Pulsed current sintering for surfaces of medical implants

a technology of medical implants and current sintering, which is applied in the direction of prosthesis, electric/magnetic/electromagnetic heating, coatings, etc., can solve the problems of loosing the implant, deteriorating the implant, and being toxic to the human body,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

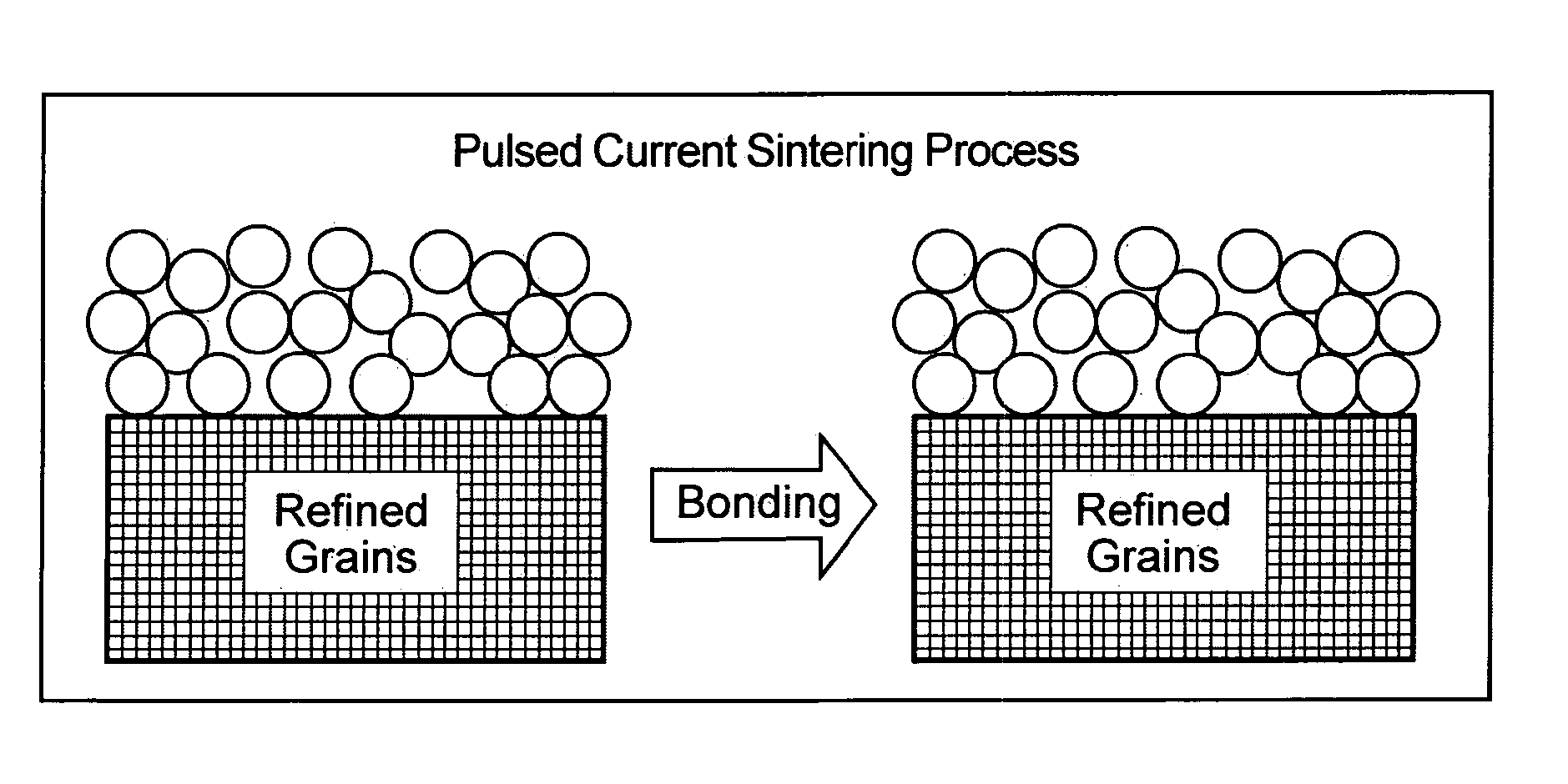

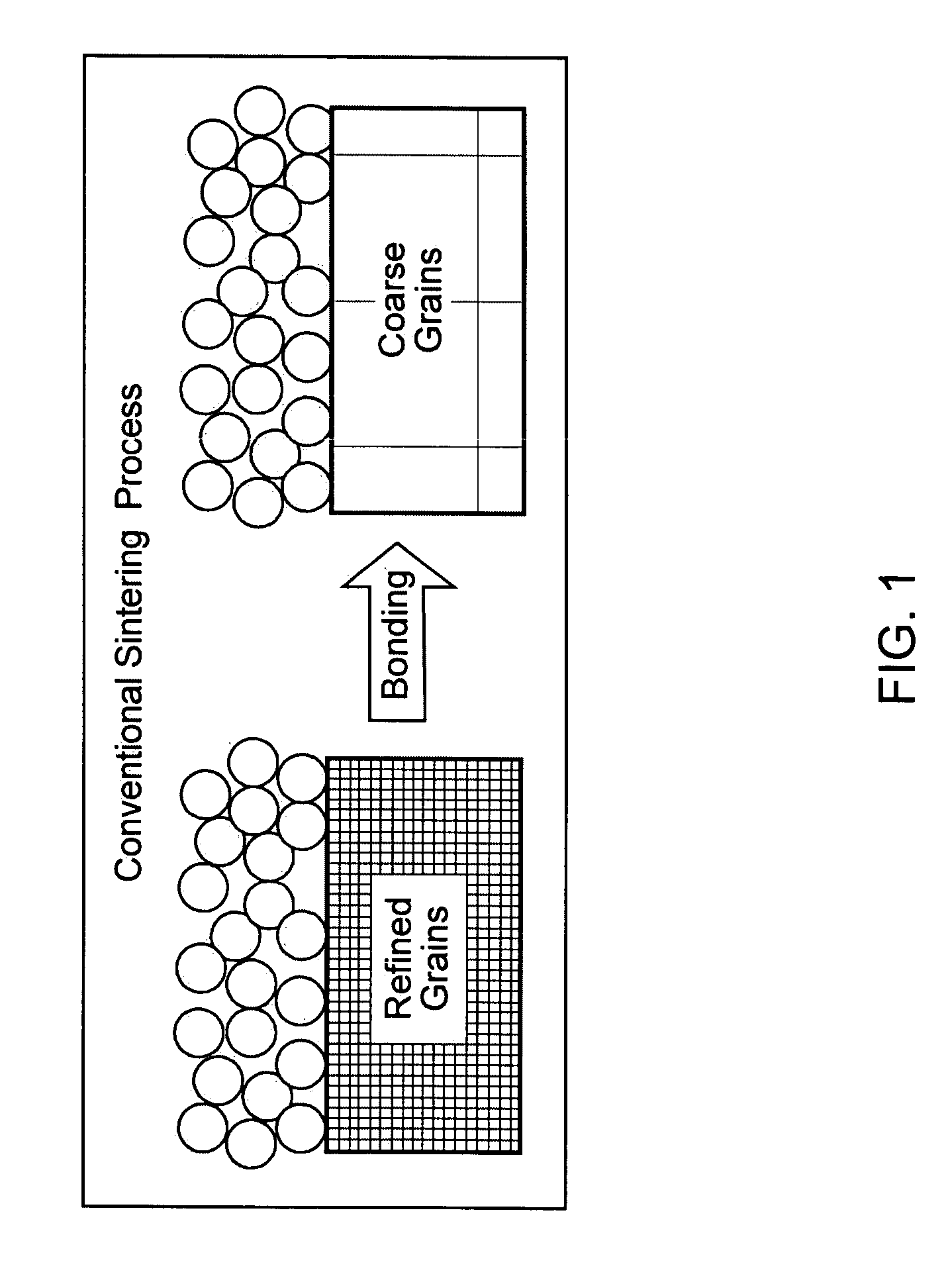

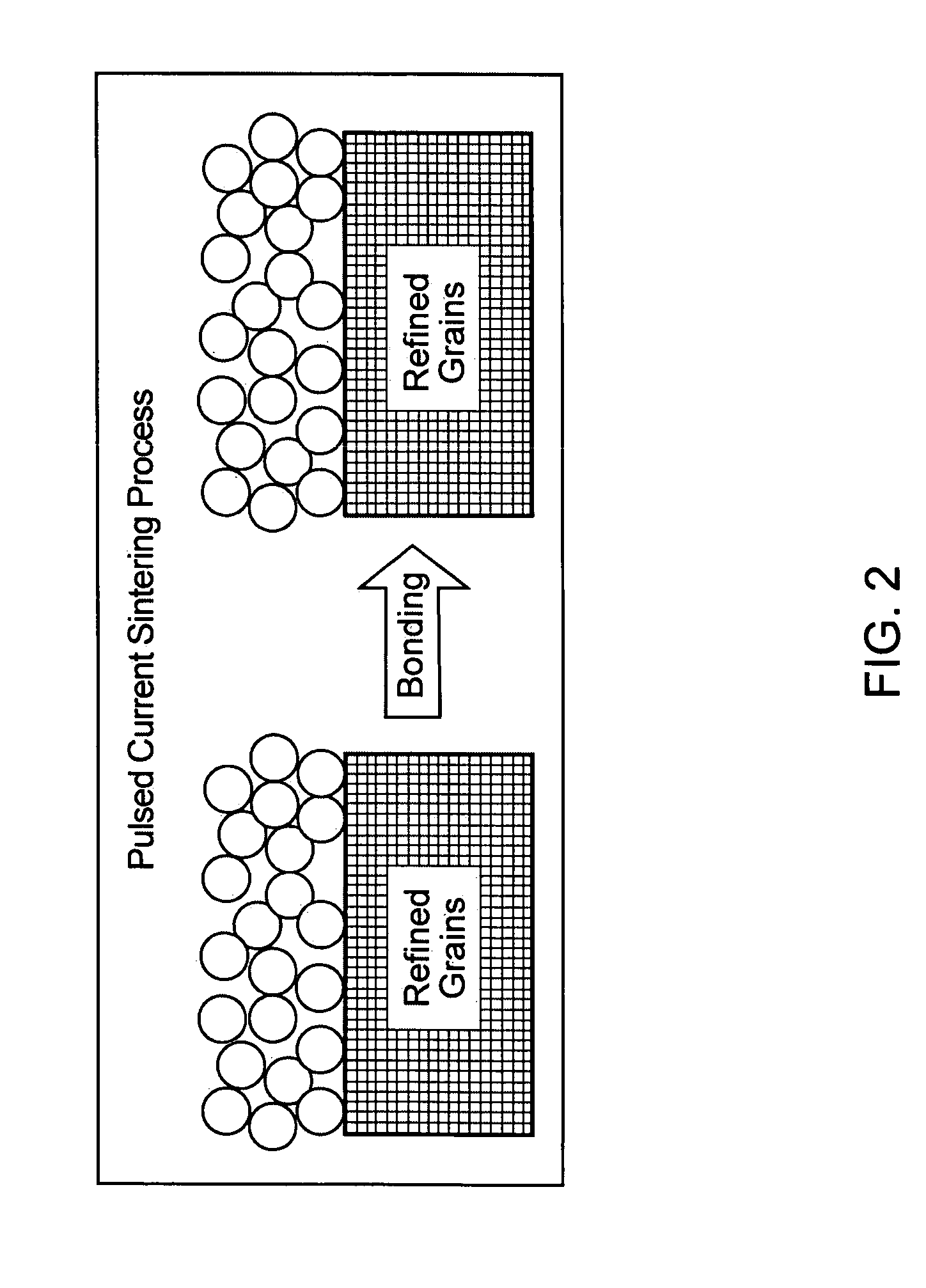

[0019] The present invention describes a medical implant and a method of making a medical implant comprising a porous surface for tissue ingrowth and ongrowth. Specifically, sintered medical implant product is described. The sintered product avoids the changes in bulk microstructure and the corresponding changes in the mechanical and tribological properties of a solid substrate which occurs when high temperature sintering is required to create and bond a porous tissue ingrowth and ongrowth surface to an implantable medical device.

[0020] As used herein, “a” or “an” is defined herein as one or more. Unless otherwise indicated or apparent by the context, the singular includes the plural and the plural includes the singular herein.

[0021] As used herein, “metal” means any material comprising a metal and includes, but is not limited to, metals and metal alloys.

[0022] As used herein, “non-refractory” means a material that melts at a relatively low temperature, typically, a temperature l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com