Conveying roller, production method thereof and conveying apparatus

a technology of conveying roller and production method, which is applied in the direction of thin material handling, web handling, article separation, etc., can solve the problems of generating the skew deteriorating the quality of edge portions of photosensitive recording paper, so as to prevent the slipping of an elastic layer and prevent the effect of conveying failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

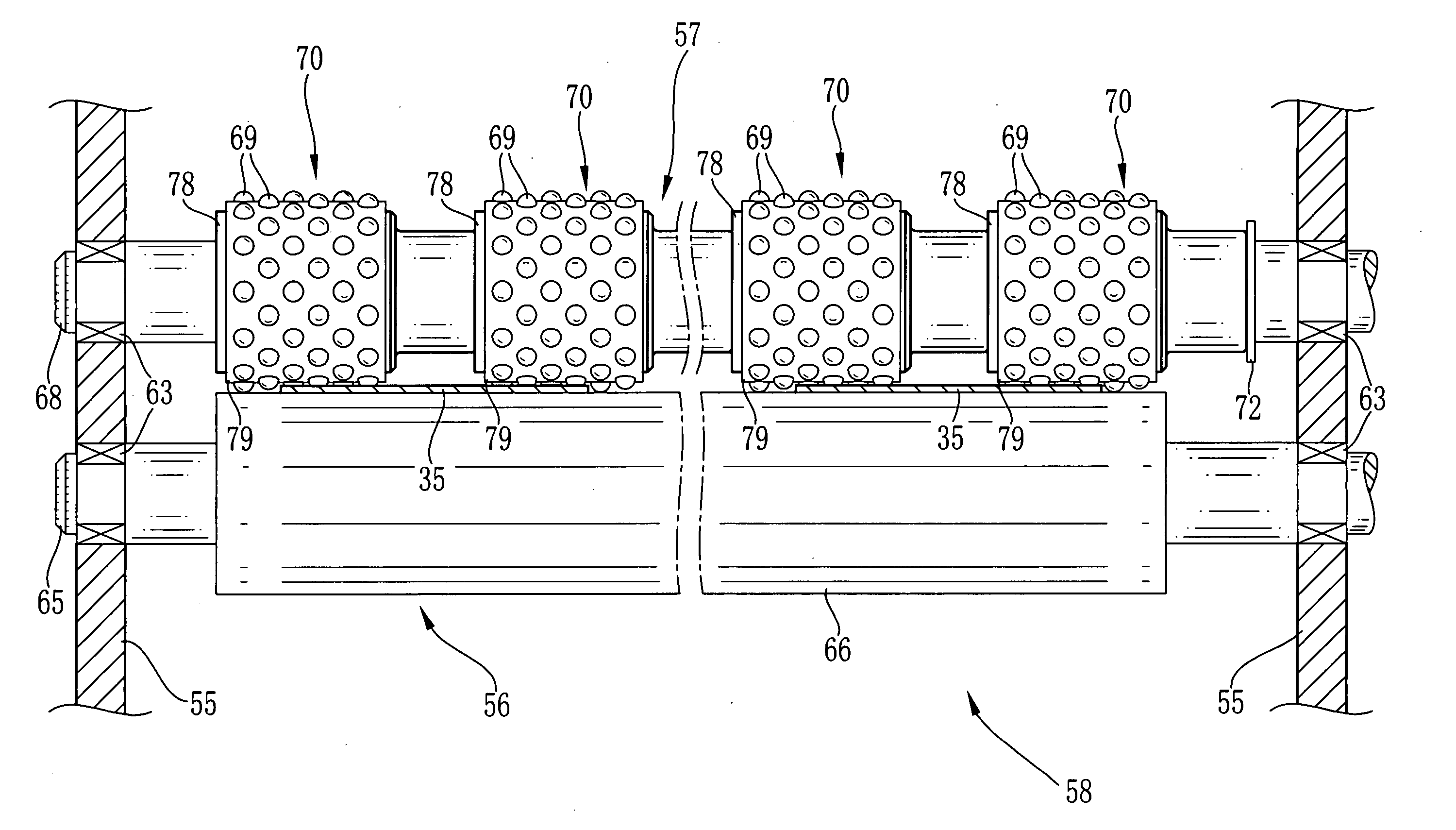

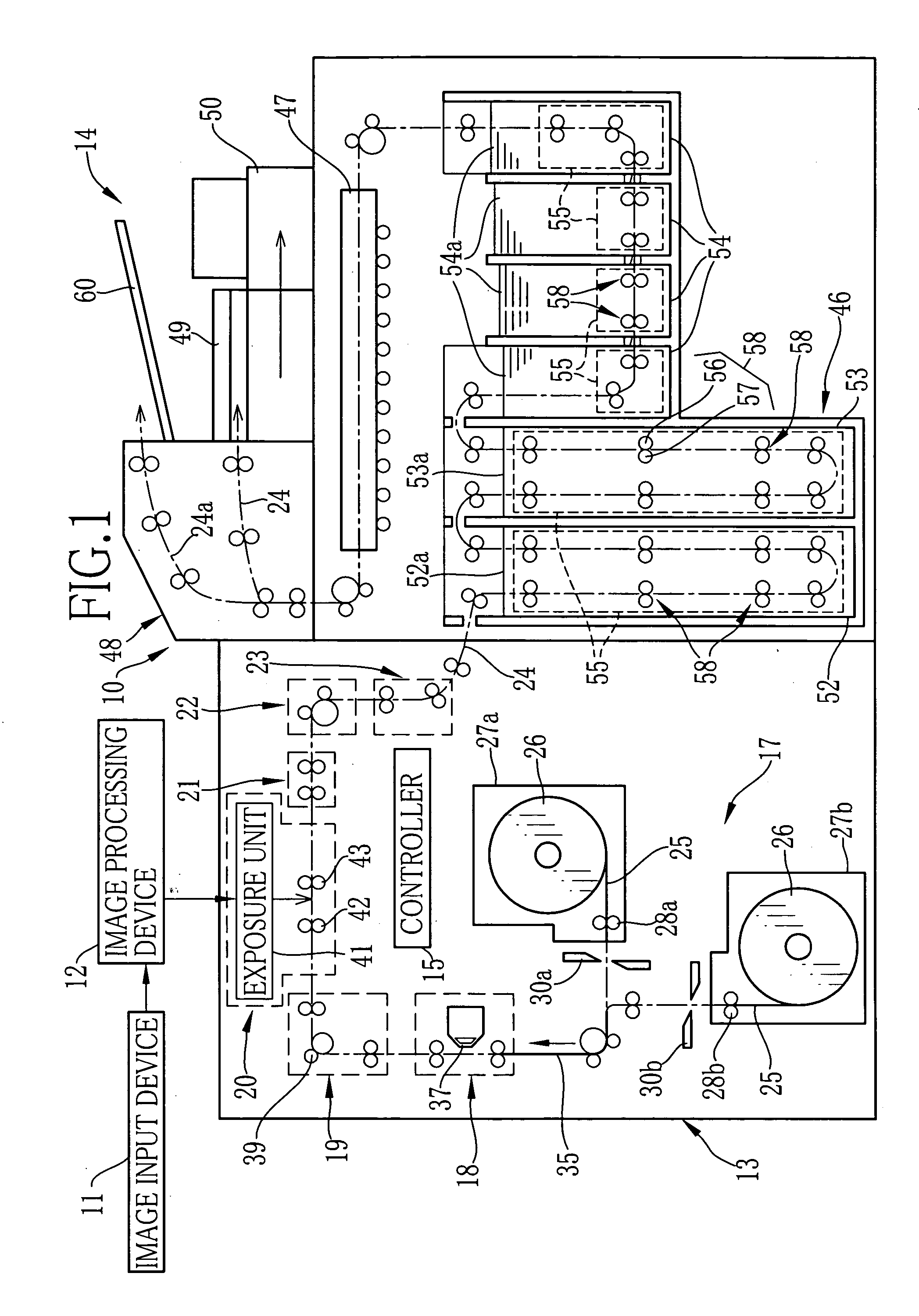

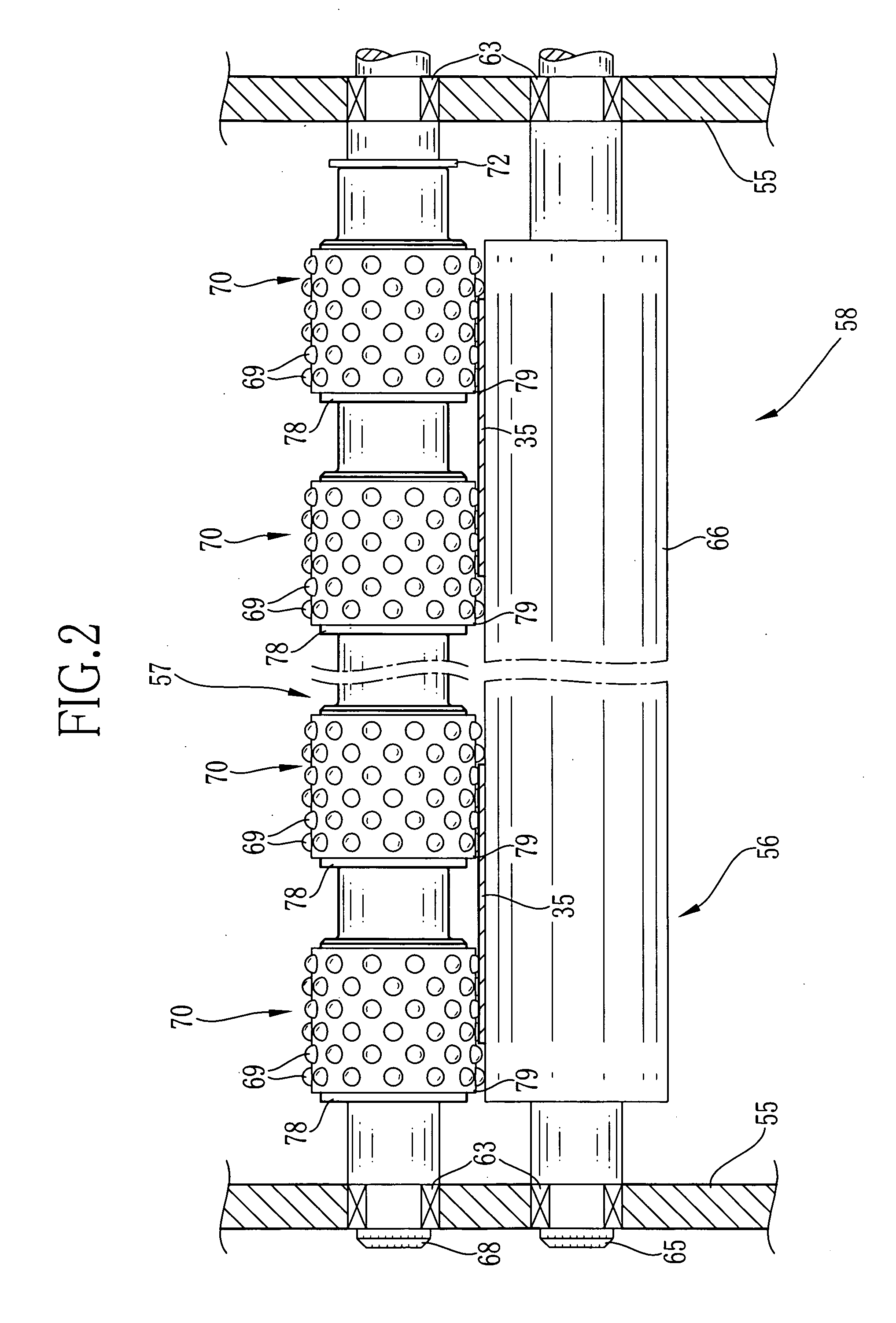

[0035] As shown in FIG. 1, a photographic printing system 10 is an image output apparatus which is constituted of an image input device 11, an image processing device 12, a printer 13, a processor 14 and the like. Each section of the photographic system 10 is connected to a controller 15 through wiring (not shown). The controller 15 controls the overall operation of the photographic system 10.

[0036] The image input device 11 generates image data by photoelectrically reading an image recorded on a photographic film by using an image capture device such as a CCD image sensor, or obtains the image data by reading the image data recorded in a recording medium such as a memory card, CDR, DVD-R and the like. The image data is sent to the image processing device 12, and image processing such as color balance correction and density correction are performed to the image data. After the image processing, the image data is sent to the printer 13.

[0037] The printer 13 records images on a phot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap