Connectors for concrete footer frames

a technology of connecting rods and concrete, applied in the field of laying up forms, can solve the problems of weak joints, inconvenient use, and often damaged forms, and achieve the effect of convenient use and inexpensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

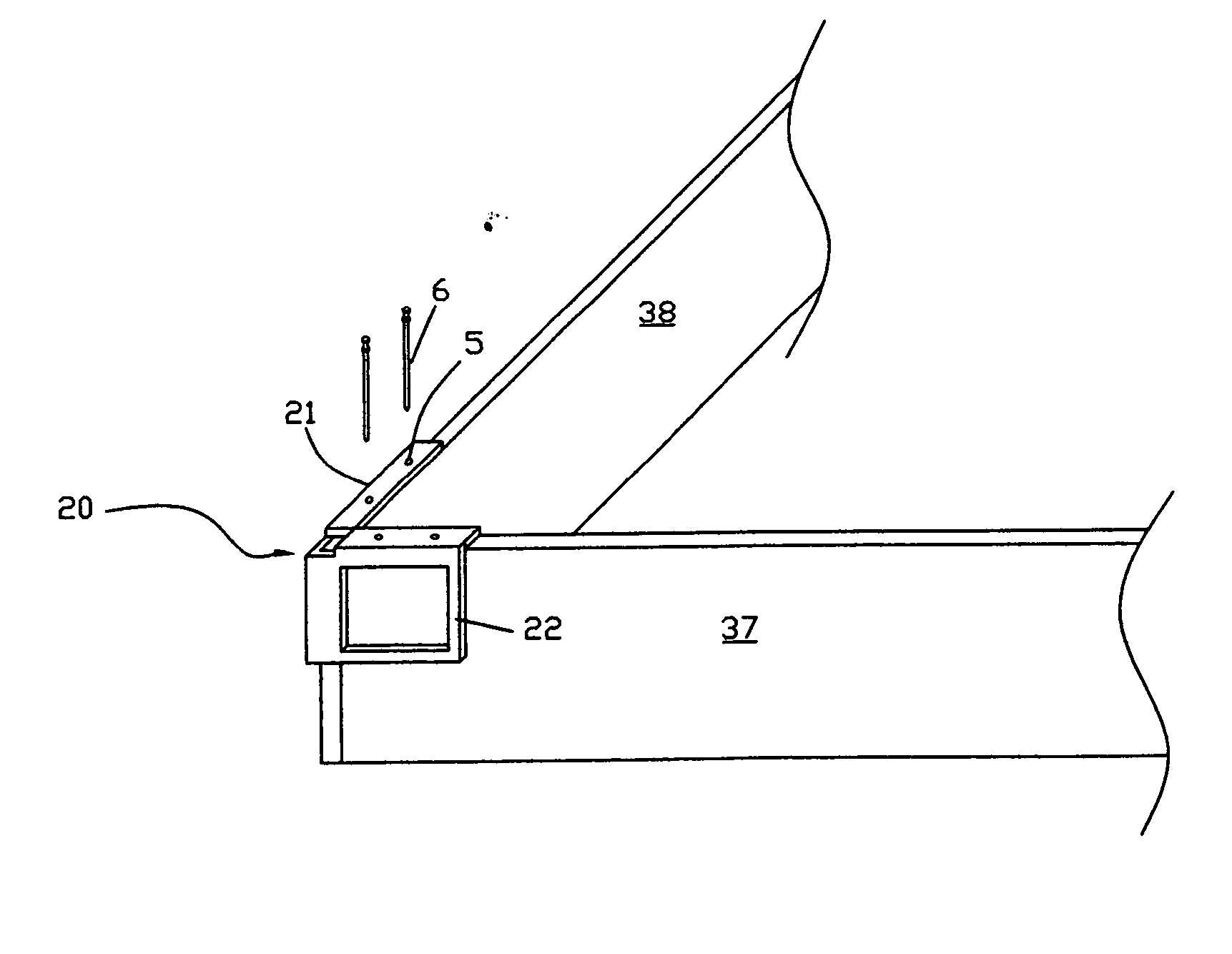

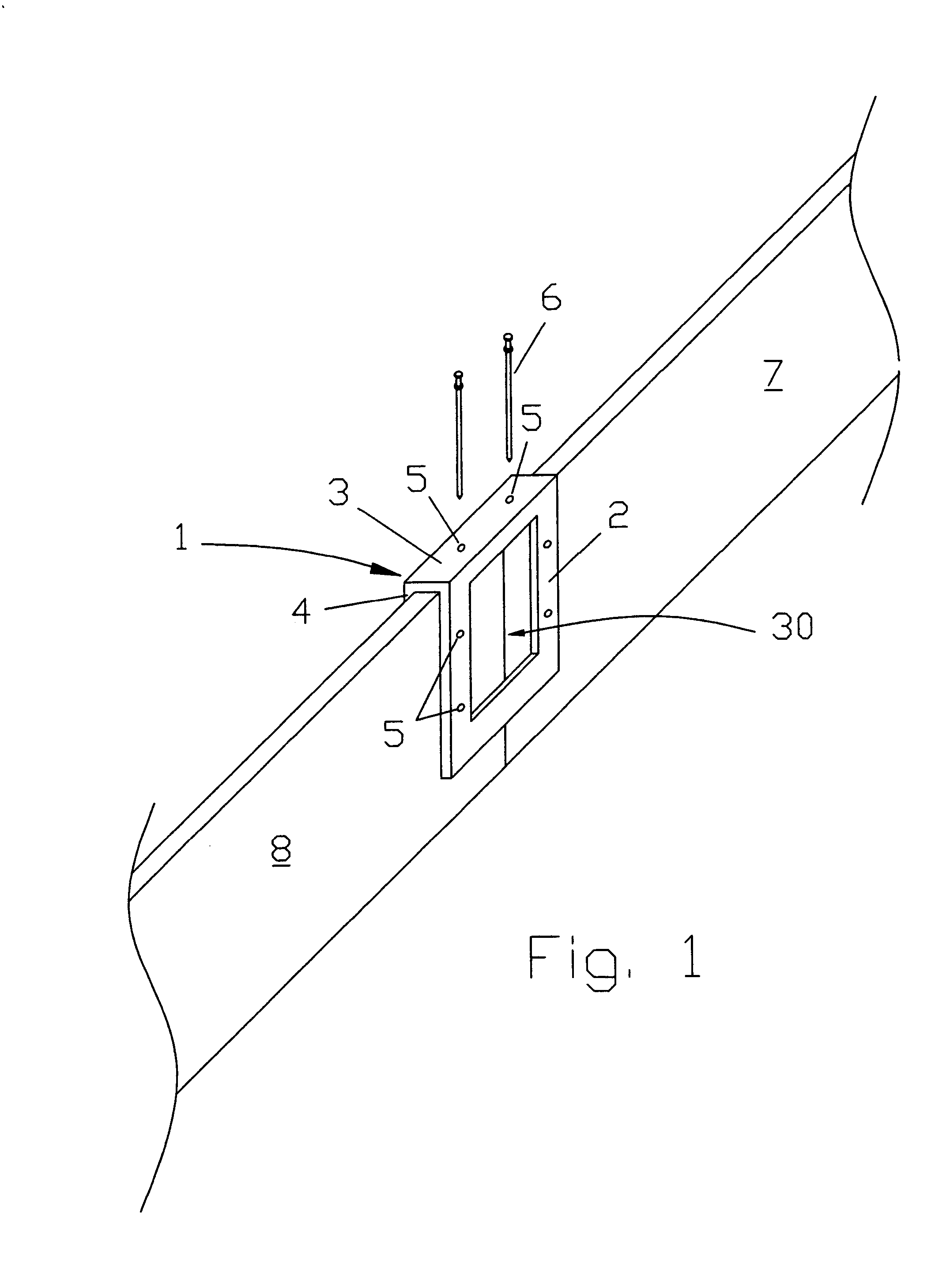

[0014]FIG. 1 shows a first embodiment of the form connector 1 in use connecting two form boards 7 and 8 in an end-to-end abutting relationship. Form connector 1 consists of a sheet metal body having an outside portion 2, a top portion 3, and an inside portion 4. Form connector 1 sits atop the joint between two form boards 7 and 8, spanning the joint therebetween. Outside portion 2 extends downwardly from the top of the form boards and extends over a portion of the outsides of the form boards. Top portion 3 is connected to the outside portion 2 and extends across the upper surface of the form boards, also spanning the joint therebetween. Connected to the top portion 3 is an inside portion 4, which extends downwardly from top portion 3 and extends over a part of the inside surface of the form boards 7 and 8. Nail holes 5 are strategically placed on the outer portion 2 and top portion 3 allowing for double headed nails 6 to pass therethrough, securing the connector 1 to the form boards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com