Microchannel heat exchanger fabricated by wire electro-discharge machining

a technology of electro-discharge machining and heat exchanger, which is applied in the direction of corrosion prevention, semiconductor device details, and semiconductor/solid-state device details, etc., can solve the problems of large pressure drop, high manufacturing cost, dirt clogging, and flow mal-distribution, and improve the efficiency of microchannel heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

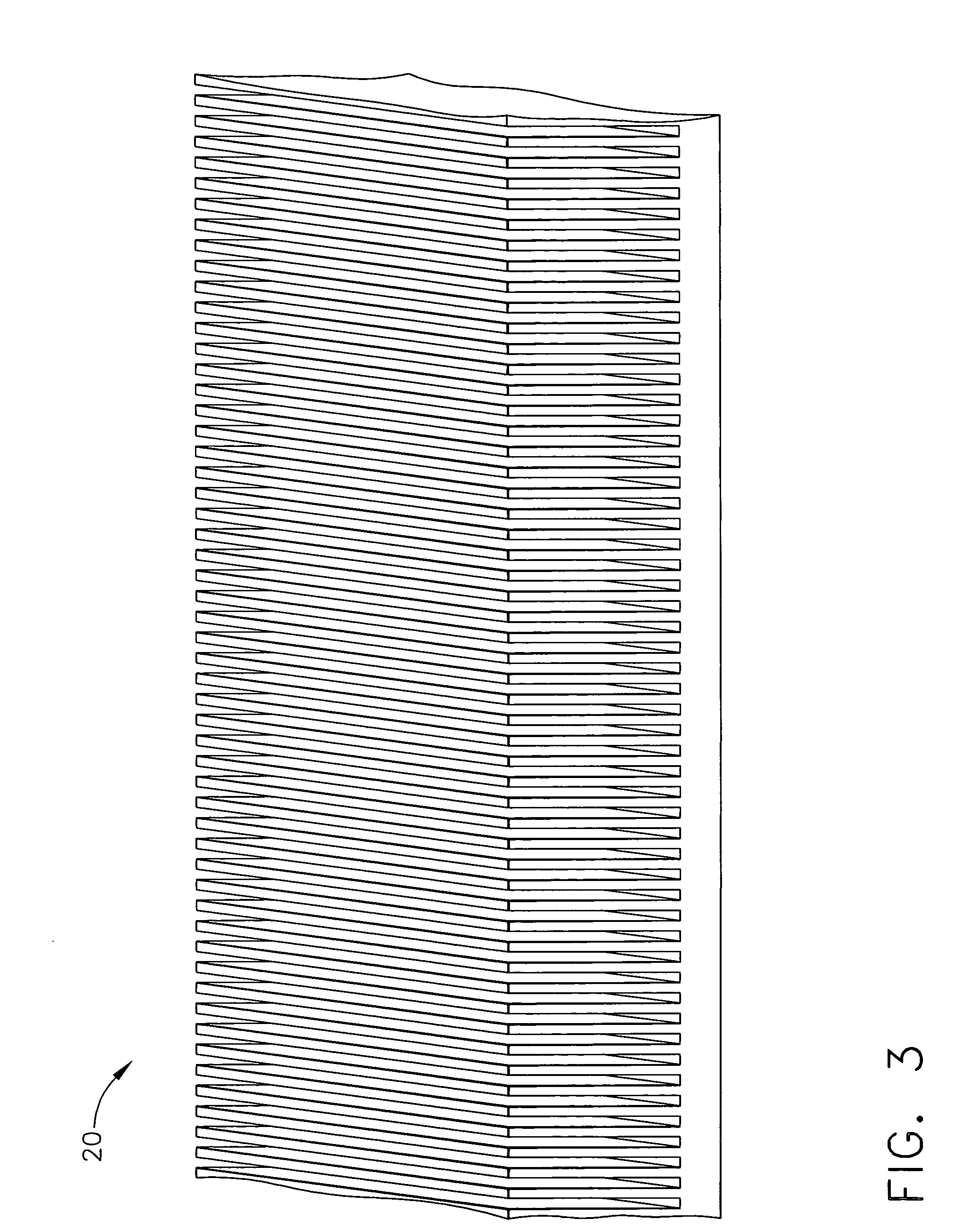

[0054] An aluminum 6061 alloy panel was fabricated having 40 width of 0.0168 inches and a length of 1.00 inch. The microchannels were traight, parallel passages with bottom round radii of 0.008 to 0.009 inches, separated by 0.0079 inch thick fins, and having an aspect ratio of 27.

example 2

[0055] An aluminum 6061 alloy panel was fabricated having 40 microchannels or fins per inch. The microchannels had a depth of 0.45 inches, a width of 0.0179 inches and a length of 1.00 inch. The microchannels were straight, parallel passages with bottom round radii of 0.008 to 0.009 inches, separated by 0.0073 inch thick fins, and having an aspect ratio of 25.

example 3

[0056] An aluminum 6061 alloy panel was fabricated having 40 microchannels or fins per inch. The microchannels had a depth of 0.45 inches, a width of 0.0197 inches and a length of 1.00 inch. The microchannels were straight parallel passages with bottom round radii of 0.008 to 0.009 inches, separated by 0.0047 to 0.0054 inch thick fins, and having an aspect ratio of 23.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com