Venturi fan

a fan and venturi technology, applied in the field of fans, can solve the problems of increasing the amount of air available to the fan, and achieve the effect of reducing noise, avoiding the generation of some fan noise, and reducing the noise of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is an improvement in venturi-style fans. Venturi fans direct a significant quantity of air in a forward direction and are suitable for large buildings such as warehouses. Unfortunately, prior art venturi fans are relatively noisy.

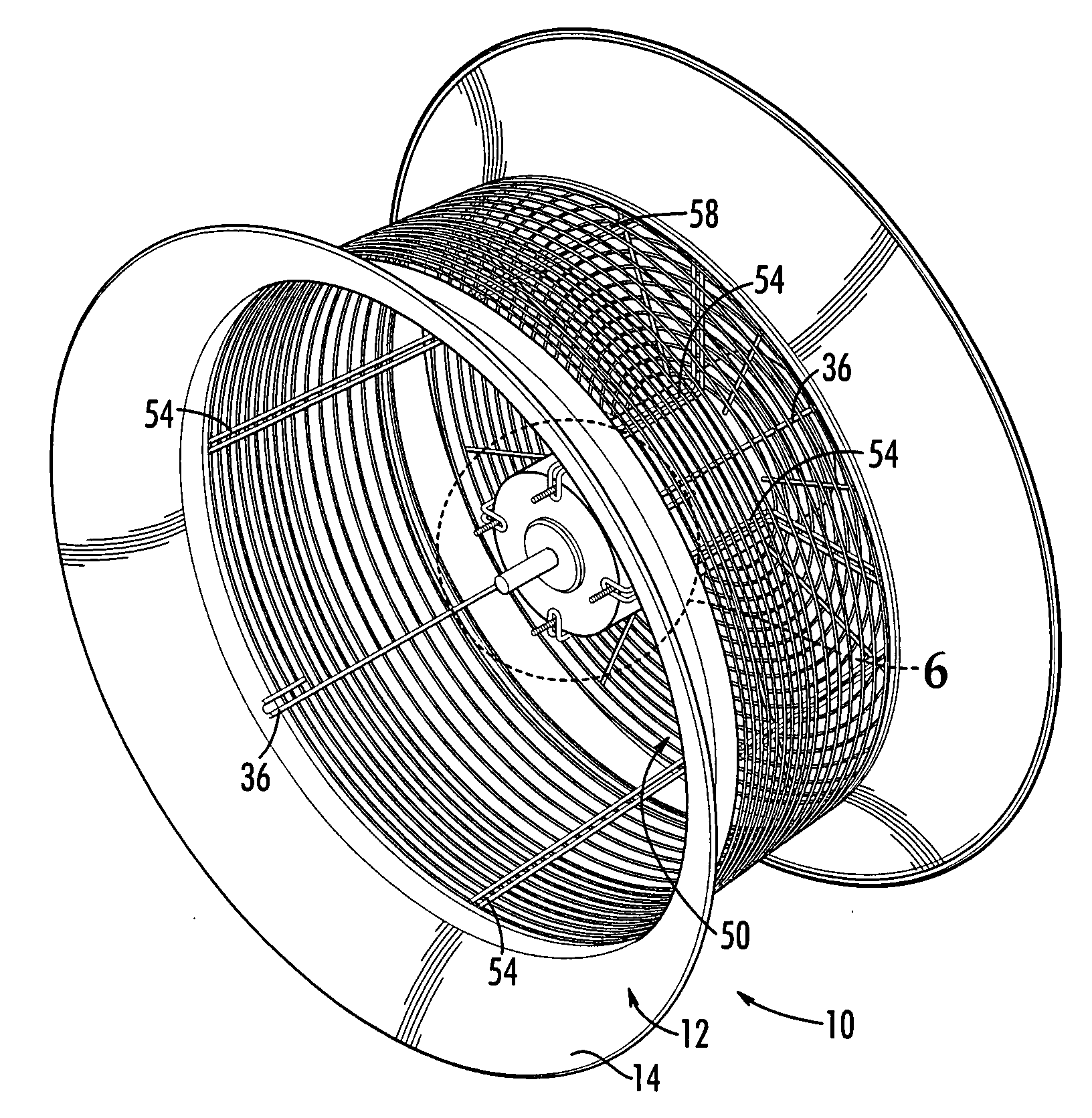

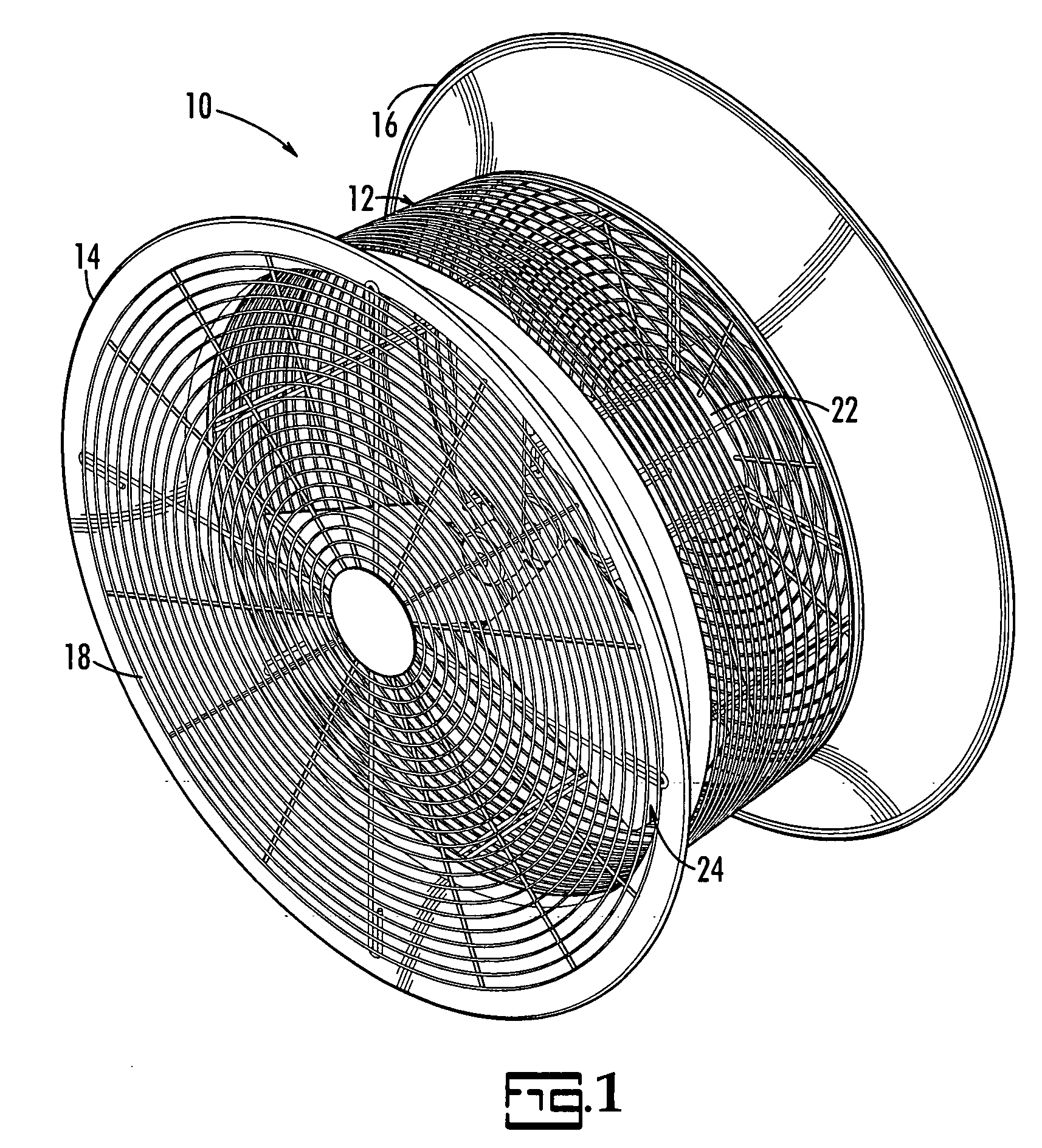

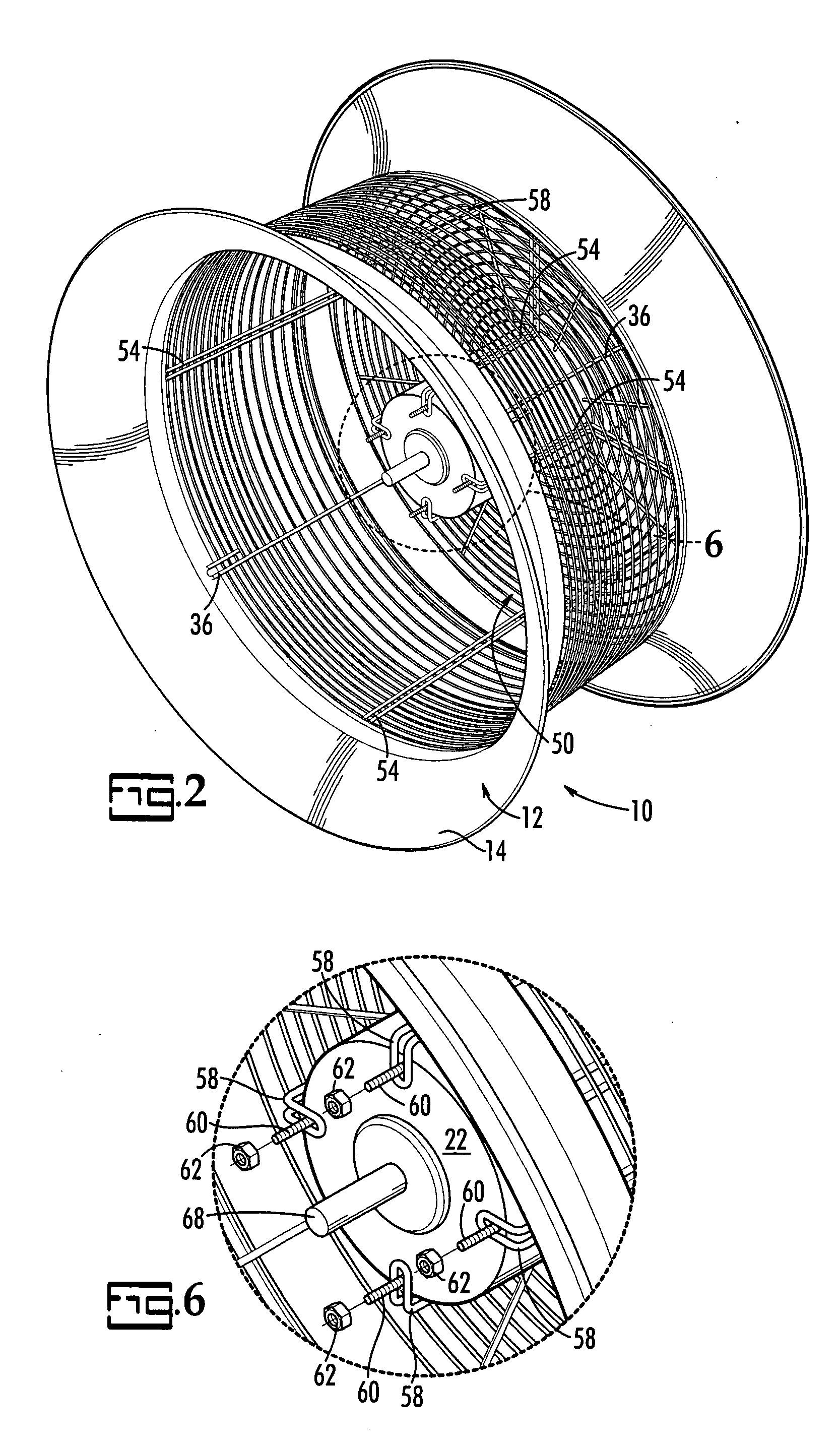

[0019]FIG. 1 illustrates in perspective the present venturi fan 10. Fan 10 has a housing 12 that is flared on both the front 14 and the rear 16, and has a front finger guard 18. Inside housing 12 is a motor 22 and a fan blade assembly 24.

[0020] Referring now to FIG. 2, there is illustrated a side view of venturi fan 10 according to a preferred embodiment of the present invention. Fan 10 is rotationally symmetric so it appears the same from all sides. Unlike prior art venturi fans, venturi fan 10, shown in FIGS. 1-6 in its preferred embodiment, has an opening formed in the side wall 28, preferably a multiplicity of openings such as perforations or an array of slots, but, most preferably, a multiplicity of openings formed by spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com