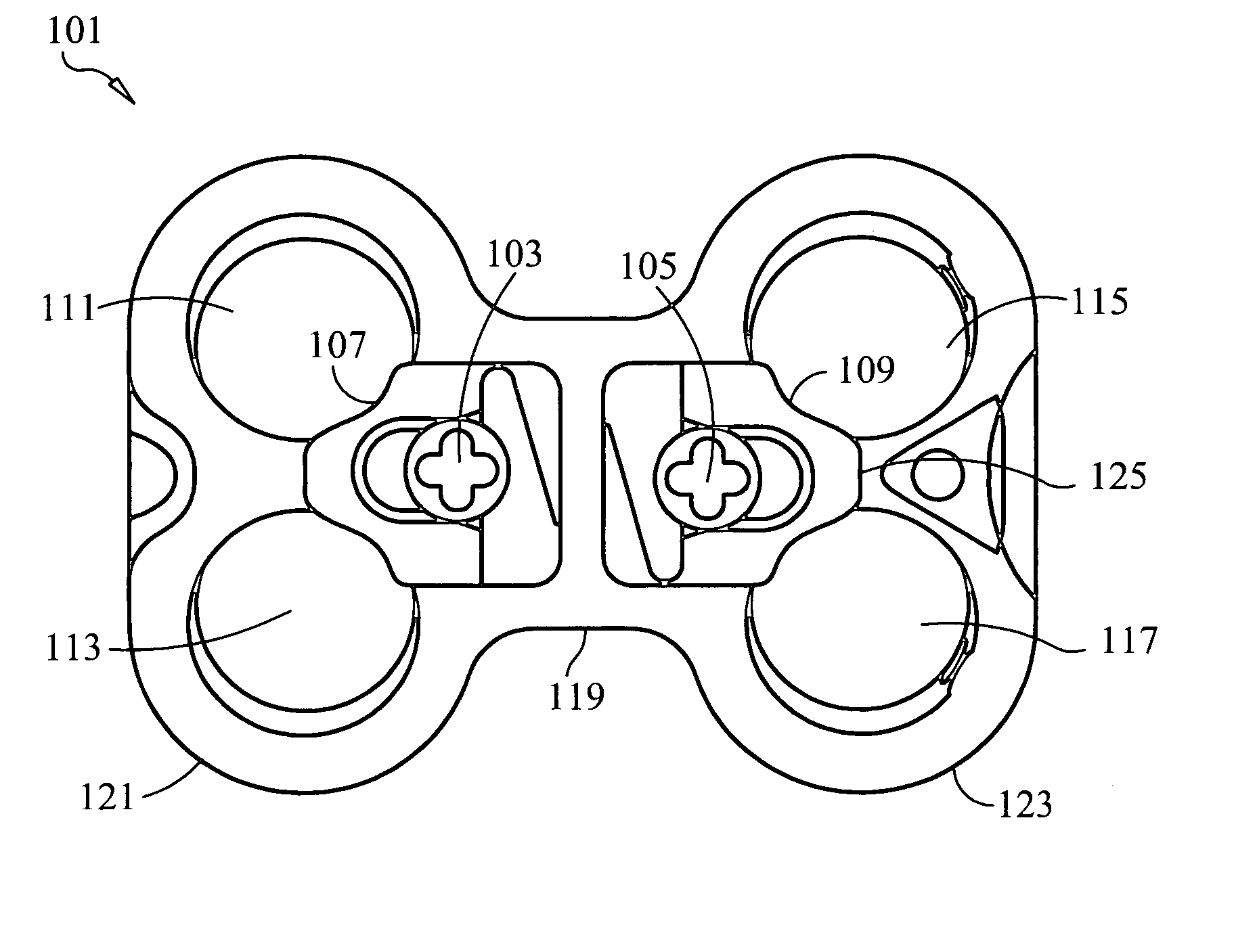

Bone fixation plate

a technology for fixing plates and bones, applied in bone drill guides, medical science, surgery, etc., can solve the problems of presenting the most challenges, and affecting the ability of bone and bony structures to provide support and structure, etc., and achieve the effect of increasing the magnitude of interferen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

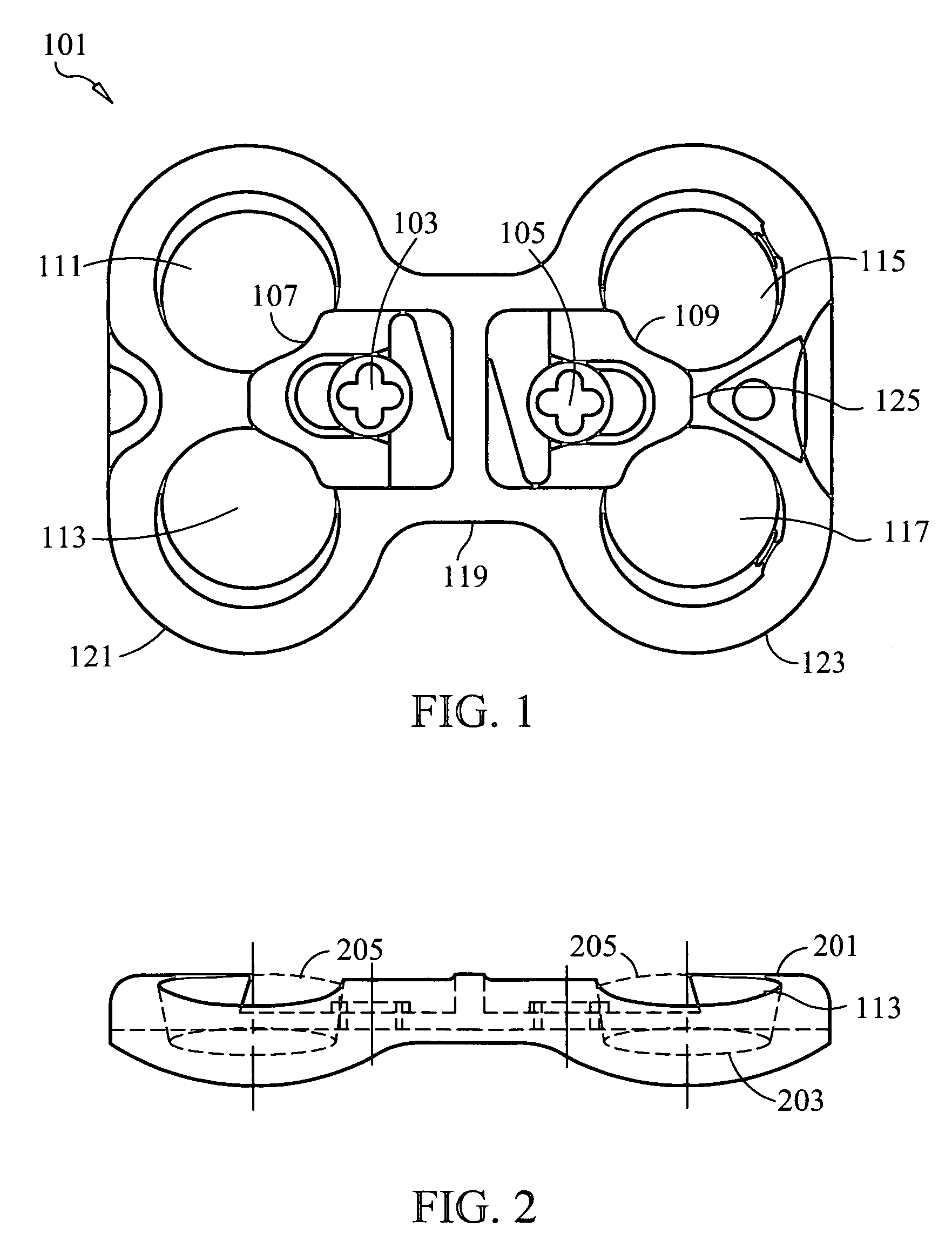

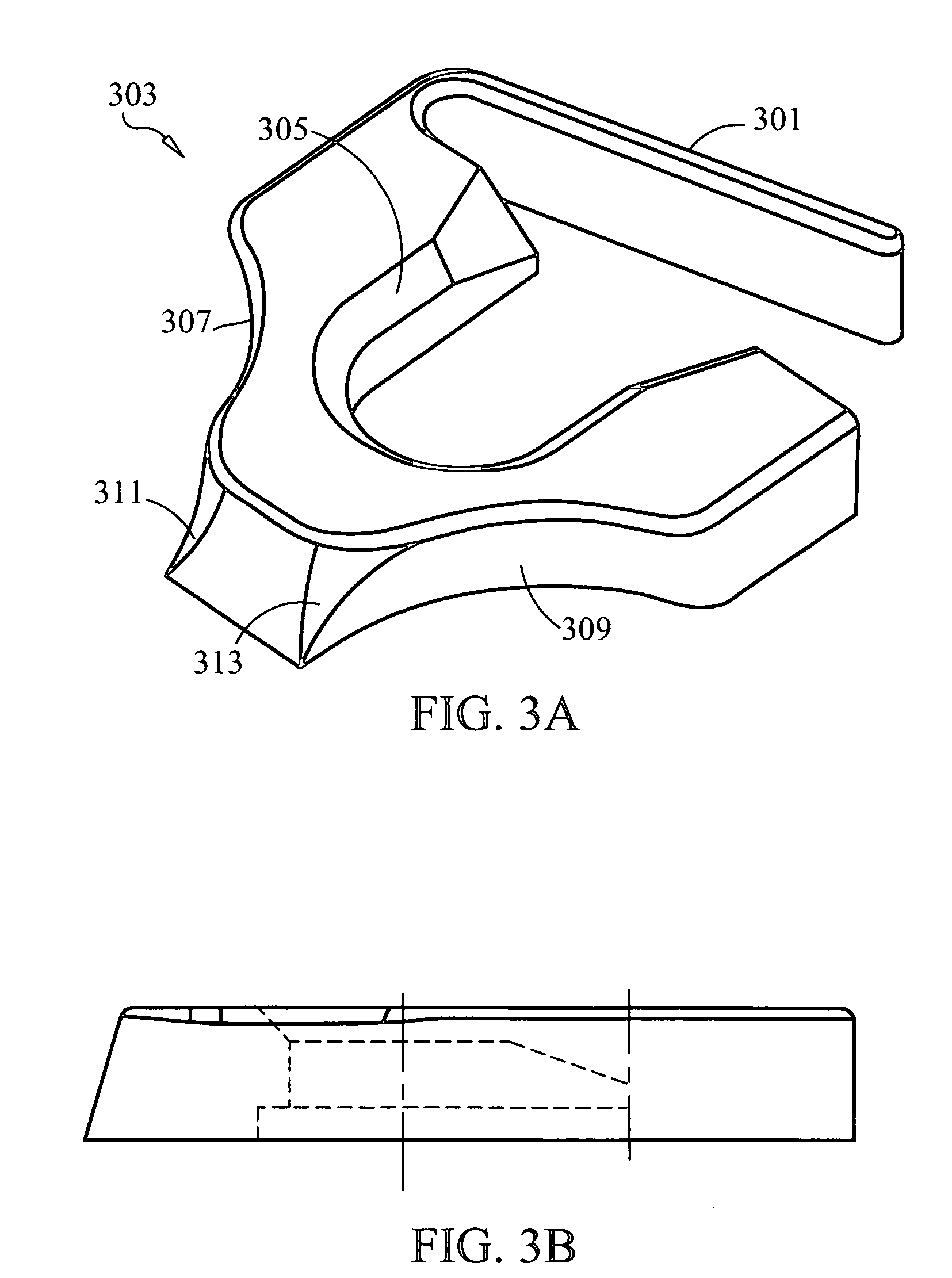

[0046] The present invention relates to a bone fixation plate that minimizes the problems associated with prior bone fixation plates while maintaining a small profile. In one embodiment, as a screw is tightened, it will begin to lag the plate to the bone. When the screw head interferes with the plate at an interference point, a slight resistance is generated. The insertion forces can easily overcome this resistance. When the screw is advanced further, it snaps into a sliding fit area and is allowed to move freely. The forces which can cause the screw to back out from the plate are preferably not strong enough to pass the screw head back past the interference section. It may be desirable to include a set screw to prevent backout of the screws due to micromotion. In other embodiments, the head of the screw may be clamped to prevent rotation, when such a restriction on the movement of the screw is desirable.

[0047] The present invention provides a locking mechanism that allows one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com