Coiled tubing vibration systems and methods

a technology of vibration system and coiled tubing, which is applied in the direction of drilling casing, drilling pipe, borehole/well accessories, etc., can solve the problems of axial, lateral and/or rotational movement of the ct, undesirable vibration is often inherent in such systems, etc., and achieves the effect of reducing friction with the system, reducing the amount of wob, and accurate determination of weight-on-bit (“wob”) measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

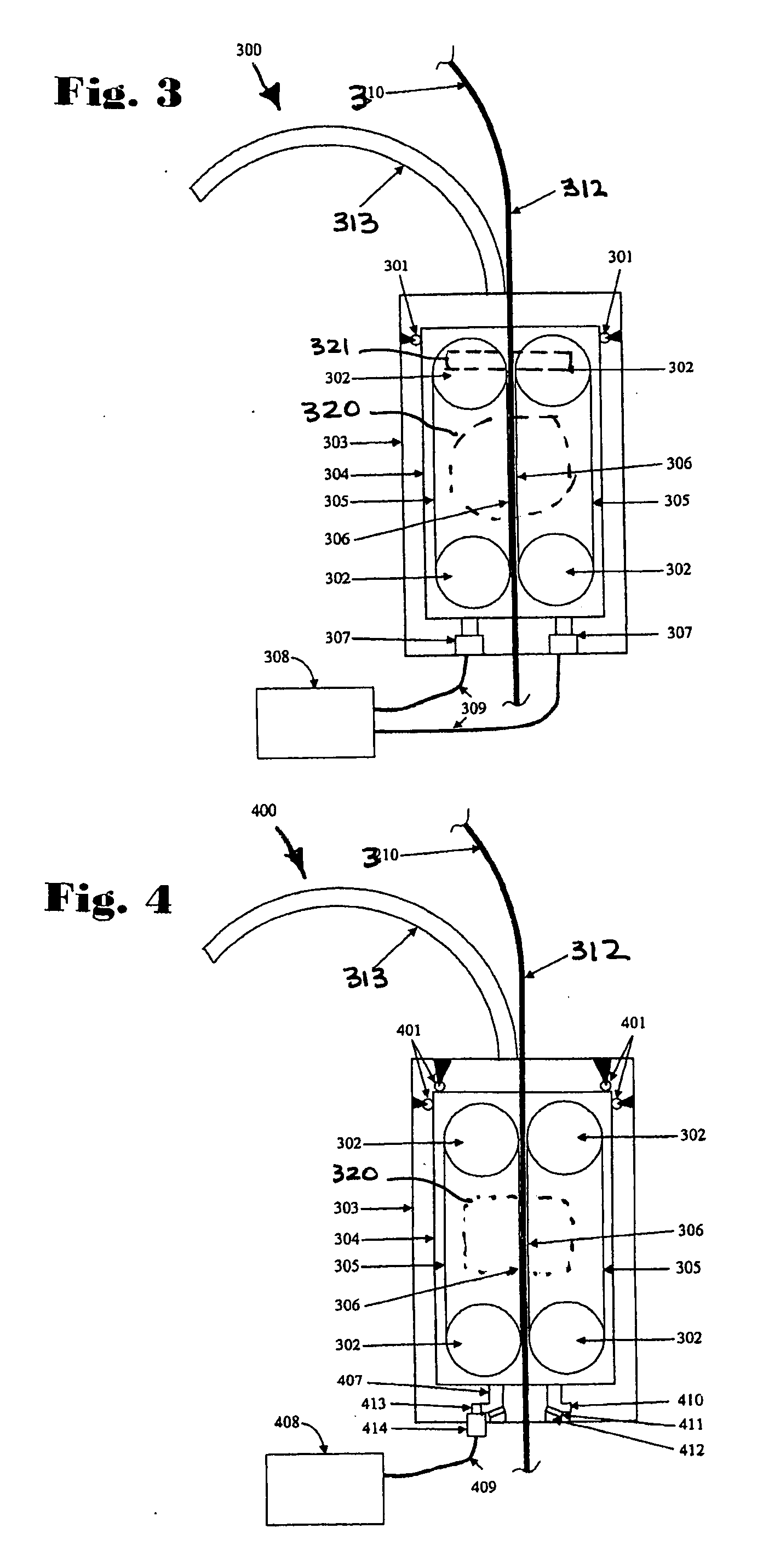

[0021] A system 300 according to the present invention as shown in FIG. 3 has a contra-rotating chain injector with vertical vibration capability. The injector. has an outer support frame 303 with an optional guide arch 313. Inside the support frame 303 there is a CT drive section 304 which contains two contra-rotating chains 305. These chains 305 pass around sprockets 302. The chains 305 are clamped against CT 312 throughout the length between the sprockets 302, this length shown as 306. A clamping system 321 is shown schematically. This clamping force holds the CT between the chains 305. The chains are then rotated by a drive system 320 (shown schematically) which turns the sprockets 302. One chain turns in one direction (clockwise or counter clockwise) and the other chain turns in the opposite direction (i.e., they are contra-rotating). As the chains turn, the CT 312 moves in our out of the well. A single or a plurality of hydraulic cylinders 307 provide vibration by moving the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com