Transportation system

a technology of transport system and wafer carrier, which is applied in the direction of roads, electrical equipment, construction, etc., can solve the problems of not having the ability to quickly swap, many such material transport system do not have the ability to supply carriers at a high rate or with the capability, and cannot offer sufficient transport flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

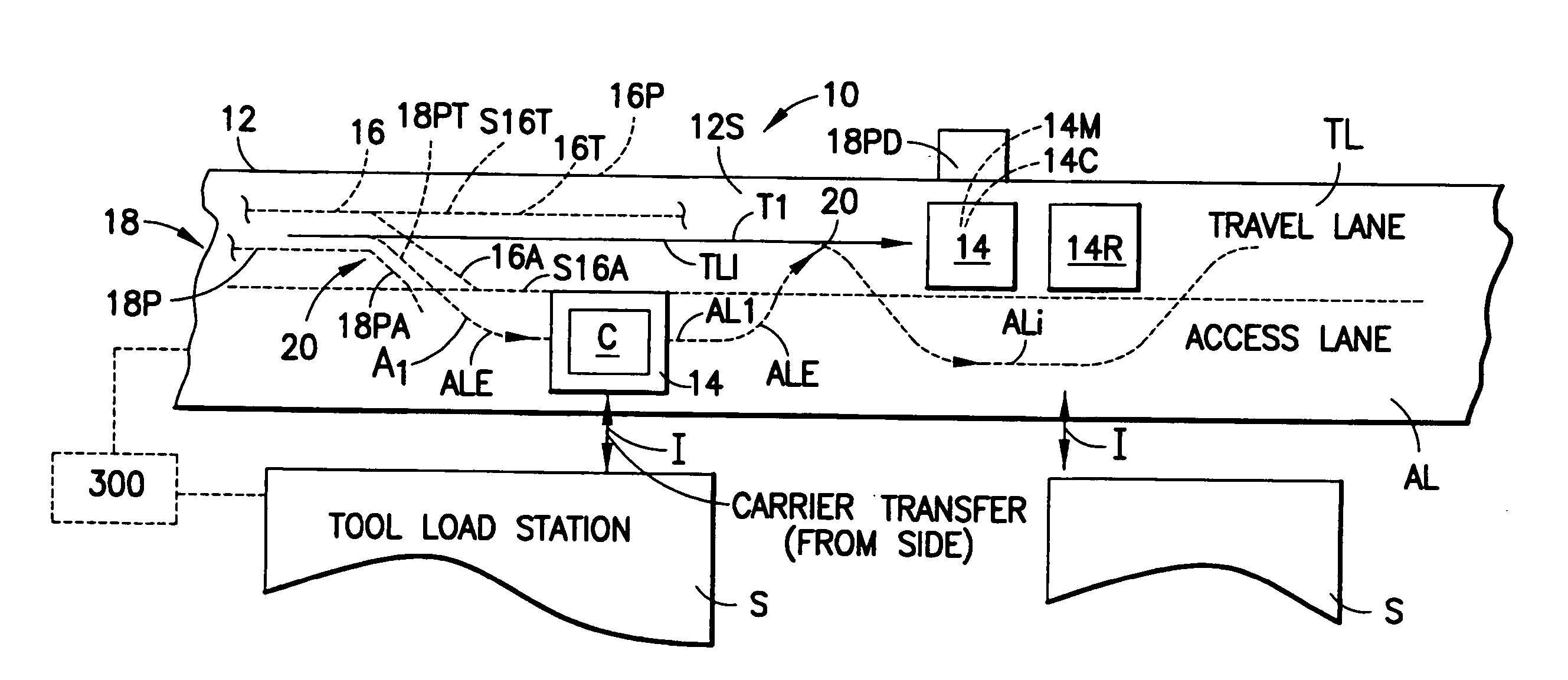

[0007] In accordance with an exemplary embodiment a substrate transport system is provided. The system has a guideway and at least one transport vehicle. The transport vehicle is adapted for holding at least one substrate and capable of being supported from and moving along the guideway. The guideway comprises at least one travel lane for the vehicle and at least one access lane offset from the travel lane allowing the vehicle selectable access on and off the travel lane.

BRIEF DESCRIPTION OF THE DRAWINGS

[0008] The foregoing aspects and other features of the present invention are explained in the following description, taken in connection with the accompanying drawings, wherein:

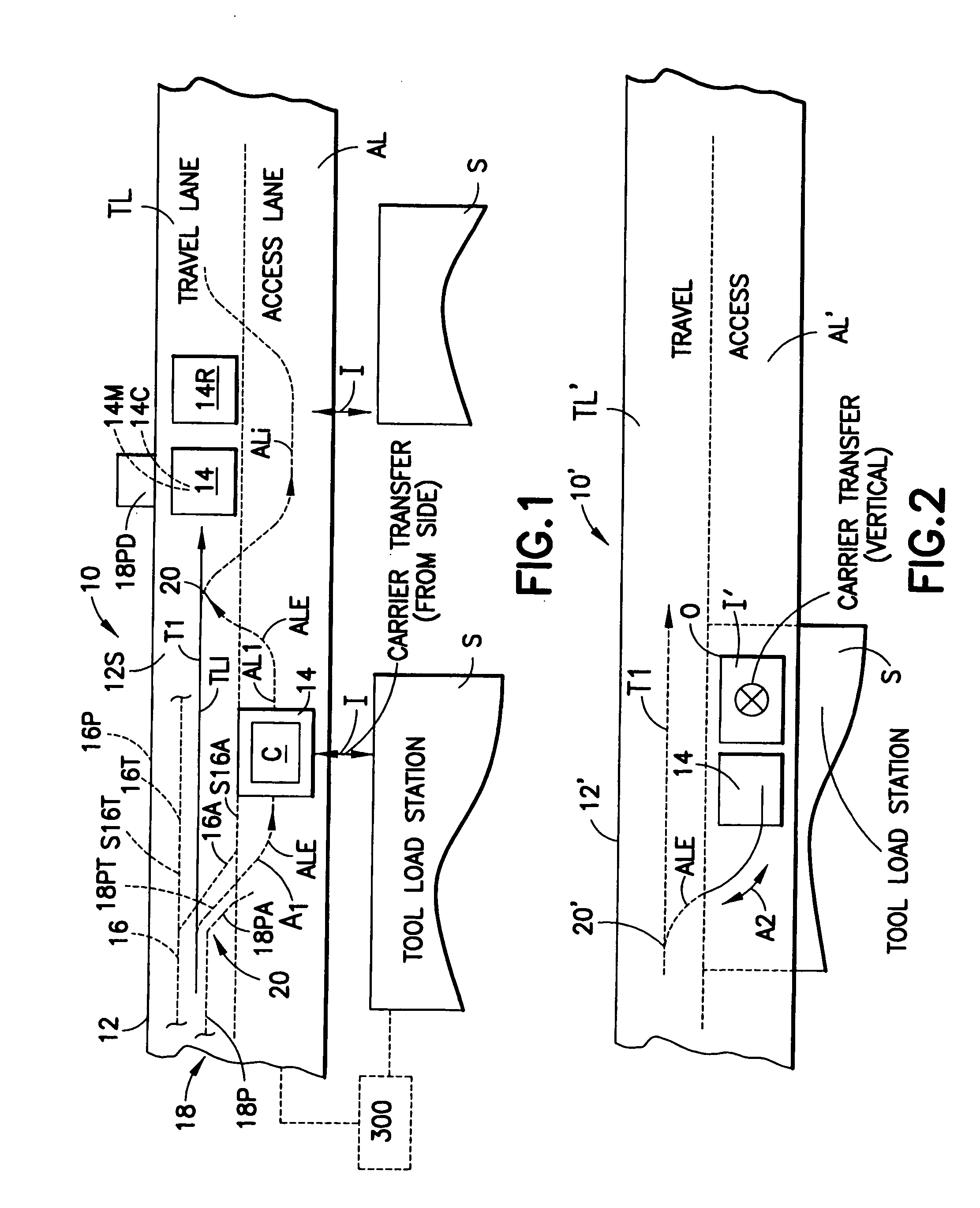

[0009]FIG. 1 is a schematic top plan view of a substrate processing system incorporating features in accordance with an exemplary embodiment;

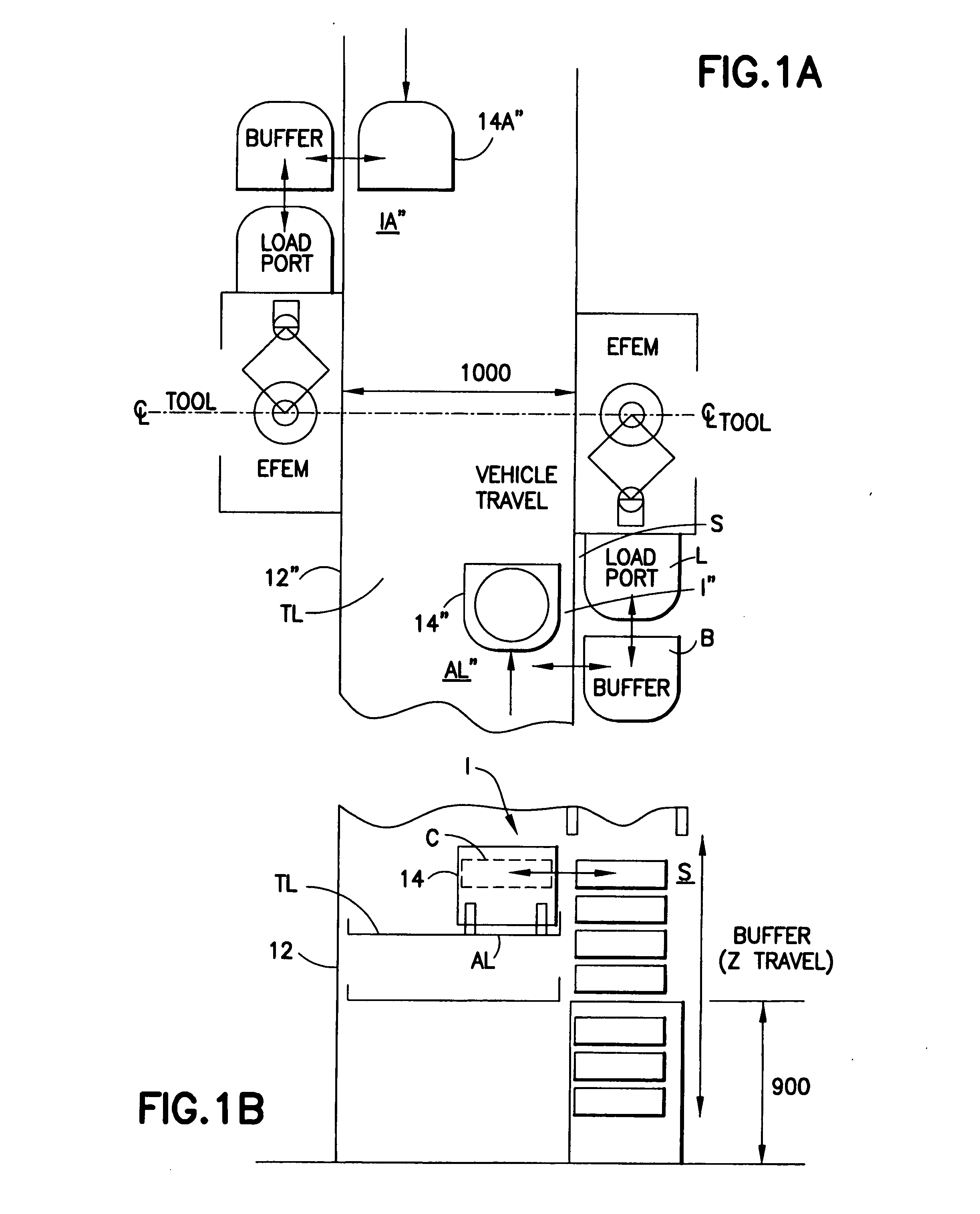

[0010]FIGS. 1A-1B are respectively another schematic top plan view and a schematic elevation view of the substrate processing system in FIG. 1;

[0011]FIG. 2 is a schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com