Holding apparatus, holding method, exposure apparatus and device manufacturing method

a technology of holding apparatus and holding method, which is applied in the direction of photomechanical apparatus, printing, instruments, etc., can solve the problems of reticle r distortion, affecting so as to improve the overall surface precision of the mask, increase the size of the whole surface of the mask, and ensure the effect of mask retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

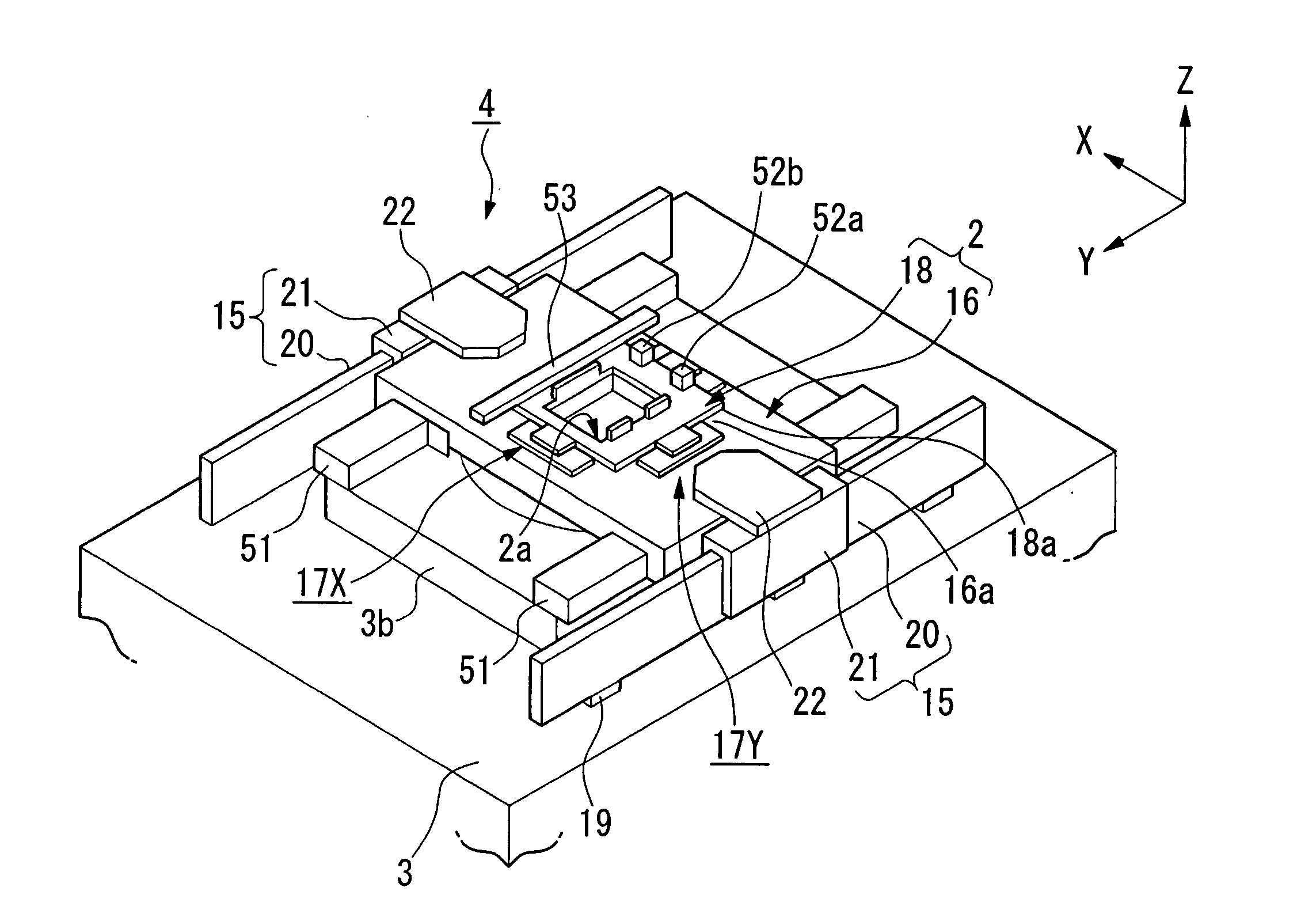

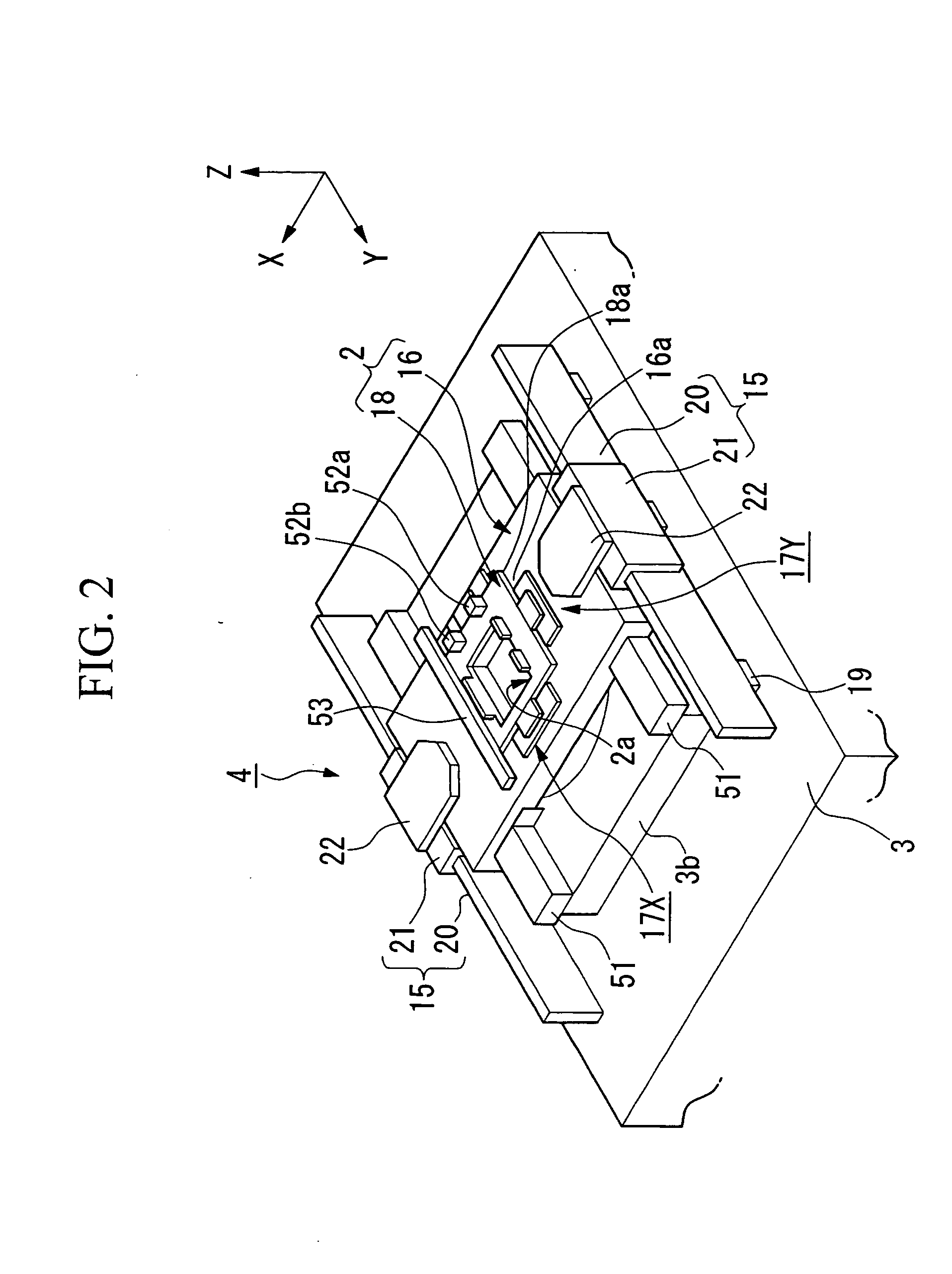

[0133]FIG. 15 to FIG. 21 illustrate a second embodiment of the present invention. This embodiment has a feature in that a so-called pin and chuck holder is used as a reticle holder 90. Other configuration of the apparatus is the same as that of the first embodiment described above.

[0134]FIG. 15 is a perspective view of the reticle holder 90. A rectangular opening 2a is formed at the center of the reticle holder 90, and suction pads 91 having a long and slender rectangular shape are formed on the opposite sides of the opening 2a on the upper face of the reticle holder 90, each aligned along the side of the opening 2a.

[0135] These suction pads 91 have, respectively, a partition wall 92 which surrounds a rectangular decompression area 95 for maintaining the degree of vacuum, a plurality of pins 96 formed in the decompression area 95, with intervals therebetween, and exhaust holes 94 which open into the decompression area 95. The width and height of the partition wall 92 are constant ...

third embodiment

[0143] In the present invention, by placing a reticle R with the end of the reticle R being curved, as shown in FIG. 23 and FIG. 24, instead of forming the tapered portion at the end of the reticle R, a similar effect can be obtained. This point will be described below.

[0144] As shown in FIG. 22, when a stress P is applied perpendicularly to the upper face of the reticle, at the opposite ends of a flat reticle R having a uniform thickness, at a position of distance x from one end of the reticle R, a stress, a shearing force, a bending moment and flexure expressed by the following equations occur, where l1 denotes an interval between a central supporting point and an outside supporting point of the reticle R in the attraction holding section (first attraction holding section) of the reticle holder, l2 denotes an interval between the central supporting points in the respective attraction holding sections, δ denotes an interval (gap) between the outside supporting point and the reticl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com