Micro optical sensor device

a sensor device and micro-optical technology, applied in the field of micro-optical sensor devices, can solve the problems of complex equipment or instrumentation, no commercial acceptance or viable, and typically requires a set up of relatively complex substances, etc., and achieves the effects of simple construction and design, high reliability, and easy us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

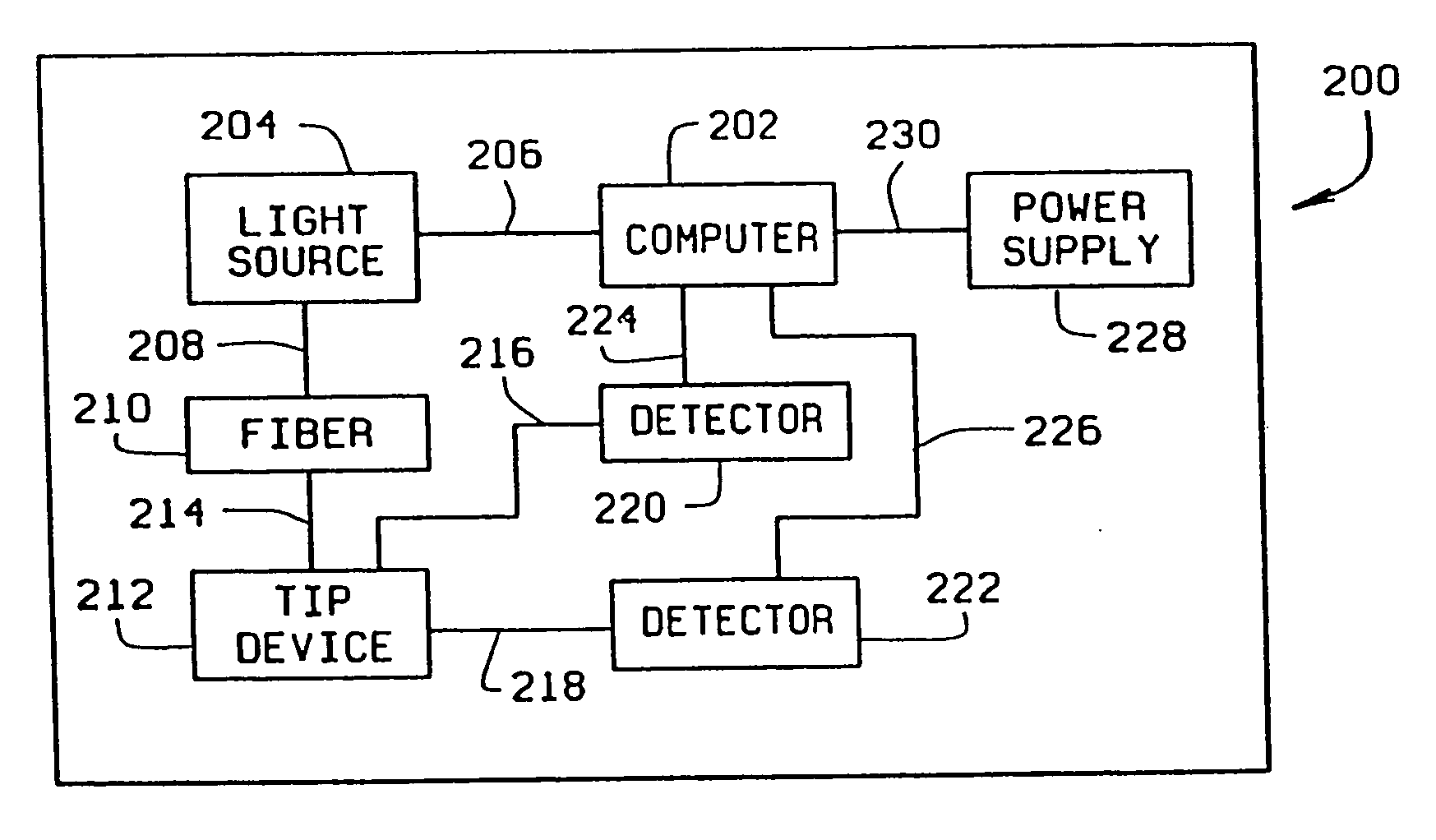

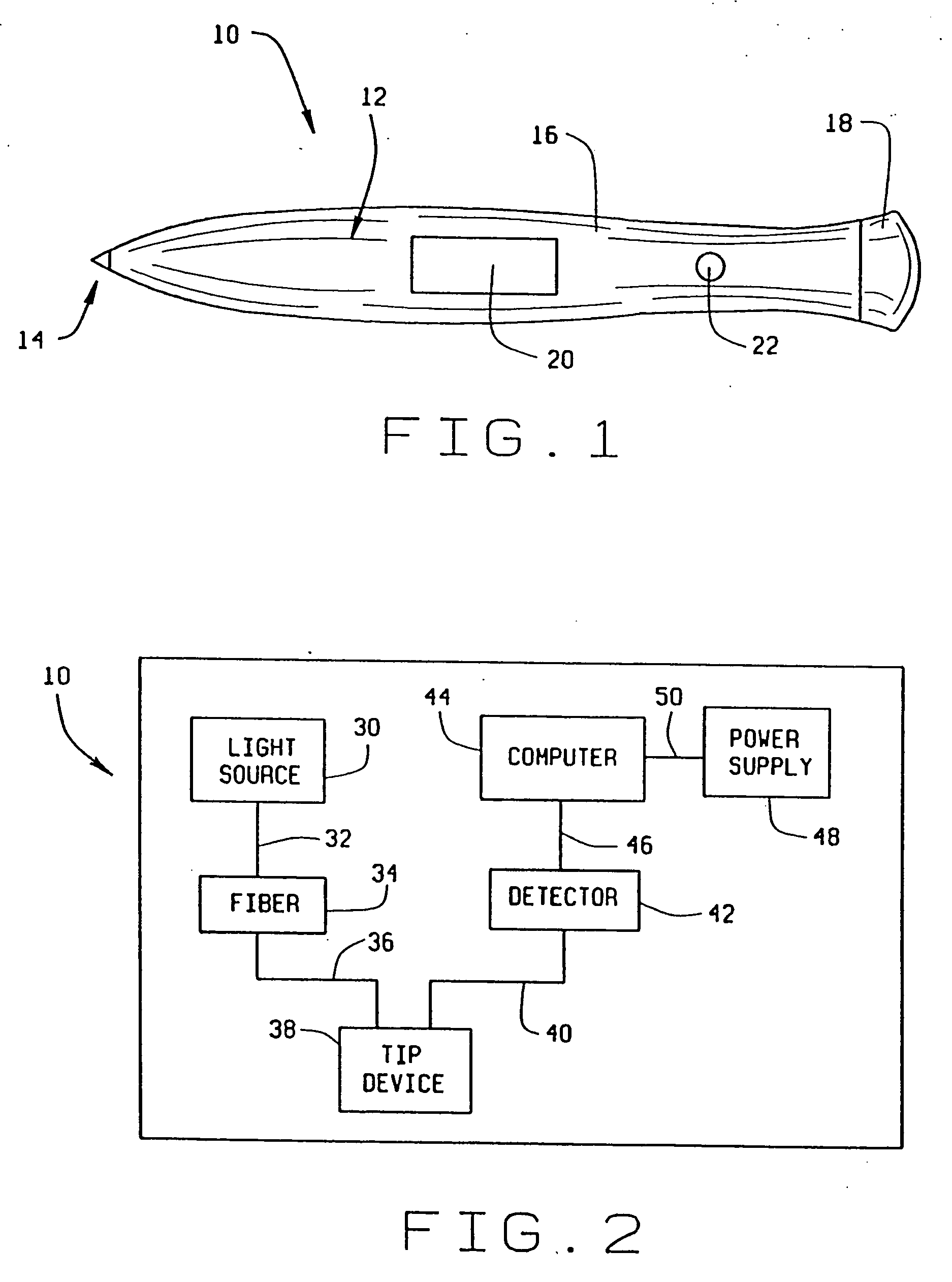

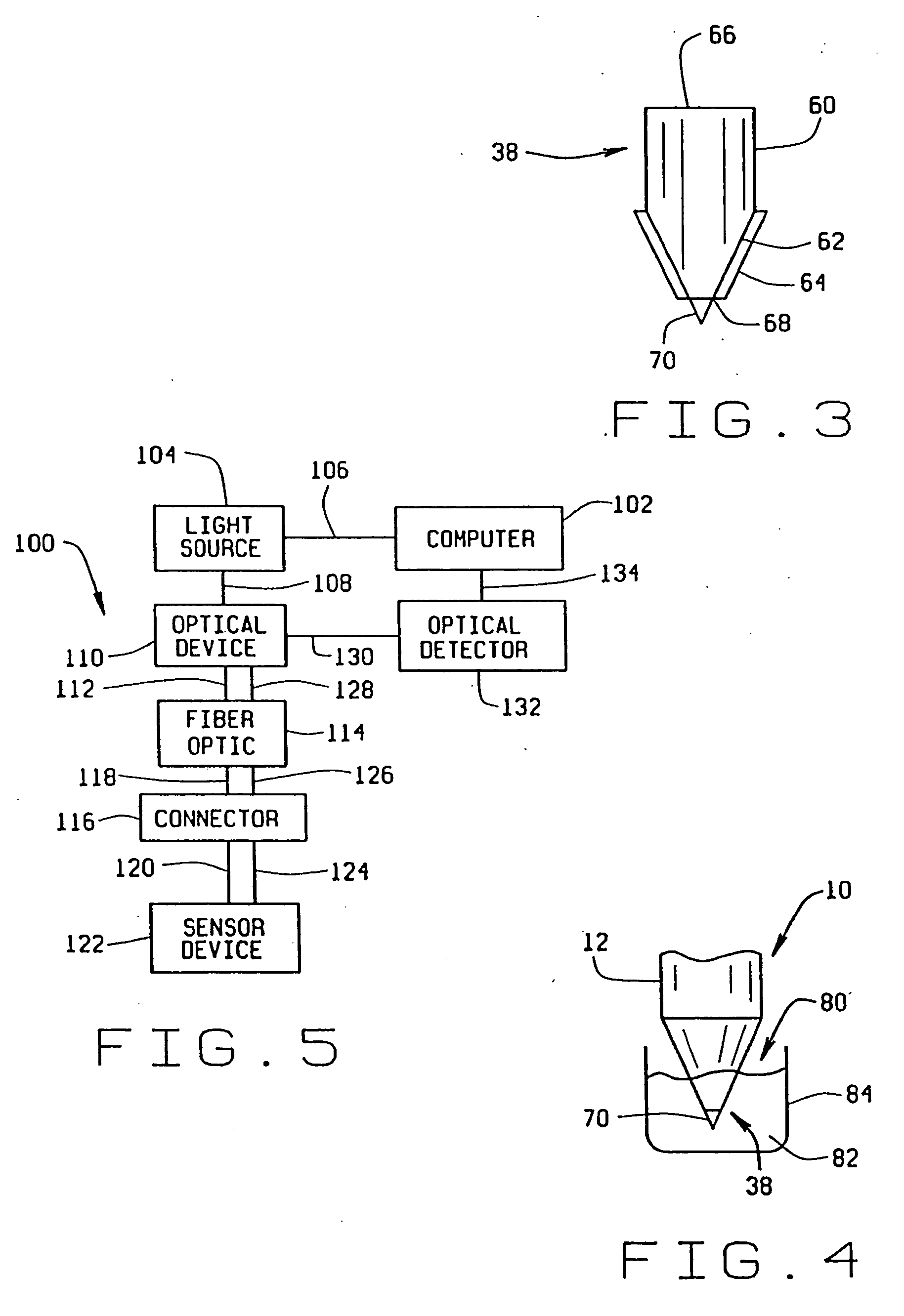

[0023] Referring now to the drawings, wherein like numbers refer to like items, number 10 identifies a preferred embodiment of a micro optical sensor device constructed according to the present invention. As illustrated in FIG. 1, the device 10 comprises a pencil or pen shaped body 12 which includes a tip portion 14, a central body portion 16, and an end cap 18. The central body portion 16 further includes a display device 20, such as an LED (light emitting diode) type display or an LCD type display, for displaying information. The end cap 18, which may be removable from the central body portion 16, is used to allow access into the interior of the central body portion 16. Batteries (not shown) can be inserted into the central body portion 16 to supply power to the device 10, as will be explained. The central body portion 16 may also include an ON / OFF switch 22 which may be used to operate the device 10. Other switches (not shown) may be incorporated into the central body portion 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com