Methods for minimizing defects when transferring a semiconductor useful layer

a technology of useful layer and defect reduction, which is applied in the direction of semiconductor devices, electrical equipment, basic electric elements, etc., can solve the problems of defects that can detrimentally affect the structural properties of the transfer layer, affecting the efficiency and quality of the bond, and thus the quality of the desired final structure, etc., and achieve the effect of minimizing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

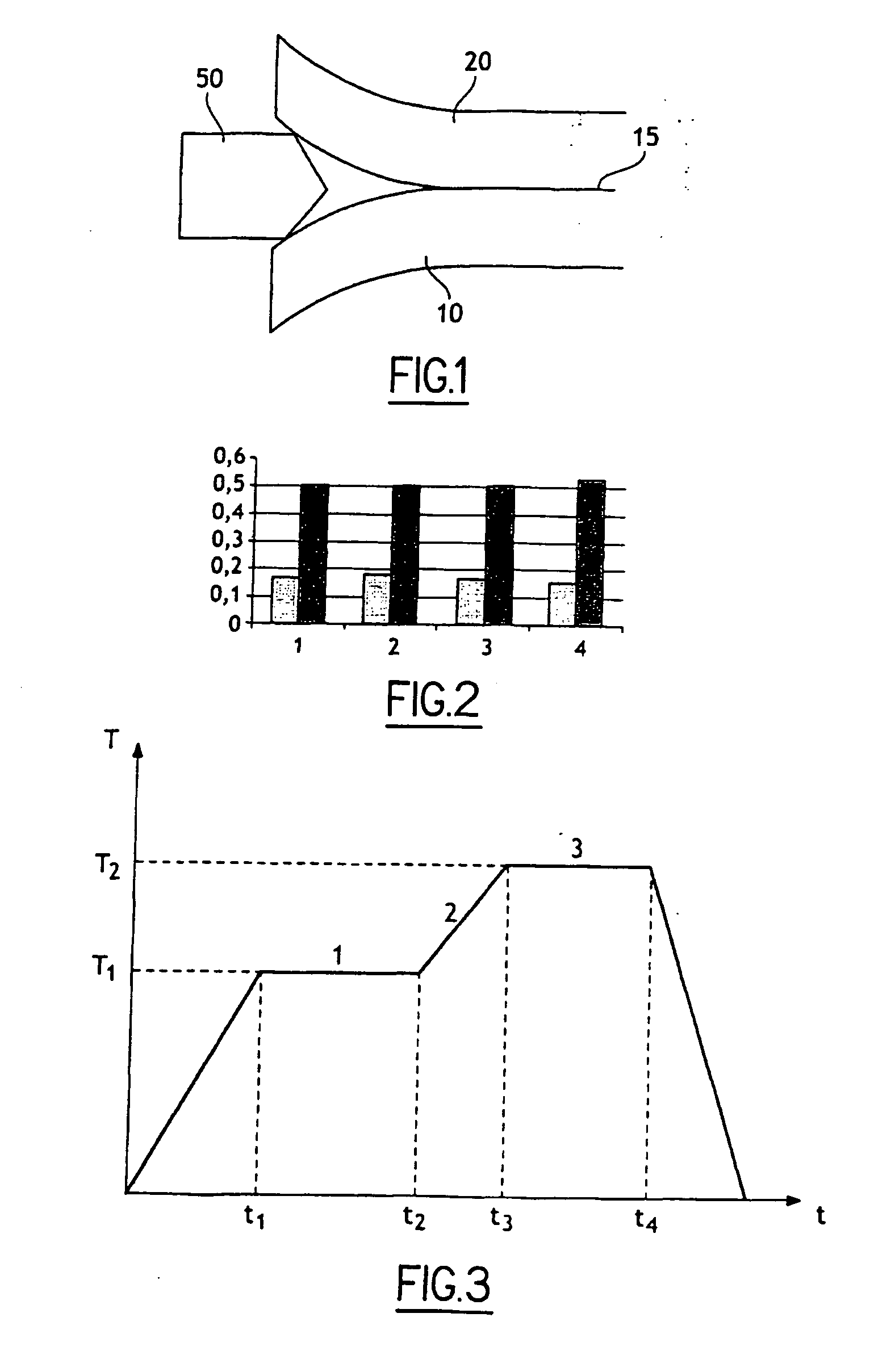

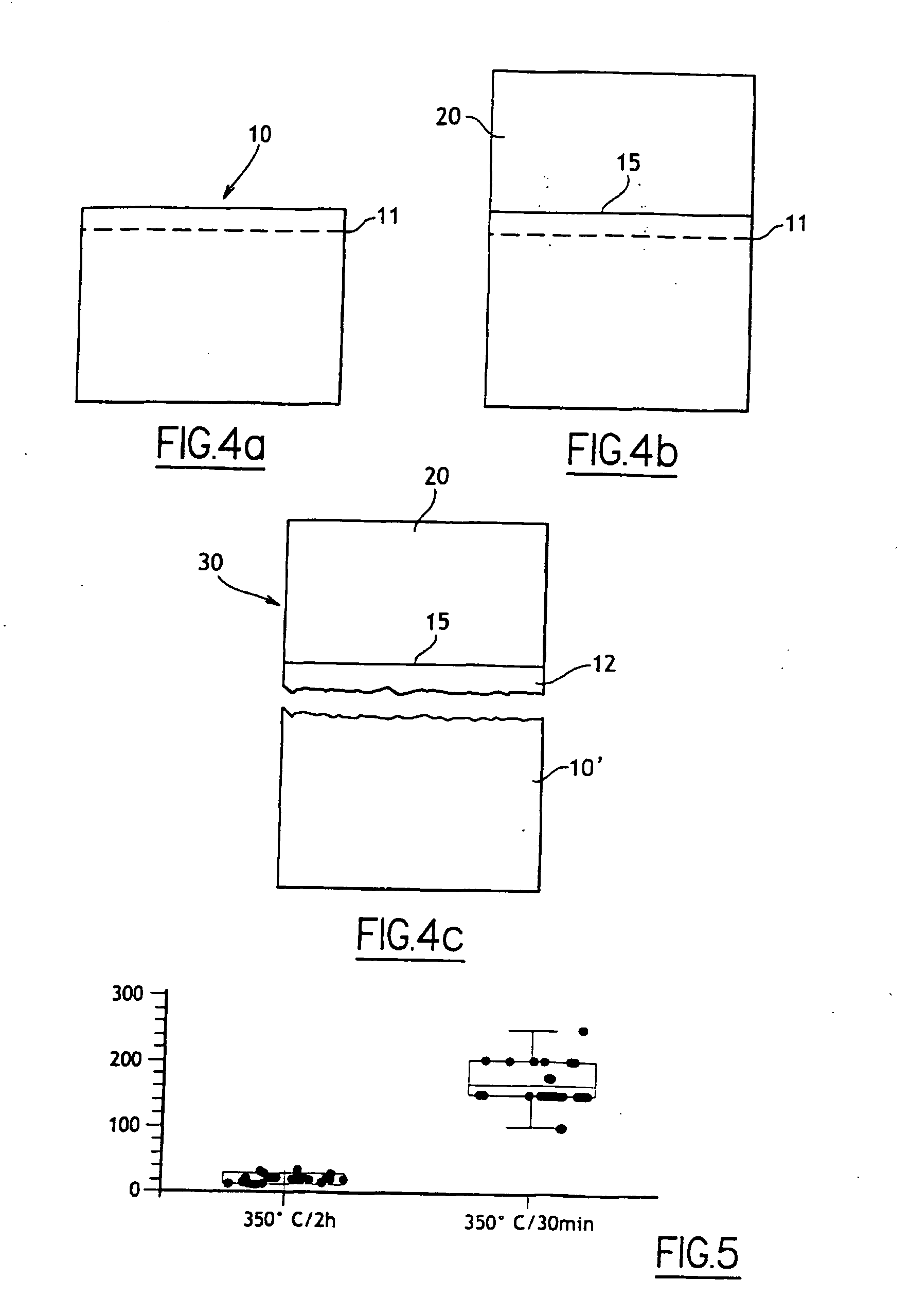

[0019] Generally, the present method seeks provide an improved method for transferring a useful layer from a first wafer to a second wafer, wherein the first wafer includes a zone of weakness that defines the useful layer. The useful layer is a semiconductor material. The technique includes bringing the surfaces of the two wafers into contact so that the surface of the useful layer is in contact with the second wafer, supplying heat energy at a first temperature that is substantially higher than ambient temperature for a first time period, and supplying additional heat energy to increase the temperature above the first temperature to detach the useful layer at the zone of weakness.

[0020] Preferred aspects of the bonding method may include any of the following features. Heat energy at a second temperature that is substantially higher than the first temperature may be applied for a second time period that follows the first application of heat, to reinforce the bonding linkages betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com