Linear Coanda flare methods and apparatus

a coanda flare and linear technology, applied in the direction of lighting and heating apparatus, incinerator apparatus, combustion types, etc., can solve the problems of limited waste flammable gas pressure in the coanda flare, heavy slots and surfaces, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

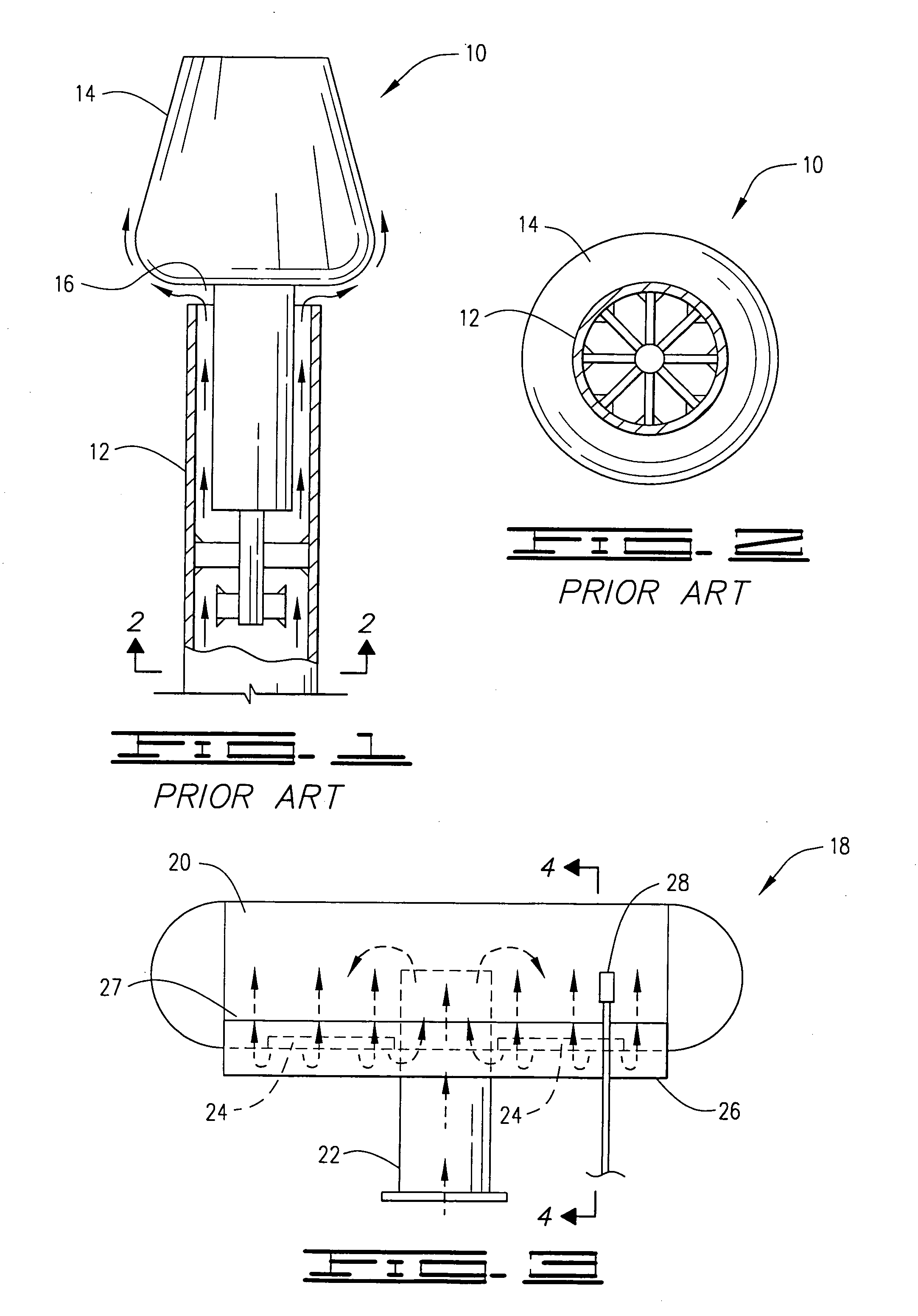

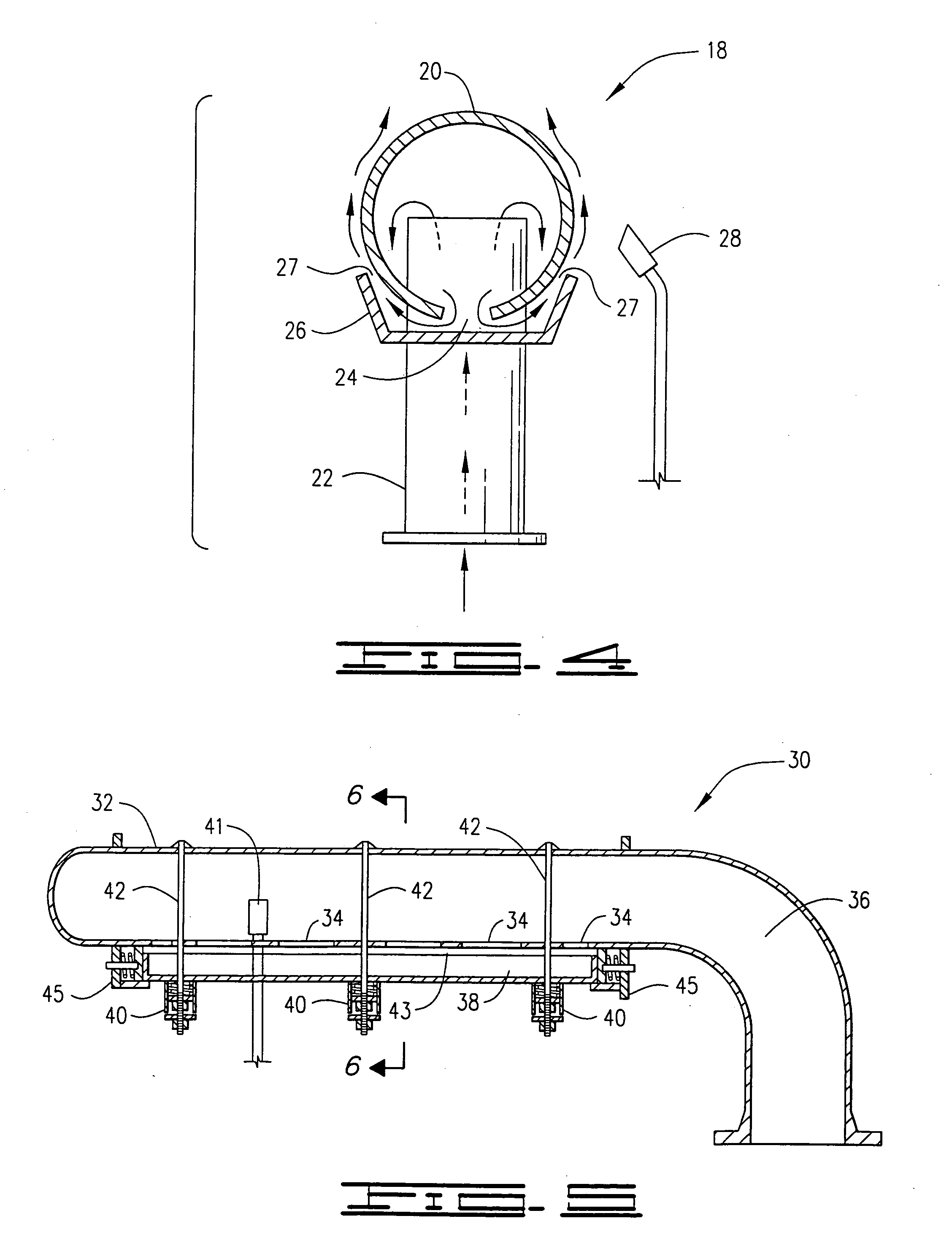

[0031] Referring now to the drawings, and particularly to FIGS. 1 and 2, a prior art Coanda flare 10 is illustrated having an upstanding waste flammable gas supply pipe 12 and a Coanda body 14 attached to the top of the supply pipe 12. A circular slot 16 is provided between the top of the pipe 12 and the bottom of the Coanda body 14 through which pressurized waste flammable gas flows at high velocity. The gas follows the Coanda surface until it has turned through approximately 90° thereby producing a very stable and efficient flare device. However, in order to achieve higher capacities, larger diameter waste flammable gas supply pipes, larger Coanda slots and larger Coanda bodies are required which are heavy and costly.

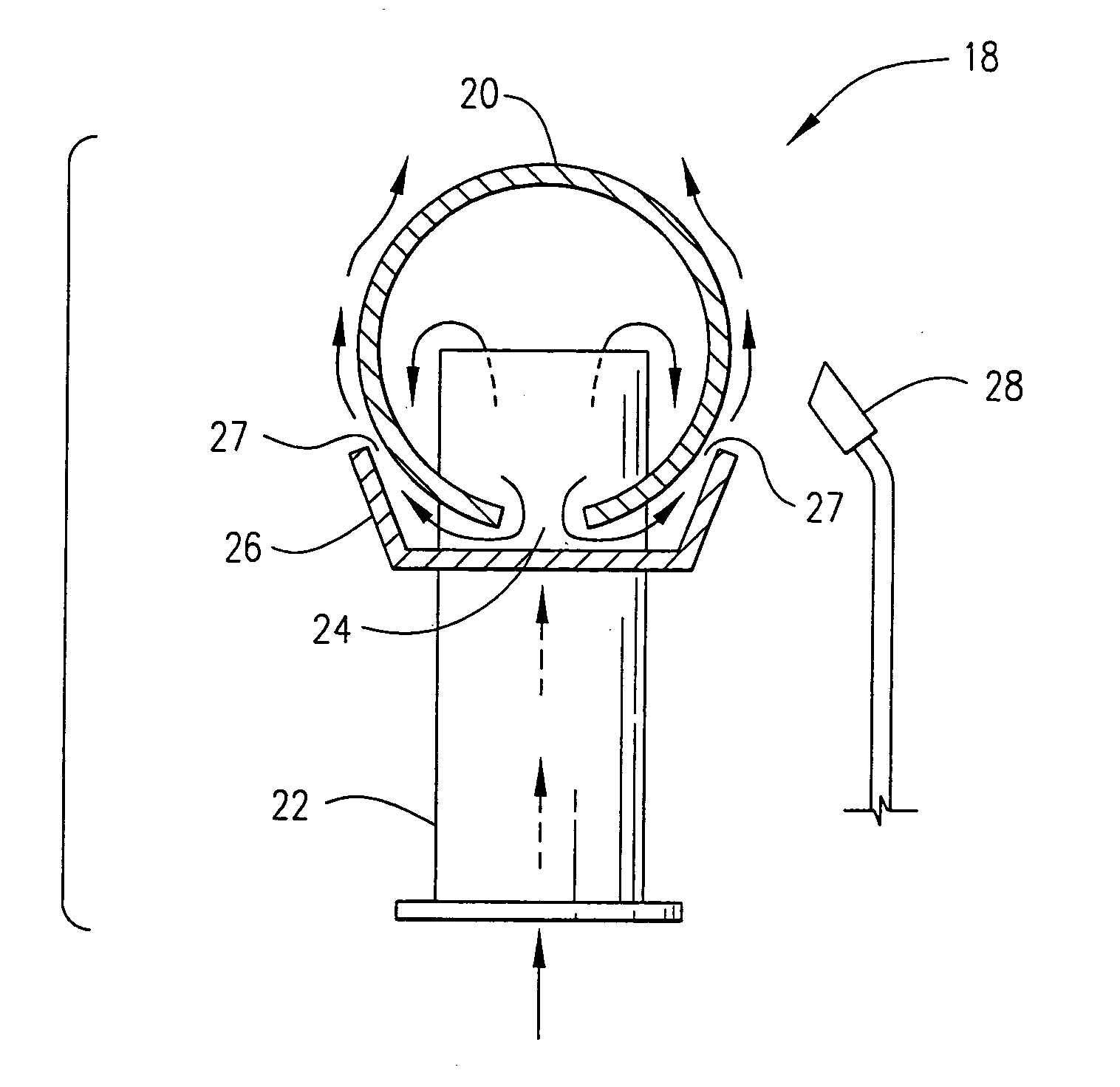

[0032] Referring now to FIGS. 3 and 4, one form of the linear Coanda flare apparatus of the present invention is illustrated and designated by the numeral 18. The linear Coanda flare apparatus 18 comprises an elongated closed end pipe 20 connected to a waste flammabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com