Golf club head having a cushion channel formed with a varied width and manufacturing method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

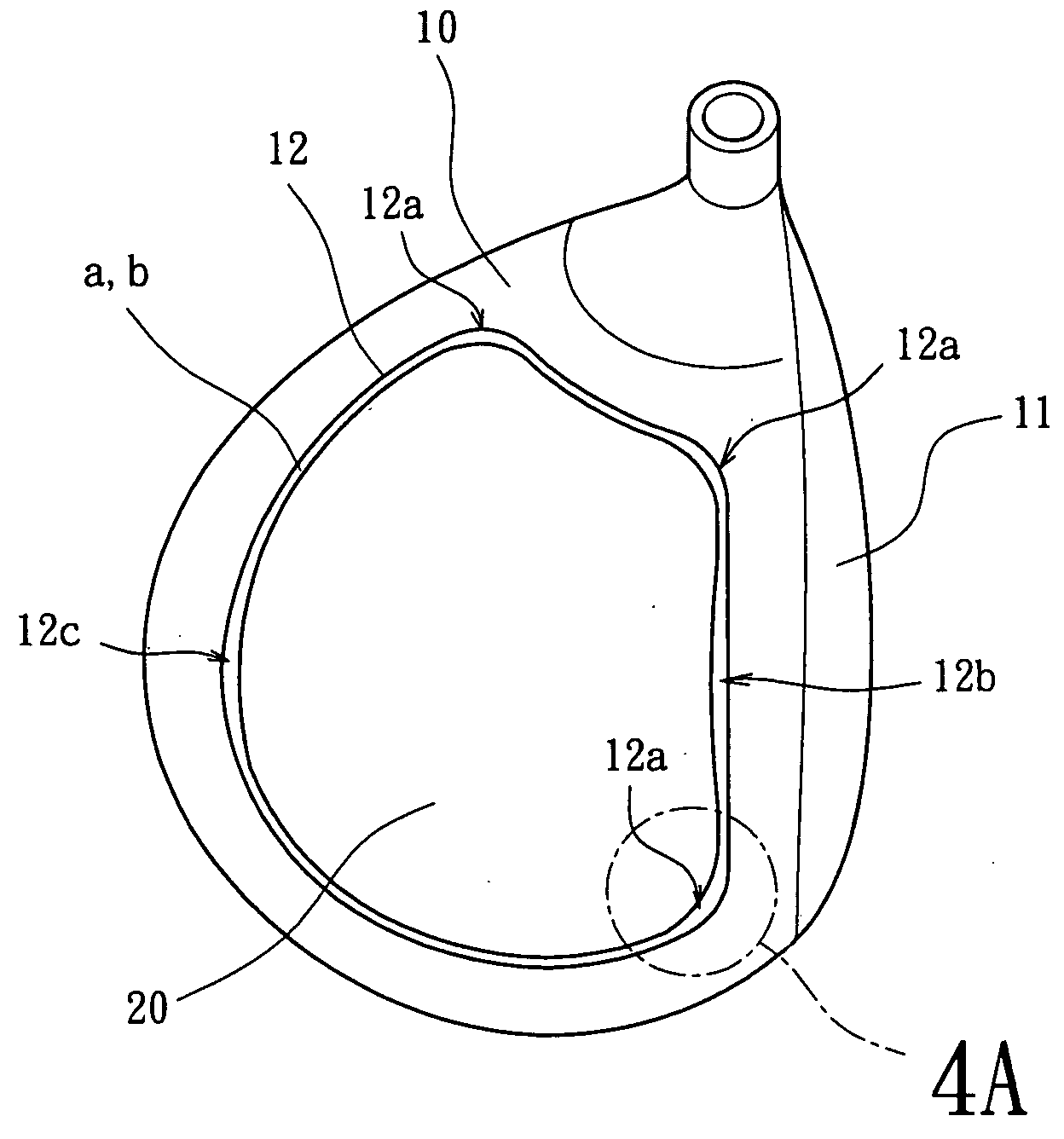

[0037] Referring to FIGS. 3, 4 and 4A, the first step of the manufacture method in accordance with the present invention is forming a plurality of through holes 12 on the surface of the main body 10 of the golf club head. The main body 10 is preferably formed as a single one-piece member by casting and the material thereof can be selected from a group consisting of stainless steel, titanium alloy, and iron etc. Generally, a striking plate 11 is attached to the front of the main body 10 by welding, integrally forming or embedding. An appropriate amount of the through holes 12 are formed on the crown plate, the sole plate or the side plate of the main body 10. A stepped portion 121 is formed on the peripheral of the through holes 12 for supporting a carbon-fiber plate 20, a weighting member 30 and a nameplate 40 (as shown in FIG. 1), which are constructed from predetermined sizes, in the following procedure.

[0038] Referring to FIGS. 3, 4 and 4A, the second step of the manufacture meth...

second embodiment

[0048] Furthermore, as shown in FIGS. 11, 11A, 12 and 12A, when the size of the through holes 12 and the carbon-fiber plate 20 is too large to form a predetermined longer distance of the cushion channel “a”, a number of disadvantage limitations exist for a CNC milling process in milling the periphery of the through holes 12 and the carbon plate 20. Alternatively, a first stepped portion 122 and a second stepped portion 123 of the second embodiment in the present invention, as best shown in FIG. 7, can be used to position the large-size carbon-fiber plate 20 on the large-size through holes 12 so as to form a desired, predetermined longer distance of the cushion channel “a” varying in width.

[0049] Advantageously, the stepped portion 122 of the through hole 12 conveniently receives the carbon-fiber plate 20 such that the large-size carbon-fiber plate 20 is adhered to the first stepped portion 122 of the through hole 12 for the ease of manufacture. Meanwhile, the second stepped portion ...

third embodiment

[0053] As shown in FIGS. 11, 11A, 12 and 12A, the short fingers 21 of the carbon-fiber plate 20 in the third embodiment can also be adapted to support a large-size carbon-fiber plate 20 on a large-size through hole 12 for forming cushion channel “a” with various widths.

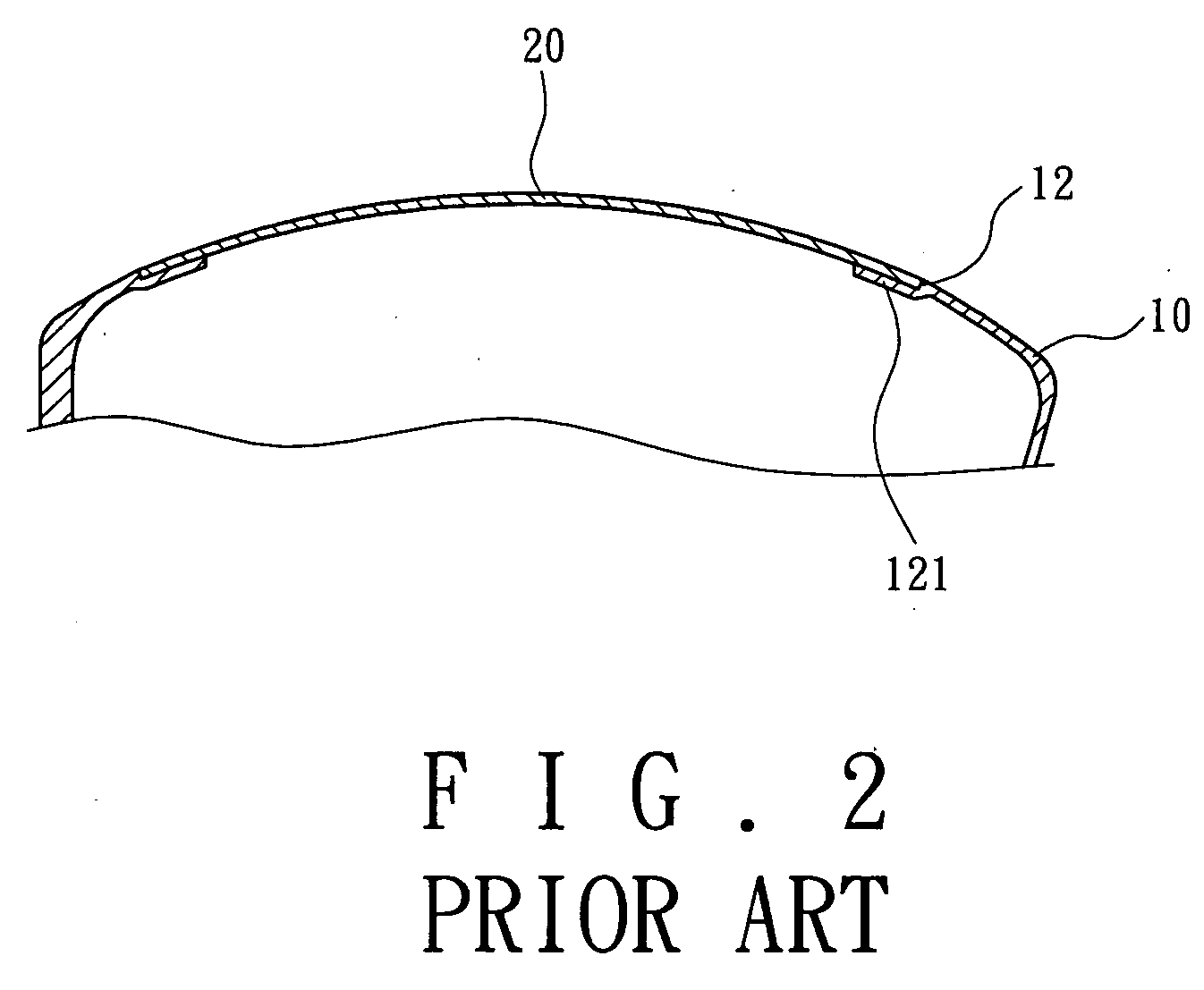

[0054] As has been described above, the conventional carbon-fiber plate 20 is closely fitted with the through hole 12 on the main body 10, thereby plastic deformation and wrinkles occur constantly, as shown in FIGS. 1 and 2. However, the golf club head and the manufacture method therefor in the present invention indeed maintain the structural strength of the main body 10 and promote the quality and the product price.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap