Wafer chuck

a technology of chuck and chuck body, which is applied in the direction of grinding machine components, grinding drives, manufacturing tools, etc., can solve the problems of unavoidable creation of microscopic defects at the wafer, and achieve the effect of preventing localized distortion or curve of the wafer, preventing easy removal, and not causing defects on the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will now be described with reference to the drawings.

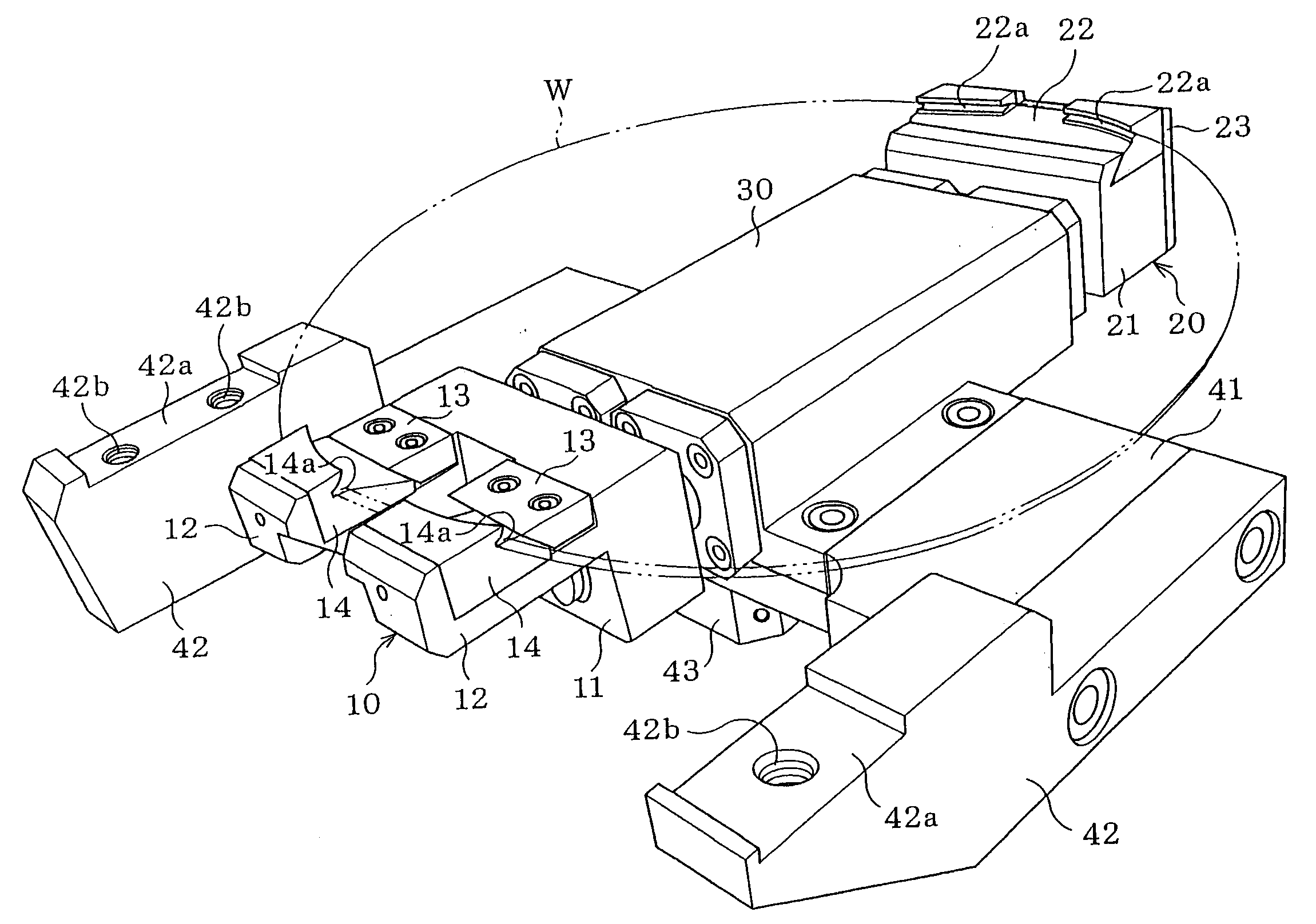

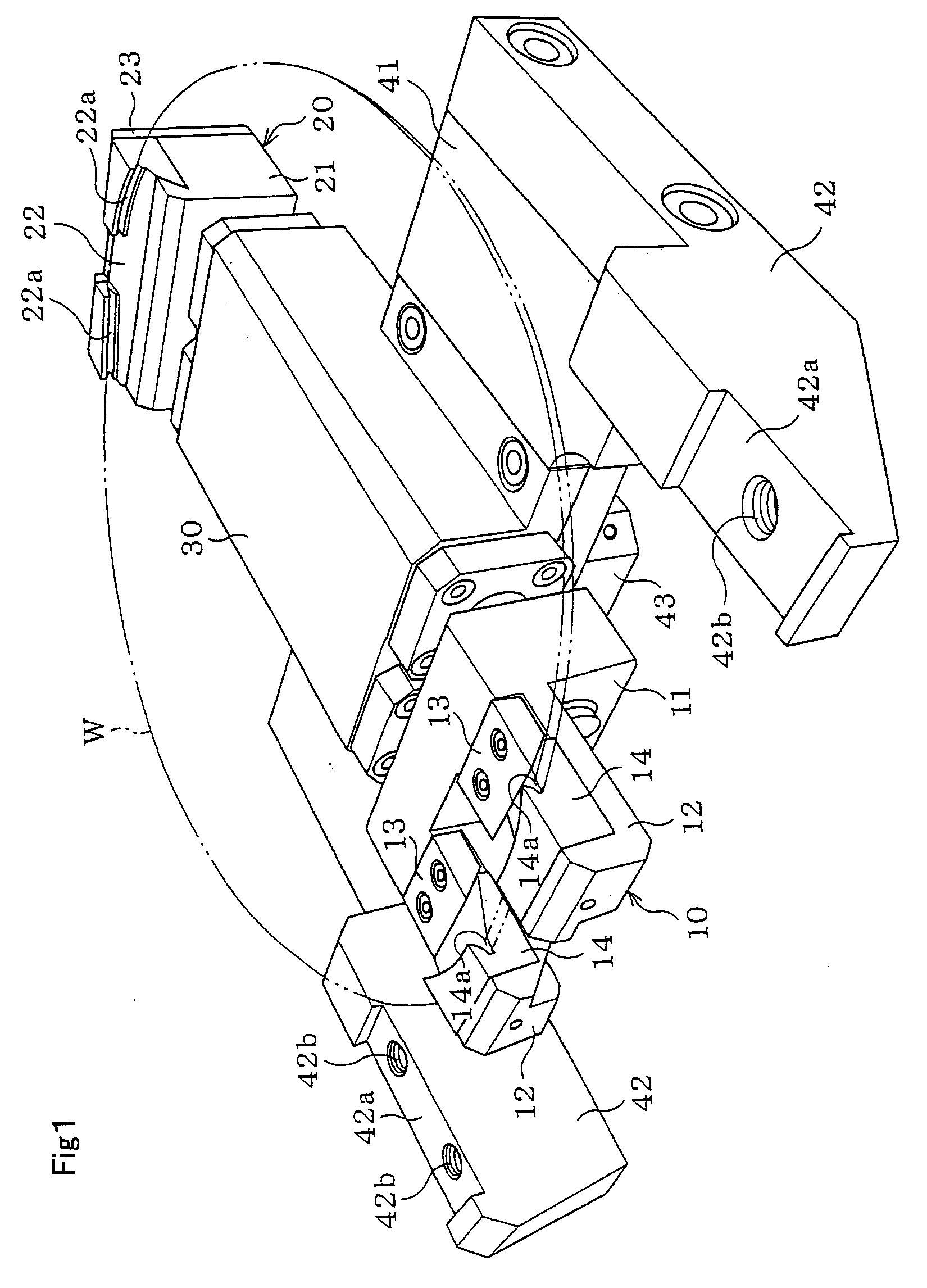

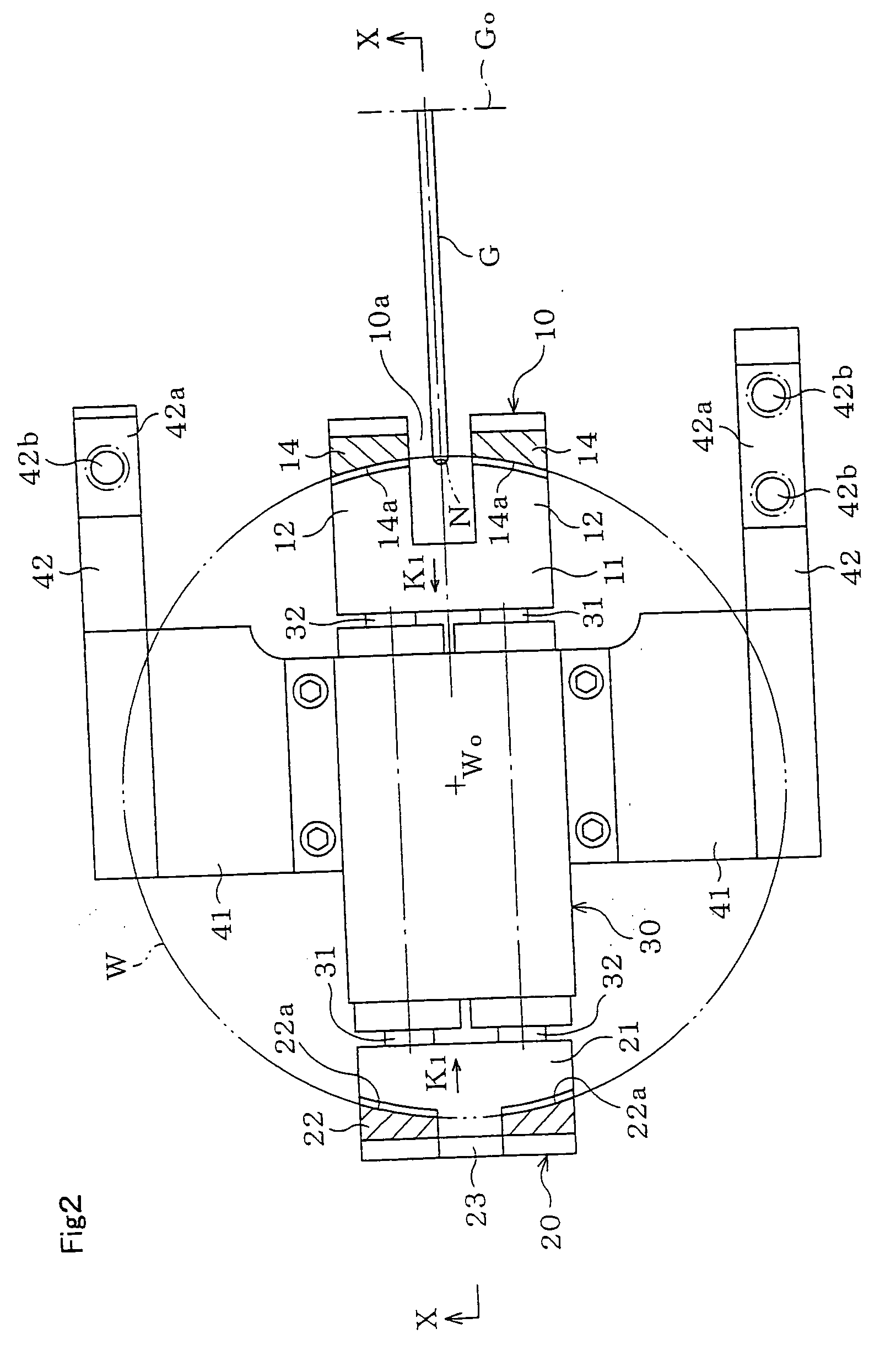

[0031] The wafer chuck is made by integrally assembling a pair of holding members 10, 20 and a driving mechanism 30 (FIG. 1, FIG. 2). The holding members 10, 20 are driven in a closing direction-(direction of arrow K1, K1 of FIG. 2) by way of the driving mechanism 30 to push the outer periphery of the wafer W towards the center Wo of the wafer W in a radial direction and hold the wafer W.

[0032] One of the holding members 10 is formed with a pair of left and right parallel fingers 12, 12 projecting horizontally from a distal end of the common base 11. The distal end of each finger 12 is bent upwards, and an elastic member 14 is attached in an exchangeable manner to the upper surface of each finger 12 by way of a press plate 13. V-shaped grooves 14a that conforms to the outer peripheral part of the wafer W is formed at each elastic member 14, 14, and the V-shaped grooves 14a, 14a, op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com