Electric blower

a blower and electric technology, applied in the direction of positive displacement liquid engine, piston pump, heating type, etc., can solve the problems of unstable rotation speed fluctuation and inability to continue to operate stably, and achieve the effect of stable operation and discharge of target airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

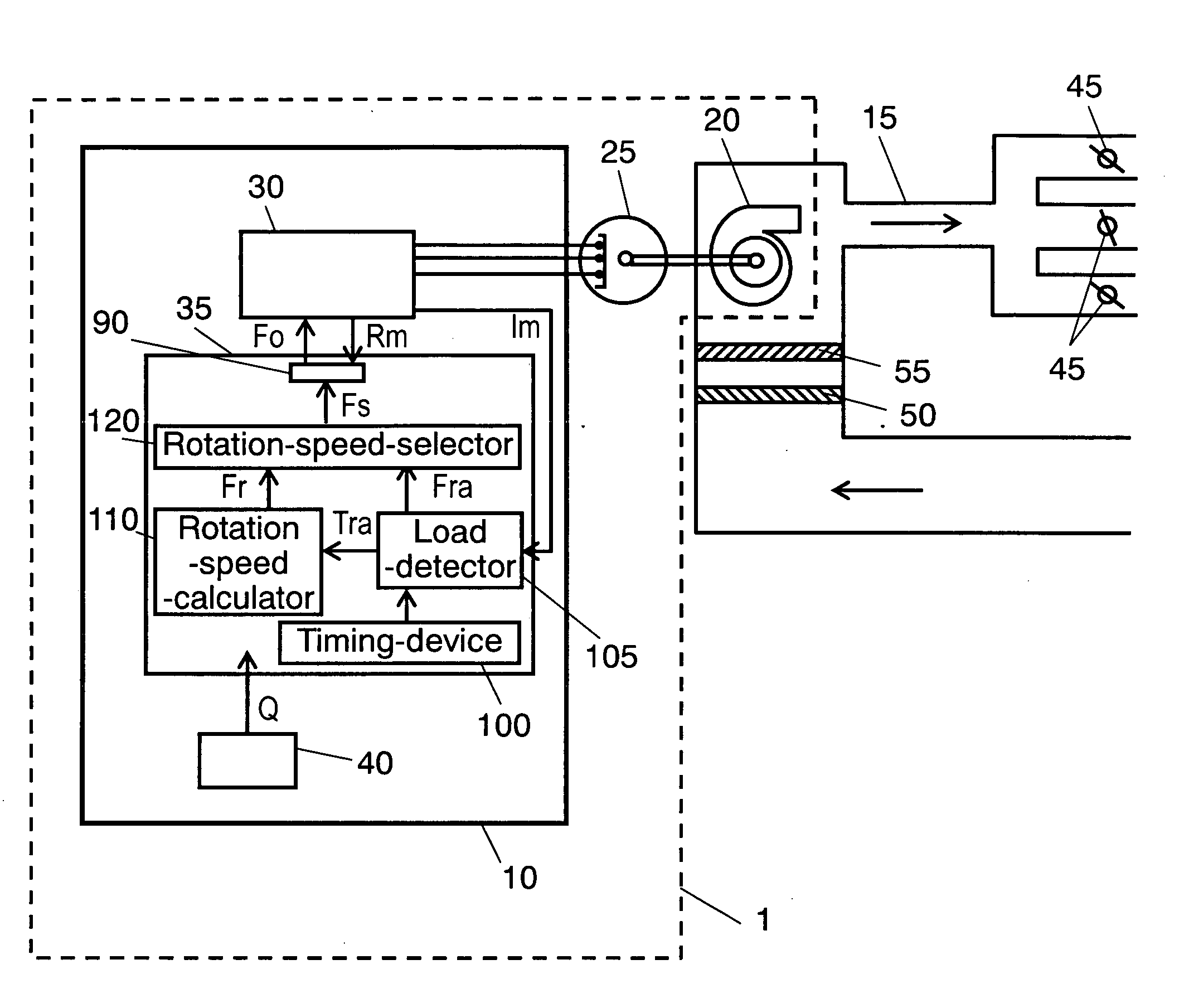

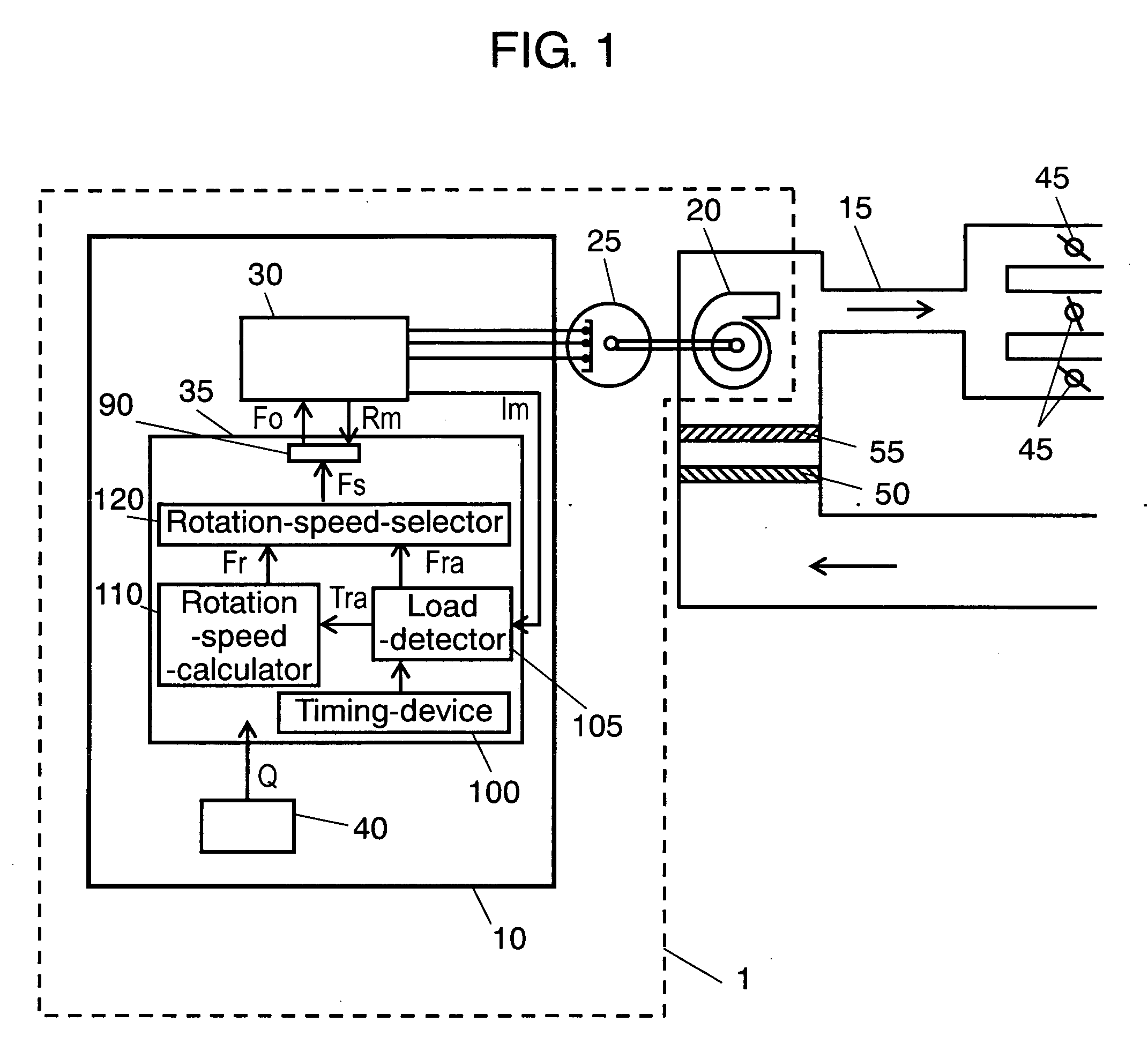

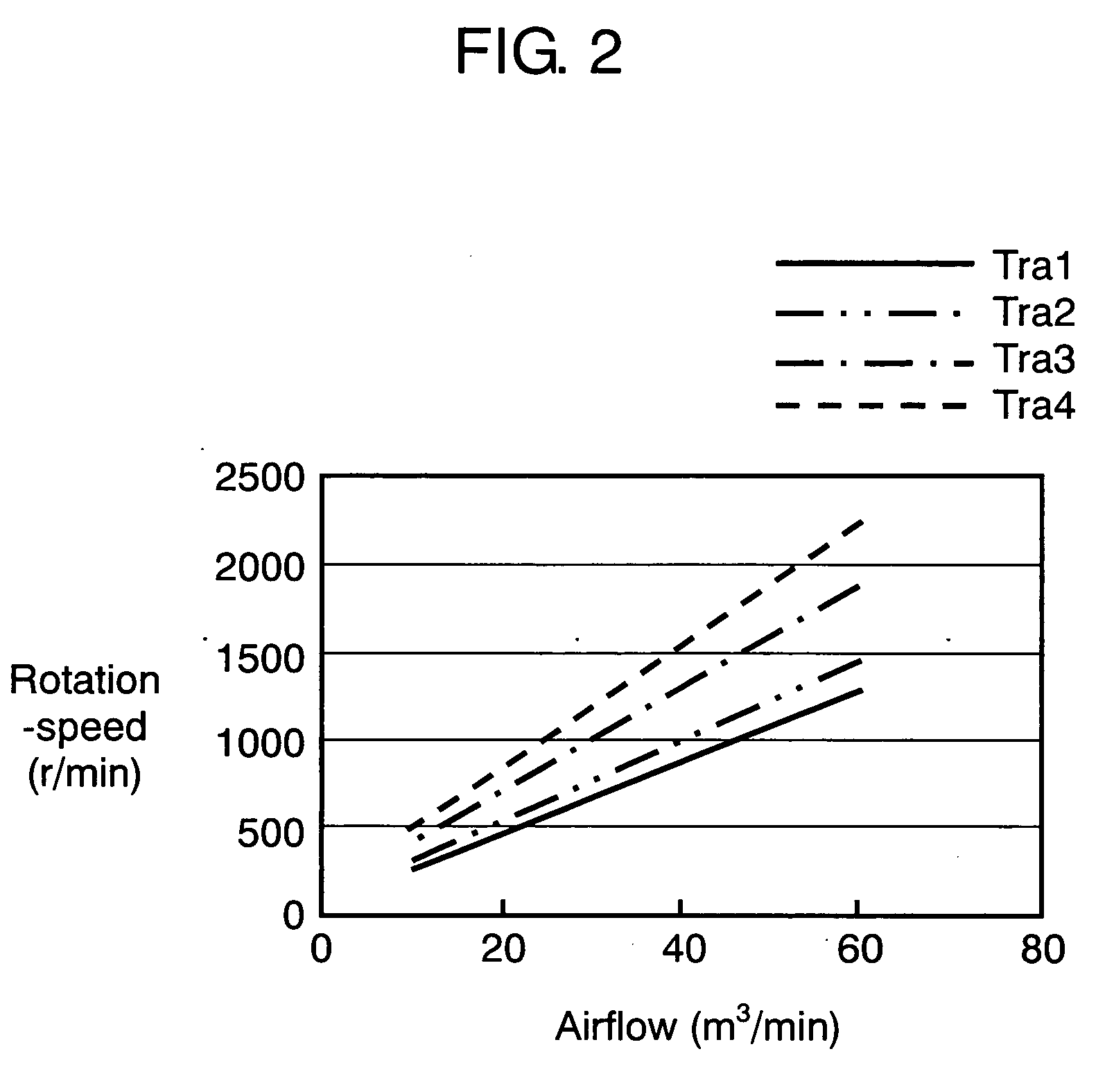

[0011] Generally, an amount of airflow is proportional to a rotation speed of a fan included in a duct when the duct condition is determined and the duct condition affects relative gradients or the like. If, therefore, the duct condition is detected somehow the relation between the amount of airflow and rotation speed can be determined. The duct condition is detectable as a load of the blower and the load of the blower is detectable as an output force of an electric motor as well. Moreover, because the output force of the electric motor is proportional to the product of the rotation speed and torque of the fan, the duct condition can be detected from the torque of the electric motor when the rotation speed is kept constant. In case of a DC motor, whose torque is proportional to the input current, the torque can be detected by measuring the motor input current. Therefore, the duct conditions can be detected by measuring the motor input current.

[0012] The present invention is to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com