Film effectiveness enhancement using tangential effusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

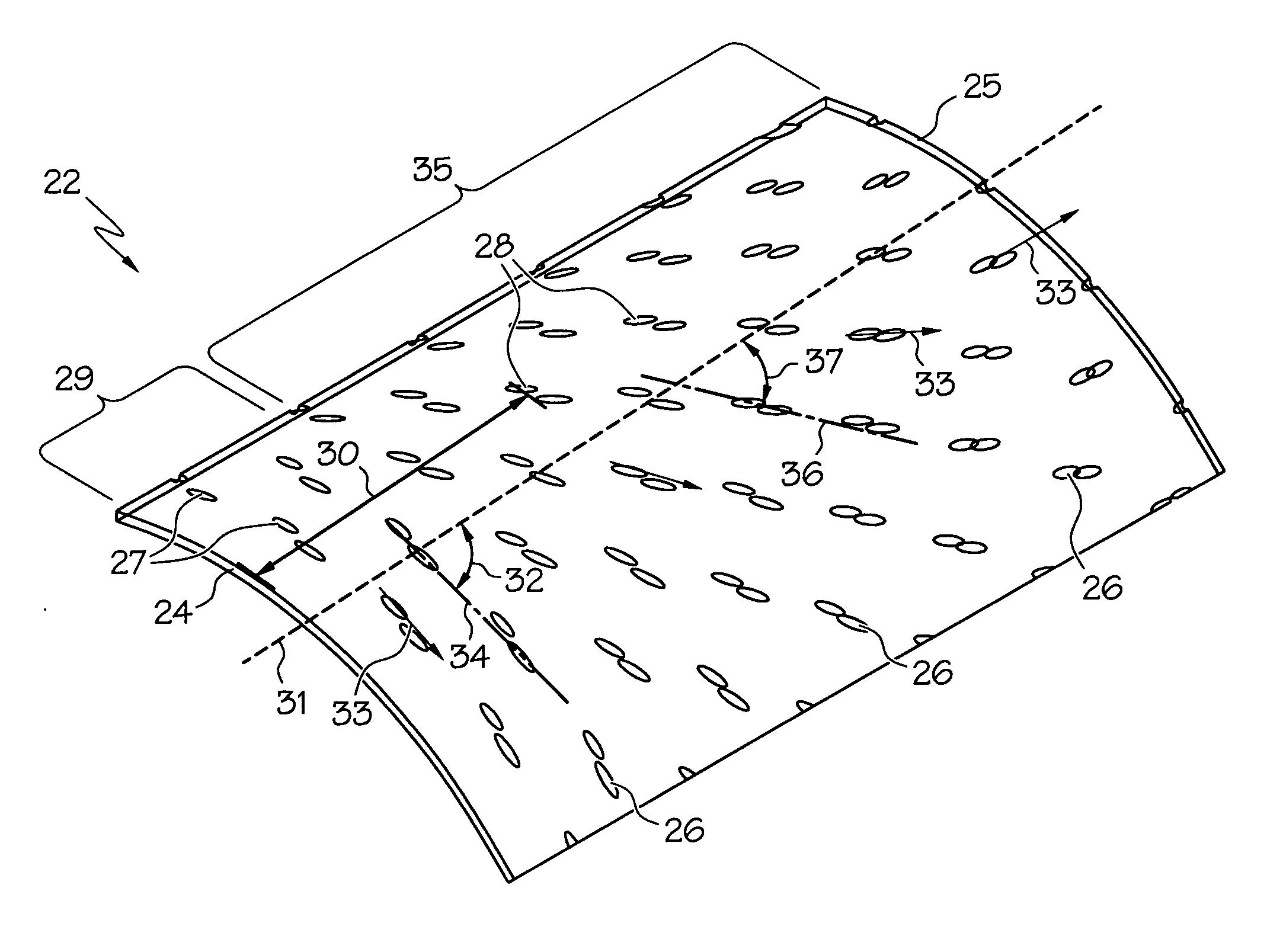

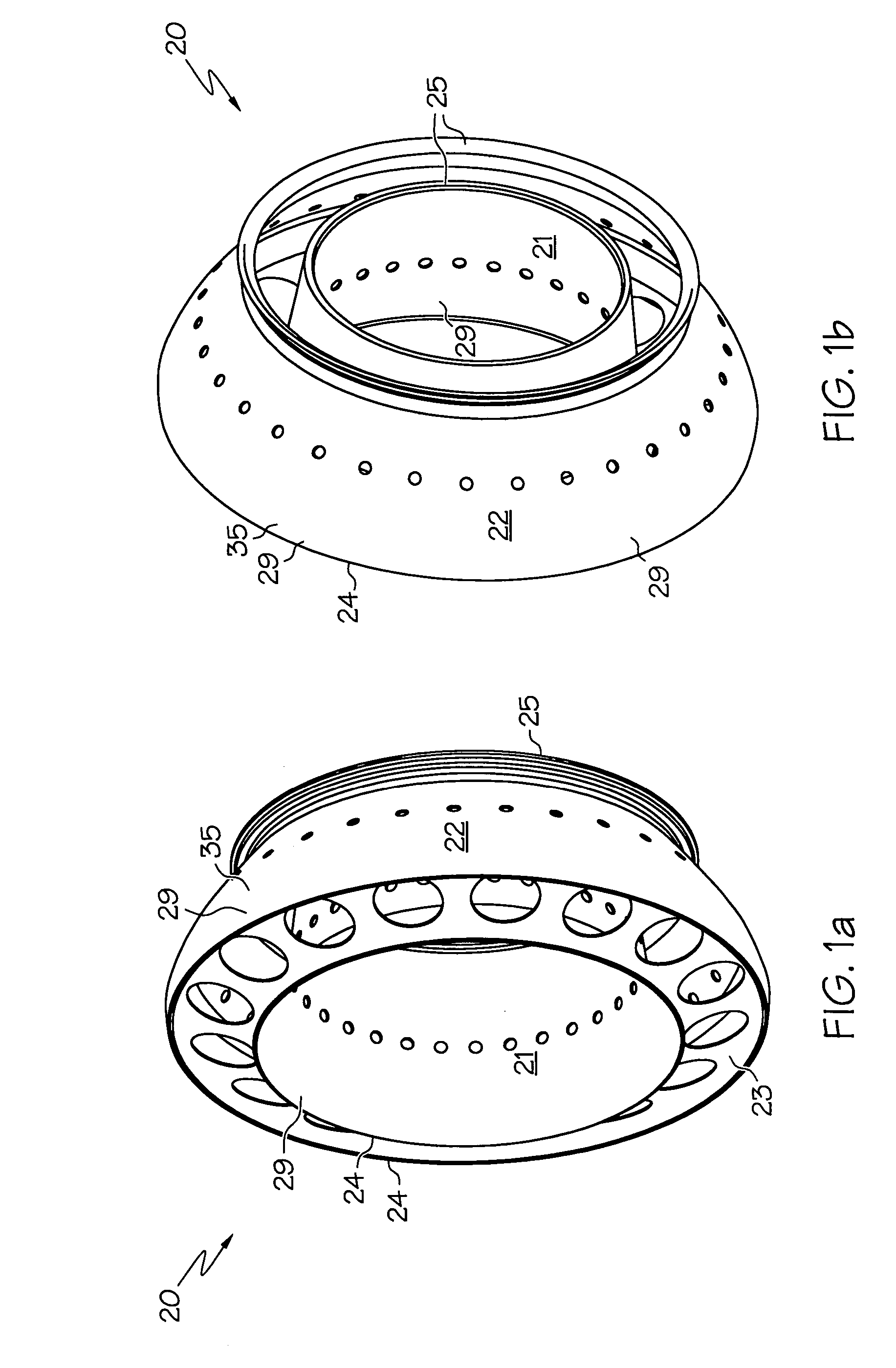

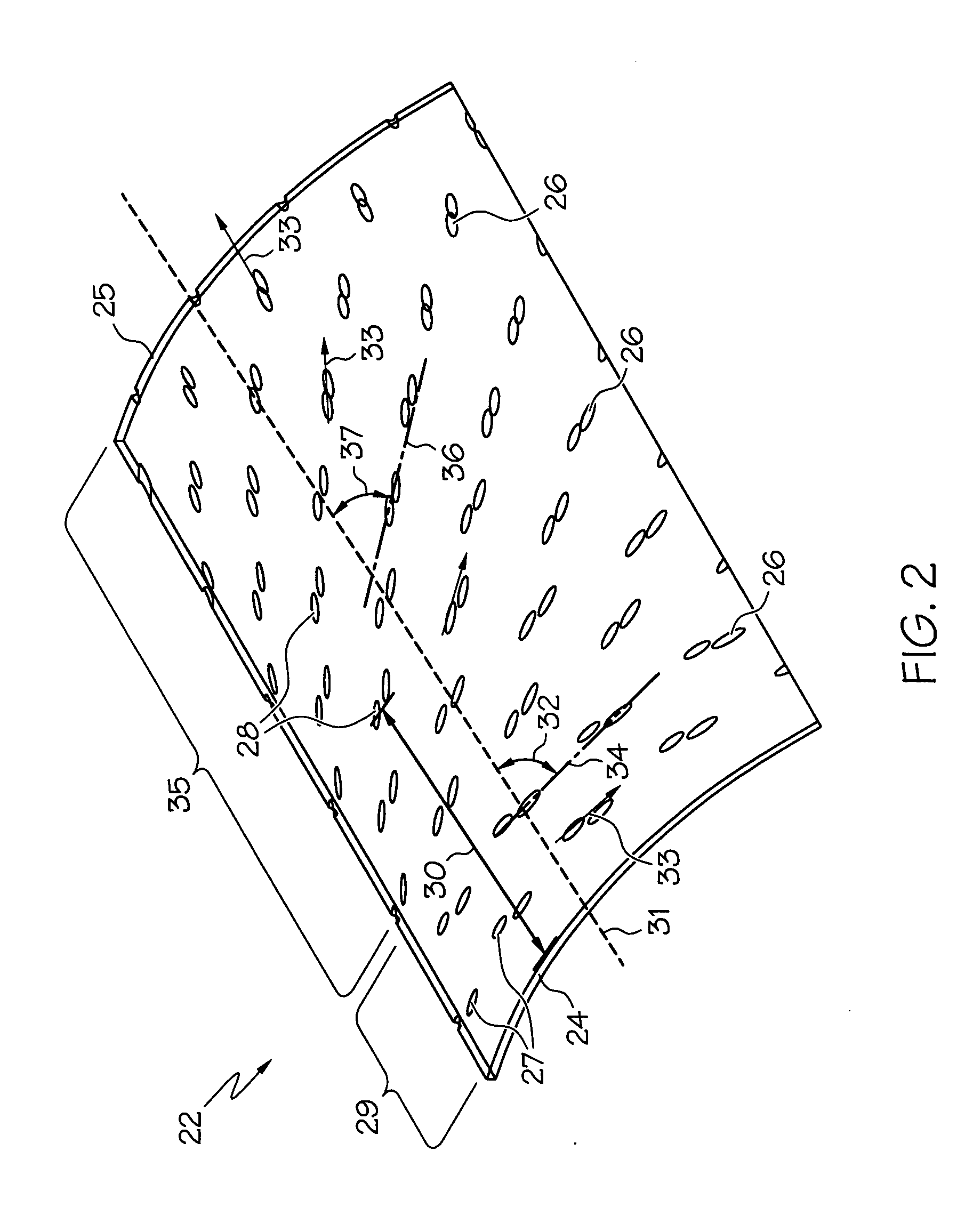

Image

Examples

example 1

[0040] The film effectiveness of a conventional effusion panel and an effusion panel of the present invention were compared. A plot of film effectiveness as a function of distance from start of panel is depicted in FIG. 4. The dashed curve represents the film effectiveness of a conventional axial orientation effusion panel. The solid line represents the film effectiveness of an effusion panel of the present invention. The present invention provides greater film effectiveness at the start of the effusion panel, the initial flow region. As can be appreciated by those skilled in the art, the present invention may decrease liner temperatures in the initial flow region of the panel, making starter skirts unnecessary.

example 2

[0041] The impact of tangential effusion can be seen in FIG. 5, which shows thermocouple measured liner metal temperatures for an annular combustor. The figure plots the maximum inner wall temperature as a function of the combustor discharge temperature. The axial orientation effusion panel used conventional axial effusion and generated the upper line of data. By changing to tangential effusion according to one embodiment of the present invention which transitioned to axial as discussed above, and without changing the amount of cooling flow, the lower line of data was generated which represents a reduction over 500° F. in liner temperature.

[0042] As can be appreciated by those skilled in the art, the present invention provides improved film effectiveness at the start of an effusion panel. This means that the complication and expense of starter skirts can be eliminated and / or effusion cooling can be effectively used in situations where a starter skirt is geometrically impossible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com