inlet and gas outlet and generates arcs to burn the volatile organic compounds when the exhaust gas enters the furnace device. The two positioning plates clamp and hold the arc generators in place. The multiple optional damping devices are mounted between the arc generator and the two positioning plates.

[0018] With reference to FIGS. 1 to 3, a preferred embodiment of the furnace device in accordance with the present invention comprises a body (10), a positioning device (20), and an arc generator (30).

[0019] The body (10) is a hollow cylinder with a flat bottom (not nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com