Phase difference control component, process for producing the same and liquid crystal display device

a phase difference and control component technology, applied in the direction of optics, instruments, optical elements, etc., can solve the problems of small visibility angle, inability to properly display, and leakage of light from pixels, and achieve excellent symmetry of visibility angle, the effect of increasing the visibility angle of liquid crystal display devices and achieving the effect of high phase difference symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0063] The following Examples further illustrate the present invention. However, it should be noted that the present invention is not limited to these Example.

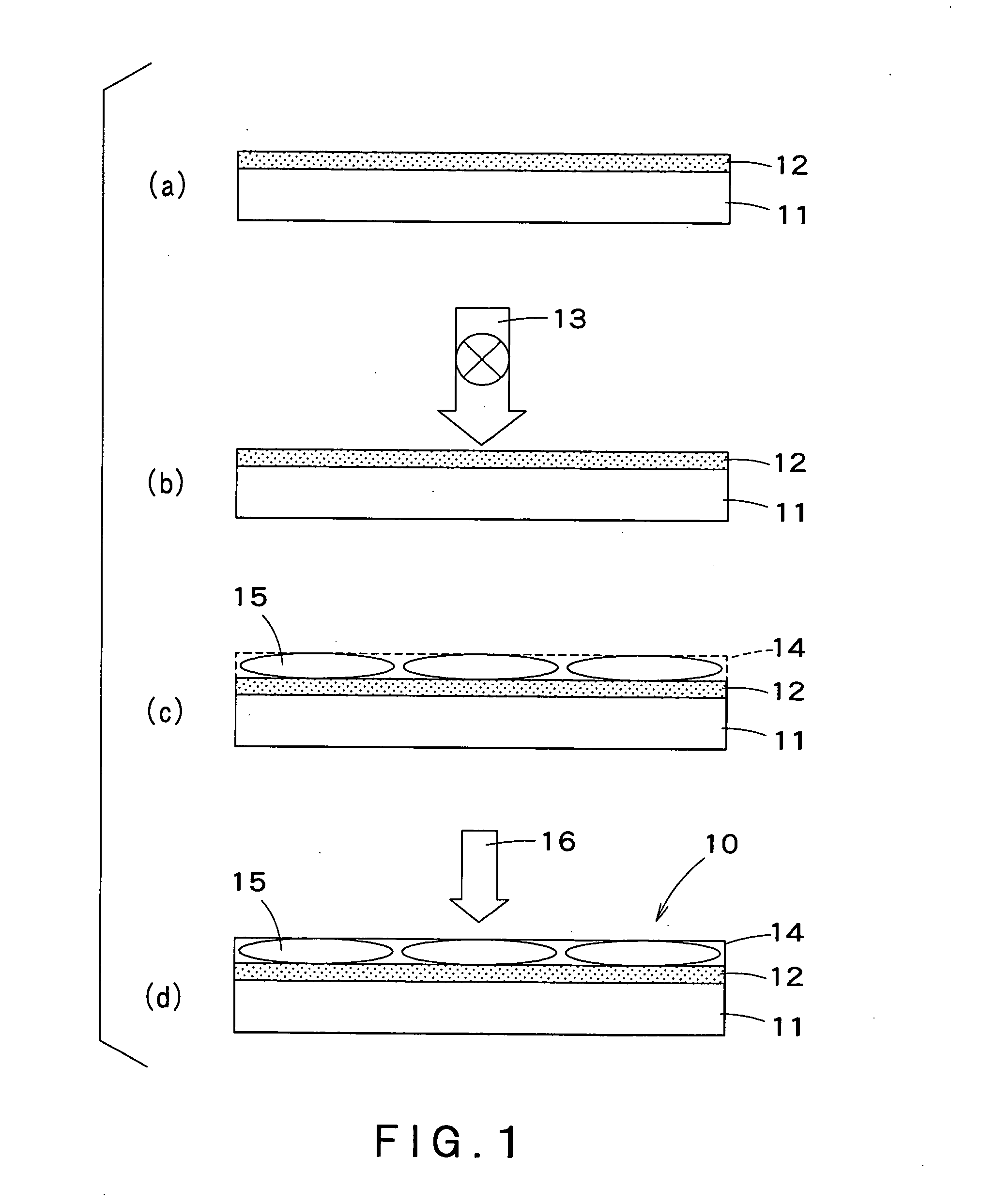

1. Preparation of Base Material With Aligning Film

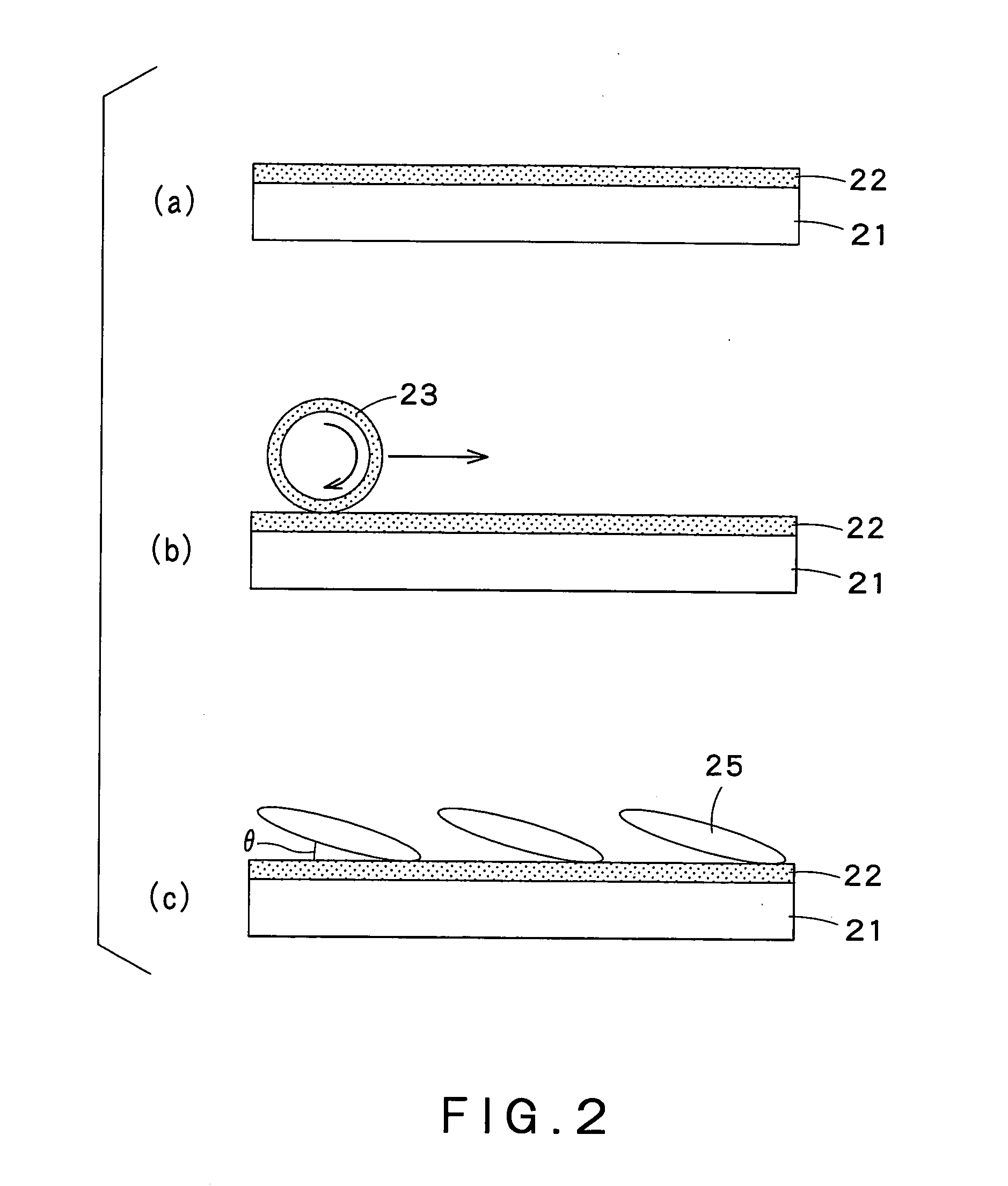

[0064] A glass substrate (1737 glass, manufactured by Corning Inc.) which had been cleaned by a predetermined method was provided as a base material, and AL 1254 (manufactured by JSR Corporation) was provided as an aligning film material. The aligning film material was coated by flexographic printing onto the glass substrate to form a 600 angstrom-thick aligning film.

[0065] Next, polarized ultraviolet light was applied to the aligning film at 5 J / cm2 in a direction vertical to the base material to form an aligning film by a photoalignment method to which monoaxial anisotropy had been imparted.

[0066] For comparison, a base material provided with an aligning film subjected to the conventional rubbing treatment was prepared.

2. Preparation of Ink for Phase Difference Control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pretilt angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase difference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com