Reservoir barrier wipes, pads and applicators

a technology of impregnated wipes and applicators, applied in the direction of packaging foodstuffs, containers preventing decay, packaging goods, etc., can solve the problems of affecting the stability of the packaging, and affecting the use effect of the packaging, so as to improve the ability of the packaging to stabilize the location or grip, and eliminate the transdermal migration of unwanted formulary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to facilitate a complete understanding of various embodiments of the invention, the remainder of the detailed description describes exemplary embodiments with reference to the drawings, wherein like elements are referenced with like numerals throughout.

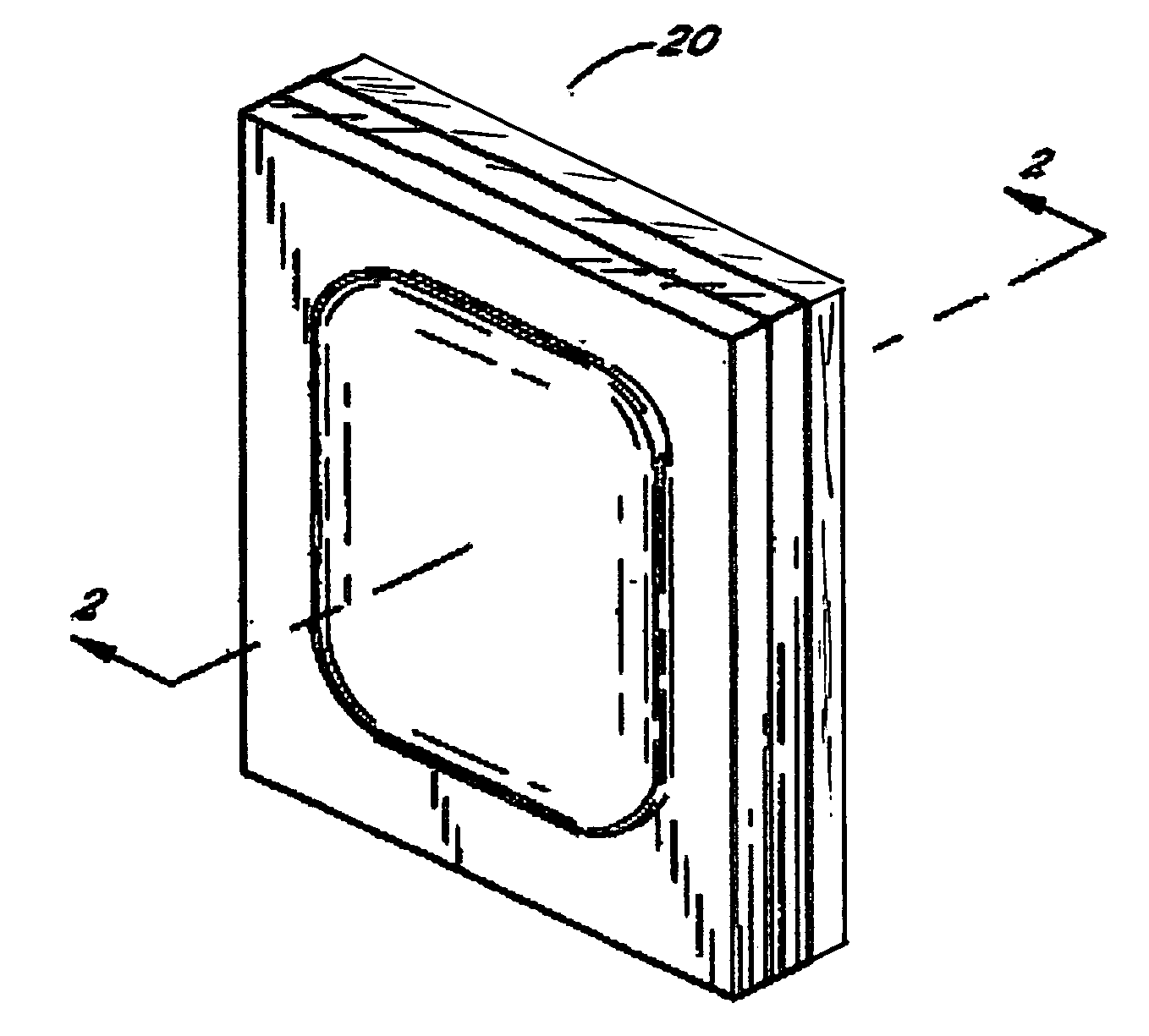

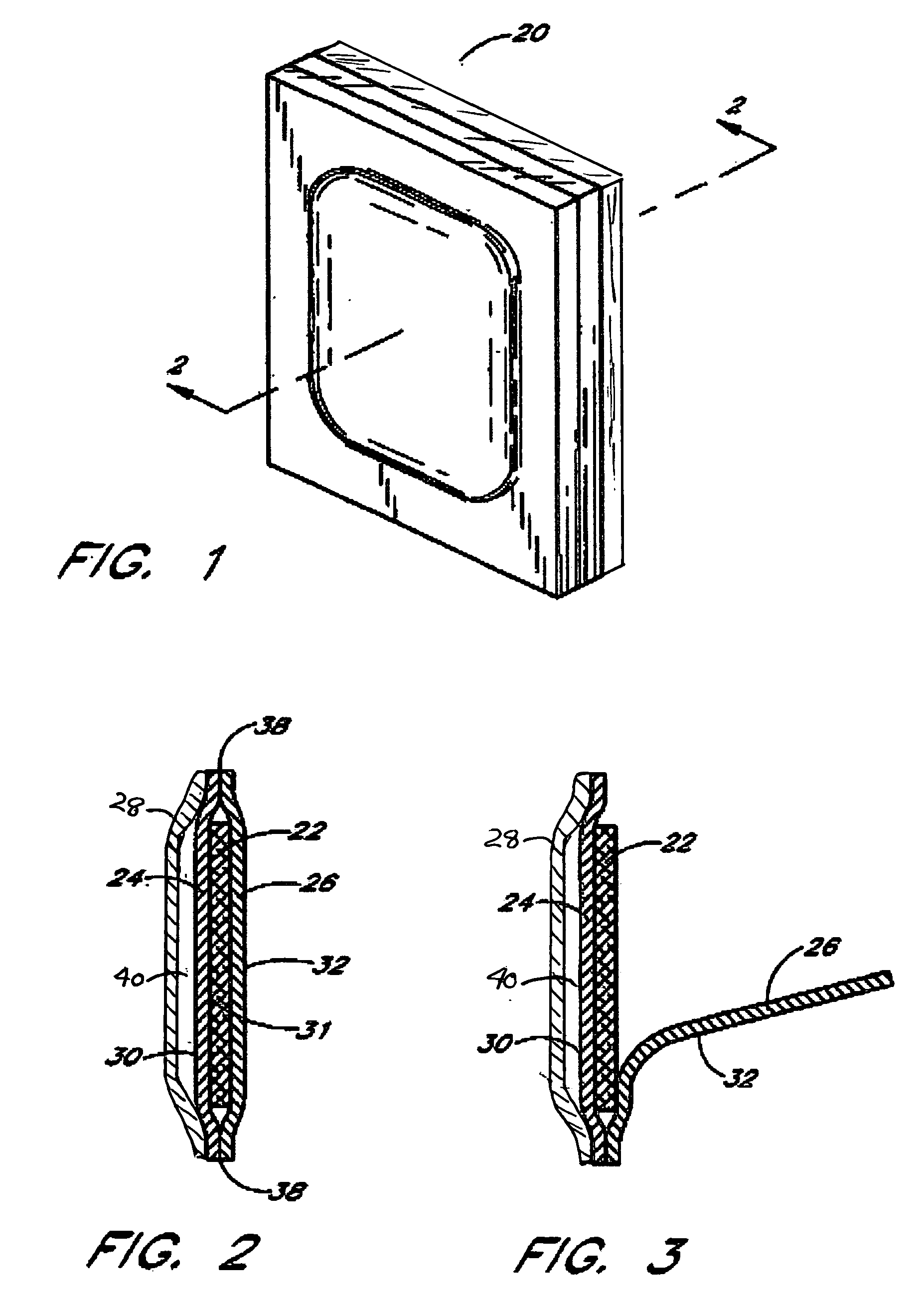

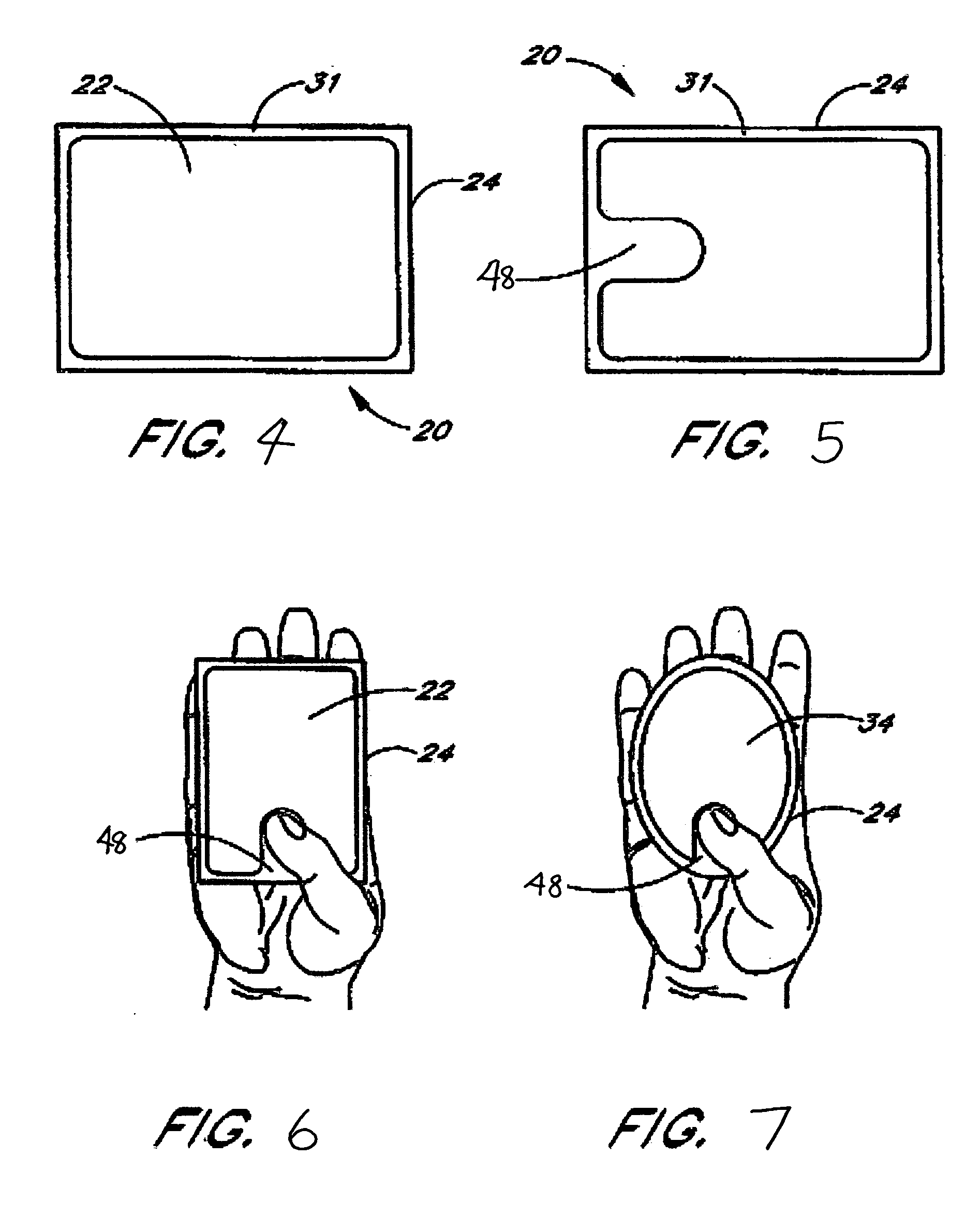

[0053]FIGS. 1-3 illustrate a package 20 containing a wipe or pad 22 in accordance with a first aspect of the present invention. The package 20 is preferably formed from thin compliant material, such as sealed paper, plastic or foil, as is well known in the art. It is important that the packaging material is sufficiently non-porous, to minimize or prevent absorption of substance on the wipe 22. In the present embodiment, the package 20 includes a front sheet 26 and a rear sheet 28 and a formulary reservoir 40 formed by the joining of the rear sheet 28 and the intermediate sheet 24. The edges 38 of sheets 24, 26 and 28 are sealed together so that the front sheet 26 can be peeled off of the package 20 if desired. Those i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| rectangular shape | aaaaa | aaaaa |

| non-permeable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com