Candle Reshaper

a reshaping and candle technology, applied in the field of candle cover or assembly, can solve the problems of too much melted wax, too deep to comfortably light, and the area surrounding the wick burns deeper and deeper into the candle, and achieves the effect of increasing the burn time, appealing and decorative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

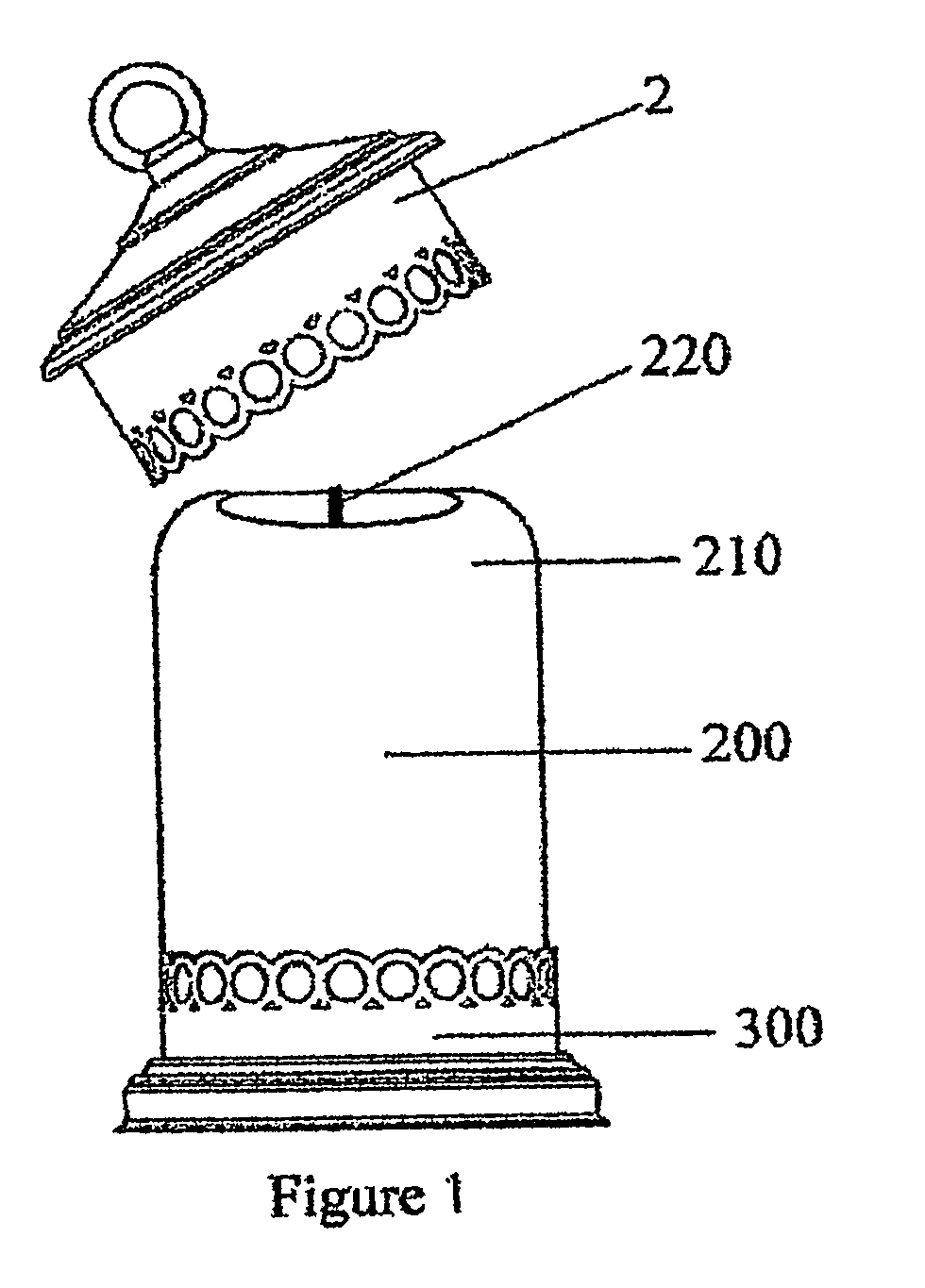

[0040] Referring to FIG. 1, there is depicted a candle top assembly 2 held above a candle 200. The candle 200 sits in an optional candle base 300. Together, candle top assembly 2, when placed over the candle, and candle base assembly 300 provide for a decorative display of the candle 200 when the candle 200 is not in use, for example when the candle is not burning. The contour of the rim 210 of candle 200 is such that the rim has been reshaped by the candle top assembly 100. The wick 220 of the candle 200 is visible in the center and at the top of the candle 200. When burning the candle, the candle top assembly 2 is removed and the wick is lit. The candle may sit in the optional base assembly 300 during burning. Recommended burning duration for a three-inch diameter pillar candle, such as depicted in FIG. 1, is three hours every time the candle is lit. The burn time of a candle is influenced by the type of wax used, be it bees wax, paraffin wax or soy wax, and also by the quality of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com