Electric puffs

a technology of electric puffs and puffs, applied in the field of electric puffs, can solve the problems of not keeping a user's, cosmetics may not be evenly applied to the desired body part, and it is difficult for users to do user's makeup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

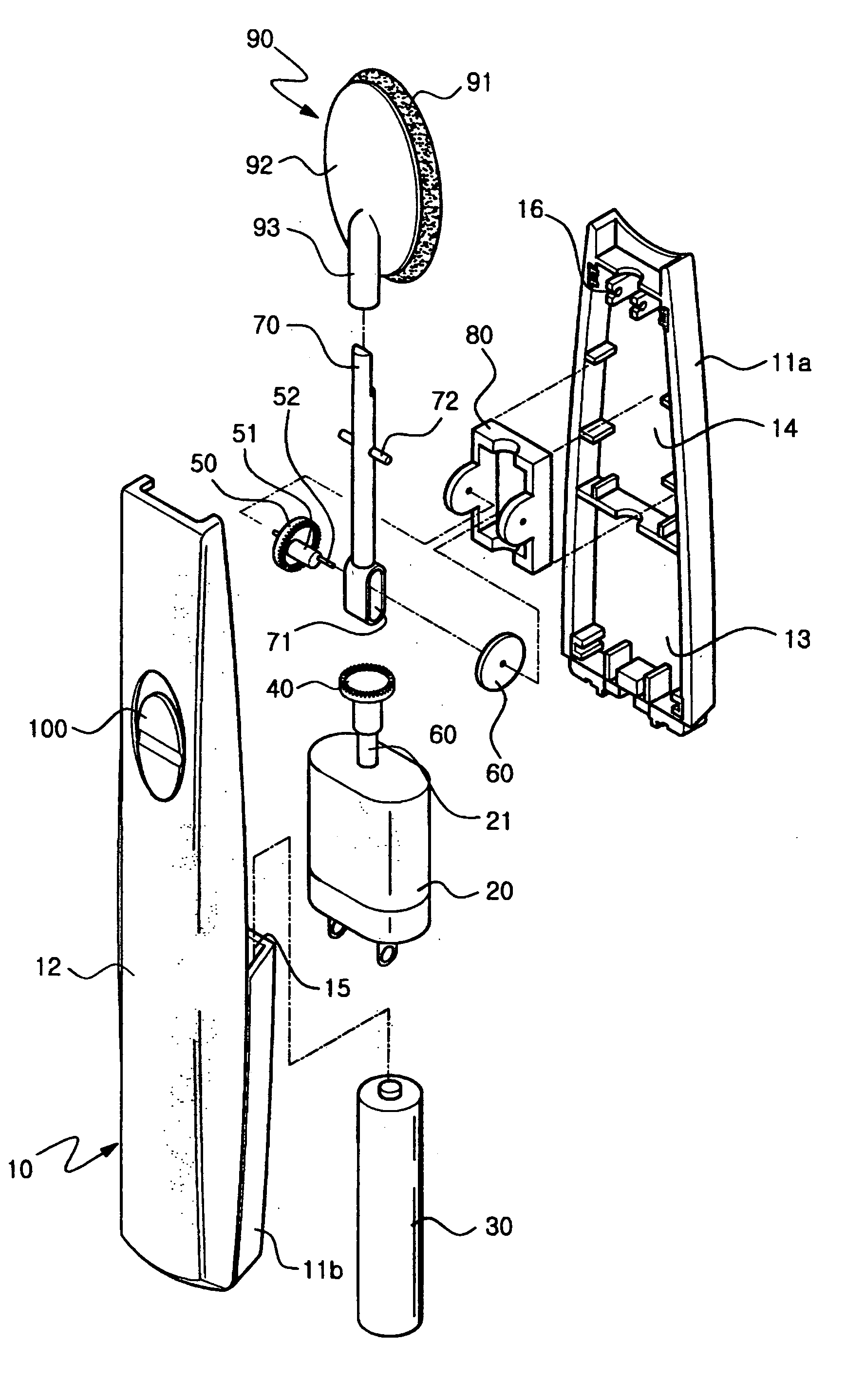

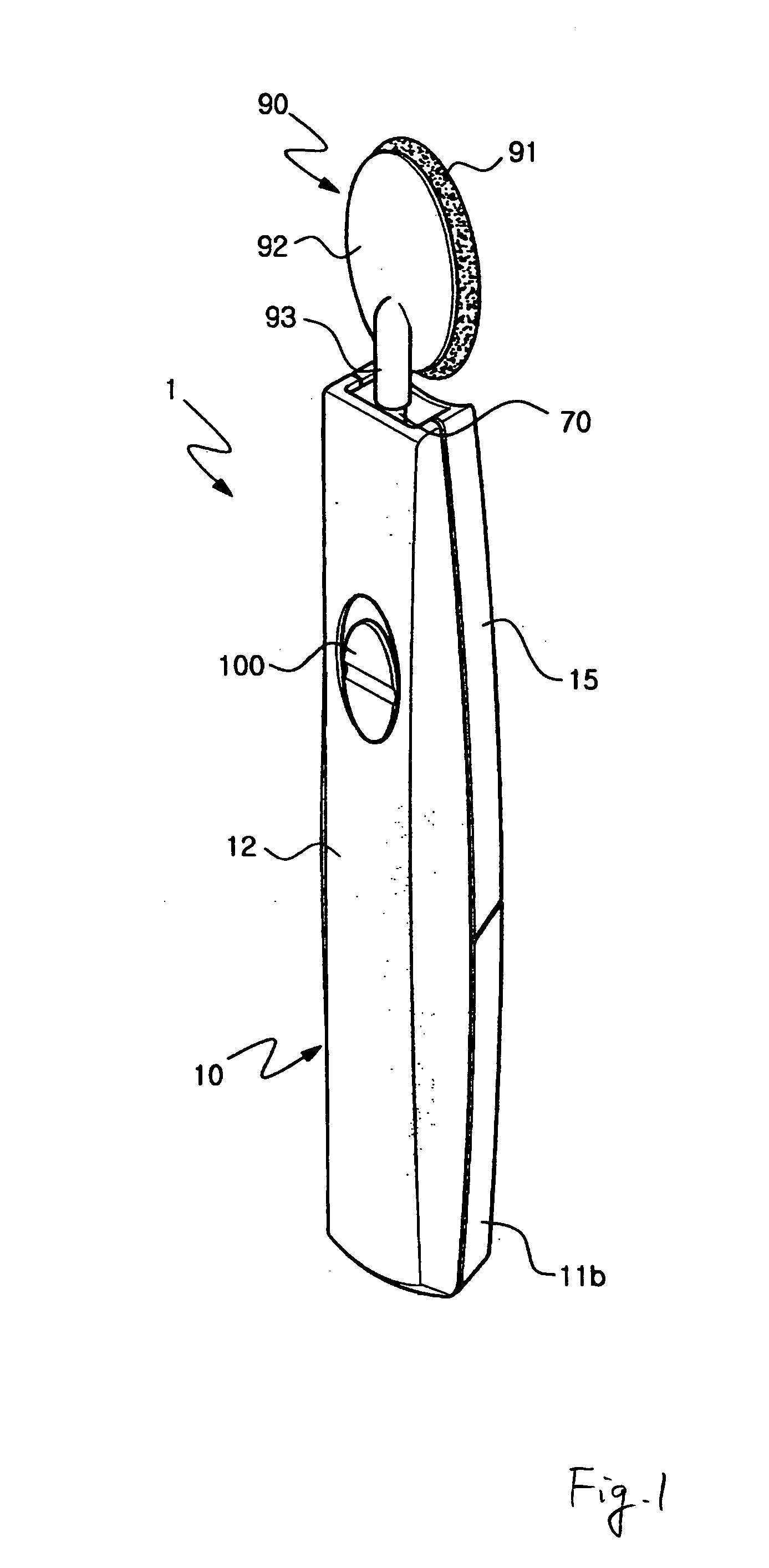

first embodiment

[0029] In the first embodiment constructed as described above, a user couples the puff head 90 to an upper end of the actuating shaft 70 which projects out of the top of the casing 10. Next, the user grips the casing 10 with one hand, and holds the puff plate 91 of the puff head 90 covered with a cosmetic, near a desired body part, especially the face. In such a state, when the electric motor 20 is operated by the power switch 100, the puff plate 91 reciprocates forward and backward, and touches the desired body part with a predetermined force, thus allowing the user to easily put on makeup.

[0030] When electricity is applied to the electric motor 20 to rotate the rotating shaft 21 and the drive gear 40, a rotating force of the drive gear 40 is transmitted to the conversion gear 50. Thus, the cam shaft 51 rotates along with the conversion gear 50. At this time, the actuating shaft 70 coupled to the cam shaft 51 through the longitudinal hole 71 swings while being supported by the supp...

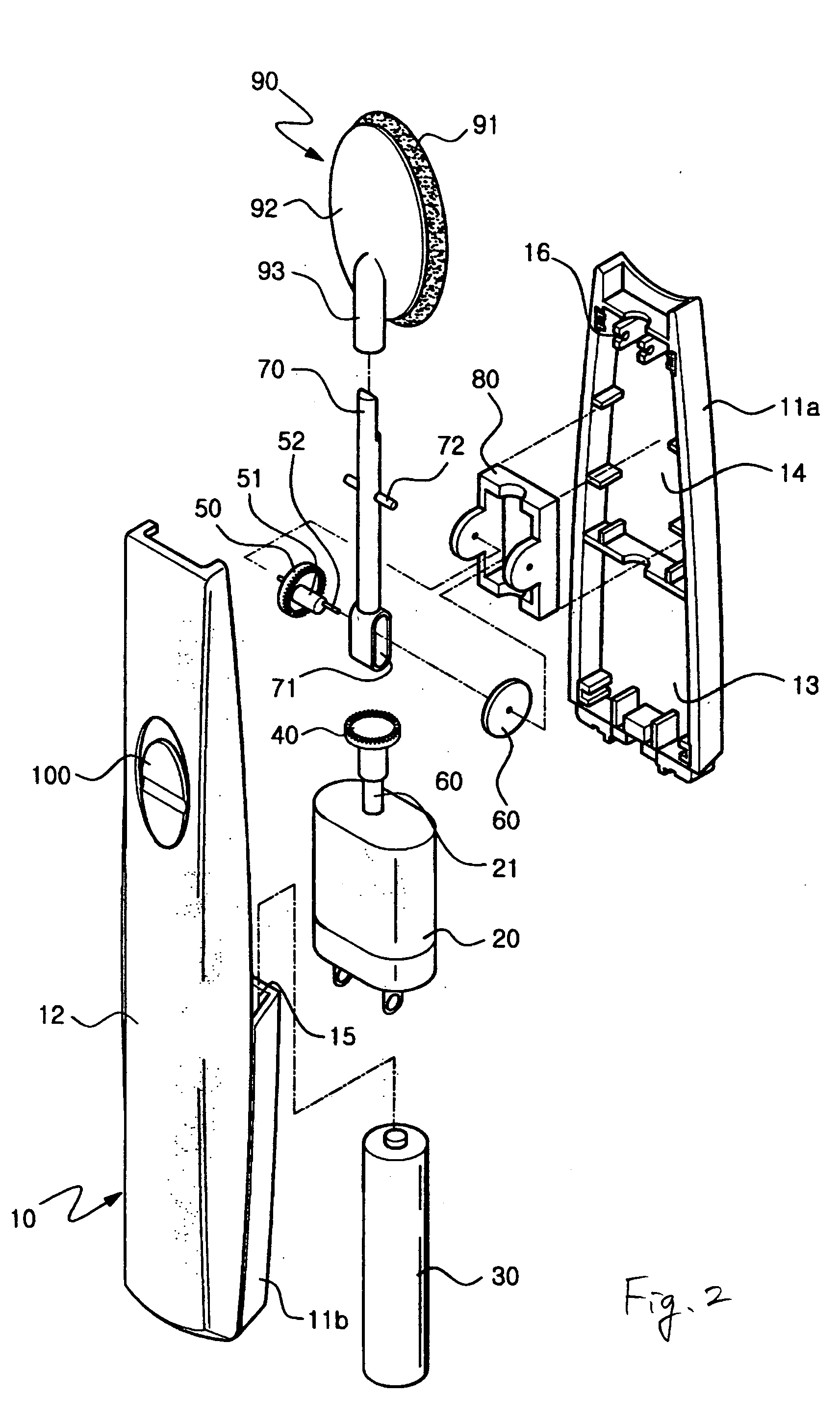

second embodiment

[0032]FIGS. 4 and 5 show the present invention.

[0033] A puff plate 91 is attached to a head part 92 of a puff head 90 with a connection pipe 93.

[0034] An actuating shaft 70 is detachably coupled to the connection pipe 93, and is swung while being supported by support pins 72.

[0035] A groove 102 is provided at a lower end of the actuating shaft 70.

[0036] Further, an eccentric unit is provided between the groove 102 and a rotating shaft 21, and is eccentrically rotated by an electric motor 20 to change the rotating movement of the rotating shaft 21 into the linear movement of the actuating shaft 70, thus oscillating the puff plate 91 forward and backward.

[0037] The eccentric unit includes a shaft support part 103 to support the rotating shaft 21 of the electric motor 20, and an eccentric shaft 104.

[0038] The eccentric shaft 104 is provided on the shaft support part 103 and eccentrically rotated by a drive force of the electric motor 20 transmitted to the shaft support part 103 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com