Method for controlling initiation of a detonator

a technology of explosive detonators and initiation methods, which is applied in the direction of impact fuzes, weapons, ammunition fuzes, etc., can solve the problems of less than complex task of specific positioning of sufficient explosives to achieve a successful blast, and inability to achieve optimal physical rock breakage performance, etc., to achieve the effect of being easily modified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0043] An example according to the present invention will now be described.

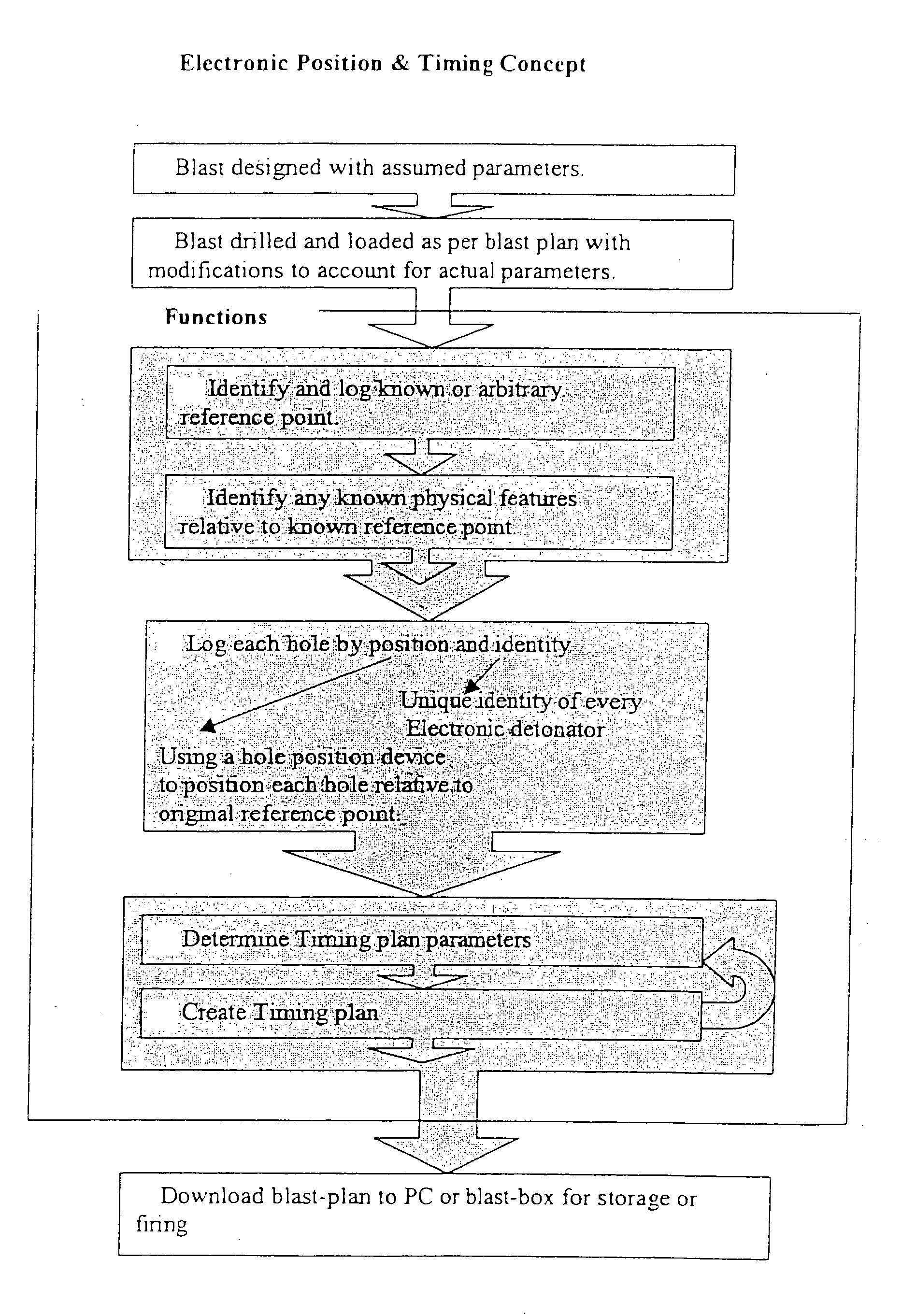

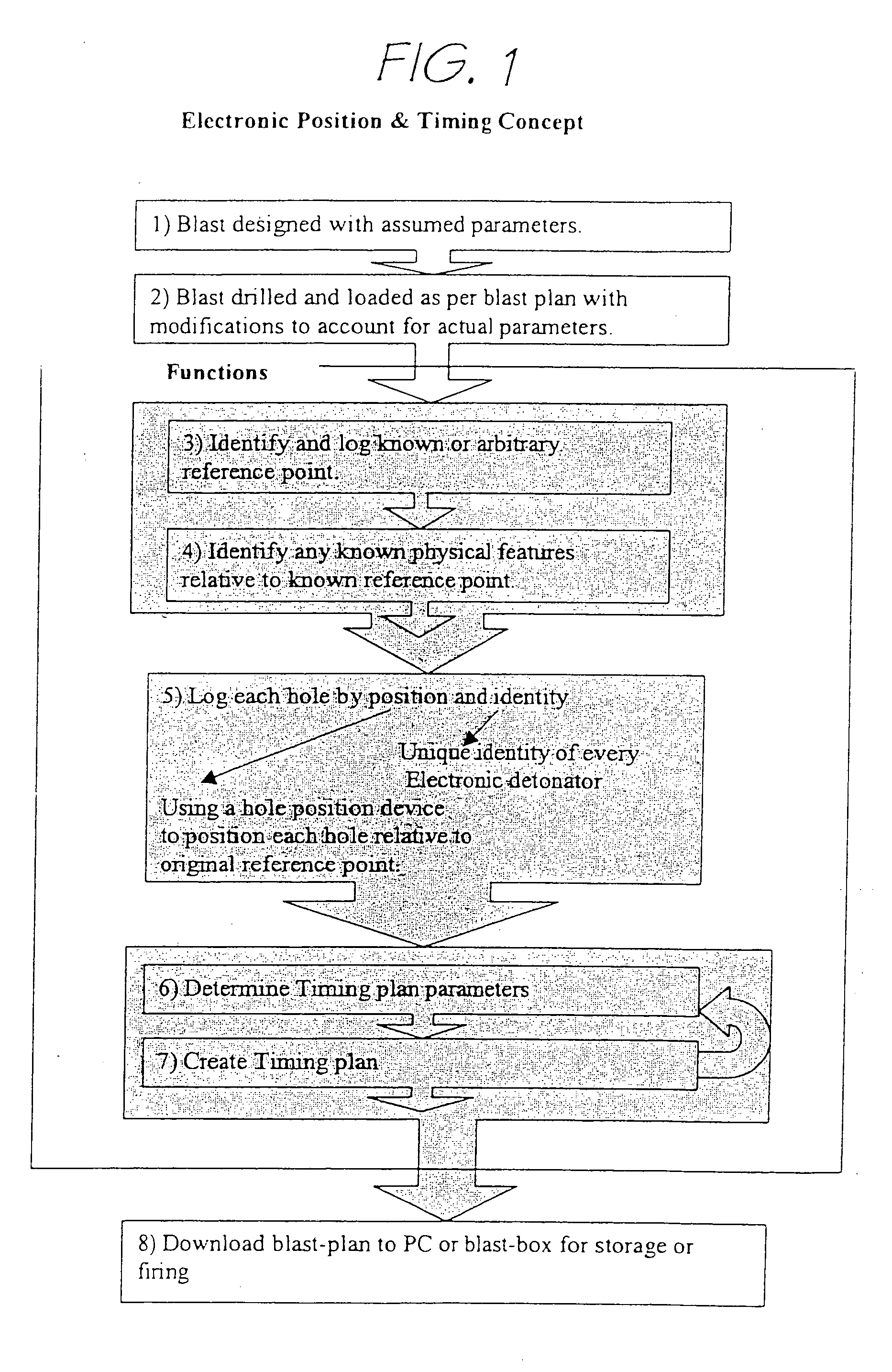

[0044] Referring to FIG. 1, in one form of the method of the present invention, there is no planned blast pattern provided and the time of initiation of an electronic detonator was controlled by a blast operator once the placement of the explosive and detonator in surrounding ground has occurred.

[0045] The blast operator measured the actual spatial position of the detonator(s) in relation to one or more adjacent detonators by first identifying and logging a known coordinate reference point, which can be one of a survey position, another blast hole or a physical feature such as the corner of the blast pattern area. Then the actual drilled blast hole spatial position was identified relative to that reference point. Each hole was also identified by a unique identity code or name, and its position was entered or logged into a recordal system. The order of identification of the blast holes in a blast pattern was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com