Plastic washing fluid container for a washing machine

a technology of washing machine and washing fluid, applied in the direction of other washing machines, cleaning using liquids, textiles and paper, etc., can solve the problem of significant complexity if the layout, design or geometry of detecting the air within the trap needs modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]FIG. 6 is a schematic lateral sectional view showing a washing machine 30 provided with a washing fluid container 1. The washing fluid container 1 consist of a cylindrically structured receptacle 2 which surrounds a drum 31. The cylindrical receptacle 2 is closed by at least one front wall or cap 3.

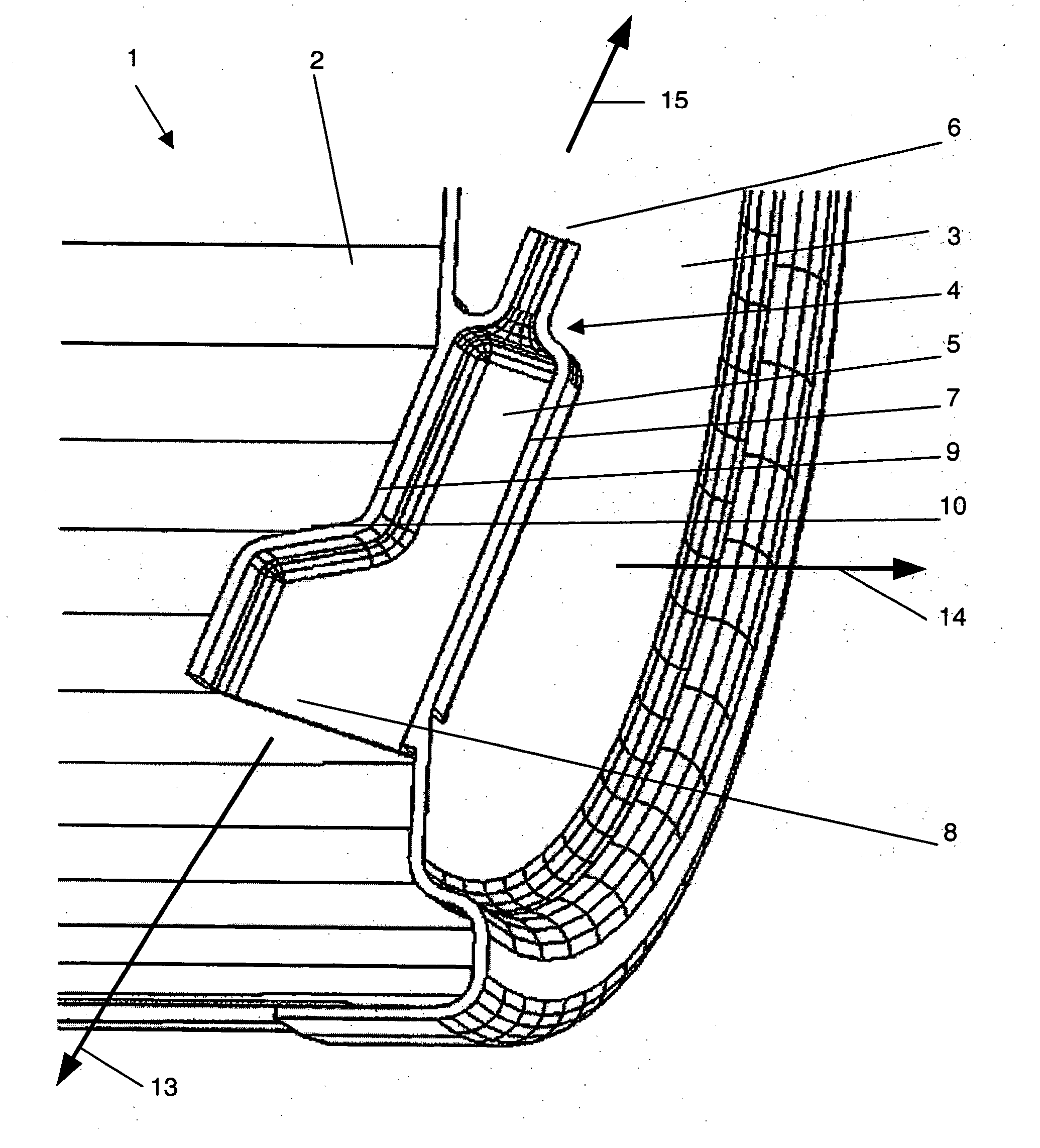

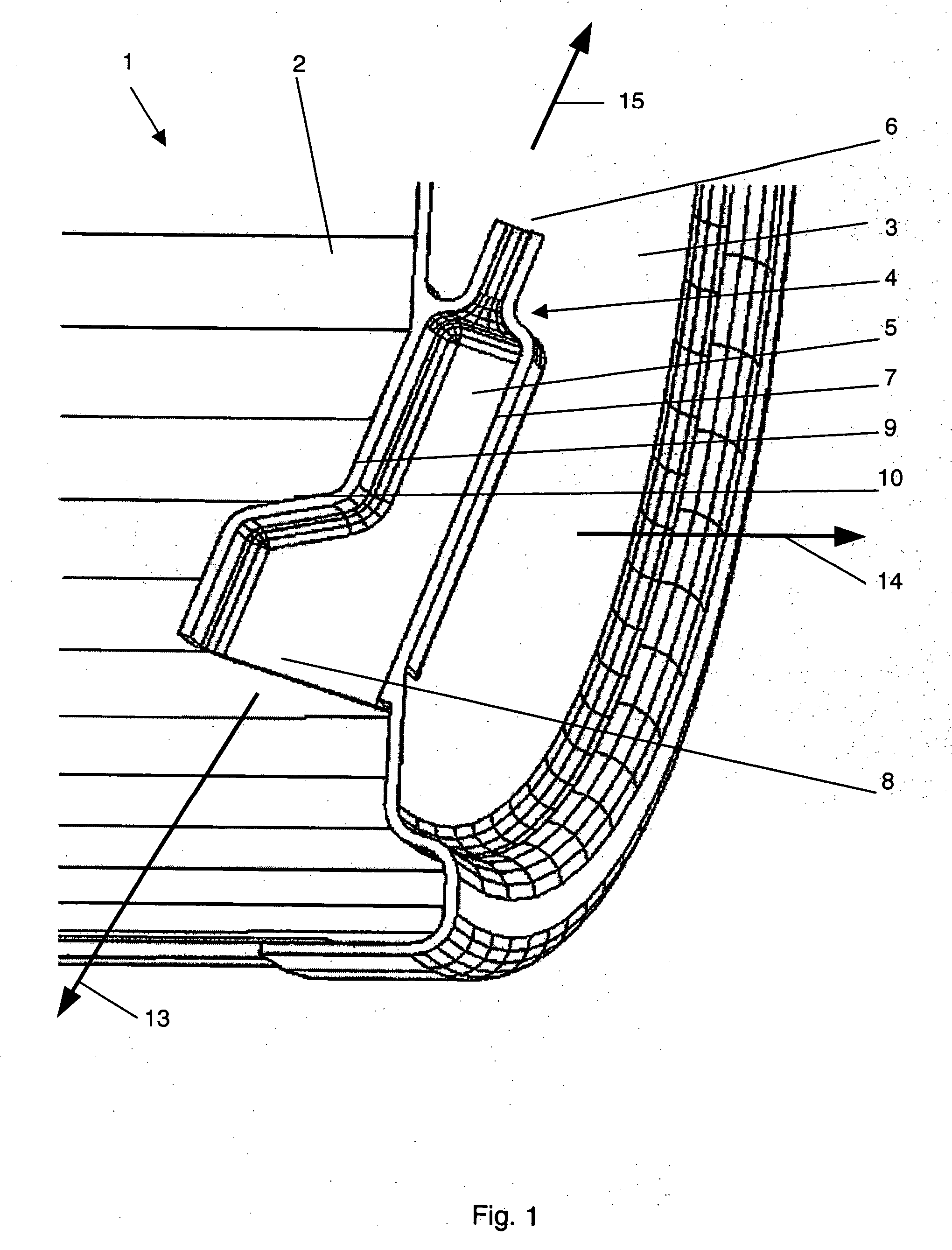

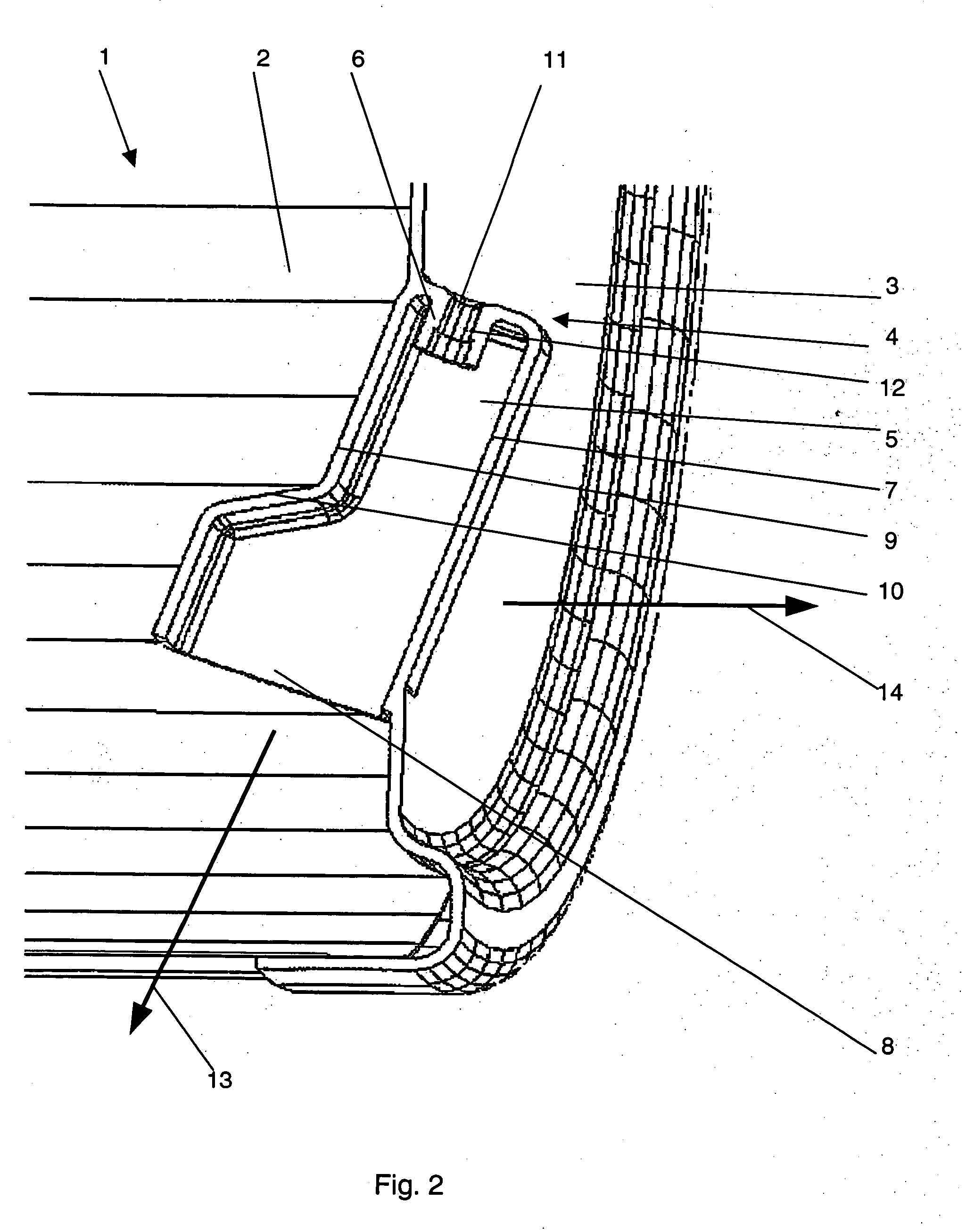

[0026]FIGS. 1 and 2 depict a section of a washing fluid container 1 made of plastic. At each end of the receptacle 2 there is provided a structured washing fluid container cap 3. As may be seen in FIGS. 1 and 2, one of the washing fluid container caps 3, which may have been retrofitted to the receptacle 2, is provided with an air trap 4 for measuring the level of washing fluid. The air trap 4 has a housing 5 which opens in a downward direction and which at its upper end is provided with an opening nipple 6 for a measuring hose (not shown). As will be understood by those skilled in the art and as indicated supra, the hose is connected to a gage (not shown) or the like for deriving a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com