Faucet quick install nut

a quick installation and nut technology, applied in water installation, construction, fastening means, etc., can solve the problems of complicated assembly of the required connections, difficult location in which to manipulate the wrench, and confined space, and achieve the effect of fast and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

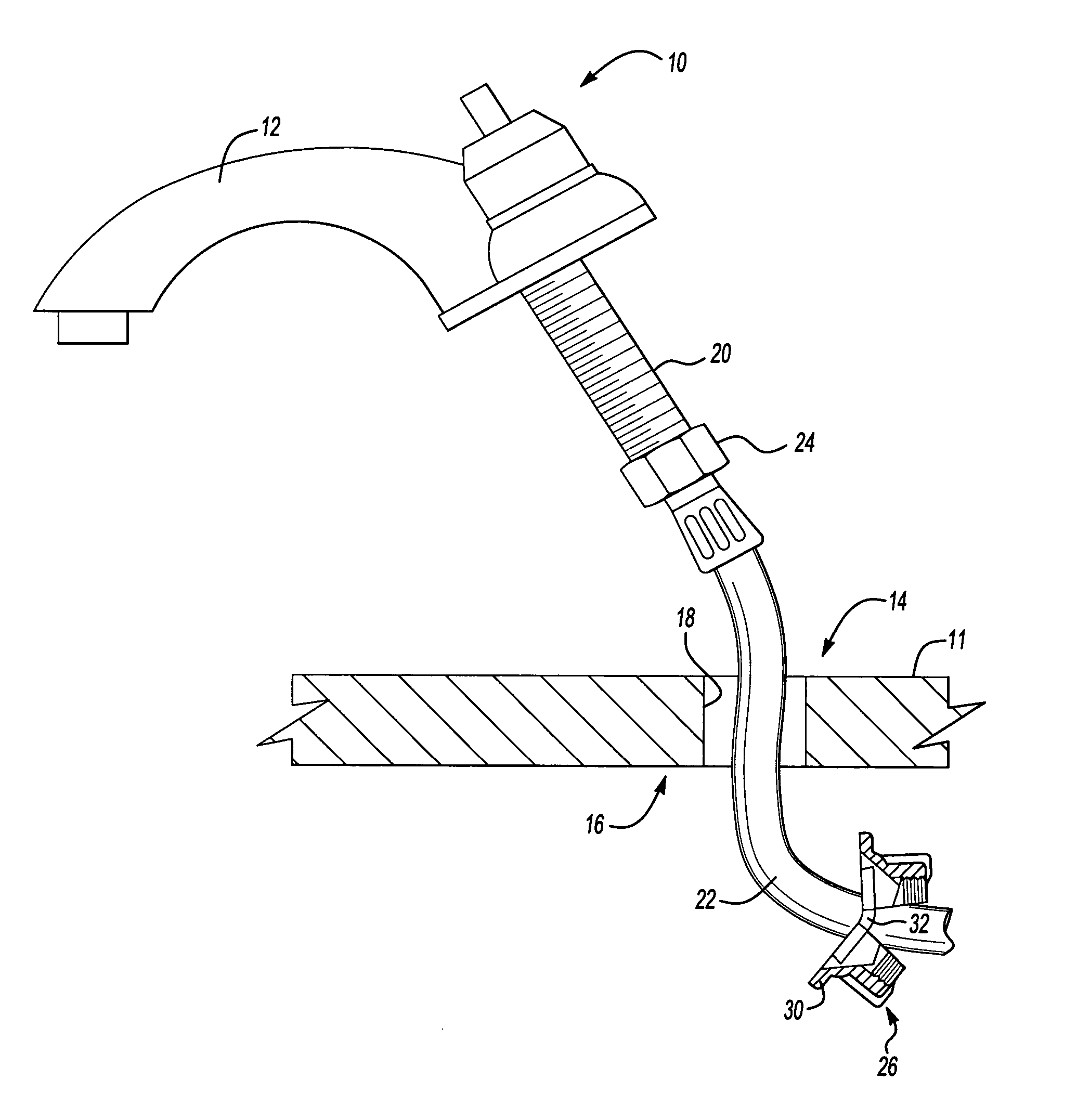

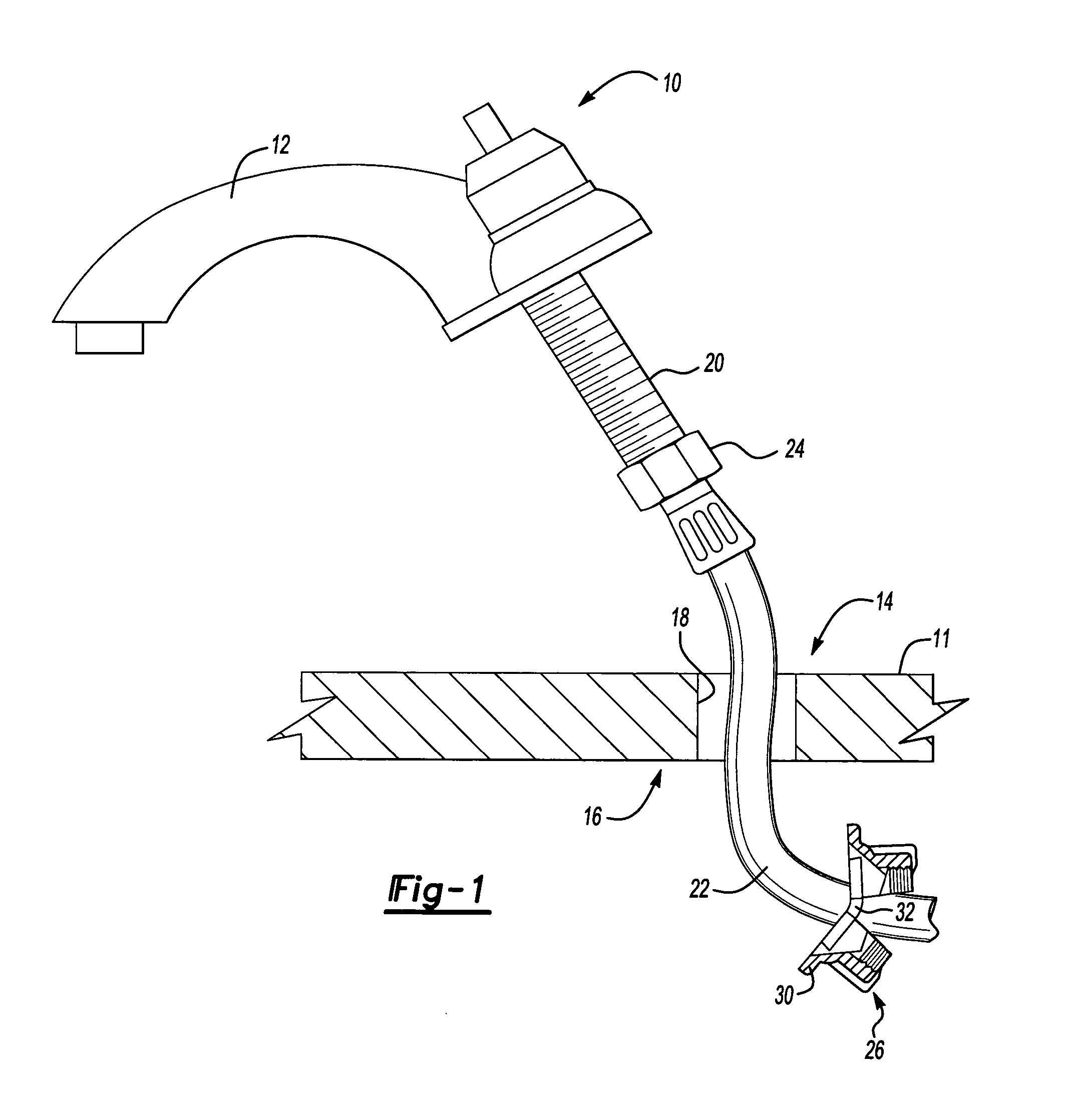

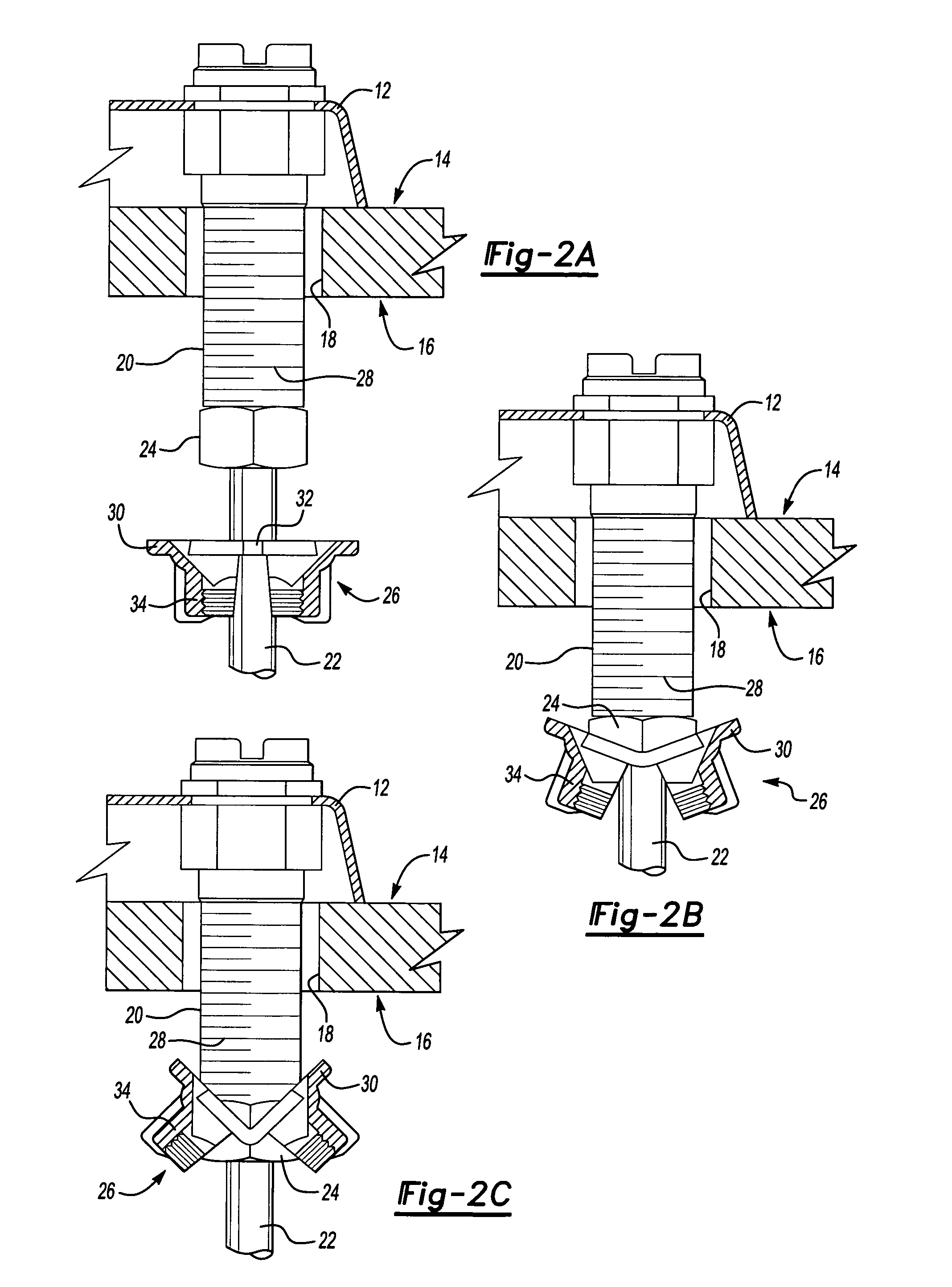

[0023] Referring to FIG. 1, a faucet assembly 10 includes a faucet 12 having a threaded water pipe 20. The threaded water pipe 20 is attached to an inlet hose 22 by way of a water connection fitting 24. The water connection fitting 24 secures to the threaded water pipe 20 and supplies water to the faucet 12. The faucet 12 is mountable to a sink deck 11. The sink deck 11 includes a top-mounting surface 14 and a bottom-mounting surface 16. The inlet hose 22 is attached at an end opposite the water connection fitting 24 to a water supply source. Although a flexible hose attached to the connection fitting 24 is shown other types of water connection conduits such as a rigid pipe or plastic pipe will also benefit from this invention. The sink deck 11 includes an opening 18 for the threaded water pipe 20. The threaded water pipe 20 extends through the opening 18 and allows the faucet 12 to sit on the top-mounting surface 14.

[0024] The water connection fitting 24 provides a secure and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com