Process for the cryogenic distillation of air

a technology of cryogenic distillation and air, which is applied in the direction of refrigeration and liquifaction, lighting and heating apparatus, solidification, etc., can solve the problems of overall oxygen recovery falling, unfavorable loss of oxygen recovery, etc., and achieve the effect of reducing the pressure of nitrogen-rich liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

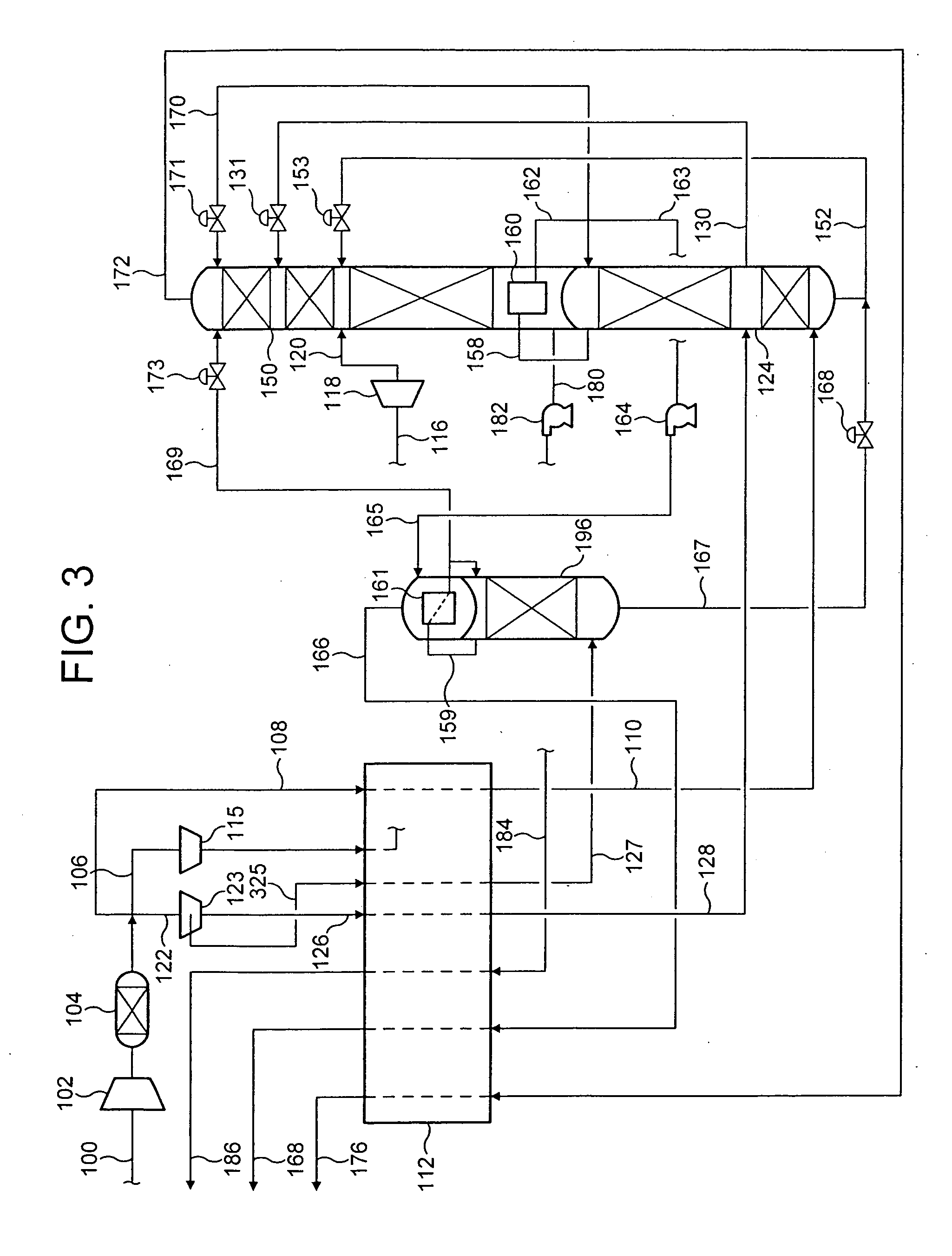

[0089] A computer simulation of the process depicted in FIG. 6 has been carried out to exemplify the invention. In the simulation, the auxiliary column 196 had only 10 theoretical stages whereas it would need about 50 stages if it were to produce pure nitrogen directly with no return of impure nitrogen to the rest of the ASU. The results of the simulation are indicated in the Table 1.

TABLE 1Feed Streams105107108122325Fkmol / h100002917466724162519Pbar13.413.413.413.413.4(MPa)(1.34)(1.34)(1.34)(1.34)(1.34)Tdeg C.3030303030% O220.9620.9620.9620.9620.96% N278.1178.1178.1178.1178.11% Ar0.930.930.930.930.93PhasevaporvaporvaporvaporvaporProduct Streams168176185186190Fkmol / h2526569342168851Pbar12.51.23433.44.9(MPa)(1.25)(0.12)(3.4)(3.34)(0.49)Tdeg C.2727−177.727−189.3% O21 ppm6.5099.8599.851 ppm% N299.8992.000.000.0099.89% Ar0.111.500.150.150.11PhasevaporvaporliquidvaporliquidIntermediate Streams127165166167169Fkmol / h25192526252611891330Pbar12.812.712.712.812.7(MPa)(1.28)(1.27)(1.27)(1.28)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com