High frequency and wide band impedance matching via

a wide band impedance and high frequency technology, applied in the field of conductive vias, can solve the problems of system instability, system damage, and reduced flexibility in circuit application, and achieve the effect of promoting electric characteristics of the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

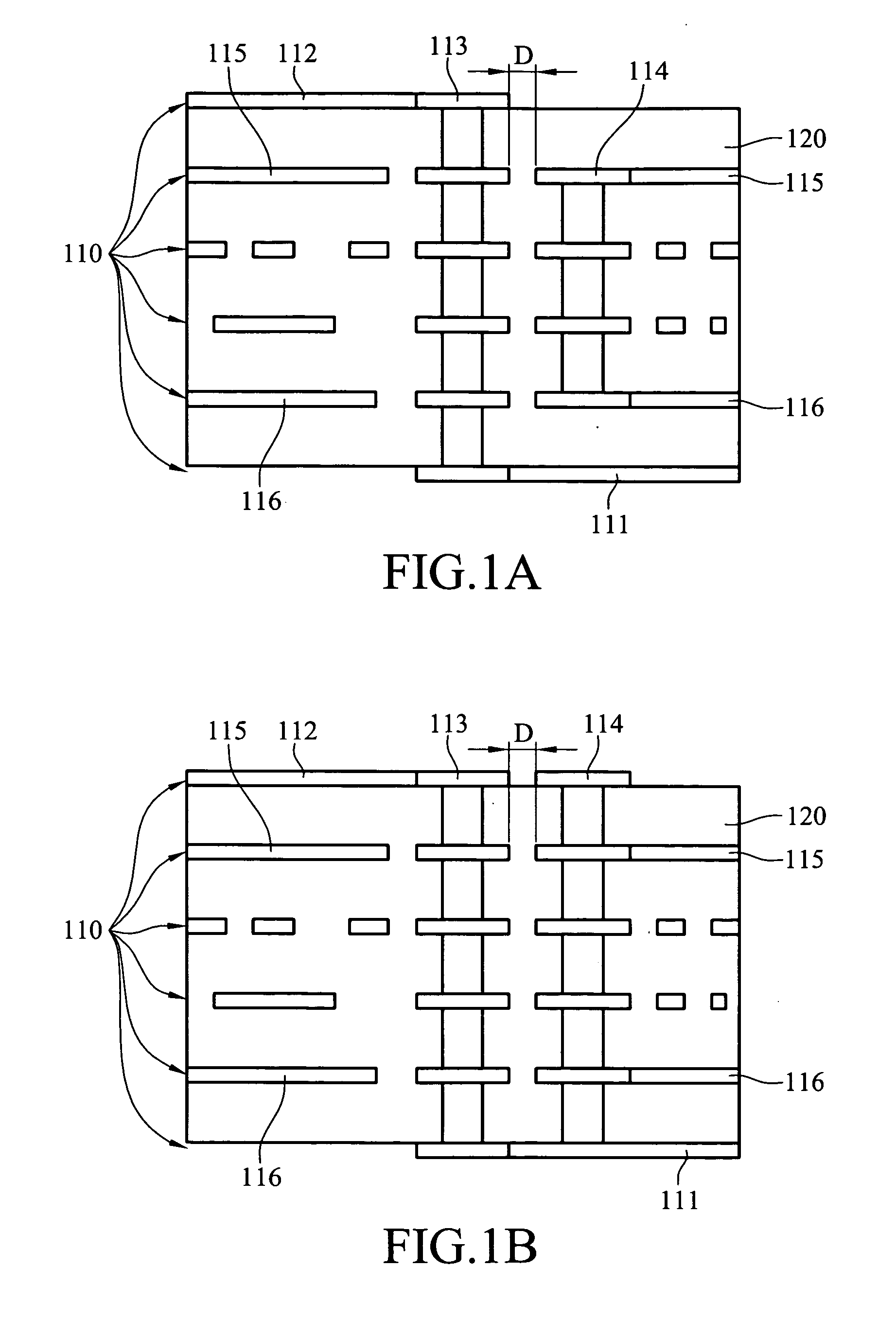

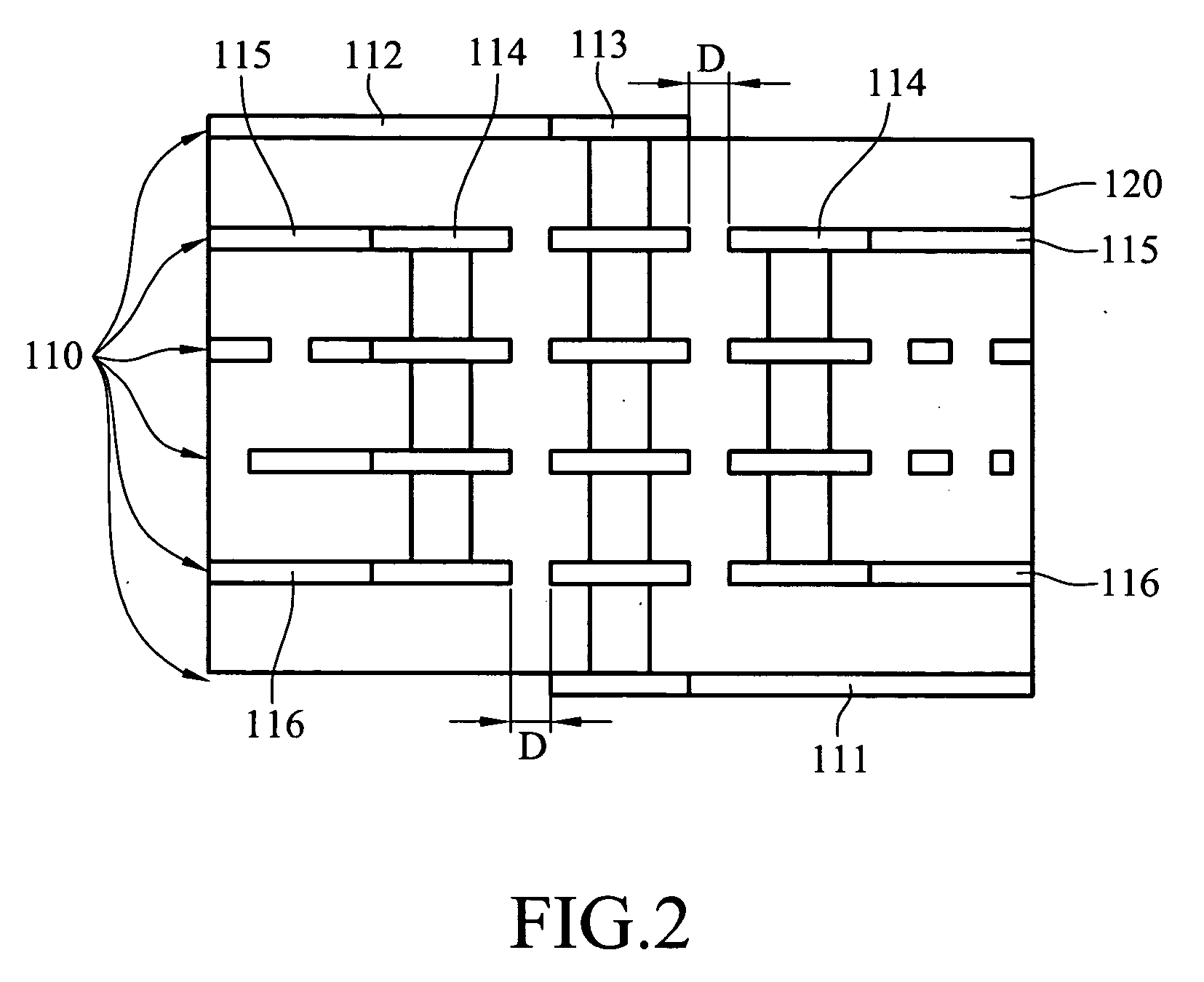

[0021] In an embodiment, the multi-layer printed circuit board is a combination of several insulation layers and several circuit layers, which are stacked staggeredly. Refer to FIG. 1A, which is a cross-section of a first embodiment according to the invention. A six-layer printed circuit board, for example, has six circuit layers 110, which are separated by insulation layers 120. The circuit layer 110 may be a signal transmission trace or a ground layer. The signal and the ground vias 113, 114 are substantially perpendicular to first and second signal transmission traces 111, 112, and first and second ground layers 115, 116. The first signal transmission trace 111 is sited on the bottom circuit layer 110, as a first surface of the substrate, the second signal transmission trace 112 is sited on the top circuit layer 110, as a second surface of the substrate, and the several insulation layers 120 separate them. The first signal transmission trace 111 is connected to the second signal ...

fourth embodiment

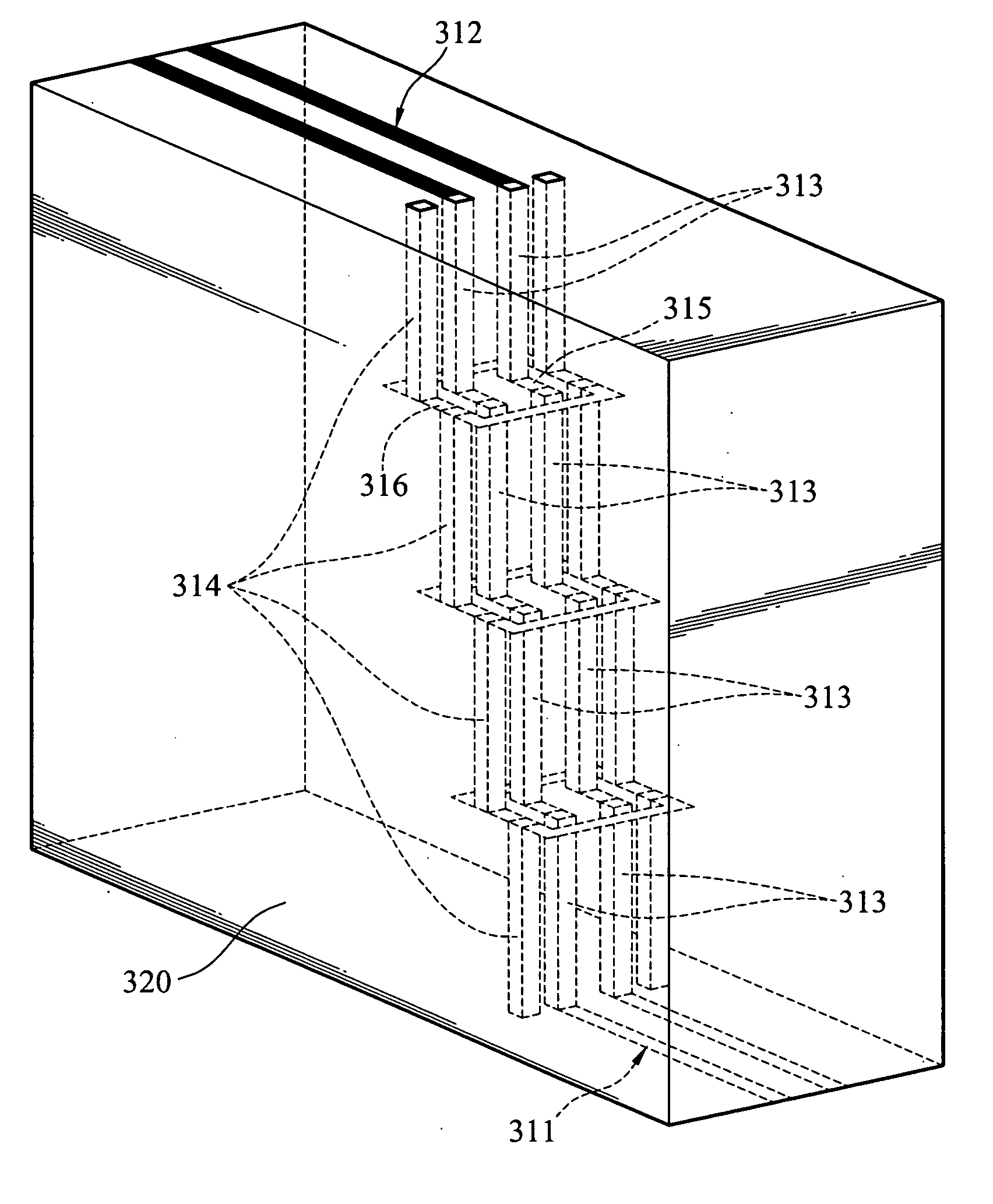

[0023] Further, the structure according to the invention is applied in the signal transmission for differential pairs. Refer to FIG. 3A, which is three-dimensional structures of a fourth embodiment according to the invention. In this embodiment, the structure comprises a first signal transmission differential pair 311, a second signal transmission differential pair 312, a pair of signal vias, several ground vias 314 and a conductor portion. In this case, the conductor portion is a hollow conductor portion 316. The pair of ground vias 314 is substantially perpendicular to the first and the second signal transmission differential pairs 311, 312. The first and the second signal transmission differential pairs 311, 312 are separated with an insulation layer 320, and the first and the second signal transmission differential pairs 311, 312 are connected by several signal vias. The signal vias comprise several vertical signal vias 313 and several plane conductor traces 315. The vertical si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com