Protective hand shield

a hand shield and hand technology, applied in the field of hand shields, can solve the problems of particles suspended in the air of the work environment, and achieve the effects of not significantly limited the mobility of the user's hand and fingers, suppressing the generation and entrainment of fine particles, and protecting from injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

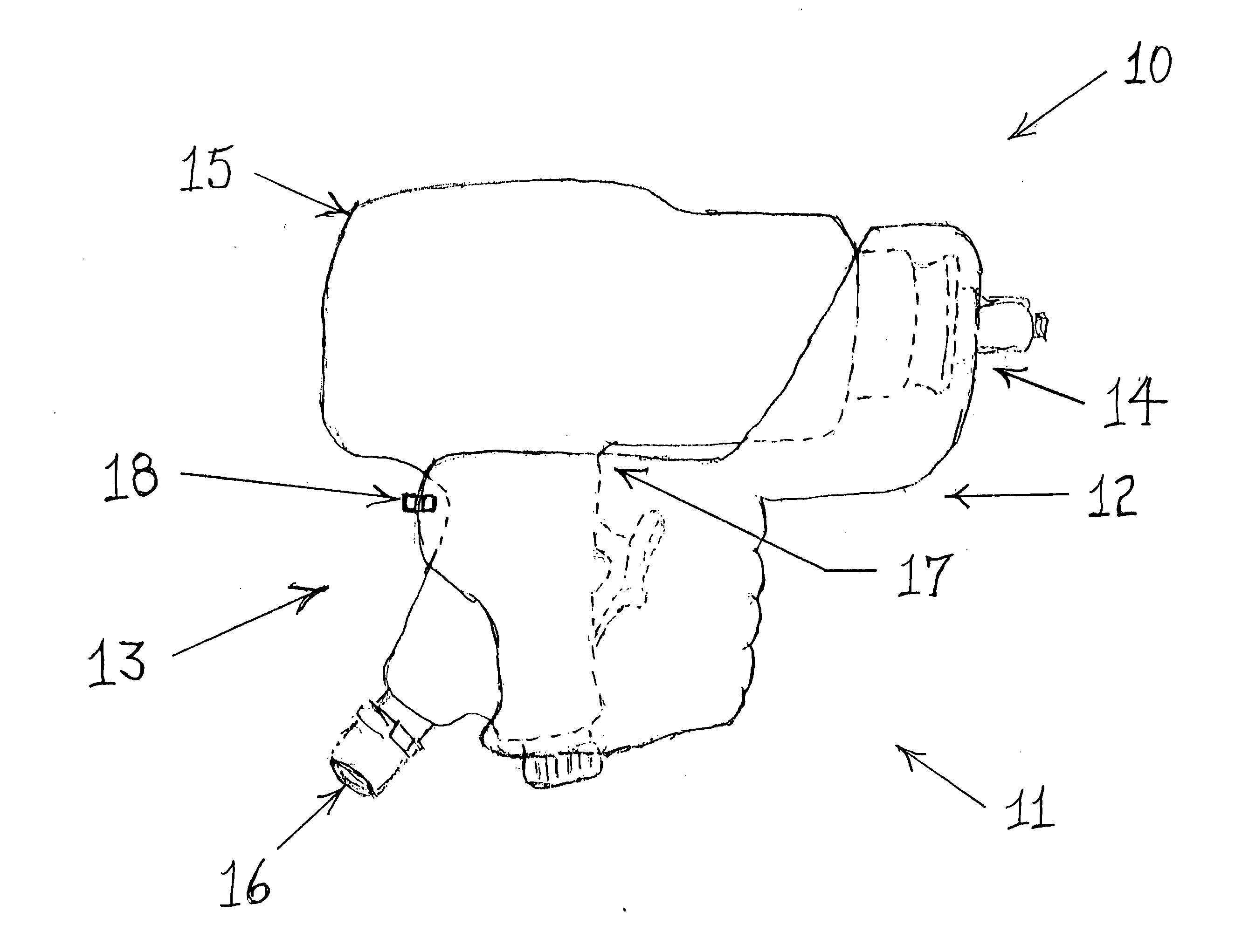

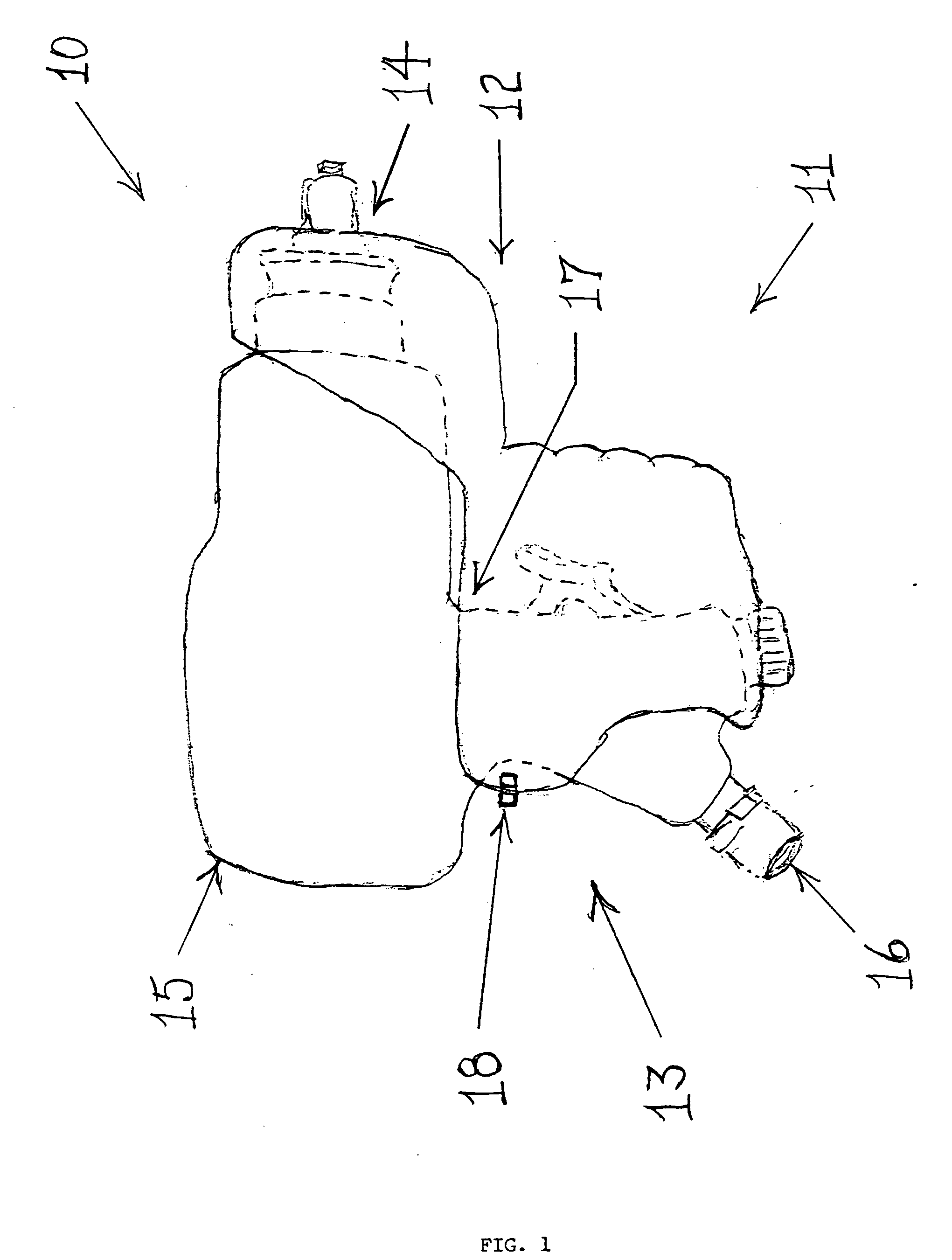

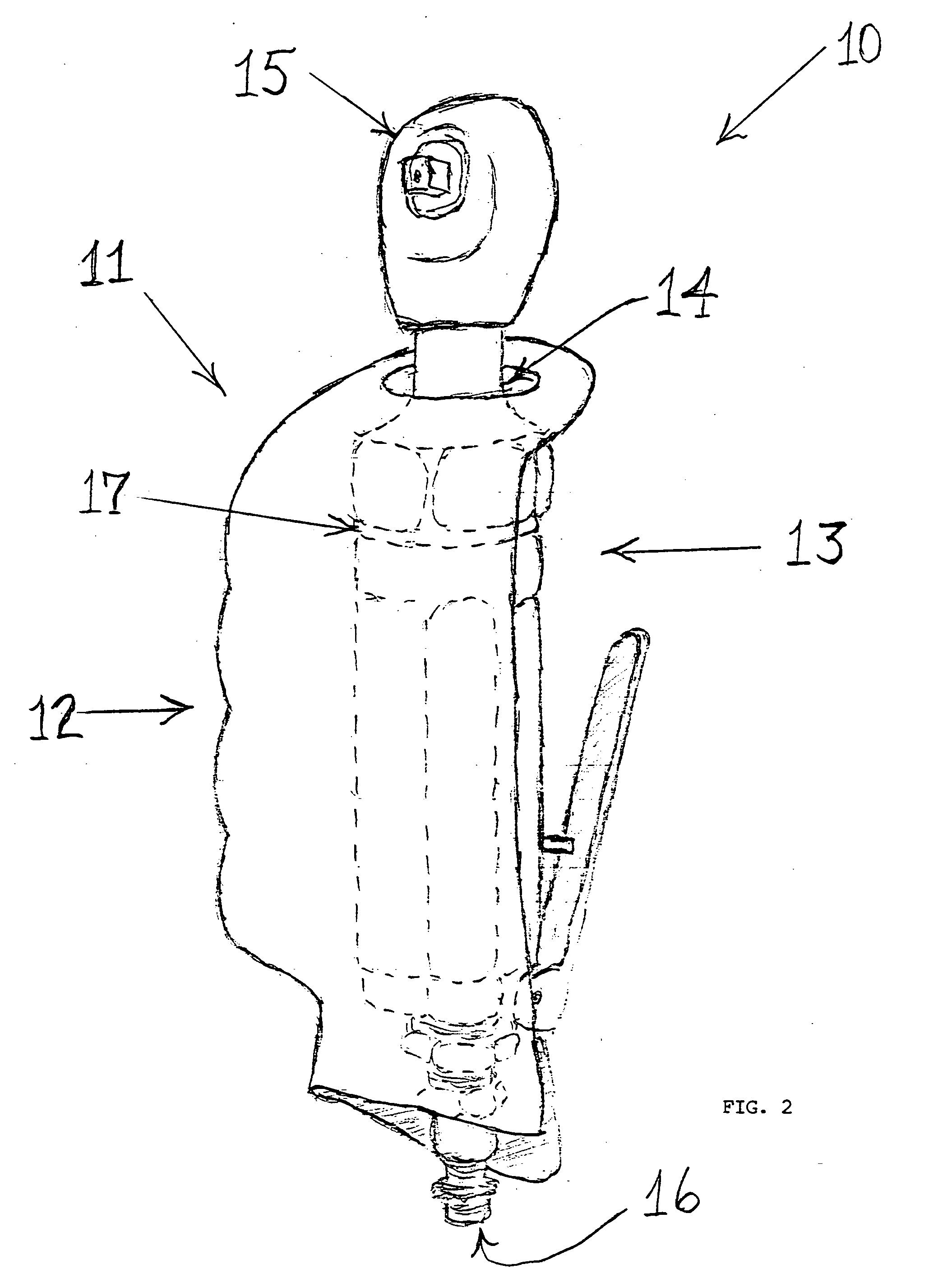

[0015] As shown in FIGS. 1 and 2, a protective hand shield embodying the features of the present invention 10 comprises a flexible shield 11 with a forward closed side 12 and a rear open side 13. The shape of the flexible shield 11 is adaptable to various hand tools 15. A typical air-powered wrench “gun”15 is shown in FIG. 1, and an air-powered ratchet 15 is shown in FIG. 2. In each case, a working opening 14 is provided in the forward closed side 12, which opening is designed to fit around the hand tool 15 yet still allow the working end of the tool 15 to protrude from the flexible shield 11 and engage the work material (not shown). Additionally, the shape of the shield 11 may be adapted to accommodate the compressed air inlet 16 on an air-powered hand tool 15. The shield 11 is fabricated from a material, such as extruded plastic or canvas cloth, which is durable and thick enough to prevent injury to the user's hand, but also light-weight and flexible enough so as not to hinder han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com