Patents

Literature

43results about How to "Efficiently joined" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

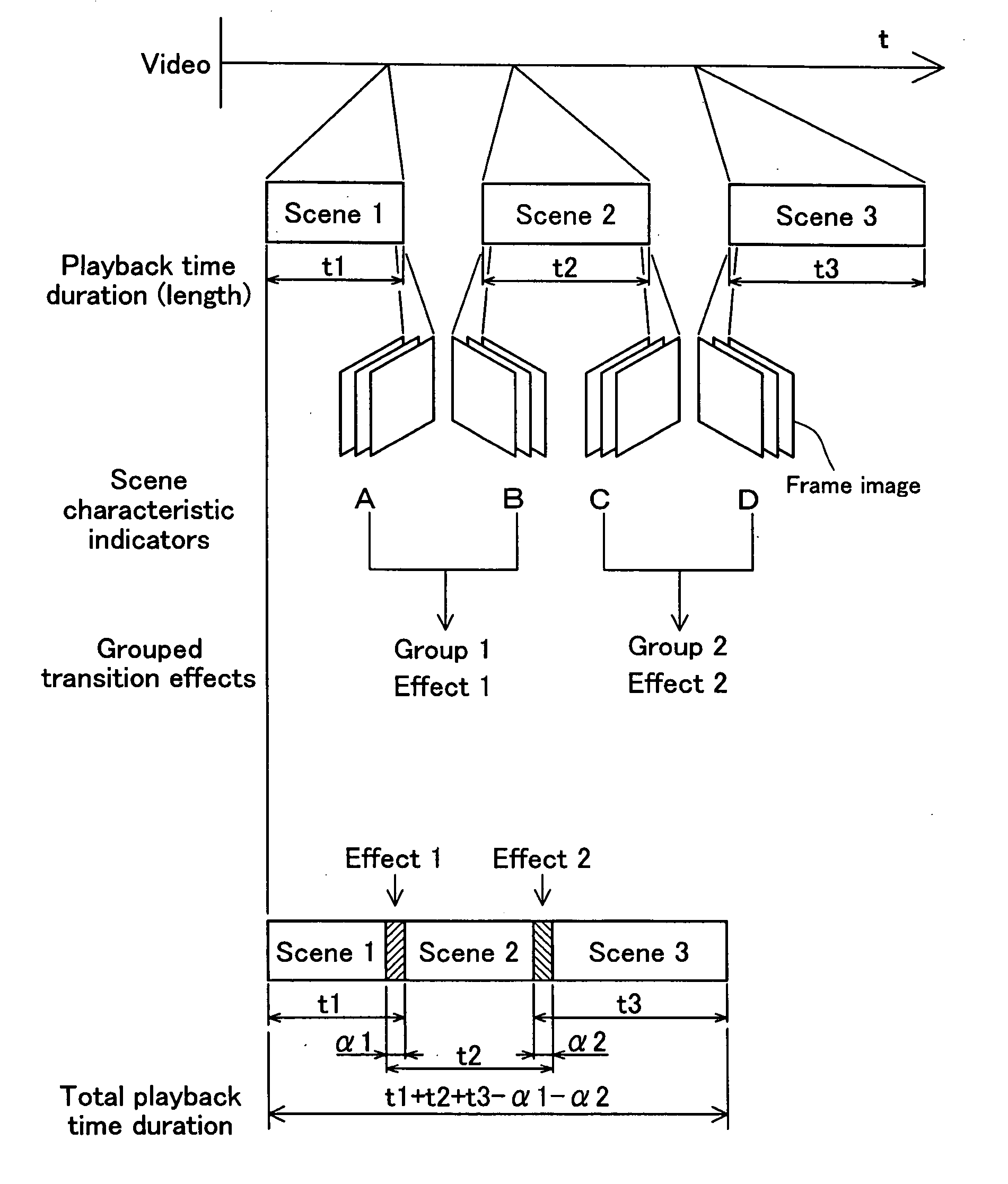

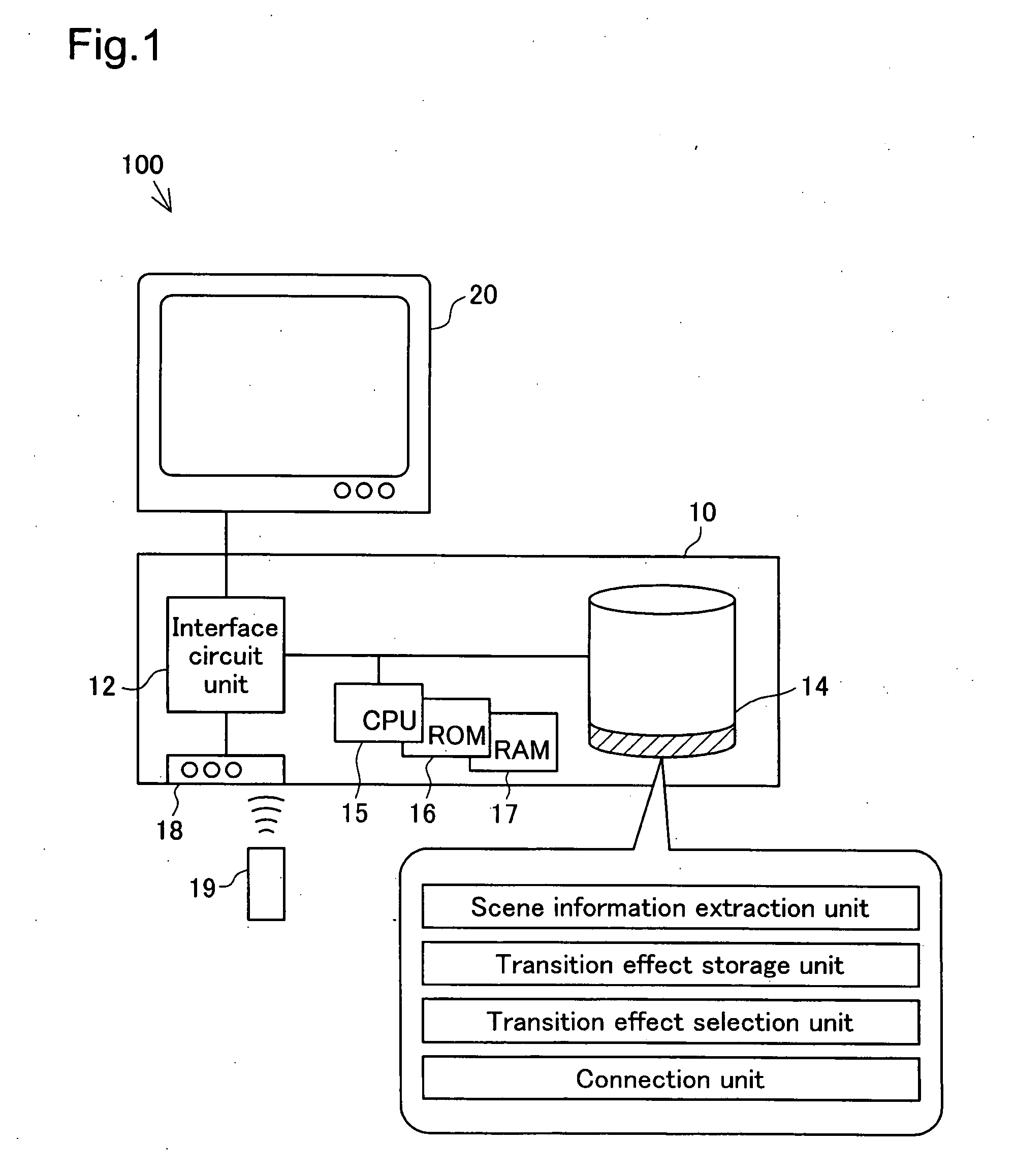

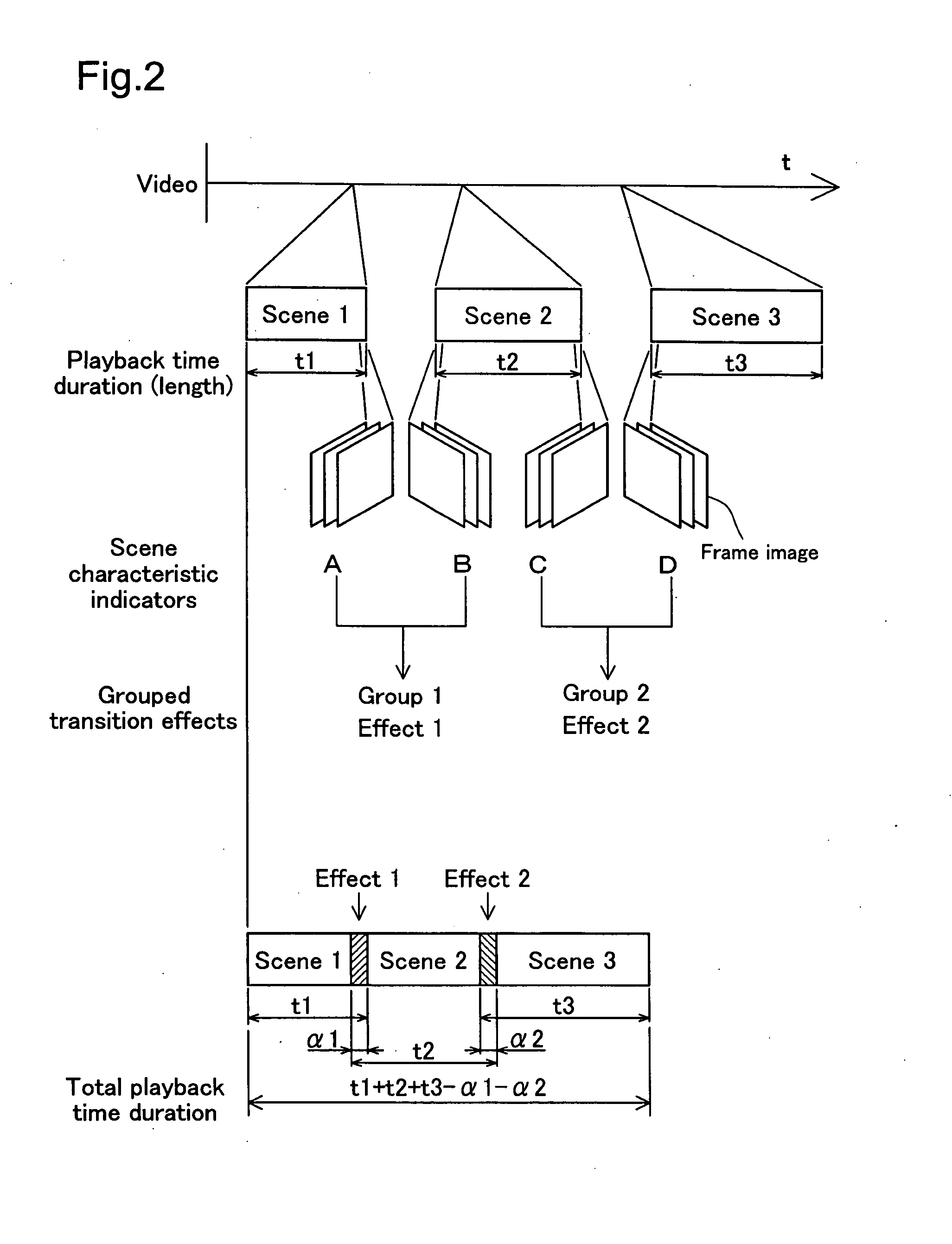

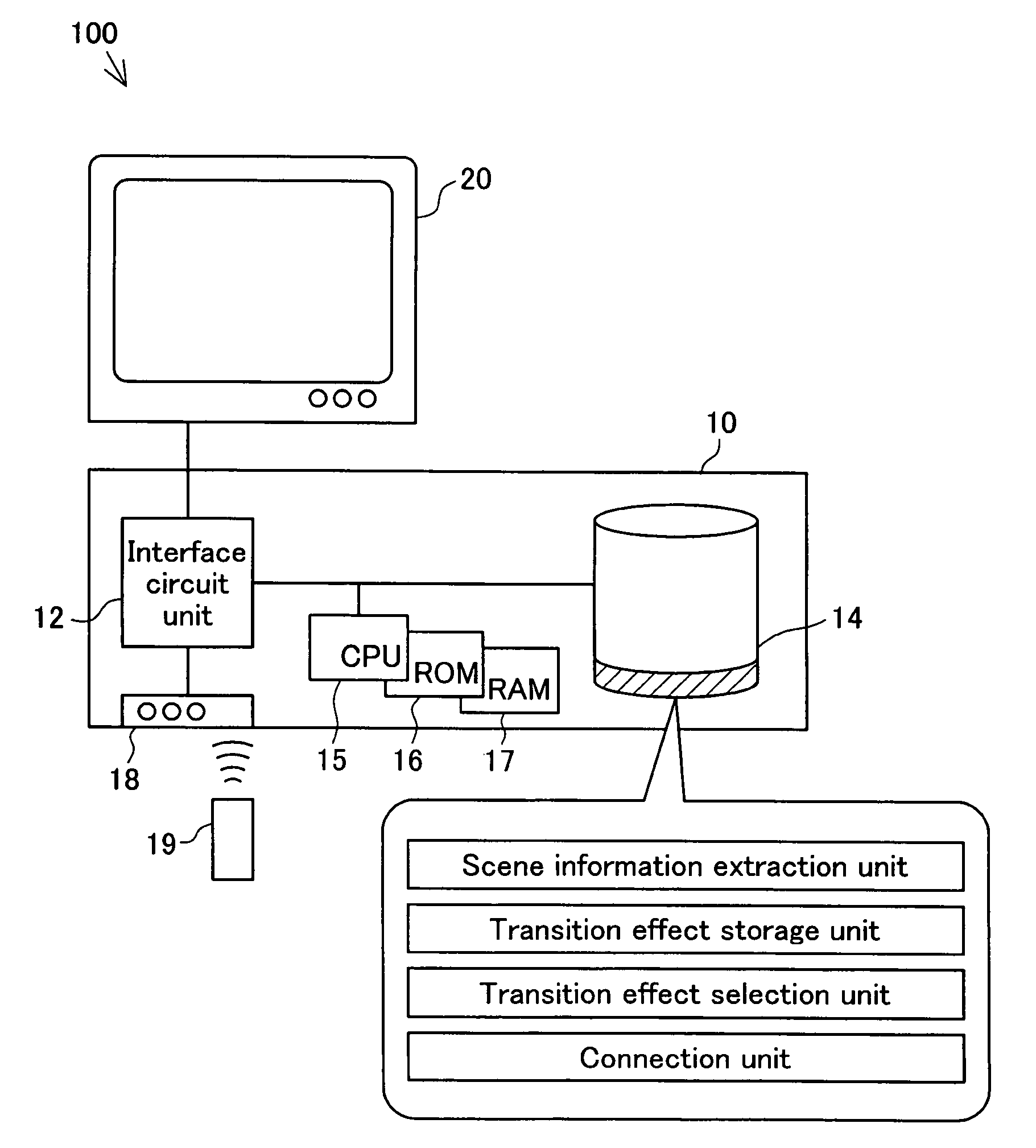

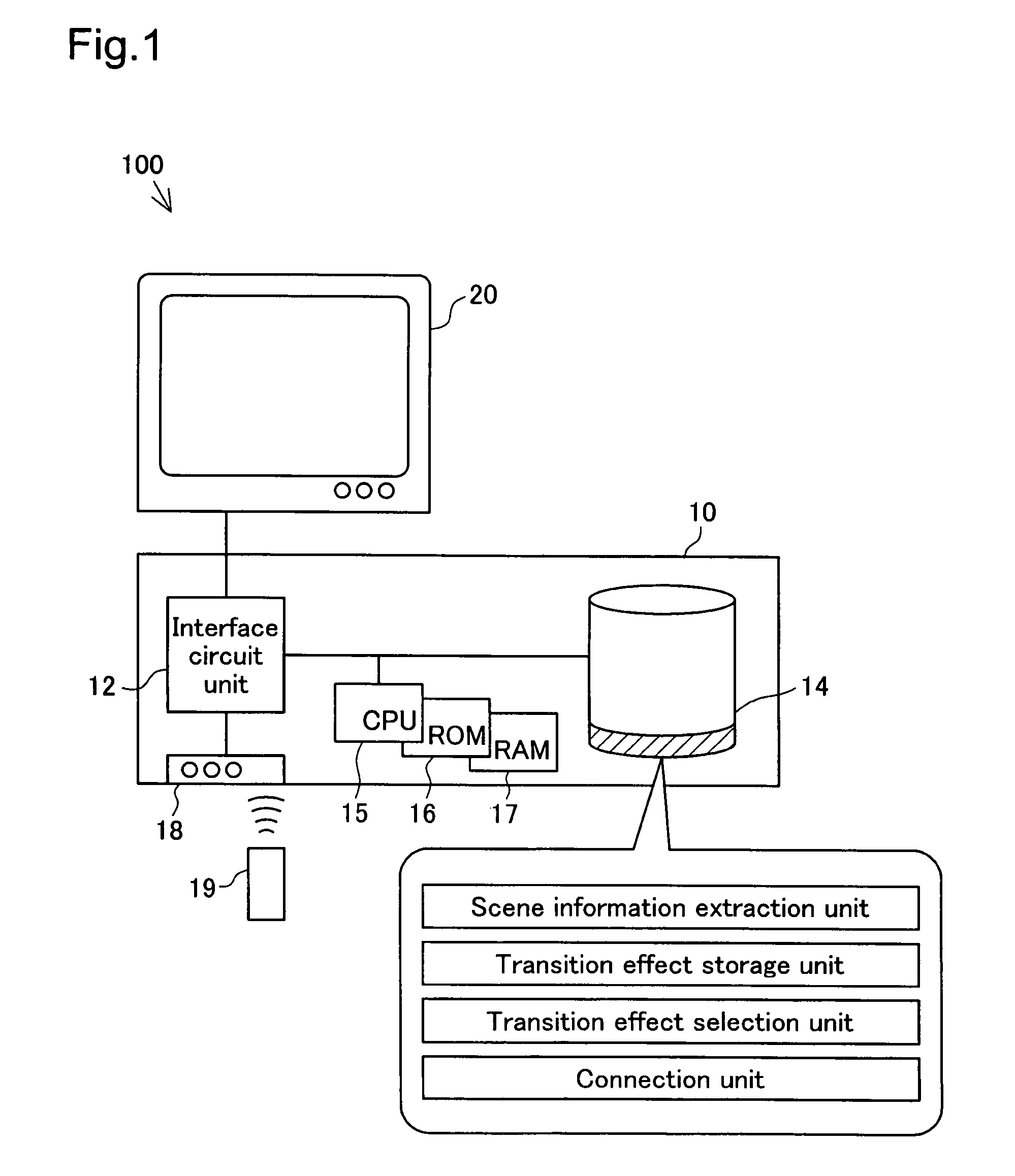

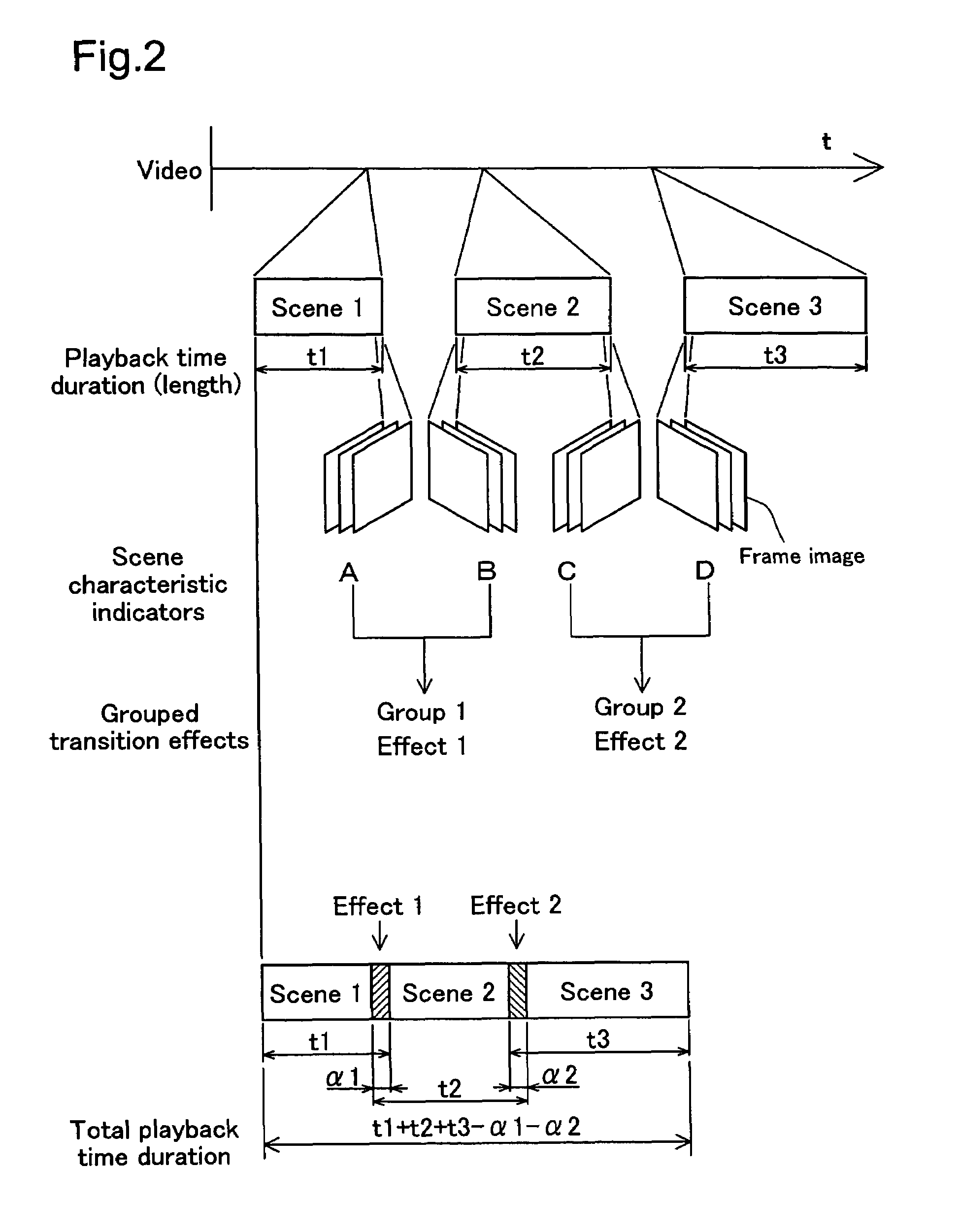

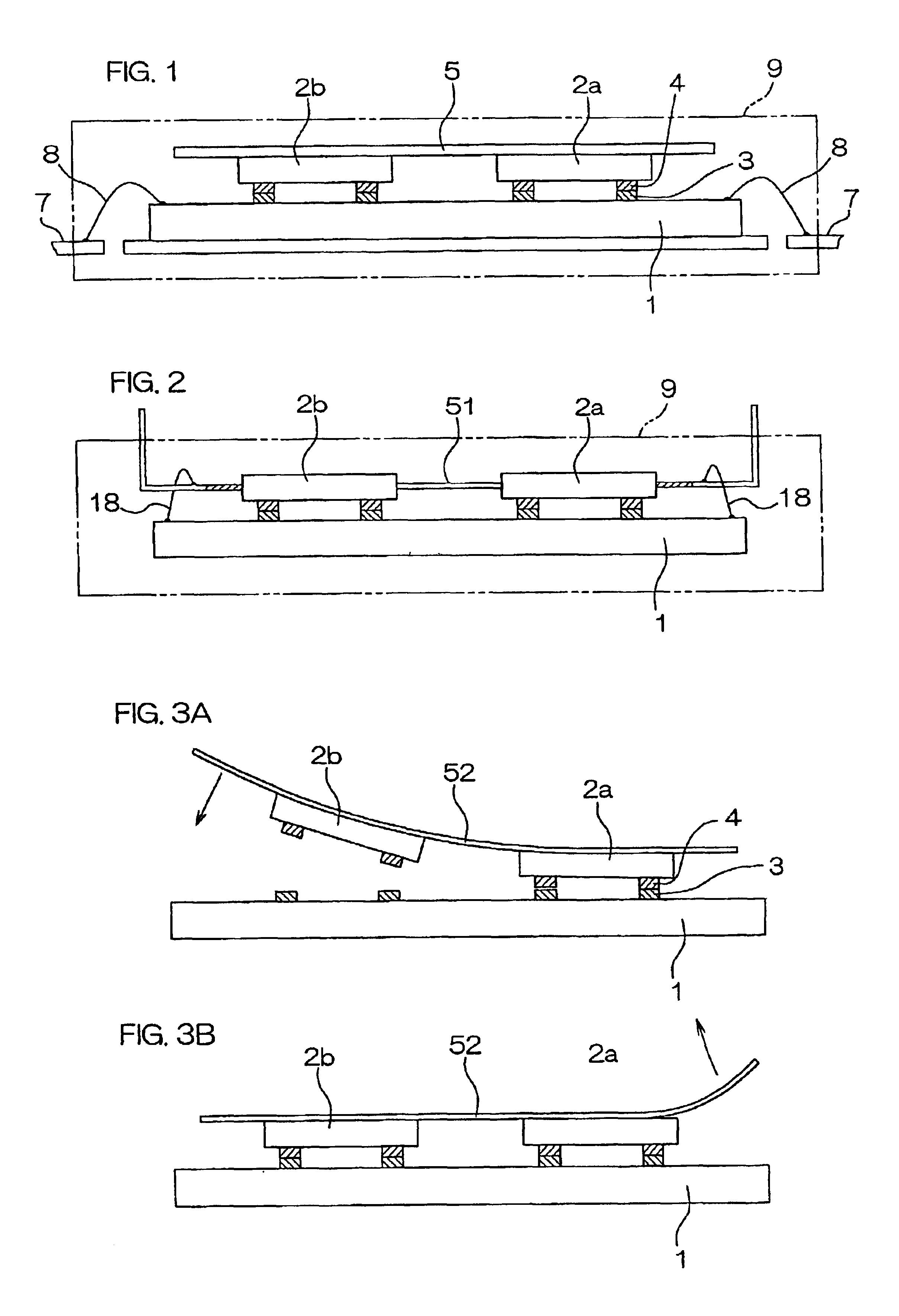

Image processing device and image processing method

InactiveUS20080019610A1Efficiently joinedTelevision system detailsColor signal processing circuitsImaging processingMultiple frame

An image processing device that joins together multiple scenes extracted from a video image, wherein scene information that indicates characteristics of the multiple scenes is extracted from multiple frame images that comprise the video image, where, when two scenes are to be joined together multiple types of transition effects to be used in the changing of the scenes is stored in advance, and a specific transition effect is selected, based on the extracted scene information, from the transition effects that have been stored in advance. For example, effects such as a slide or a wipe are selected based on the characteristics of the video image, such as the direction of movement of an object. The specific transition effect that has been selected is used to join together the two scenes. The result is that it is possible to set up effective scene changes to enable each scene to be joined together.

Owner:SEIKO EPSON CORP

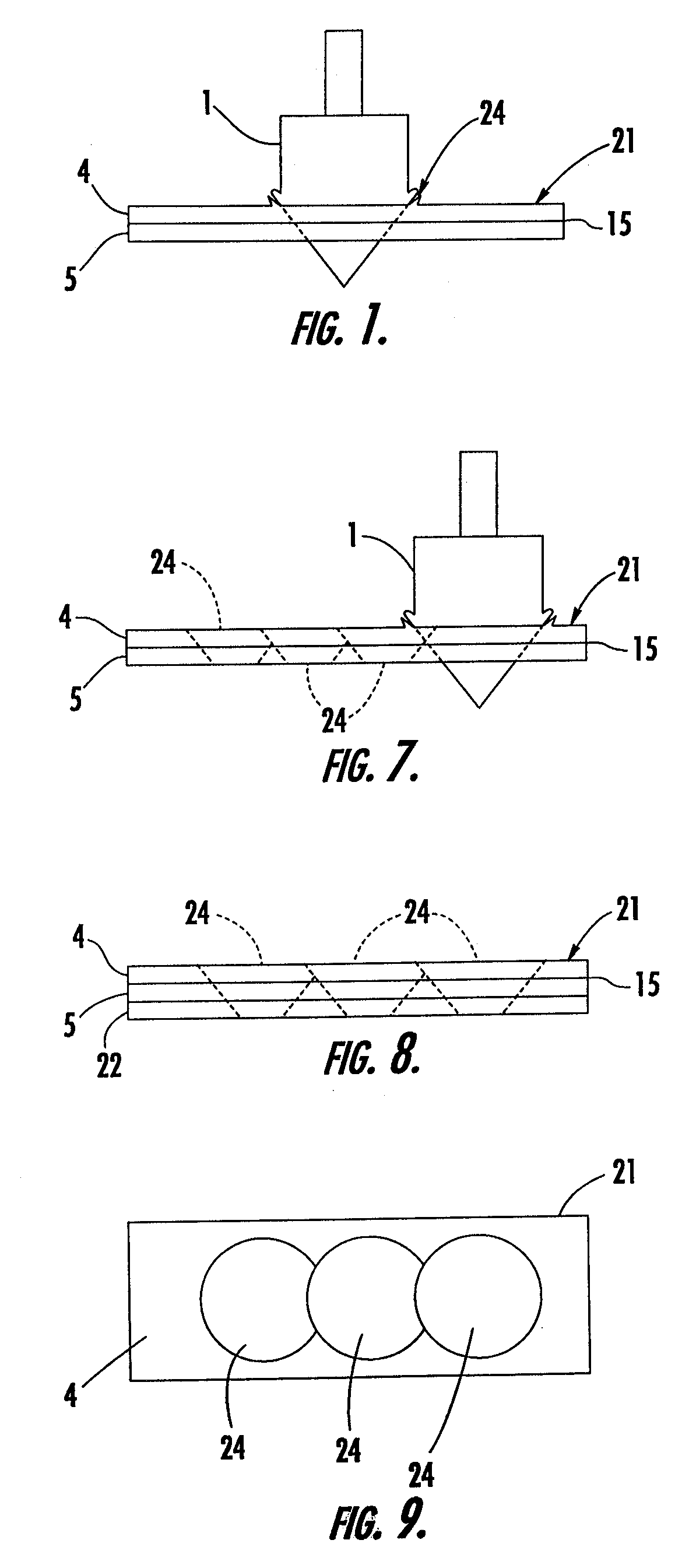

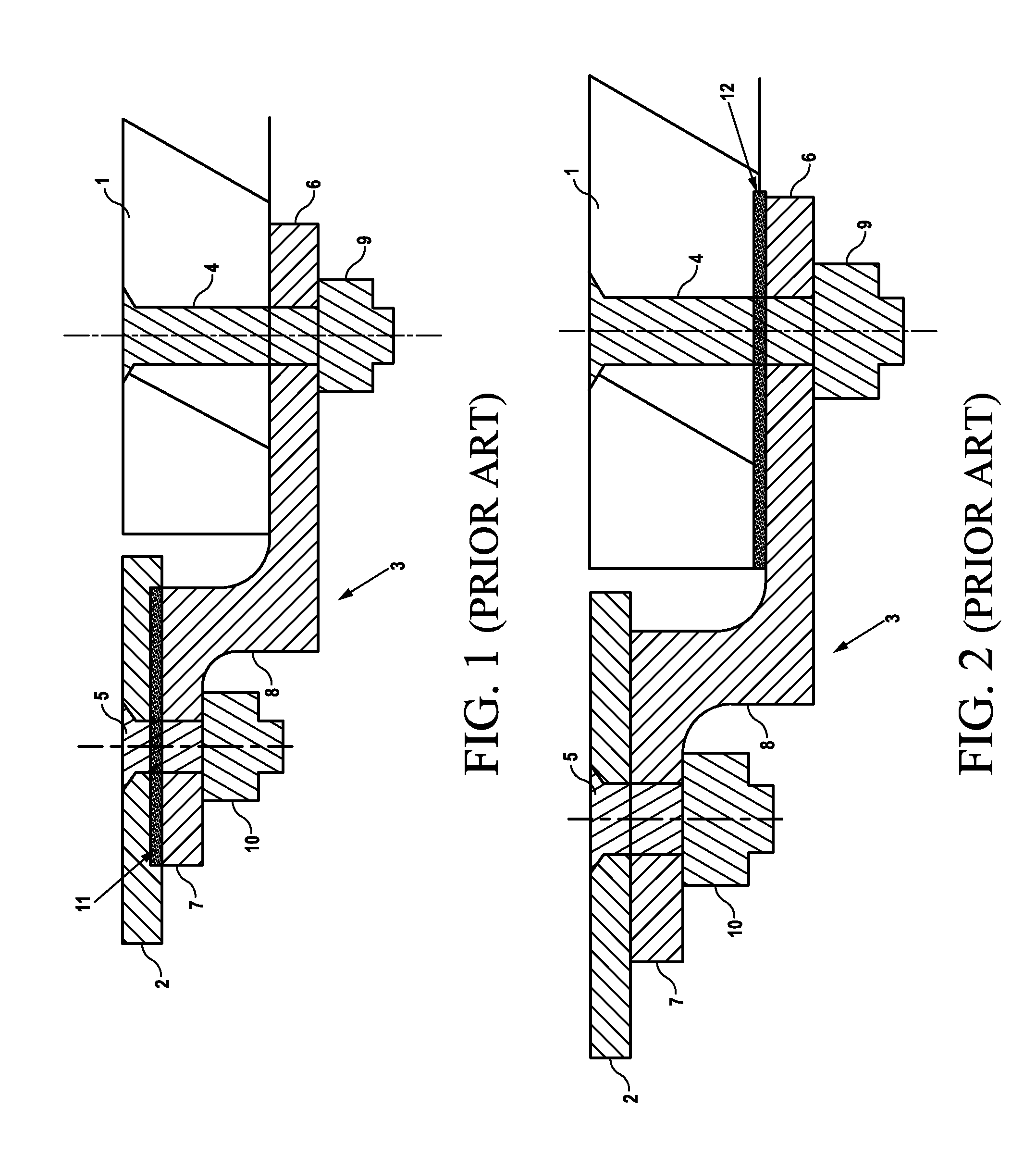

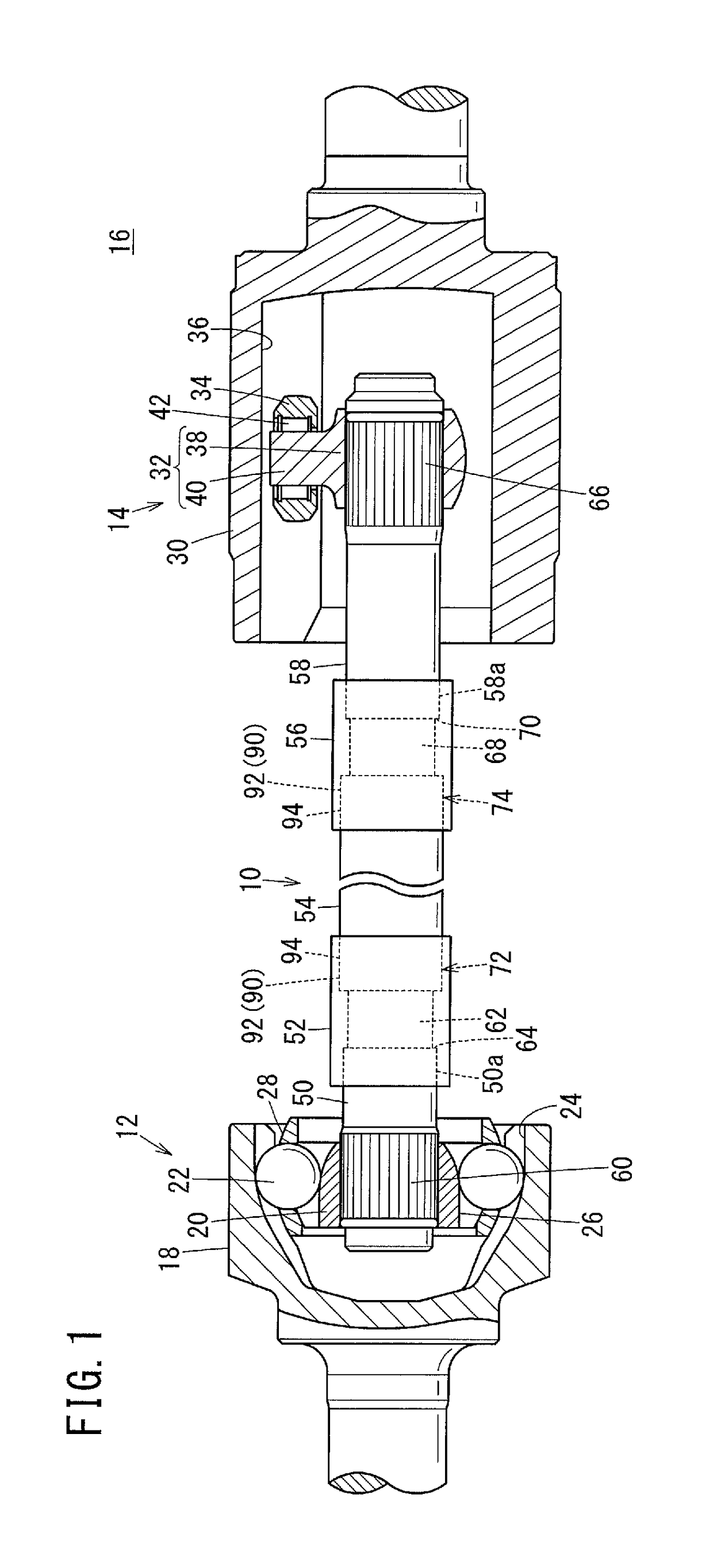

Joining of structural members by friction plug welding

InactiveUS20030201306A1Cost effectiveEfficiently joinedWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

Abstract of the Disclosure The method of manufacturing a structural assembly includes positioning a first structural member at least partially adjacent a second structural member to define an interface therebetween and inserting a rotating plug into the first and second structural members at the interface to thereby join the first structural member to the second structural member. The resulting friction plug weld provides a relatively strong joint between the structural members, requires less forming and machining time, and is compatible with single-sided tooling. Additionally, the friction plug weld is compatible with other joining methods, such as friction stir welding.

Owner:THE BOEING CO

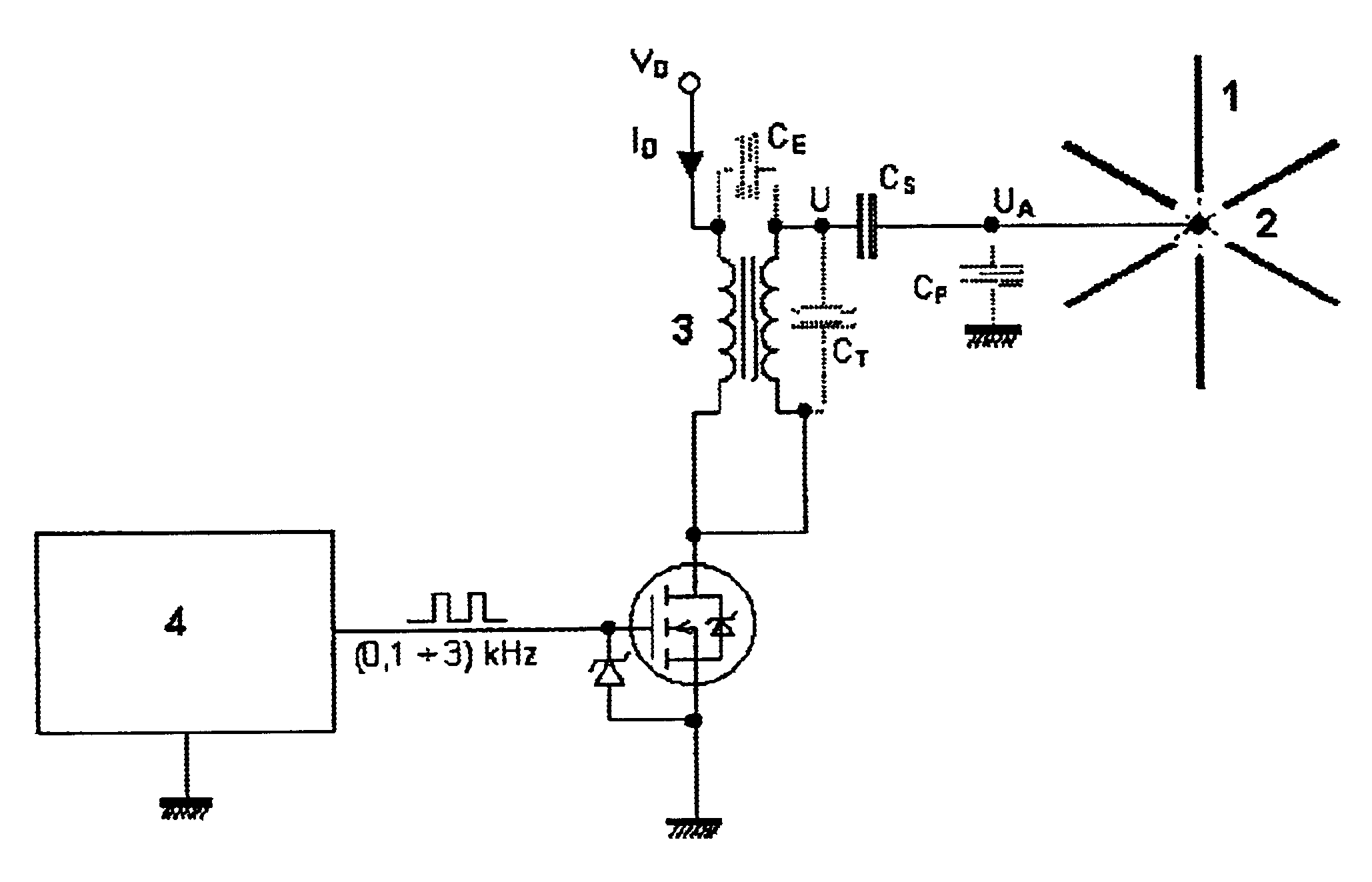

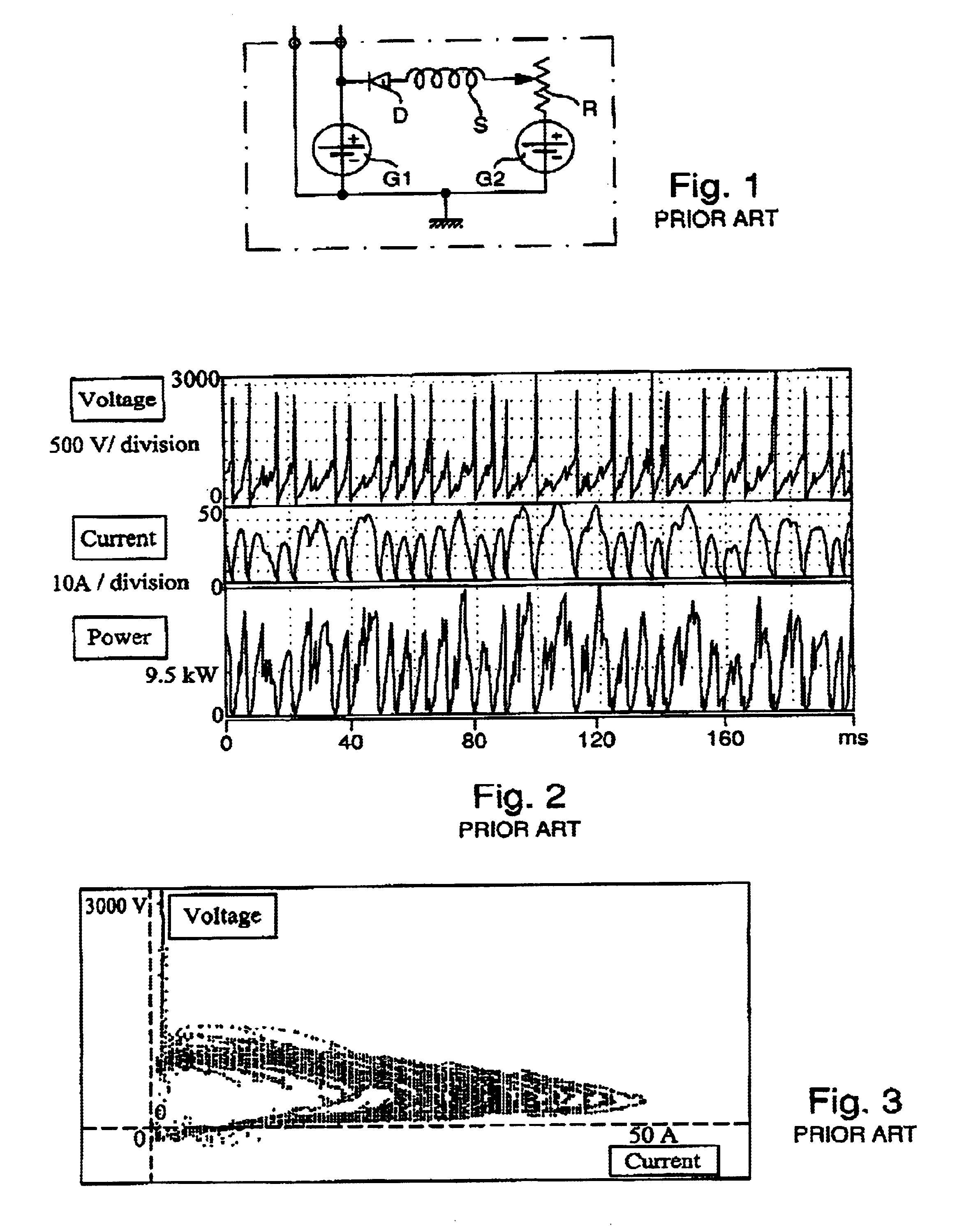

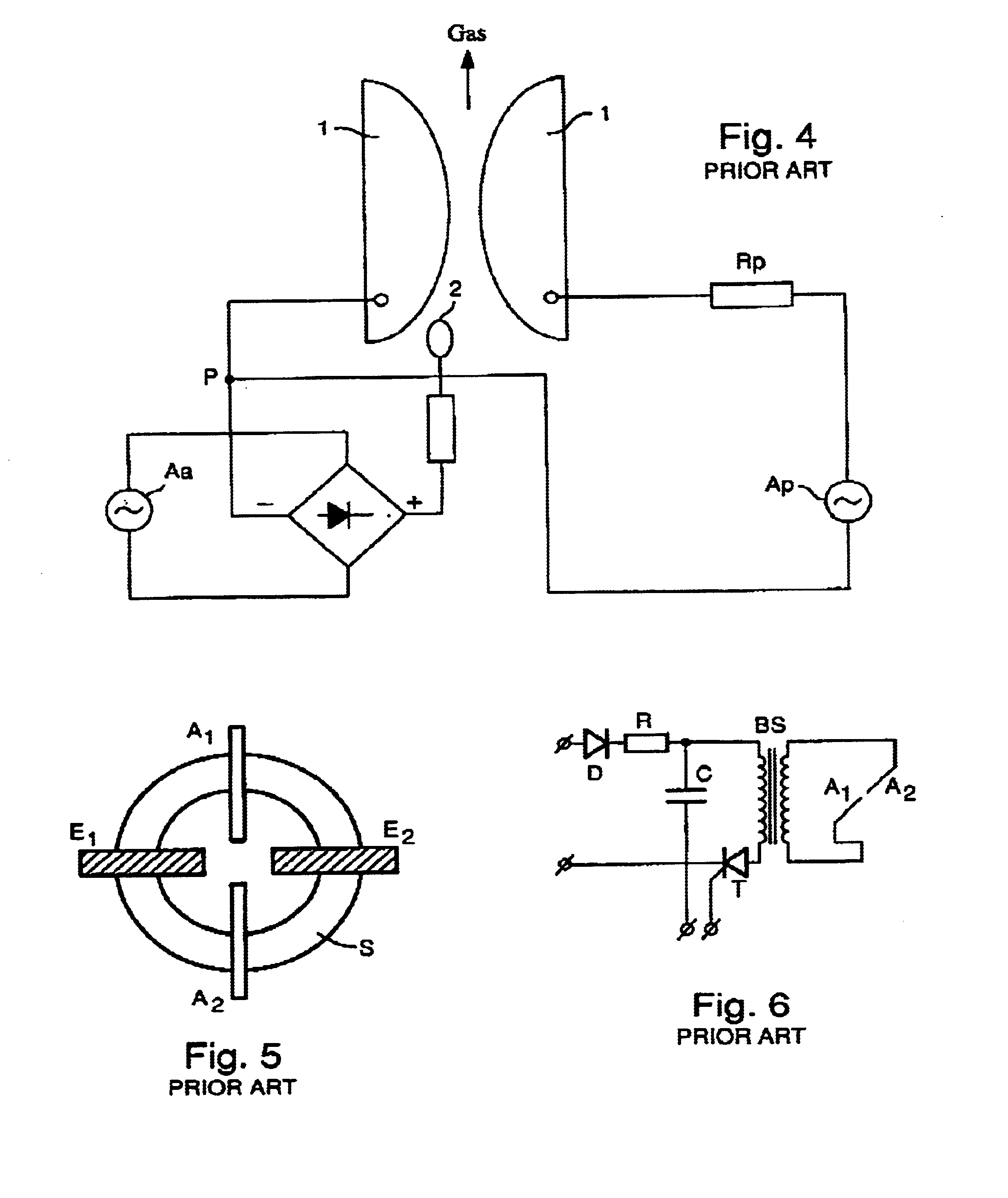

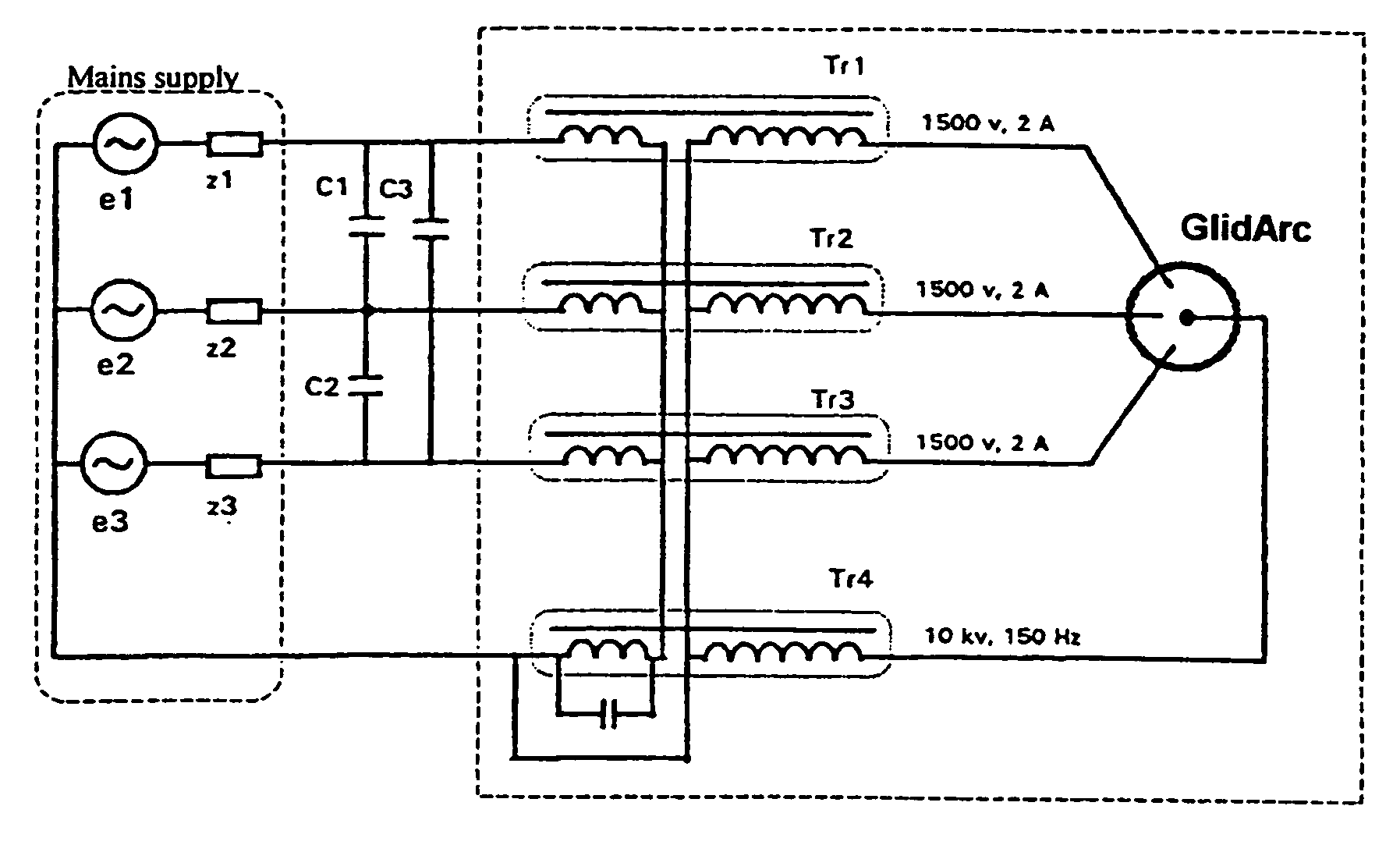

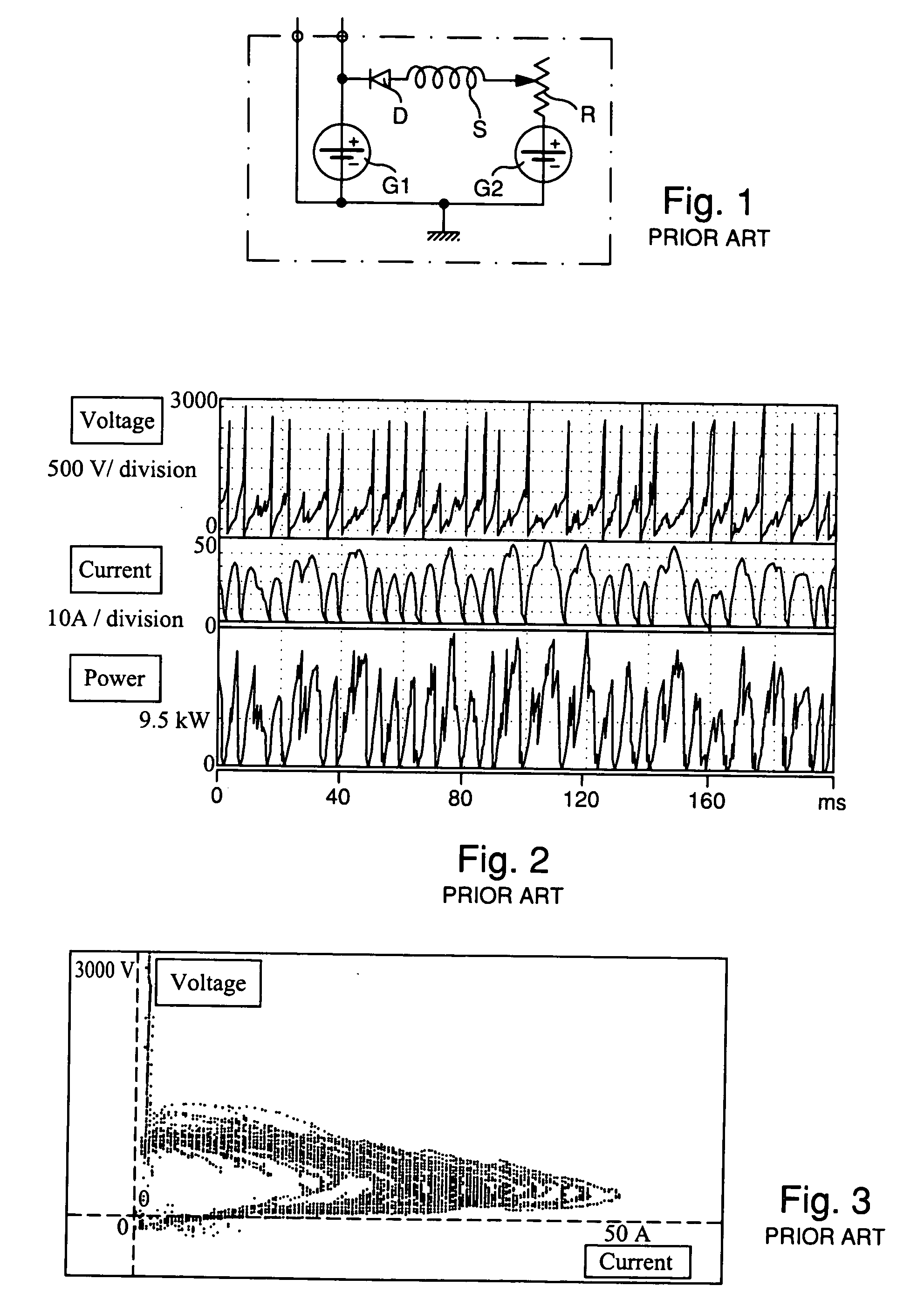

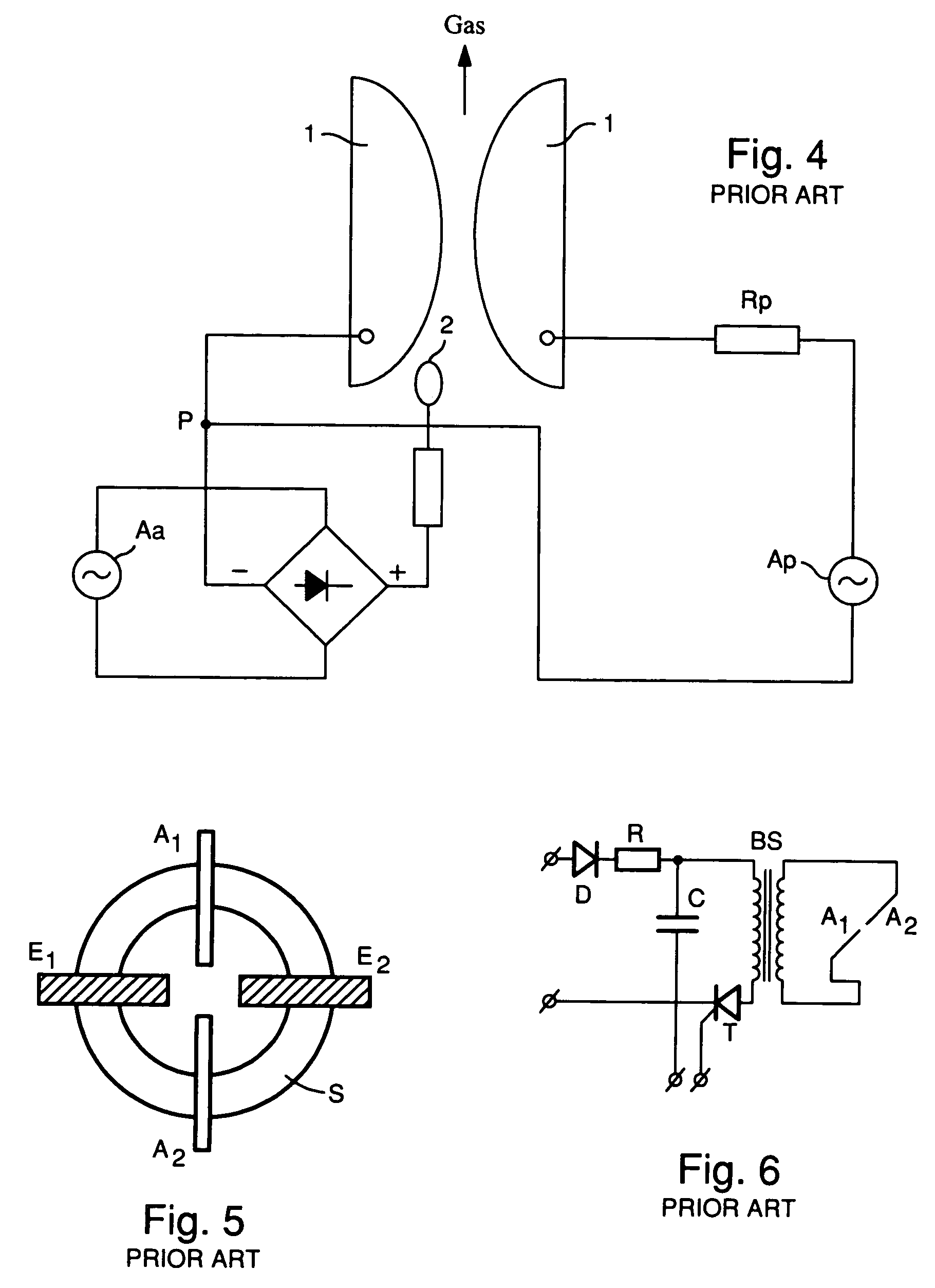

System and method for ignition and reignition of unstable electrical discharges

InactiveUS6924608B2Reduce needLess needSpark gaps with auxillary triggeringElectric discharge heatingVoltage pulseEngineering

Systems and methods for ignition and reignition of unstable electrical discharges wherein a secondary electrode positioned is between a set of primary electrodes and a high voltage is applied between the secondary electrode and successive ones of the primary electrodes to produce pilot discharges that ionize a gas there between and thereby reduce the voltage necessary to ignite a primary discharge between the primary electrodes. Power is provided to the secondary electrode by a circuit which is independent of the circuit that supplies power to the primary electrodes and generates voltage pulses which are substantially higher than the voltage between the primary electrodes.

Owner:CERAMTEC

Image processing device and image processing method

InactiveUS7630021B2Efficiently joinedTelevision system detailsColor signal processing circuitsImaging processingComputer graphics (images)

An image processing device that joins together multiple scenes extracted from a video image, wherein scene information that indicates characteristics of the multiple scenes is extracted from multiple frame images that comprise the video image, where, when two scenes are to be joined together multiple types of transition effects to be used in the changing of the scenes is stored in advance, and a specific transition effect is selected, based on the extracted scene information, from the transition effects that have been stored in advance. For example, effects such as a slide or a wipe are selected based on the characteristics of the video image, such as the direction of movement of an object. The specific transition effect that has been selected is used to join together the two scenes. The result is that it is possible to set up effective scene changes to enable each scene to be joined together.

Owner:SEIKO EPSON CORP

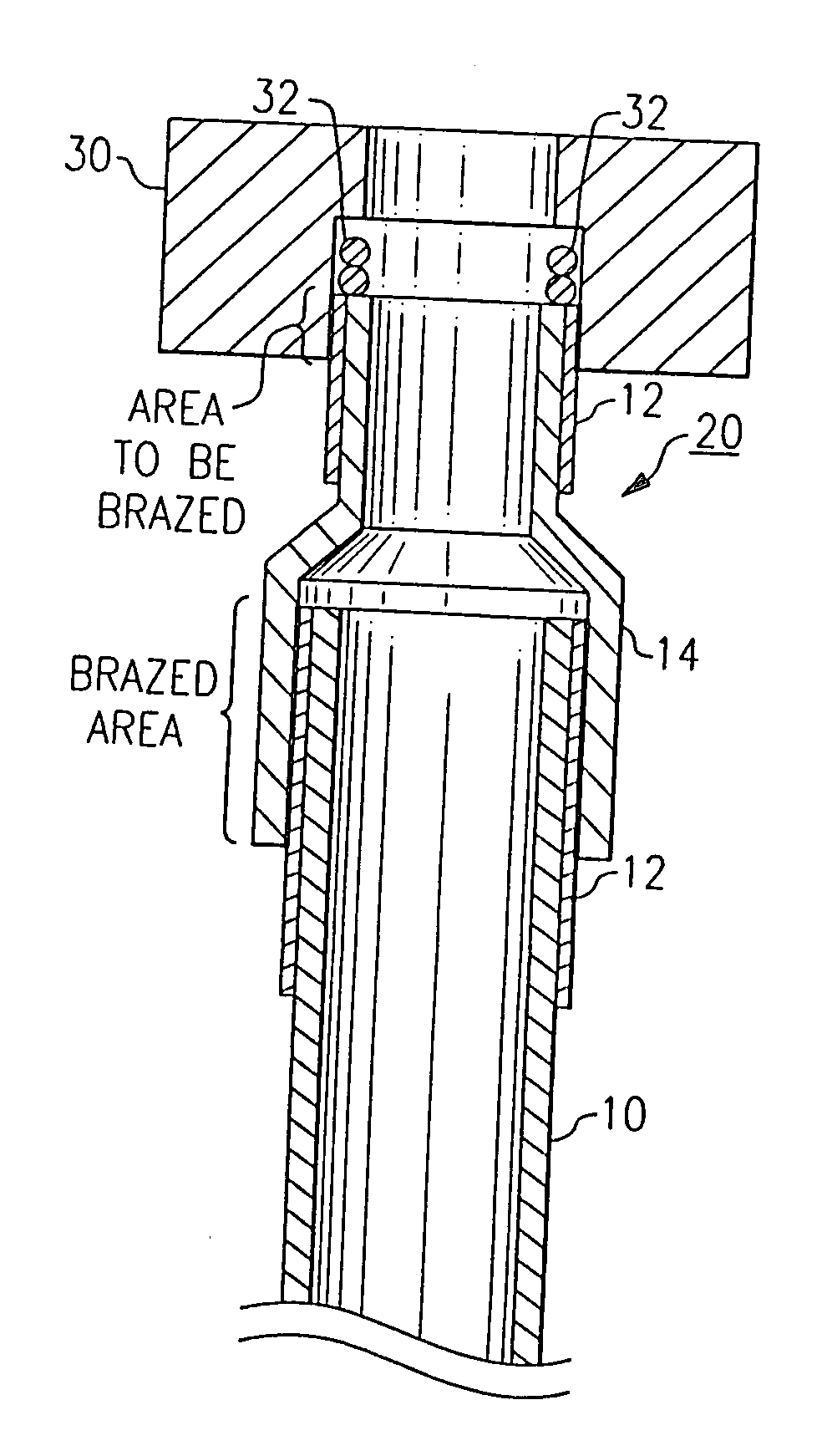

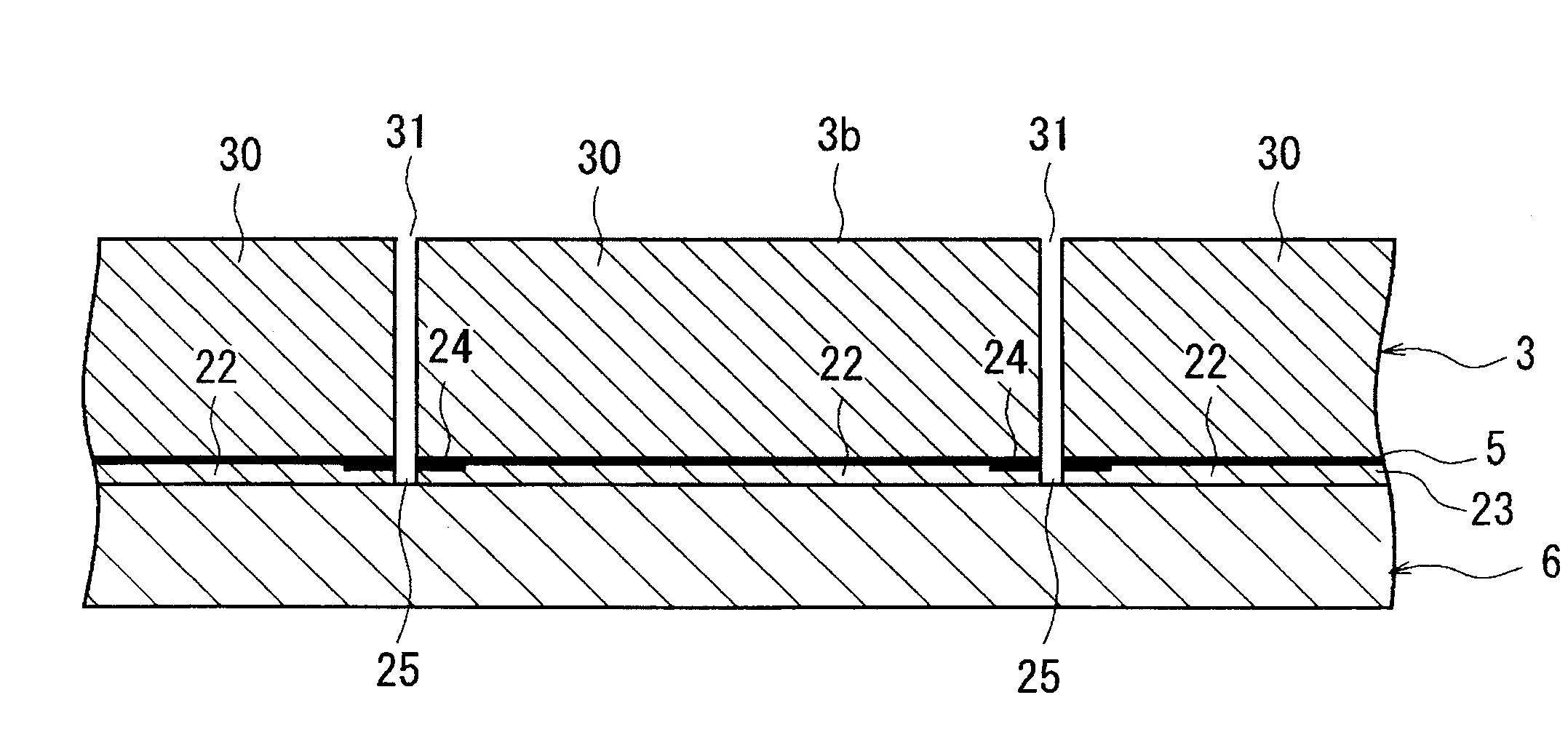

Process for joining silicon-containing ceramic articles and components produced thereby

InactiveUS20120177488A1Complex shapeReduce manufacturing costPump componentsSoldering apparatusSiliconMetal

A process for joining silicon-containing ceramic articles, and particularly ceramic articles and CMC articles that contain both silicon carbide and free silicon. The process entails providing a reactive metal-containing braze material between the articles, and then heating the braze material and the articles to react the reactive metal with the silicon within the articles to form a brazement containing a silicide phase of the reactive metal. The brazement and articles are then cooled to produce a component comprising the two articles and the silicide phase-containing brazement. The process is preferably carried out at temperatures below that which would thermally degrade constituents of the articles, and more preferably below the melting point of silicon.

Owner:GENERAL ELECTRIC CO

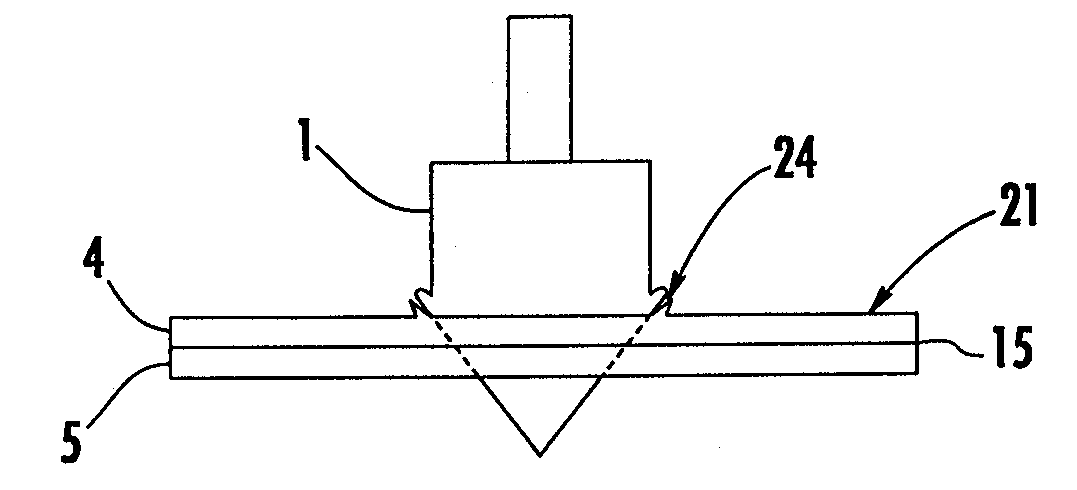

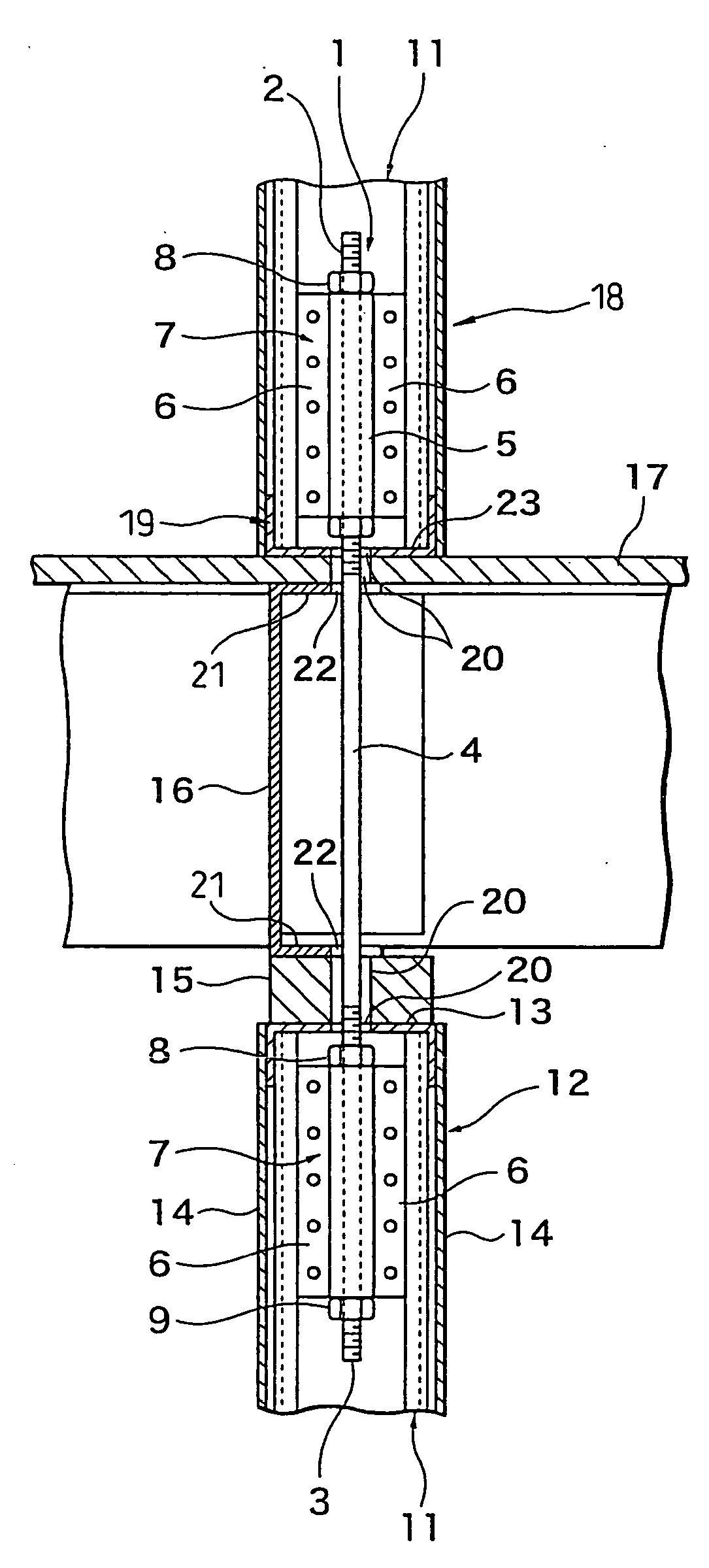

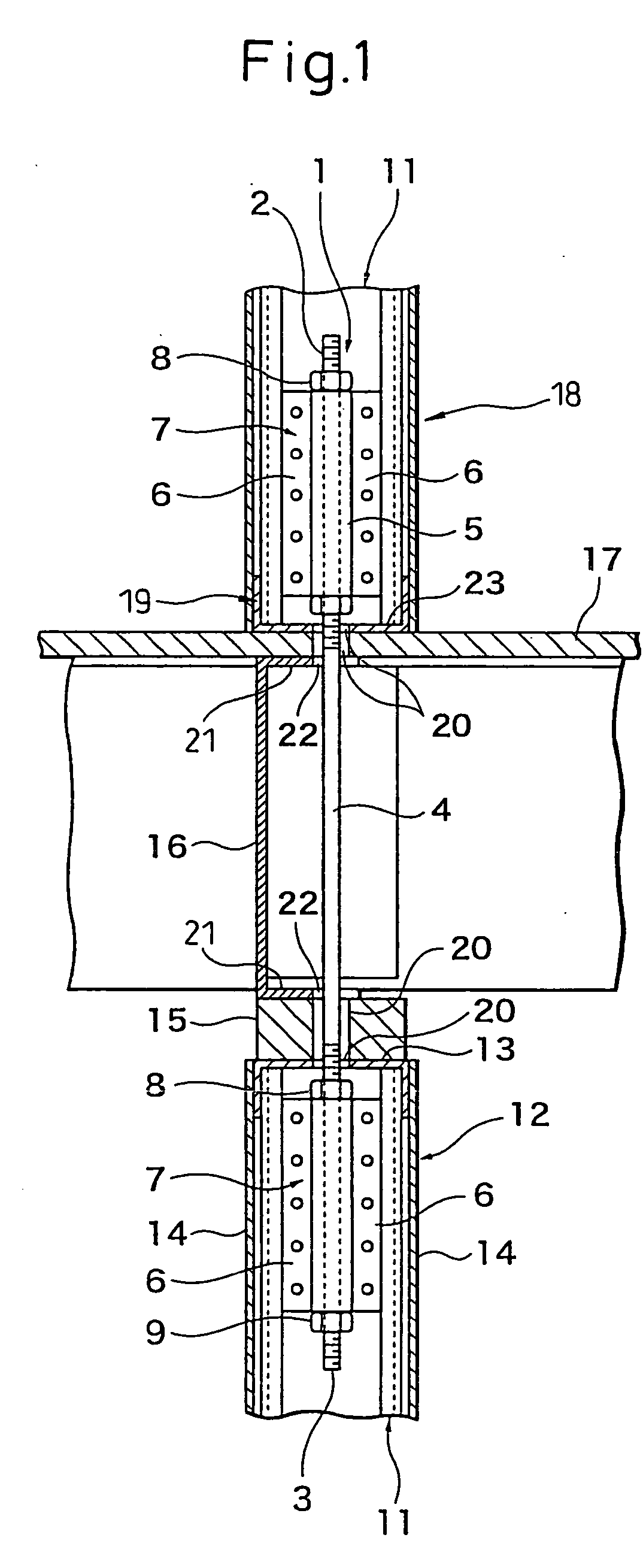

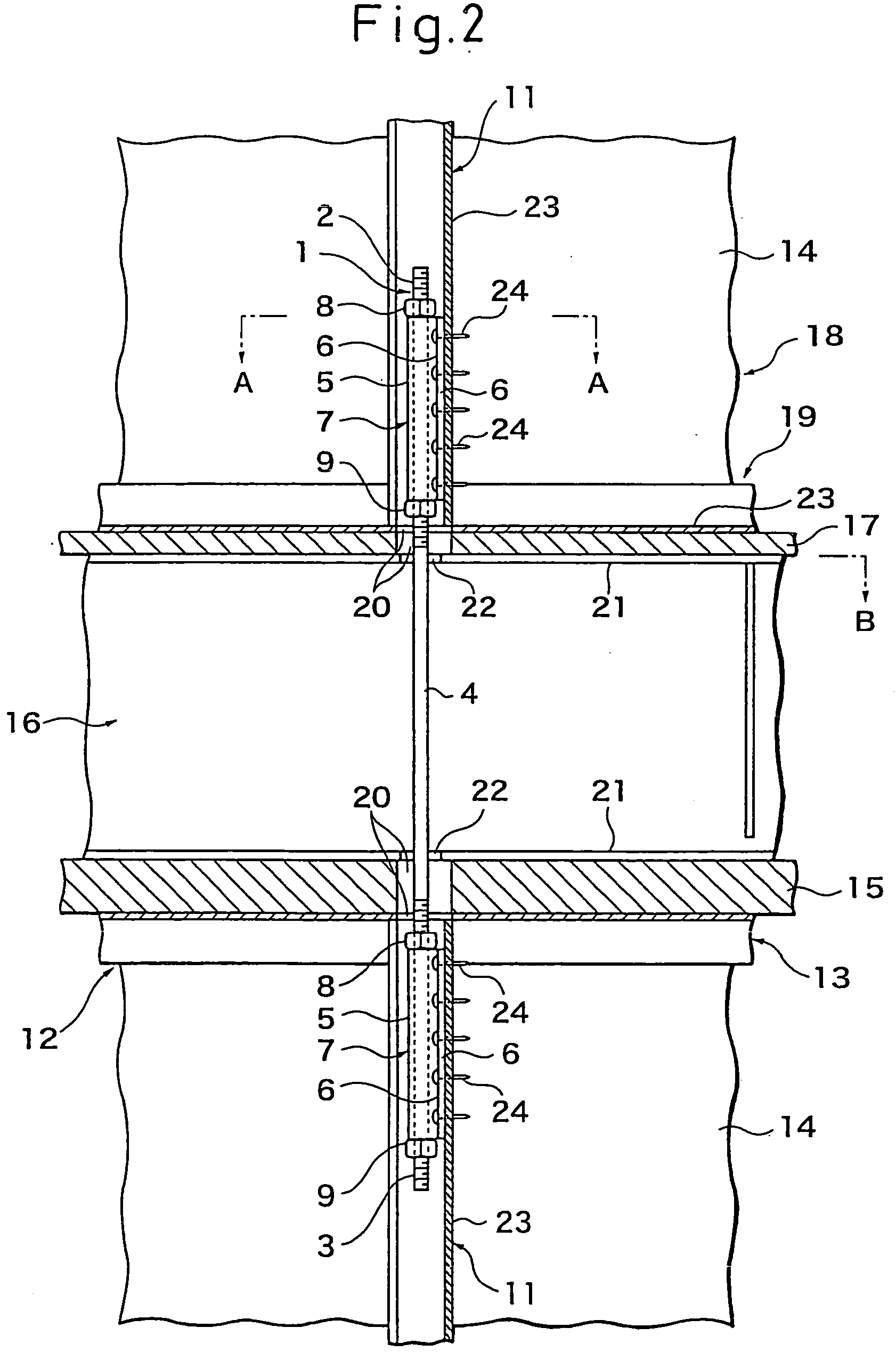

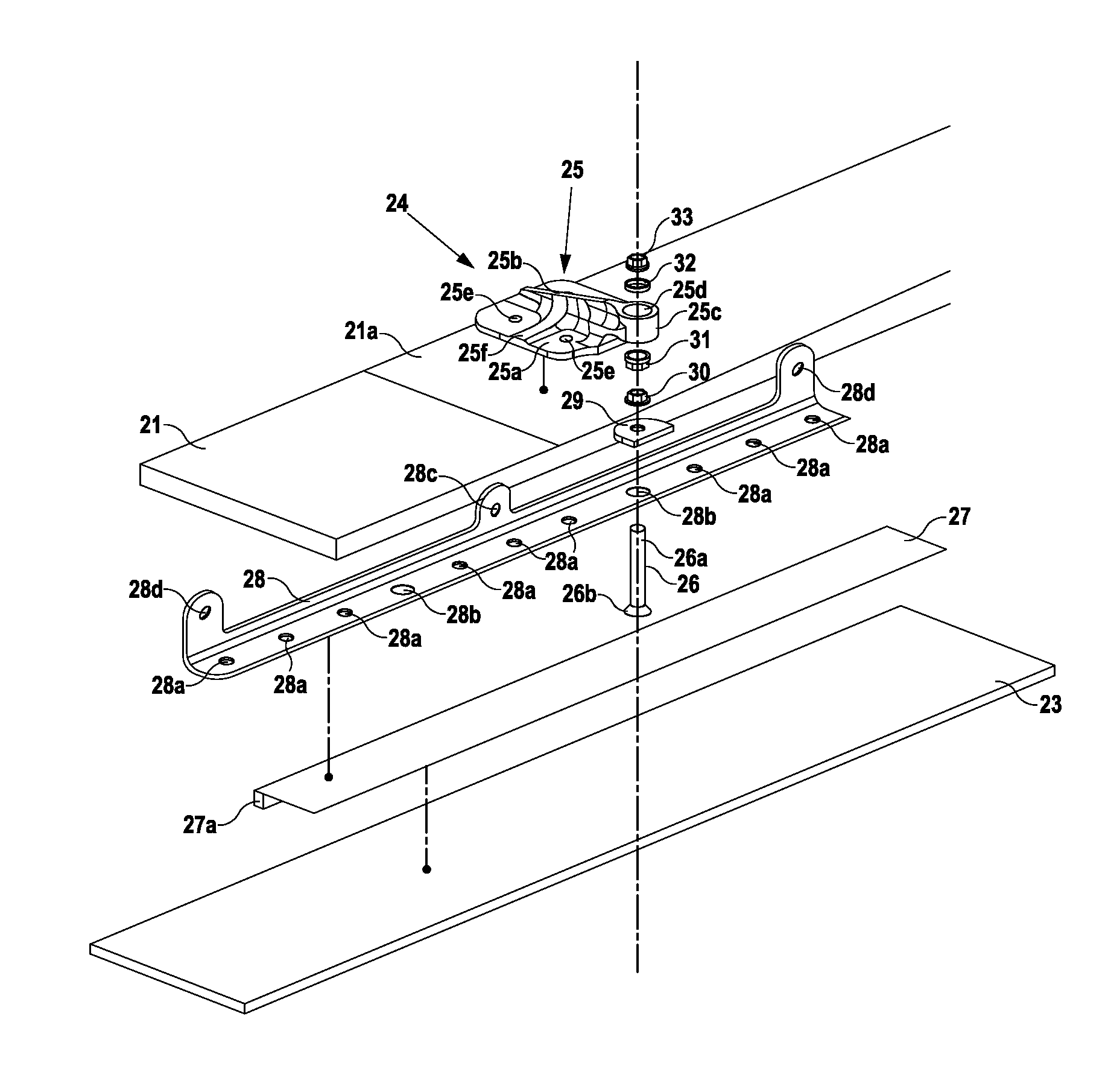

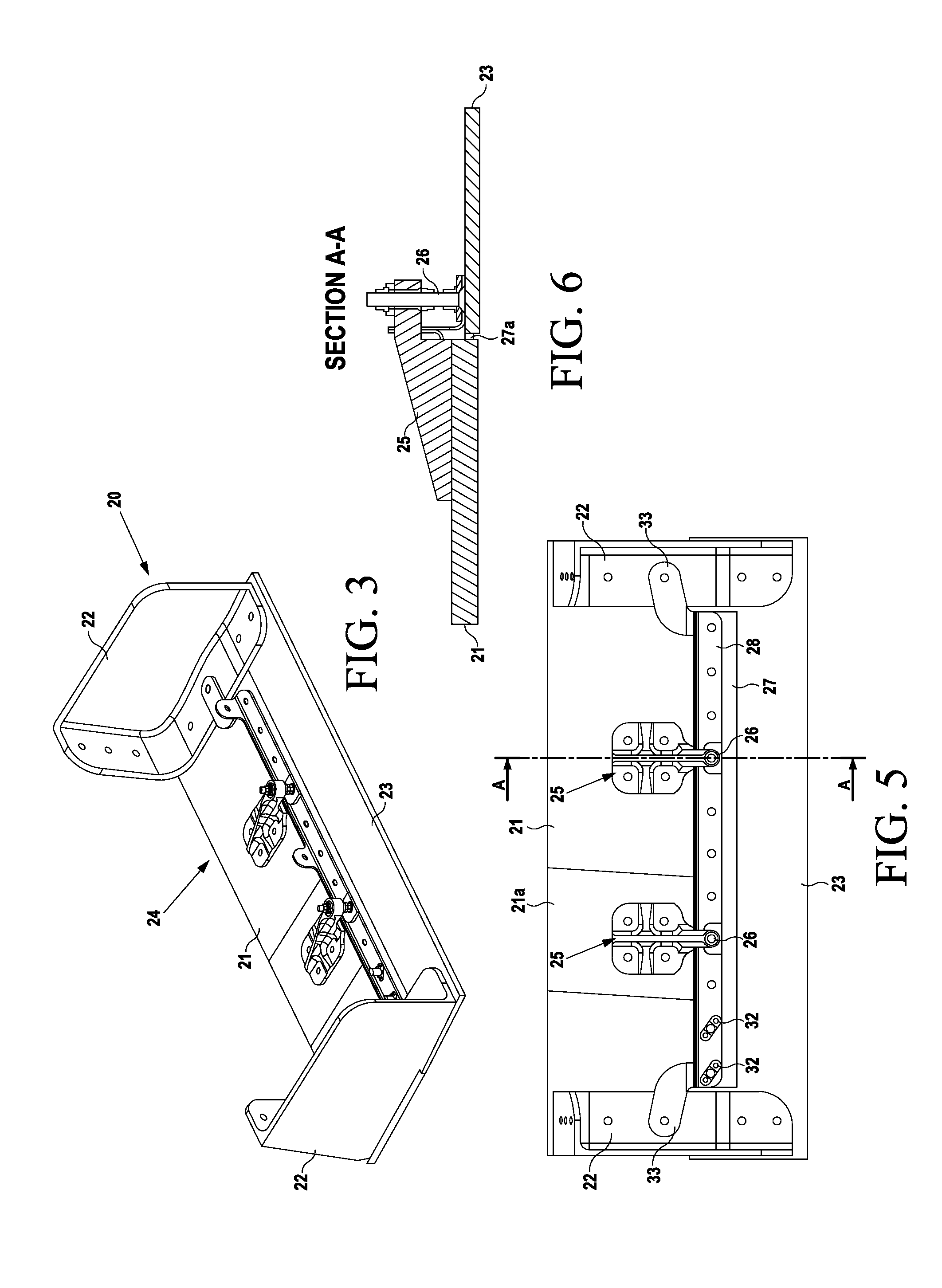

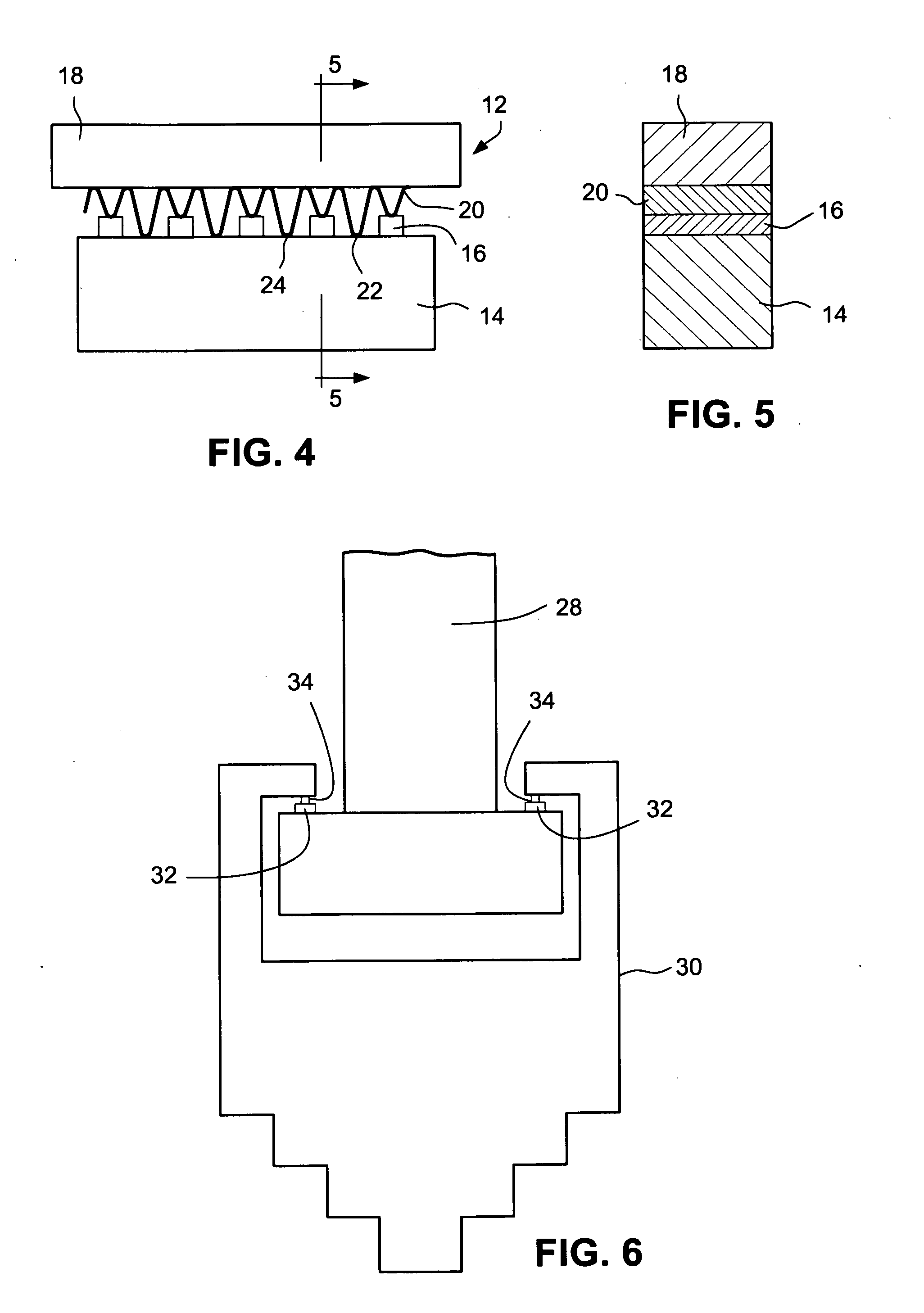

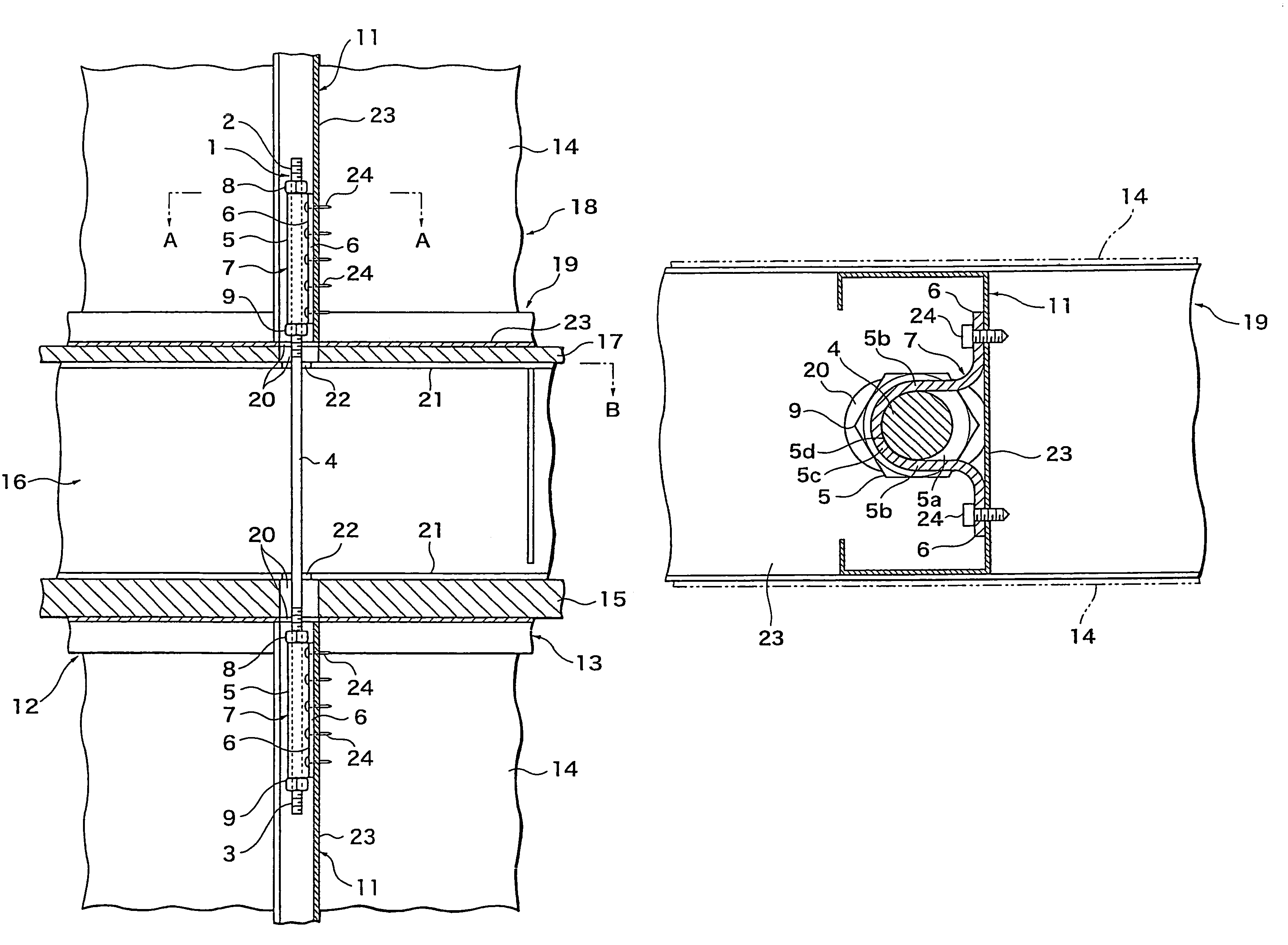

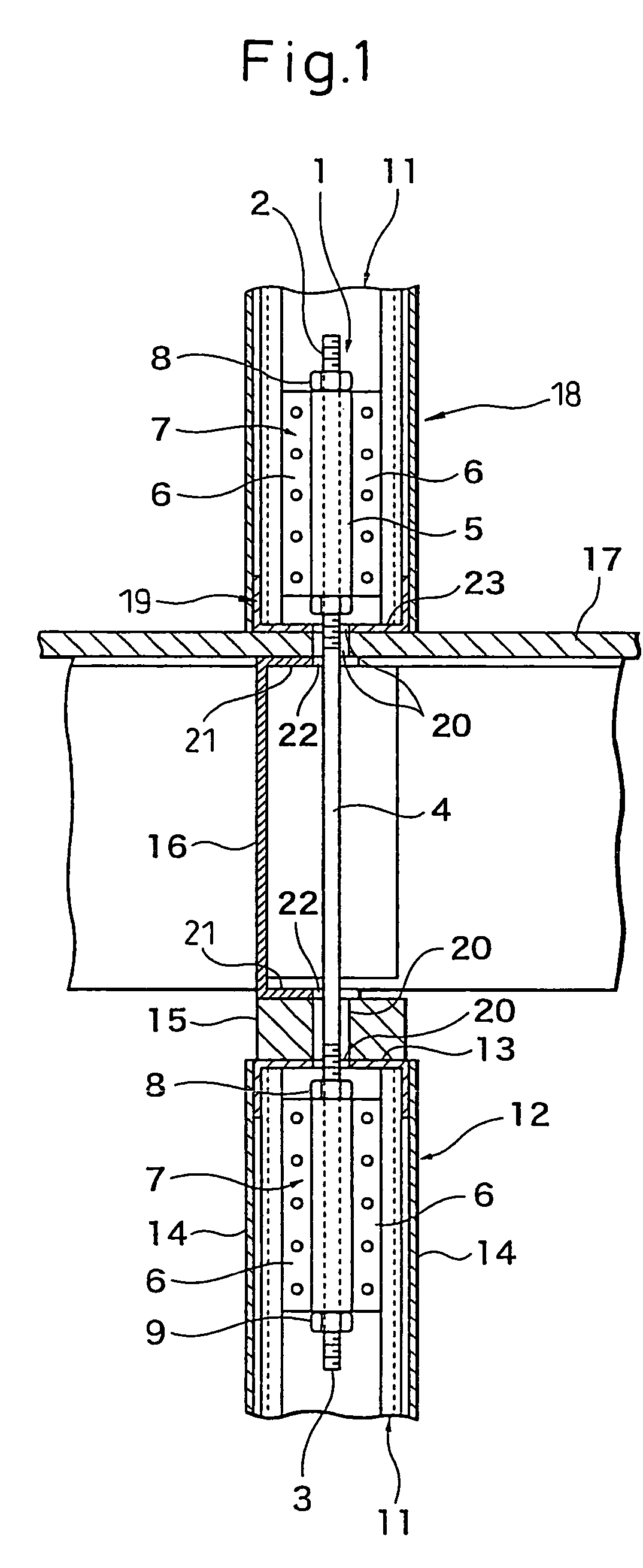

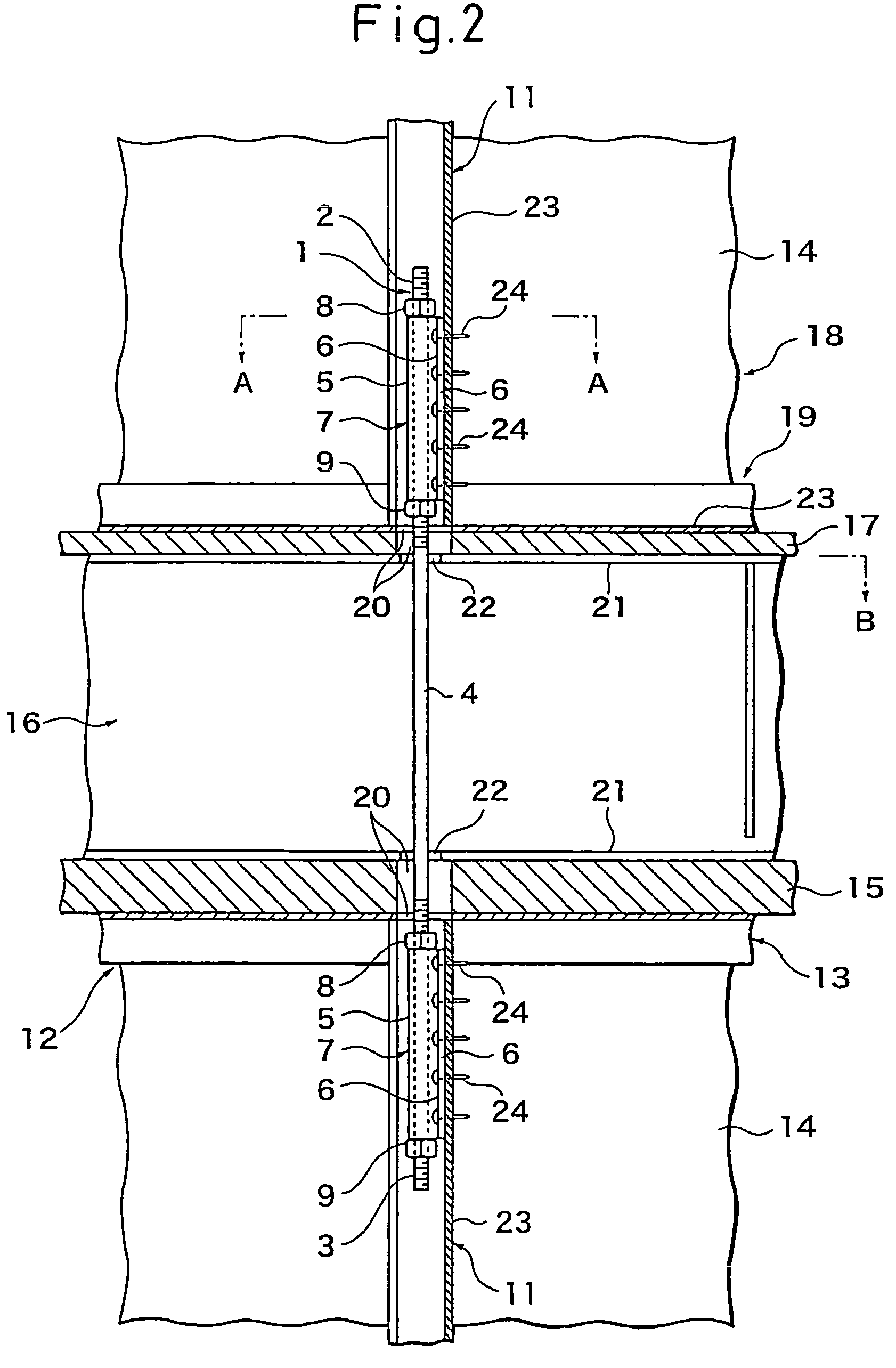

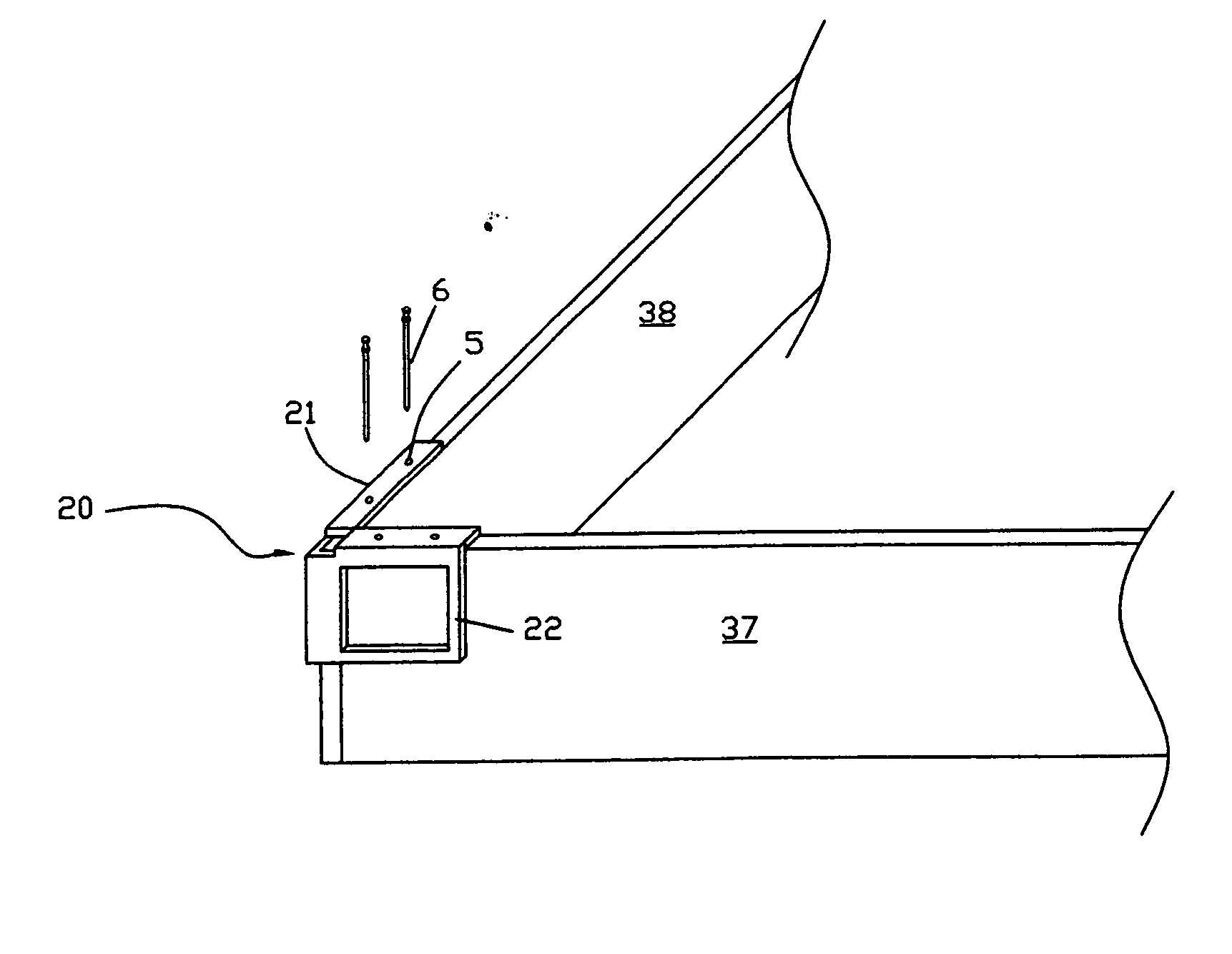

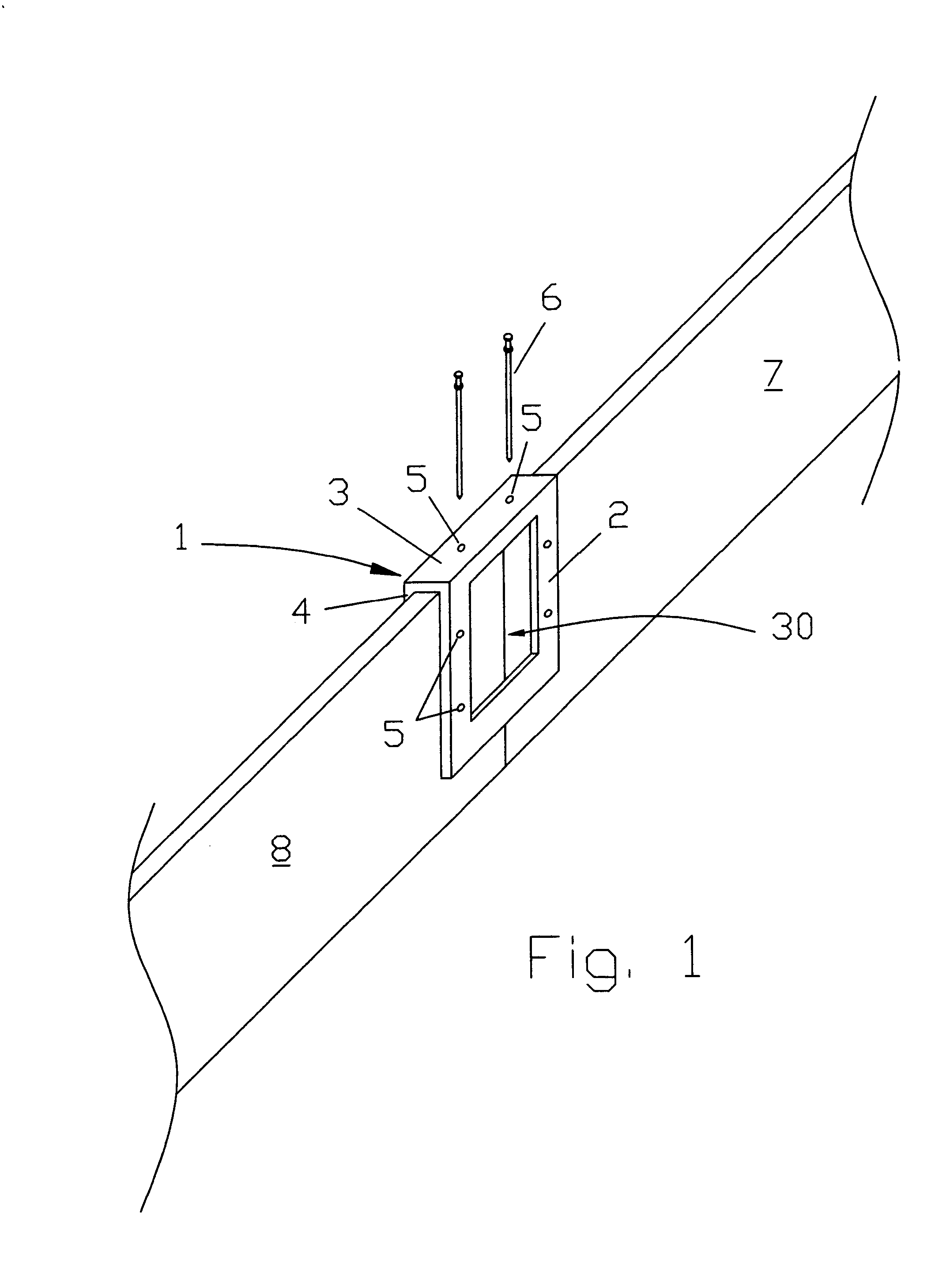

Joint fitting between members and joint structure and joining method of upper and lower floor vertical frame members

InactiveUS20070110513A1Stress transmittedEasy to placeBuilding roofsRecord information storageHorizontal orientationUpper floor

The present invention provides a joint fitting between members of a simple structure able to transmit stress of both compressive force and tensile force and a joint structure and method of joining, that is, a joint fitting 1 between members comprising a single bolt 4 having a length enabling it to be arranged vertically oriented bridging an upper floor vertical frame member and a lower floor vertical frame member at intervals along the axial direction of which bolt joint hardware 7 to be fastened to vertical frame members of the floors arranged at the upper floor side and lower floor side and having side opening groove cross-sections are arranged, the side opening grooves in the joint hardware 7 being able to detachably receive the bolt, and the joint hardware 7 being attached to be able to be fastened positioned along the longitudinal direction of the bolt 4, the joint hardware arranged at the upper and lower floors in the joint hardware being butted against vertical side surfaces of the vertical frame members 11 of the floors and fastened by drill screws 24 or other fasteners screwed in bridging the joint hardware 7 and the vertical frame members 11 in a horizontal orientation. Further, a method of joining members using the joint fitting 1 between members.

Owner:NIPPON STEEL CORP

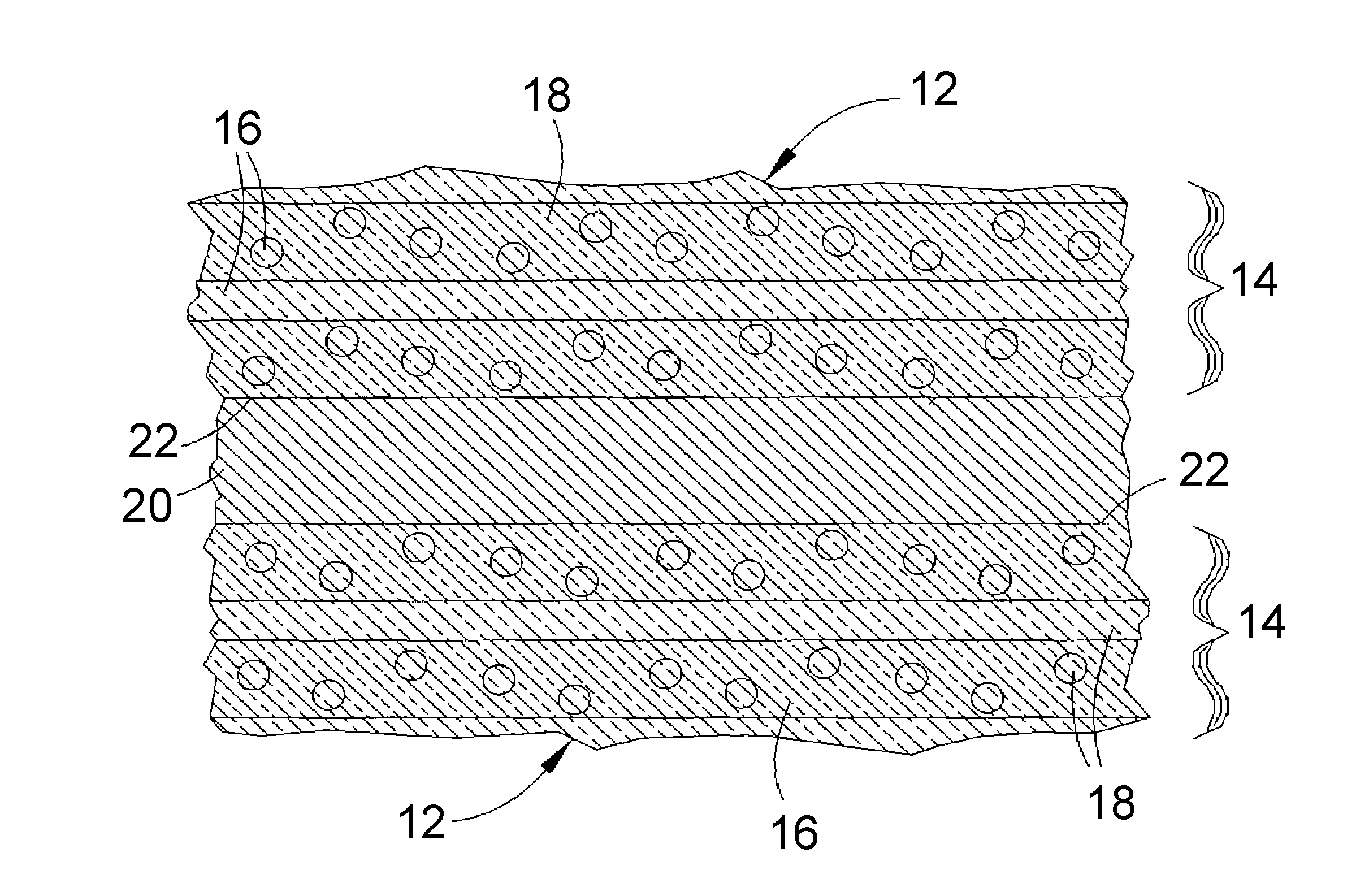

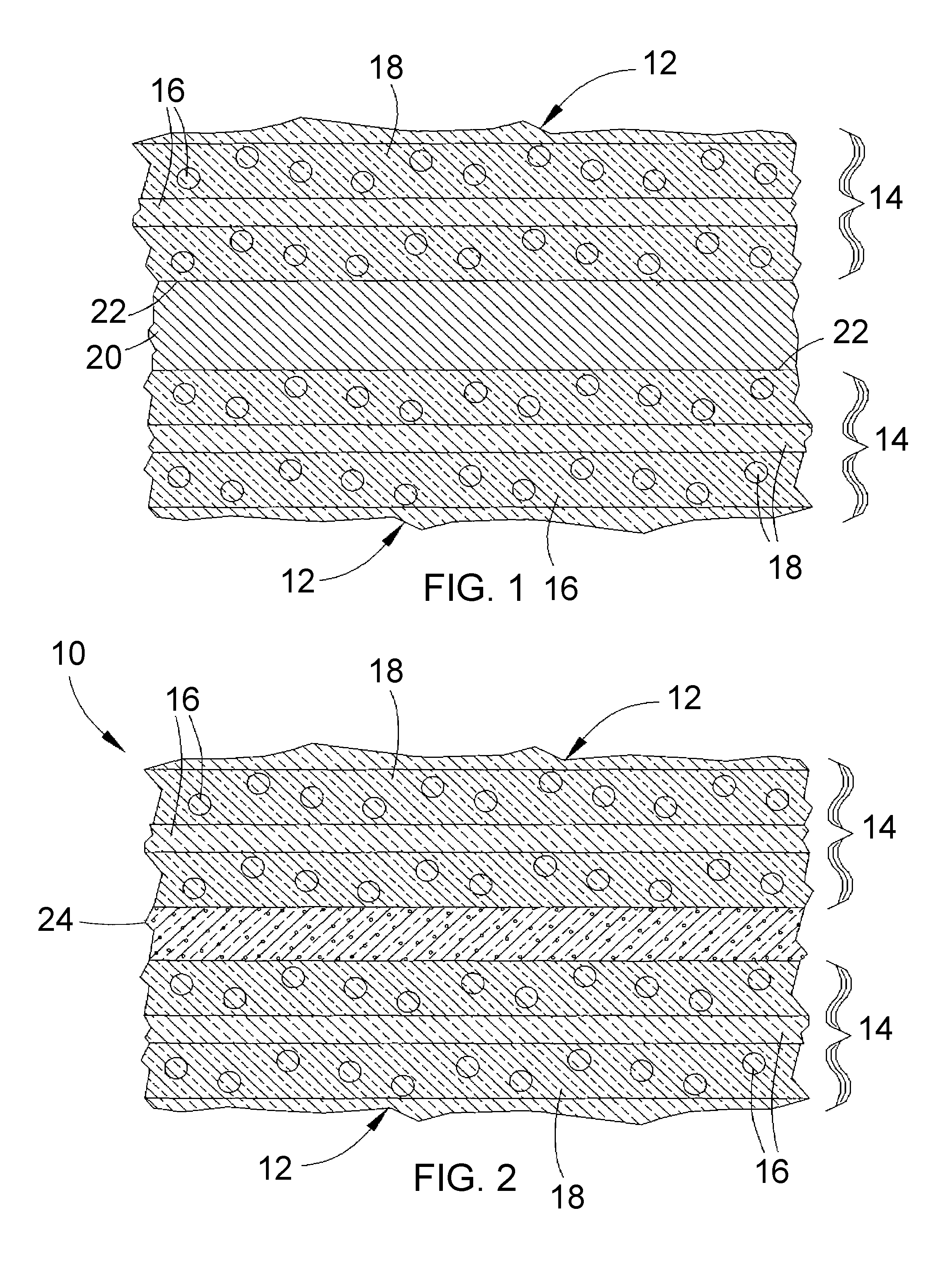

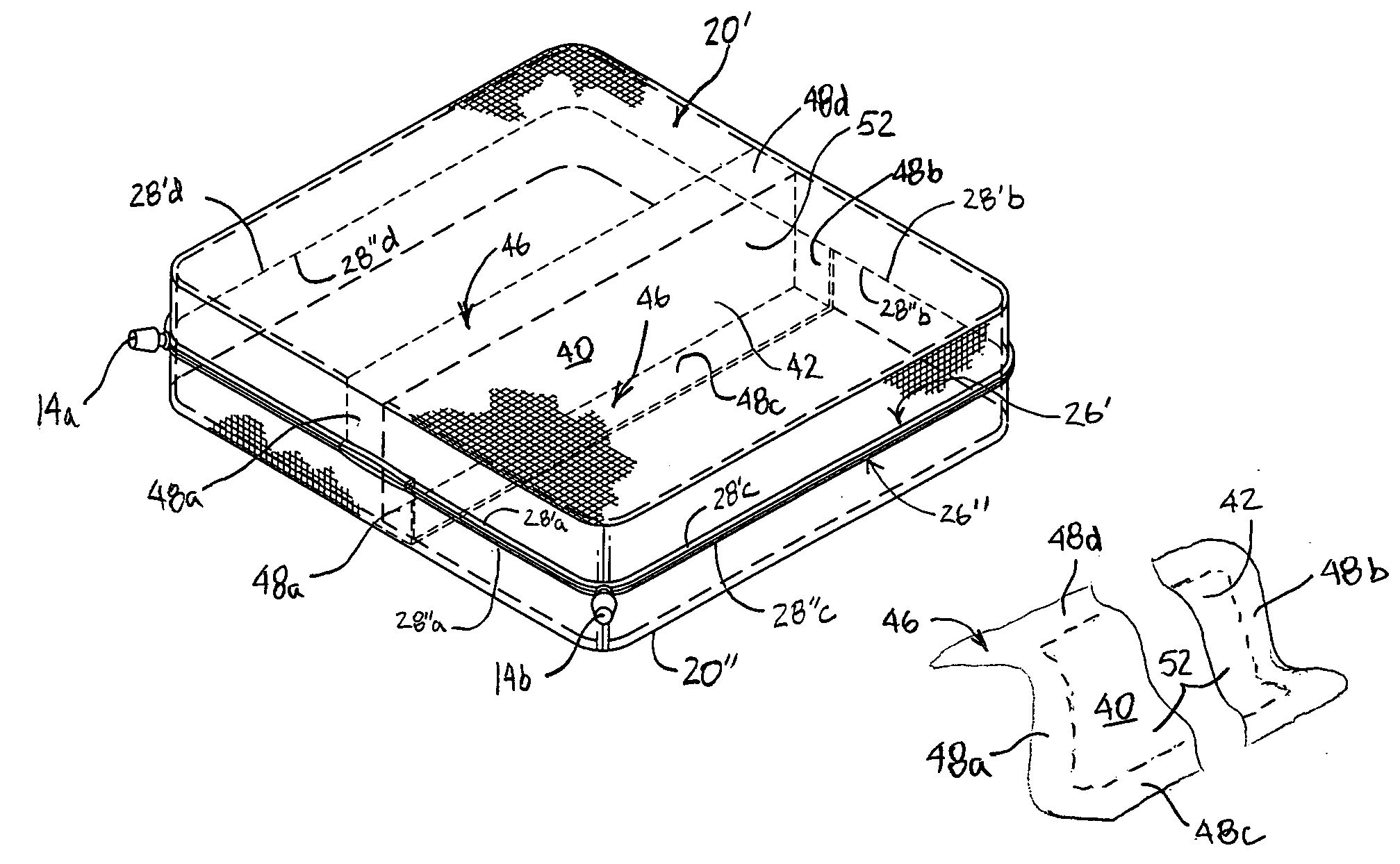

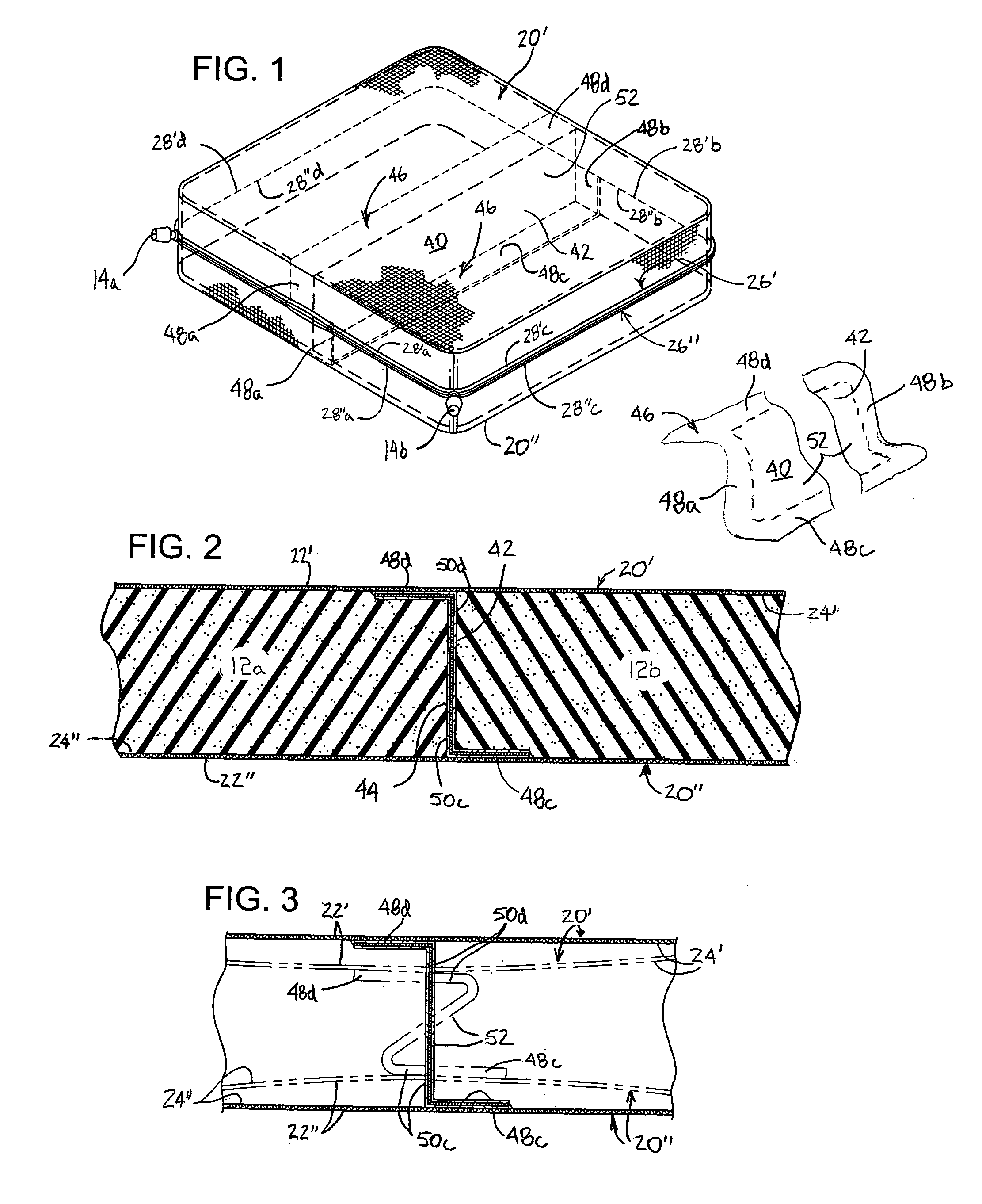

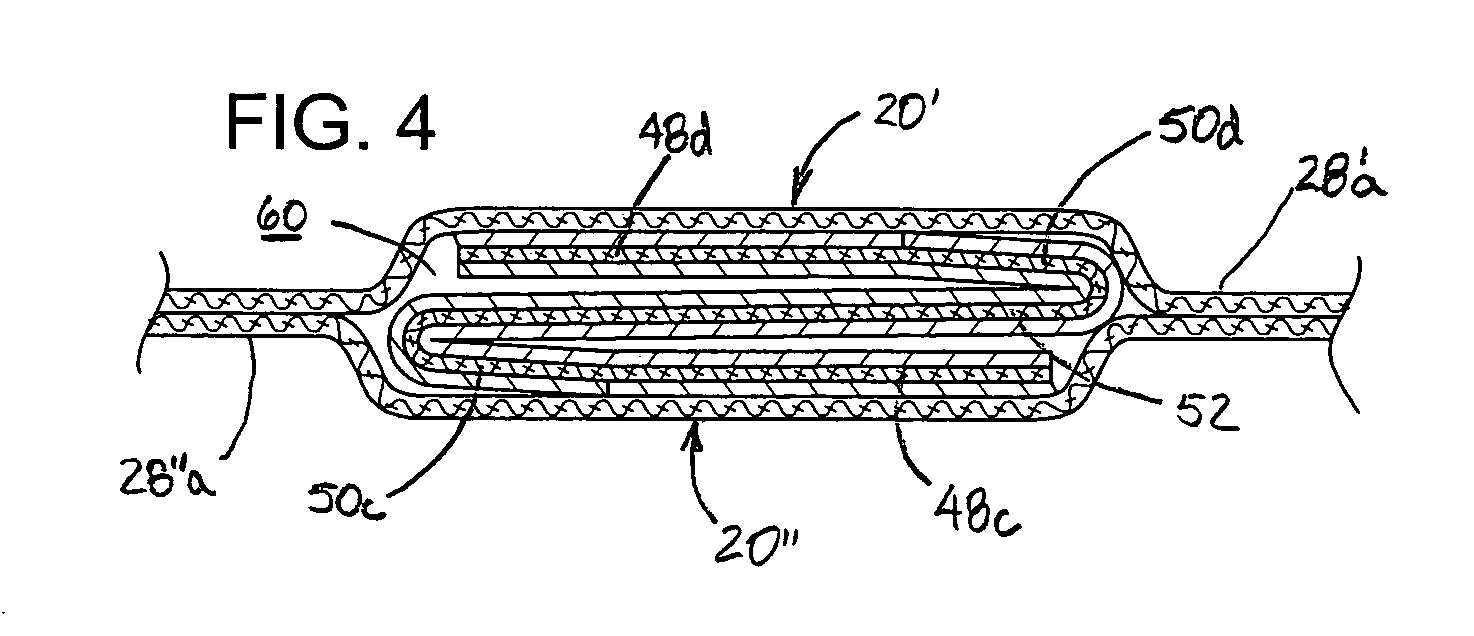

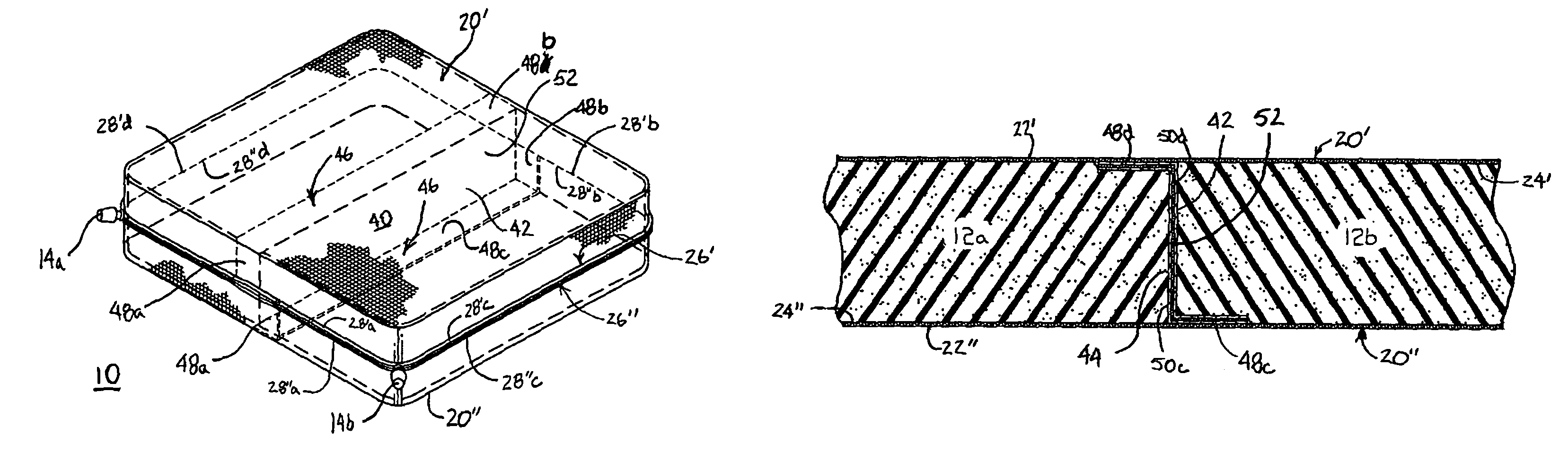

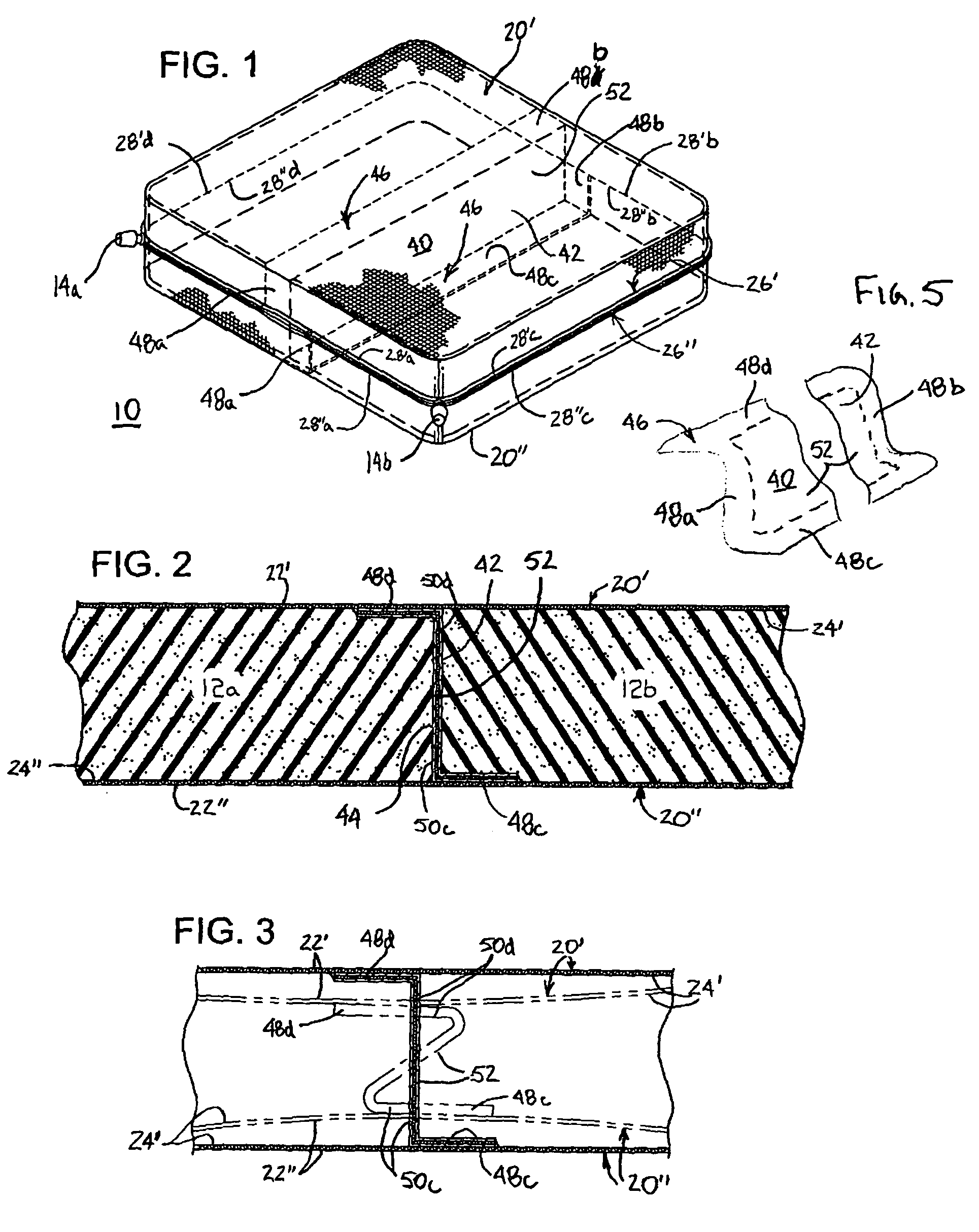

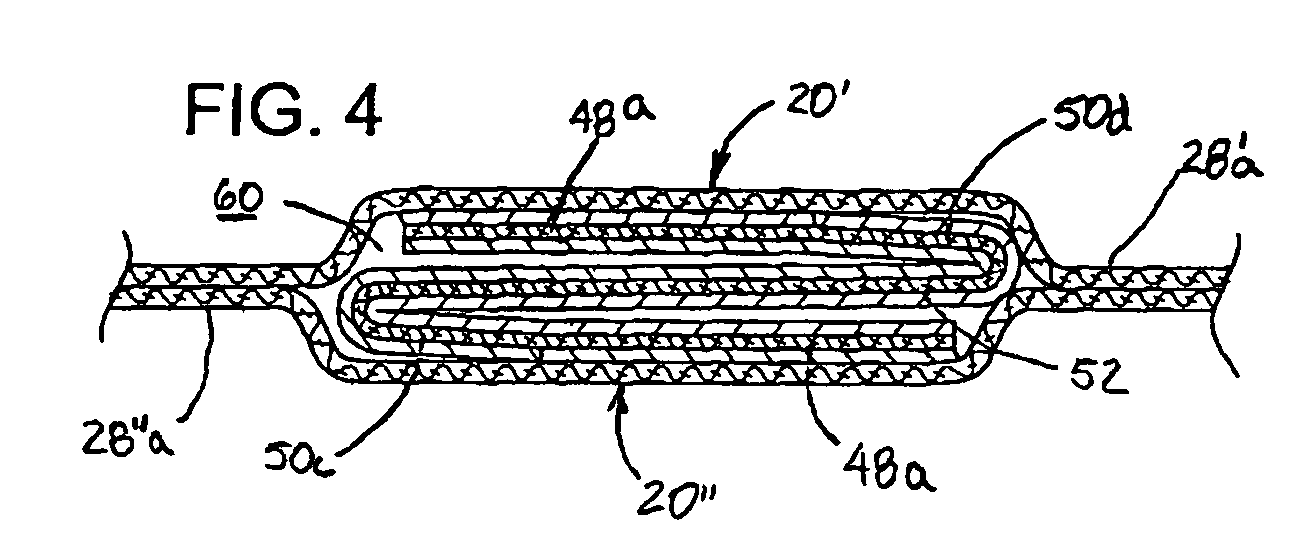

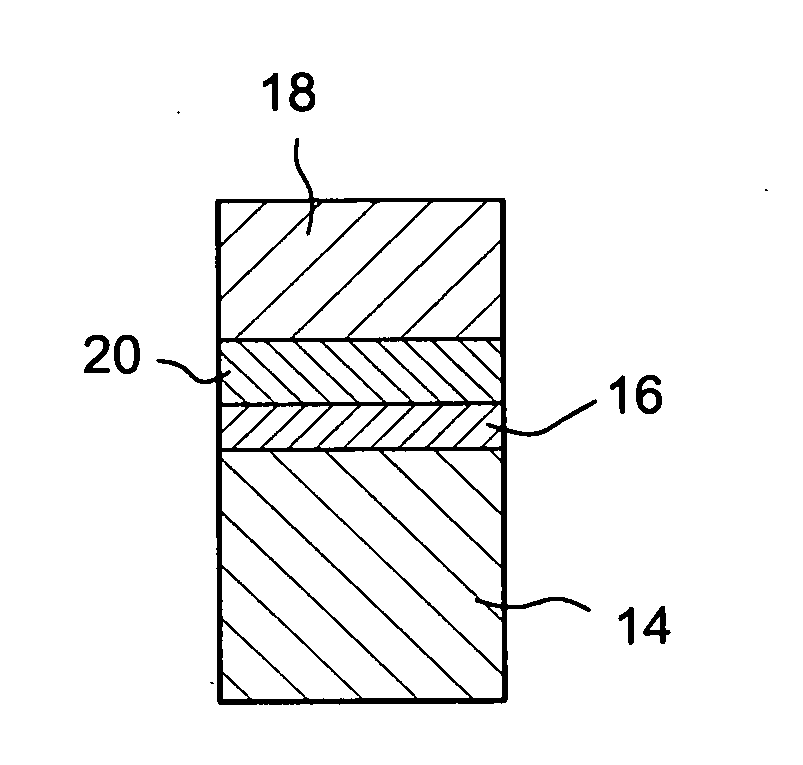

Inflatable body with independent chambers and methods for making the same

ActiveUS20060101743A1Low melting pointEfficiently joinedStuffed mattressesPublic buildingsEngineeringSurface plate

An inflatable body including first and second fluid impervious major panels, each having an outer surface, an inner surface and a perimeter, and further including a fluid impervious intermediate panel having a first surface, a second surface and a perimeter. A first perimeter portion of the intermediate panel is joined to the inner surface of the first major panel from one perimeter portion thereof to a generally opposed perimeter portion thereof, and a second perimeter portion of the intermediate panel, which is generally opposed to the first perimeter portion, is joined to the inner surface of the second major panel from one perimeter portion thereof to a generally opposed perimeter portion thereof. The first and second major panel perimeters are joined to each other, defining a primary enclosure having first and second chambers separated by the intermediate panel, and at least one sealable orifice in fluid communication with the environment and at least one chamber.

Owner:CASCADE DESIGNS INC

Systems and method for ignition and reignition of unstable electrical discharges

InactiveUS20050269978A1Reduce needEfficiently joinedSpark gaps with auxillary triggeringElectric discharge heatingVoltage pulseHigh voltage

Systems and methods for ignition and reignition of unstable electrical discharges wherein a secondary electrode positioned is between a set of primary electrodes and a high voltage is applied between the secondary electrode and successive ones of the primary electrodes to produce pilot discharges that ionize a gas there between and thereby reduce the voltage necessary to ignite a primary discharge between the primary electrodes. Power is provided to the secondary electrode by a circuit which is independent of the circuit that supplies power to the primary electrodes and generates voltage pulses which are substantially higher than the voltage between the primary electrodes.

Owner:CERAMTEC

Coupling assembly

InactiveUS20120006942A1Reduce in quantityManufacturing toleranceFuselage framesWingsSpherical bearingCoupling

A coupling assembly for joining a first component to a second component, the assembly comprising a shaft for connecting to a first component, and a bracket including a mounting plate for connecting to a second component. The bracket has a bracket arm extending from the mounting plate, and a head having a through-bore on the bracket arm. The shaft is received in the through-bore. A setting device acts between the head and the shaft for setting of the position of the shaft with respect to the head in the axial direction of the shaft. The assembly further includes one or more spherical bearing surfaces, which permit self-alignment of the setting device to accommodate tilting of the shaft with respect to the head about a central point in two orthogonal directions. Also, a joint comprising a first component joined to a second component by one or more of the coupling assemblies. Also, a method of forming a joint using one or more of the coupling assemblies.

Owner:AIRBUS OPERATIONS LTD

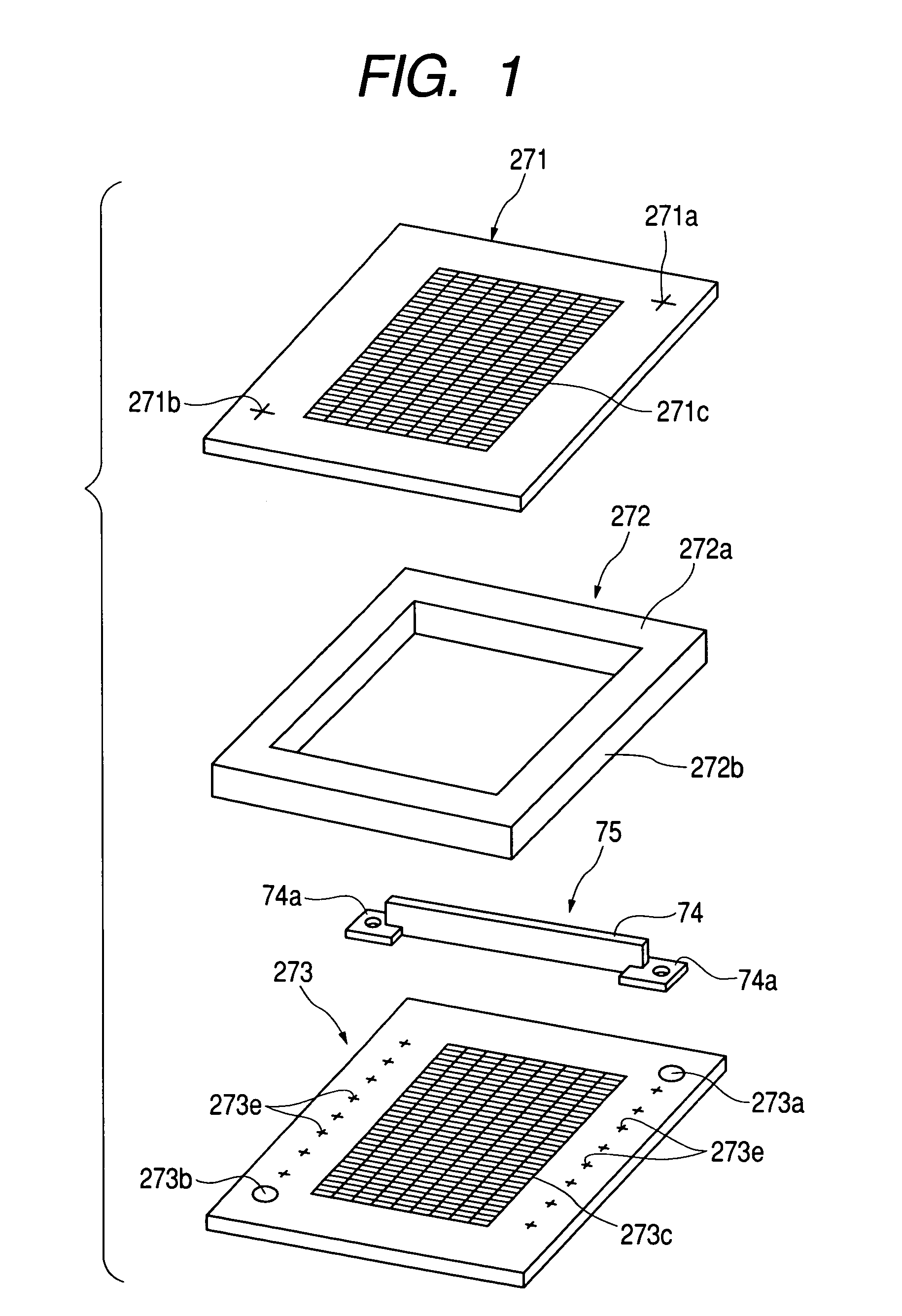

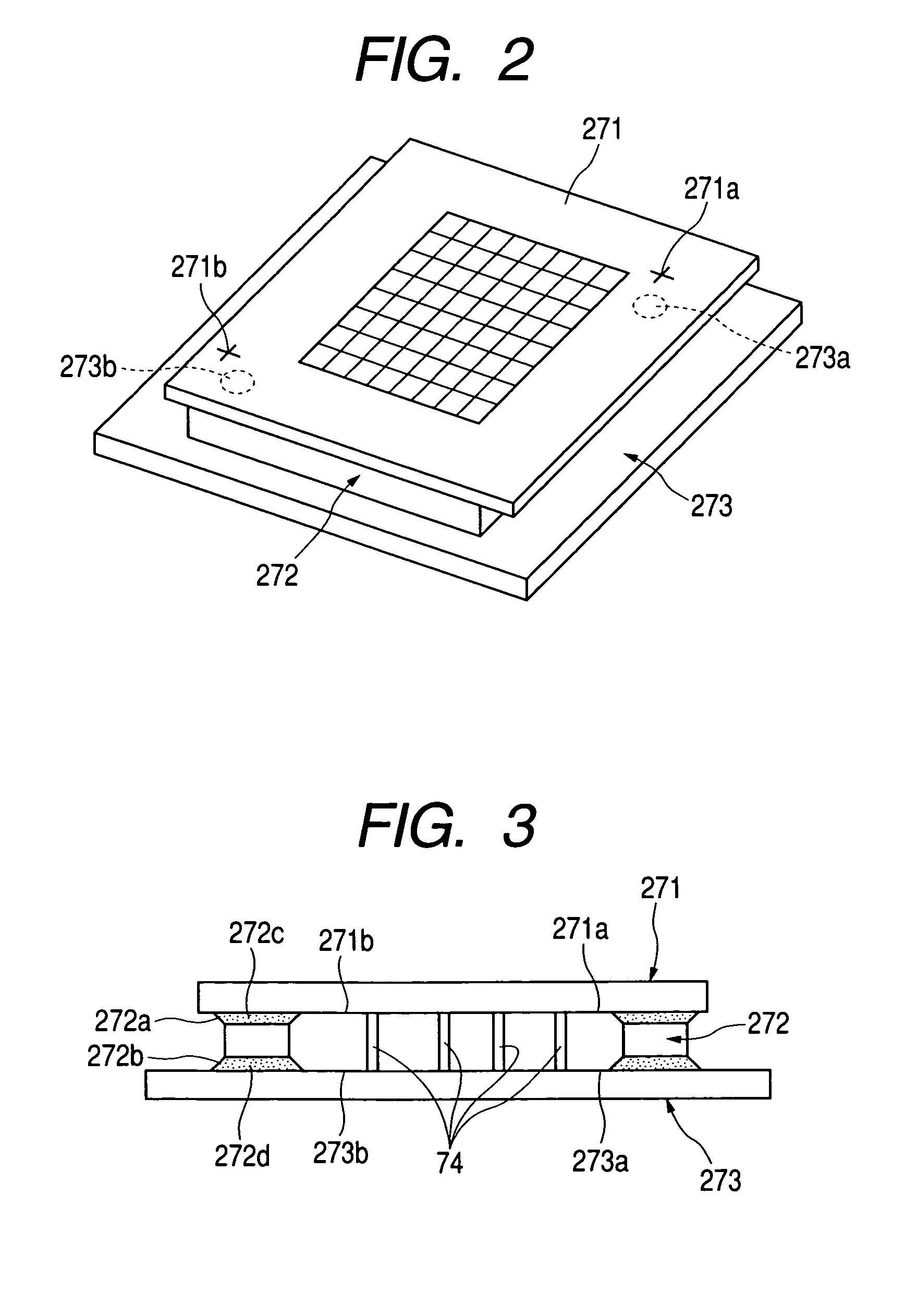

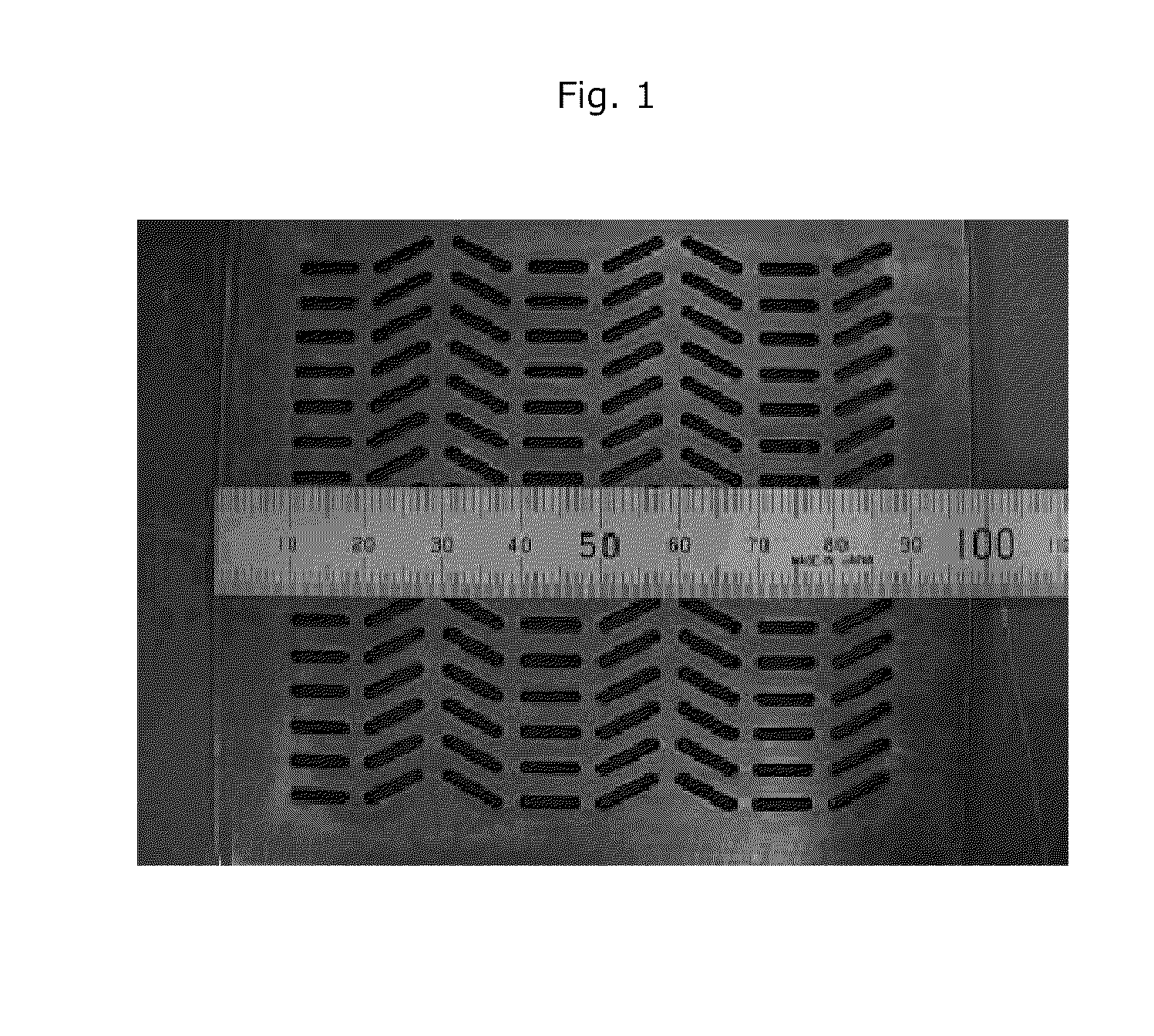

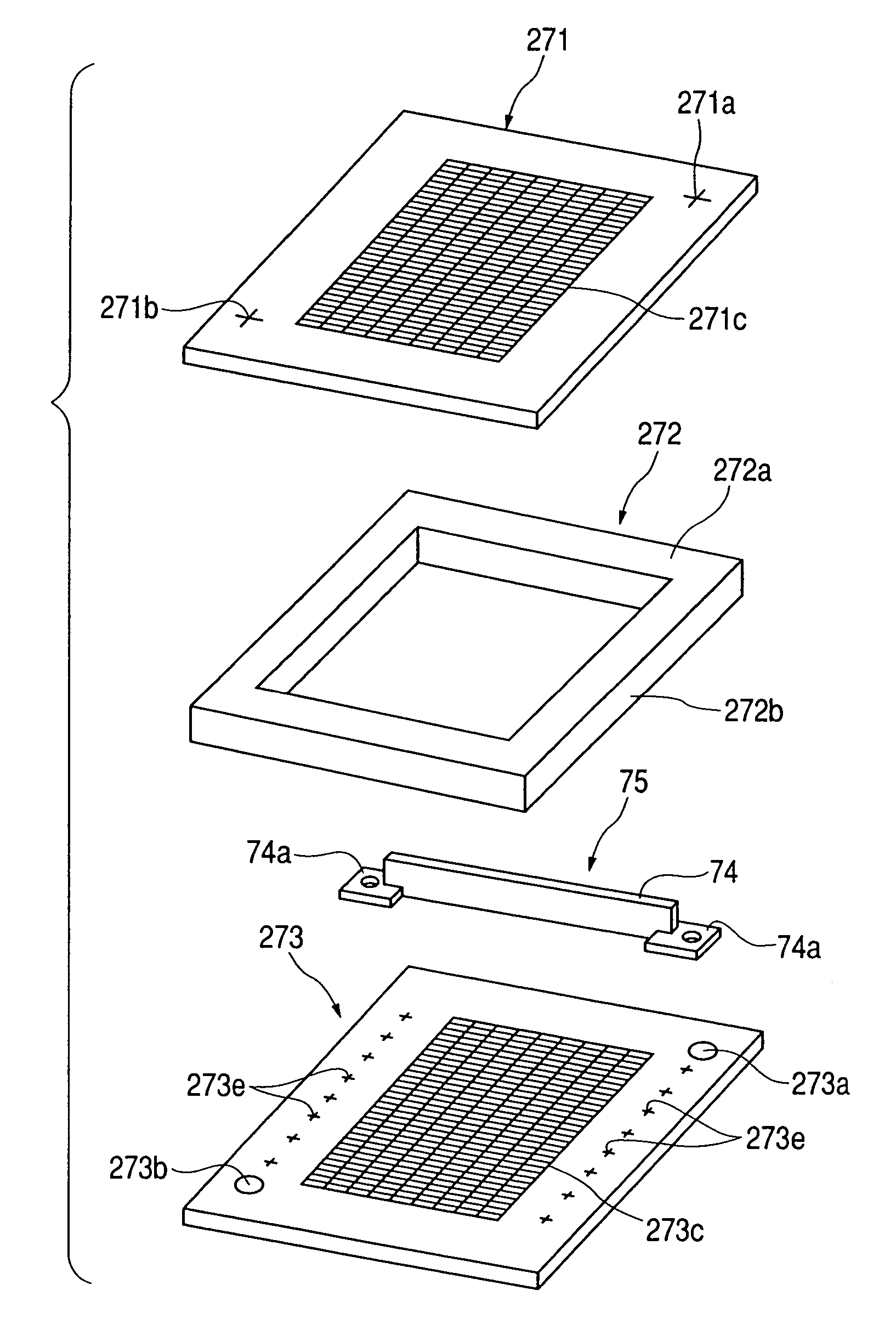

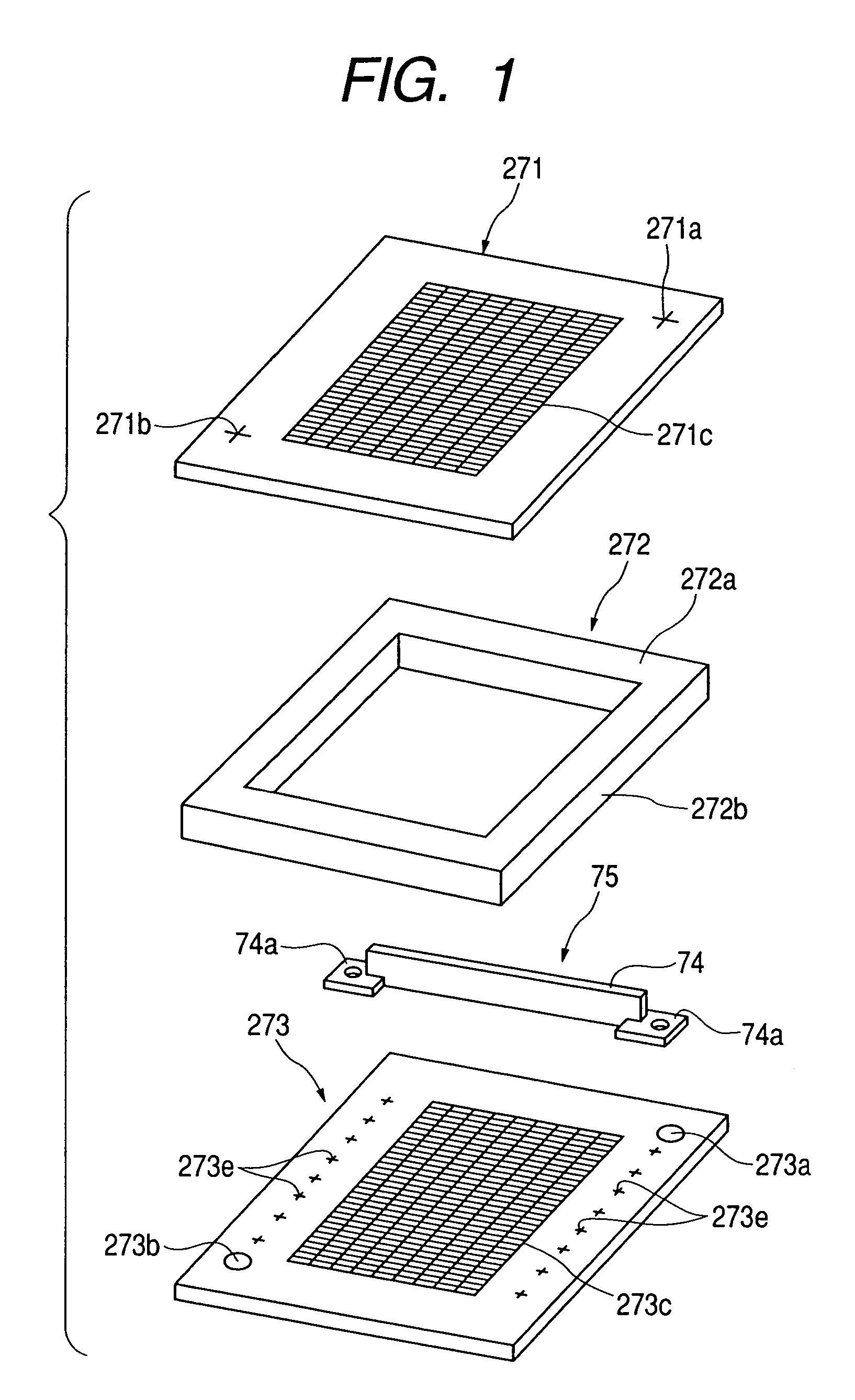

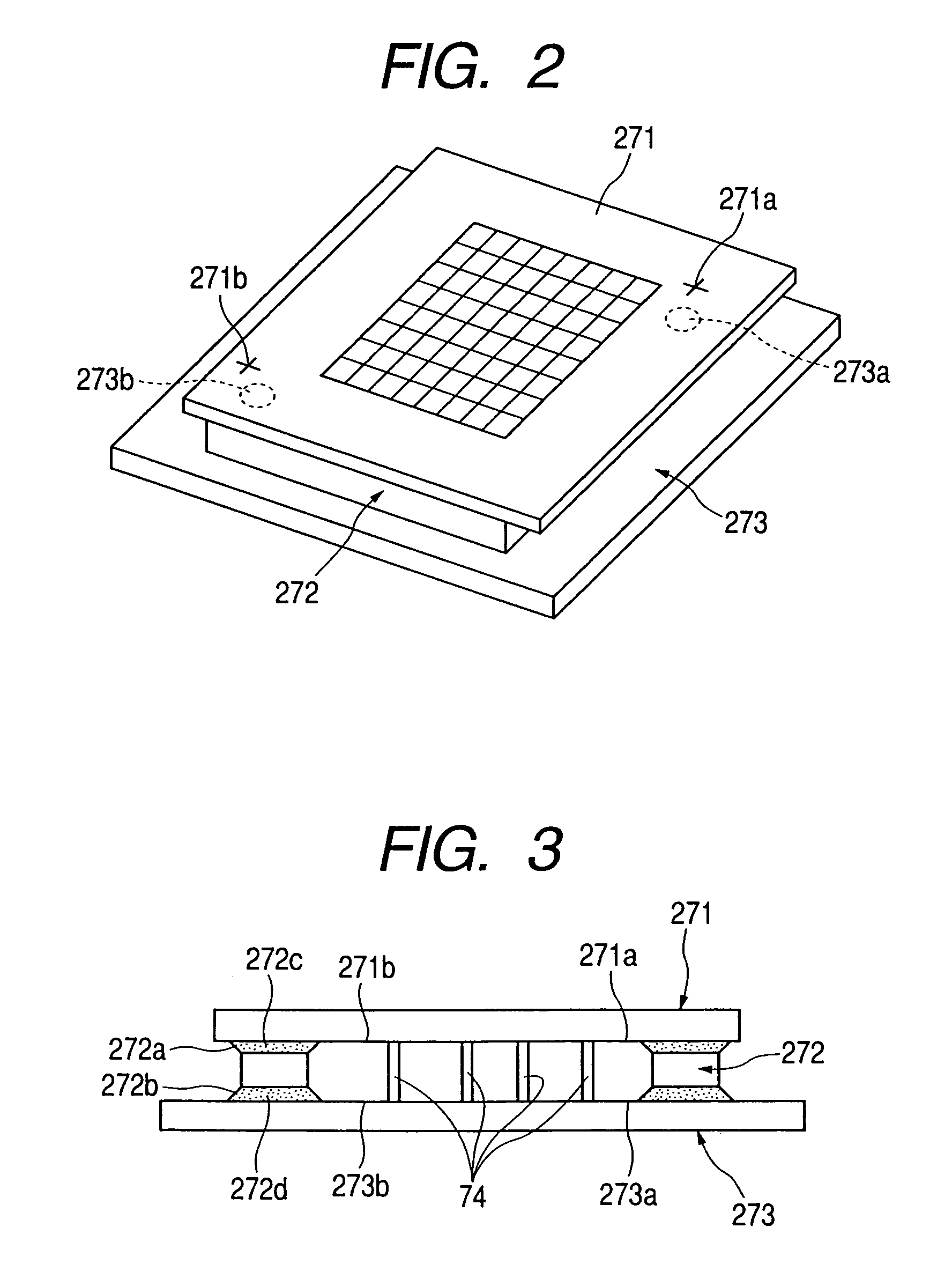

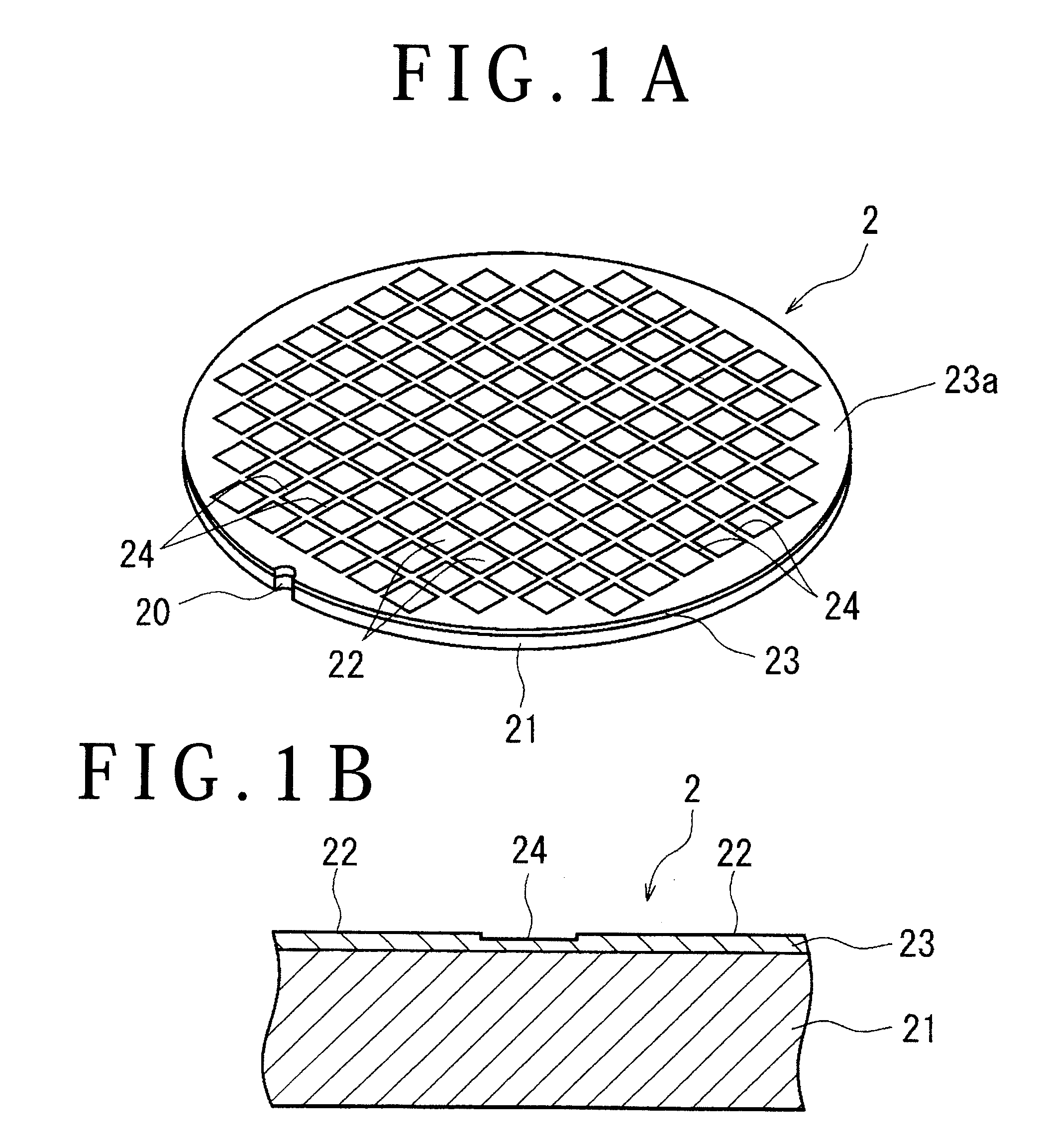

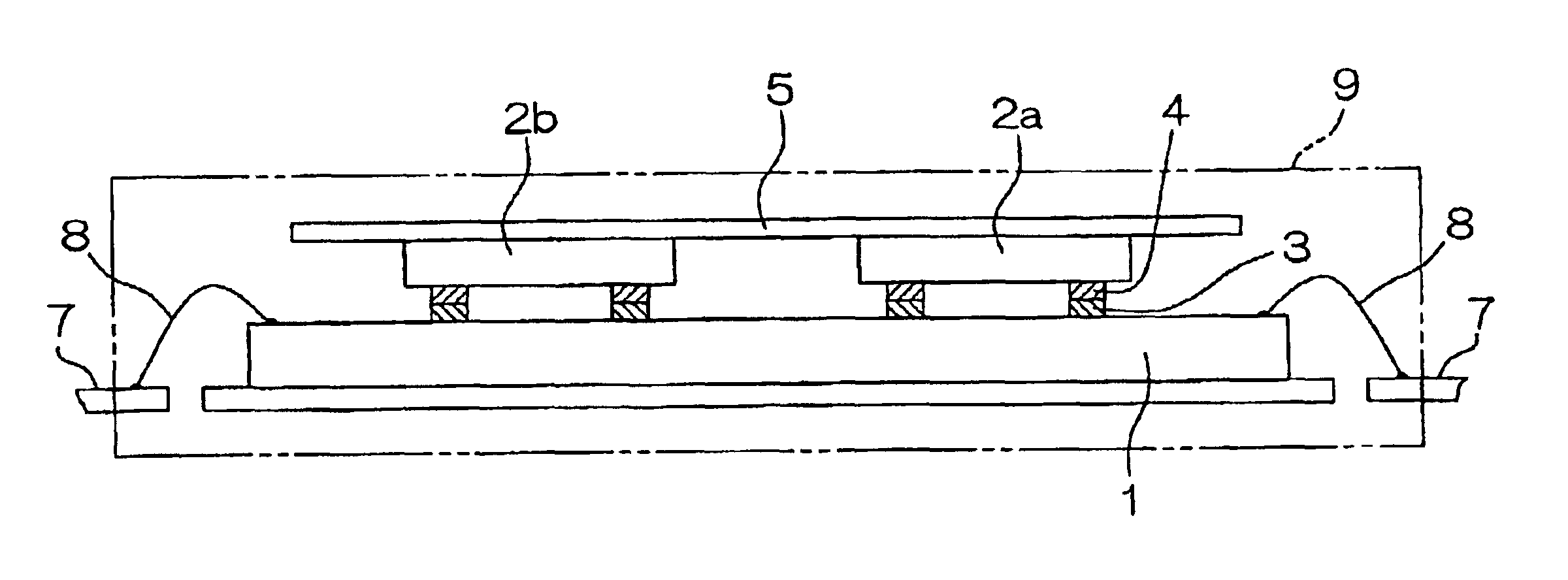

Method of manufacturing image display device

InactiveUS6981905B2Minimize loadHigh accuracyElectroluminescent light sourcesImage/pattern display tubesEngineeringDisplay device

In installing spacers between a pair of substrates of an image display device, both end portions in a longitudinal direction of each spacer are gripped in a pair of hands. Thus, long spacers can be joined to the substrate efficiently and with high accuracy.

Owner:CANON KK

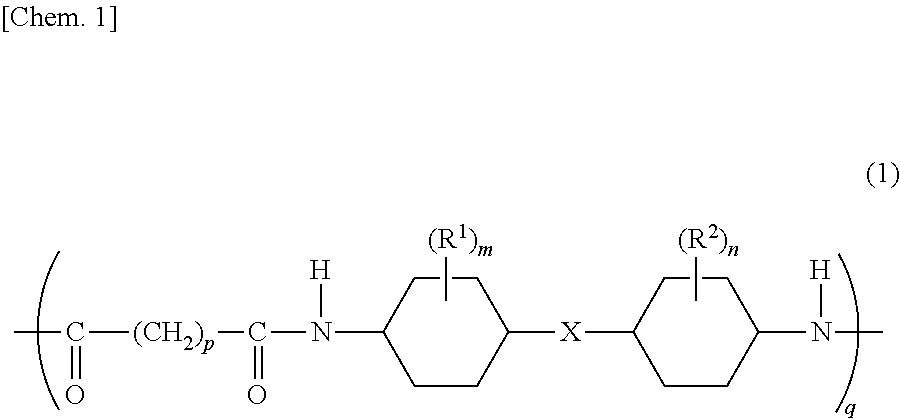

Sheet for shoe sole and shoe sole including the same

ActiveUS20130318835A1Efficiently joinedHigh workability without deformationSolesSynthetic resin layered productsPolyamideMelting point

A sheet for forming a shoe sole, useful for efficiently joining a crosslinked rubber layer as a stud and a thermoplastic elastomer layer as a sole, is provided.The sheet comprises a resin component (A) containing a polyamide resin (a) and having an amino group concentration of not less than 10 mmol / kg and a flexural modulus of not less than 300 MPa in accordance with ISO178. The polyamide resin (a) may contain a polyamide resin having a melting point of not less than 165° C. at a predetermined concentration (e.g., not less than 30% by weight) in the total polyamide resin (a).

Owner:DAICEL EVONIK LTD

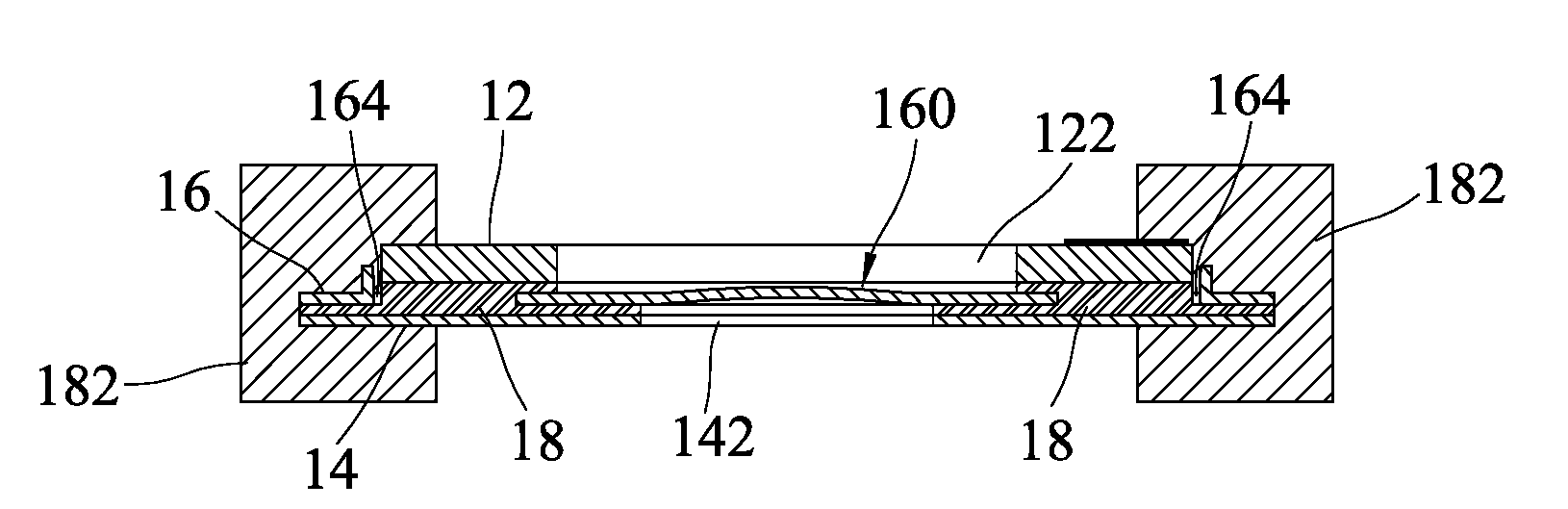

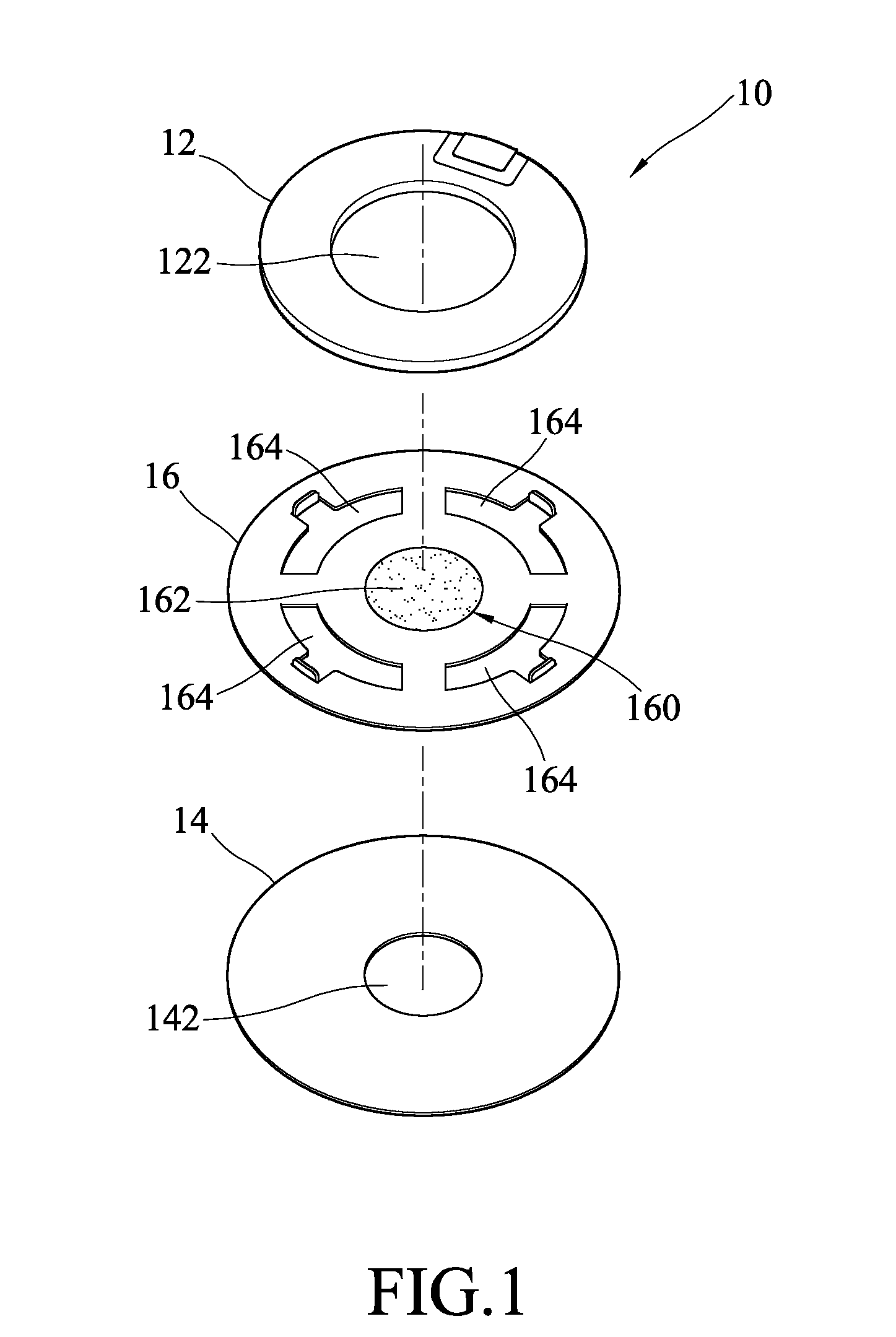

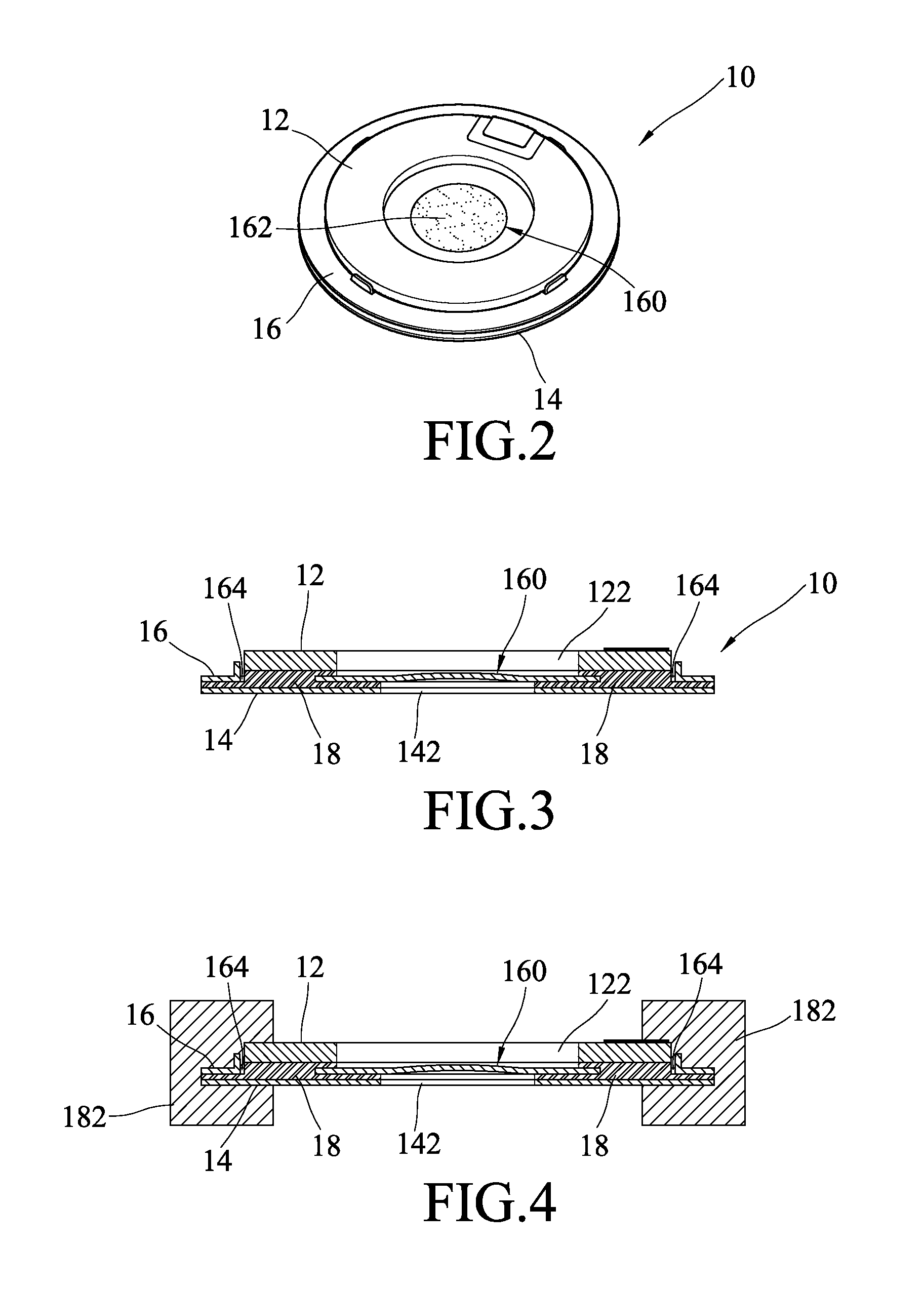

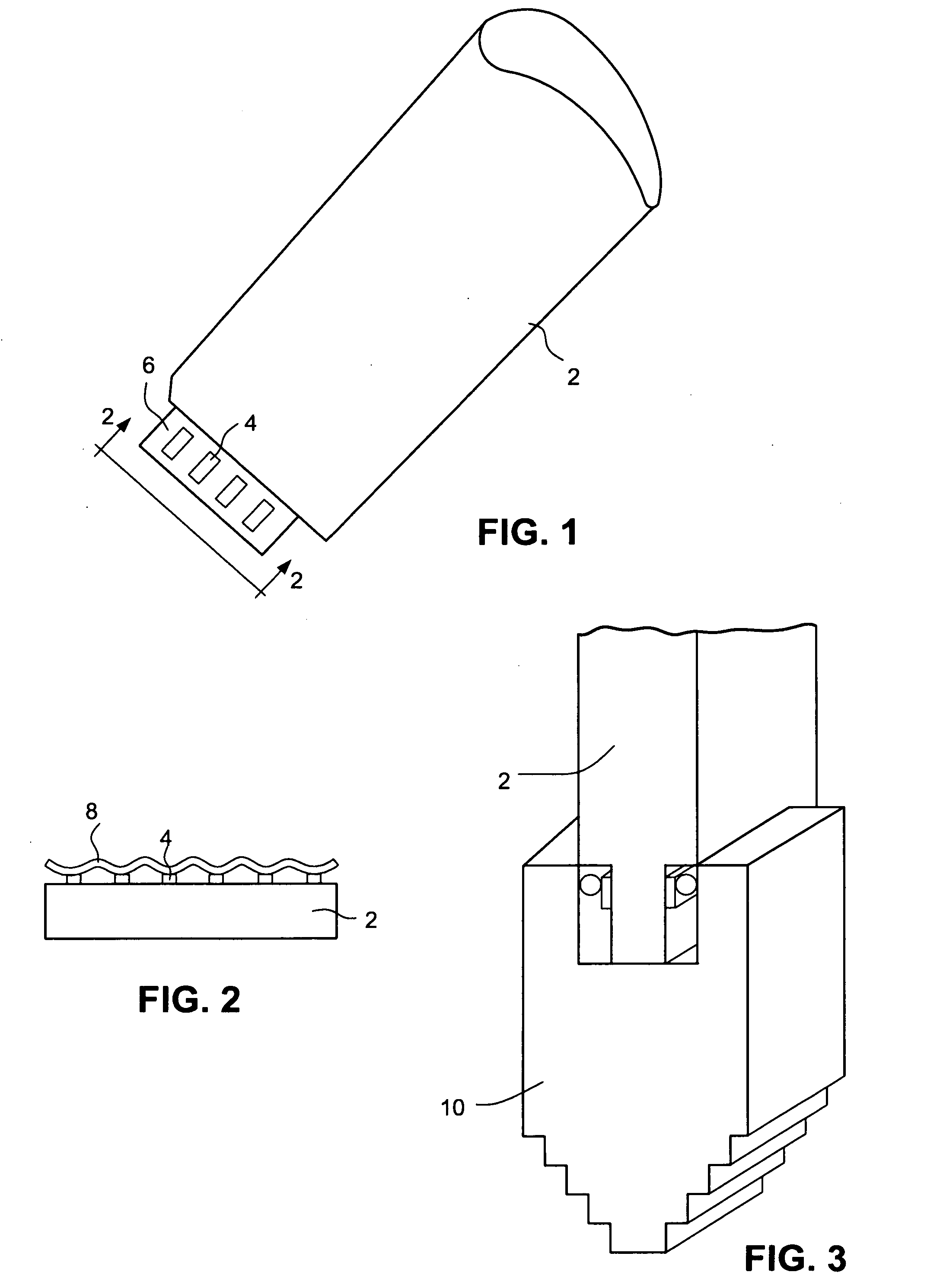

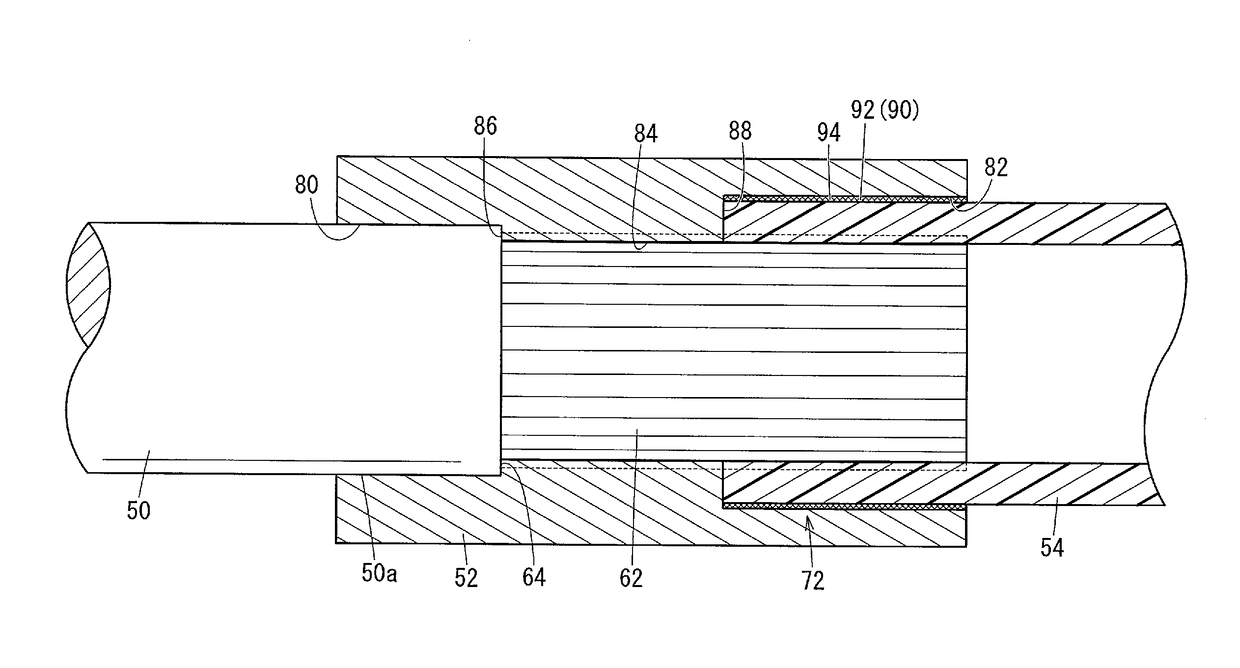

Microdroplet Generation Apparatus

InactiveUS20100213274A1Improve atomizationFavorable joiningMovable spraying apparatusSpray nozzlesEngineeringNozzle

A microdroplet generation apparatus comprises an oscillation plate, a connection plate, a nozzle disc and a bonding material, wherein the nozzle disc is interposed between the oscillation plate and connection plate, and wherein the oscillation plate, connection plate and nozzle disc are joined with the bonding material. The oscillation plate and the connection plate respectively have a first through-hole and a second through-hole corresponding to each other. The nozzle disc has injection holes on the area corresponding to the first and second through-holes. The nozzle disc has via-holes on the area not corresponding to the first through-hole and the second through-hole. The bonding material passes through the via-holes of the nozzle disc to join the oscillation plate and the connection plate and fasten the nozzle disc to between the oscillation plate and the connection plate. Thus, vibration energy can be effectively transmitted from the vibration plate to the nozzle disc.

Owner:HEALTH & LIFE CO LTD

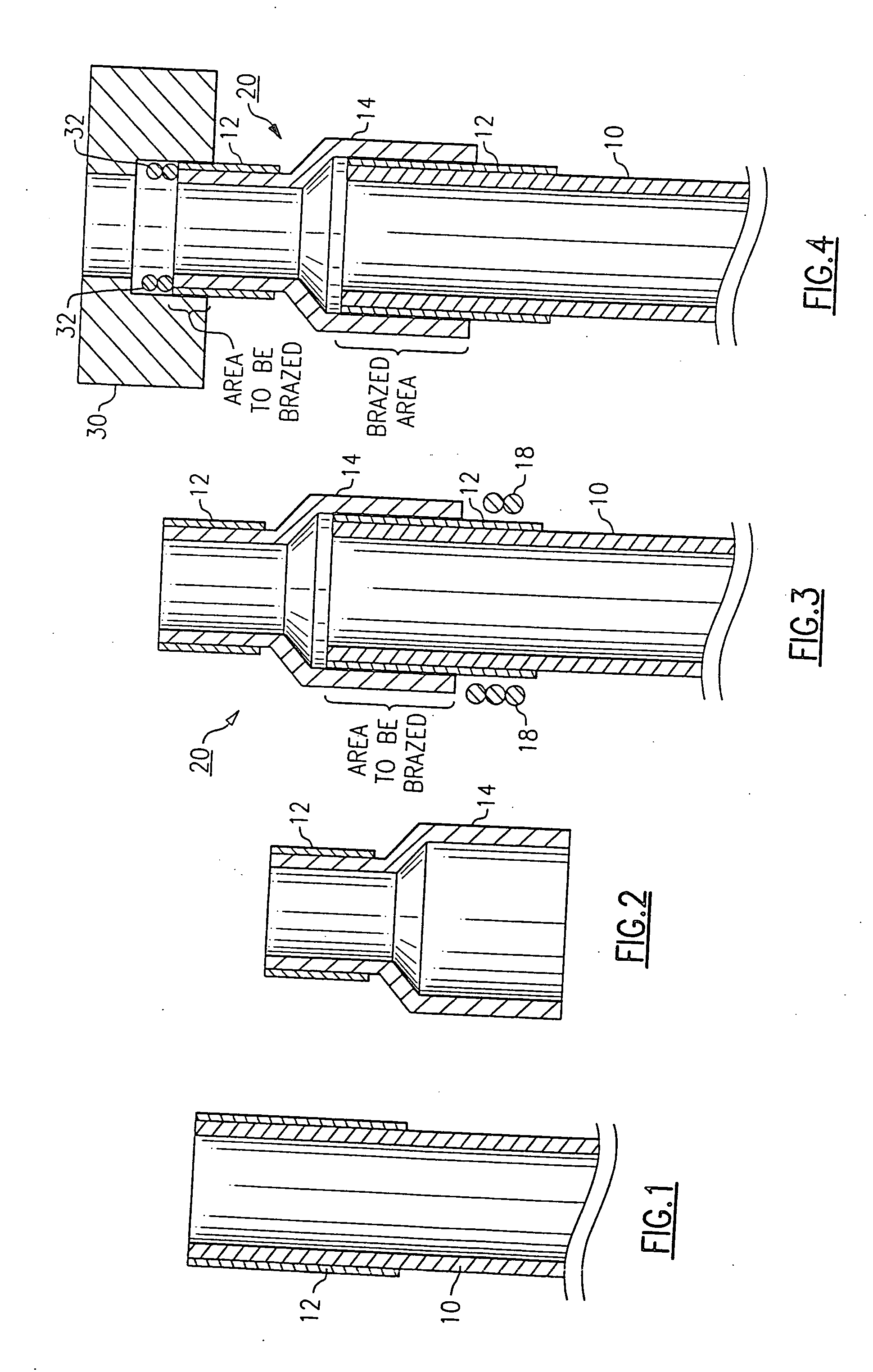

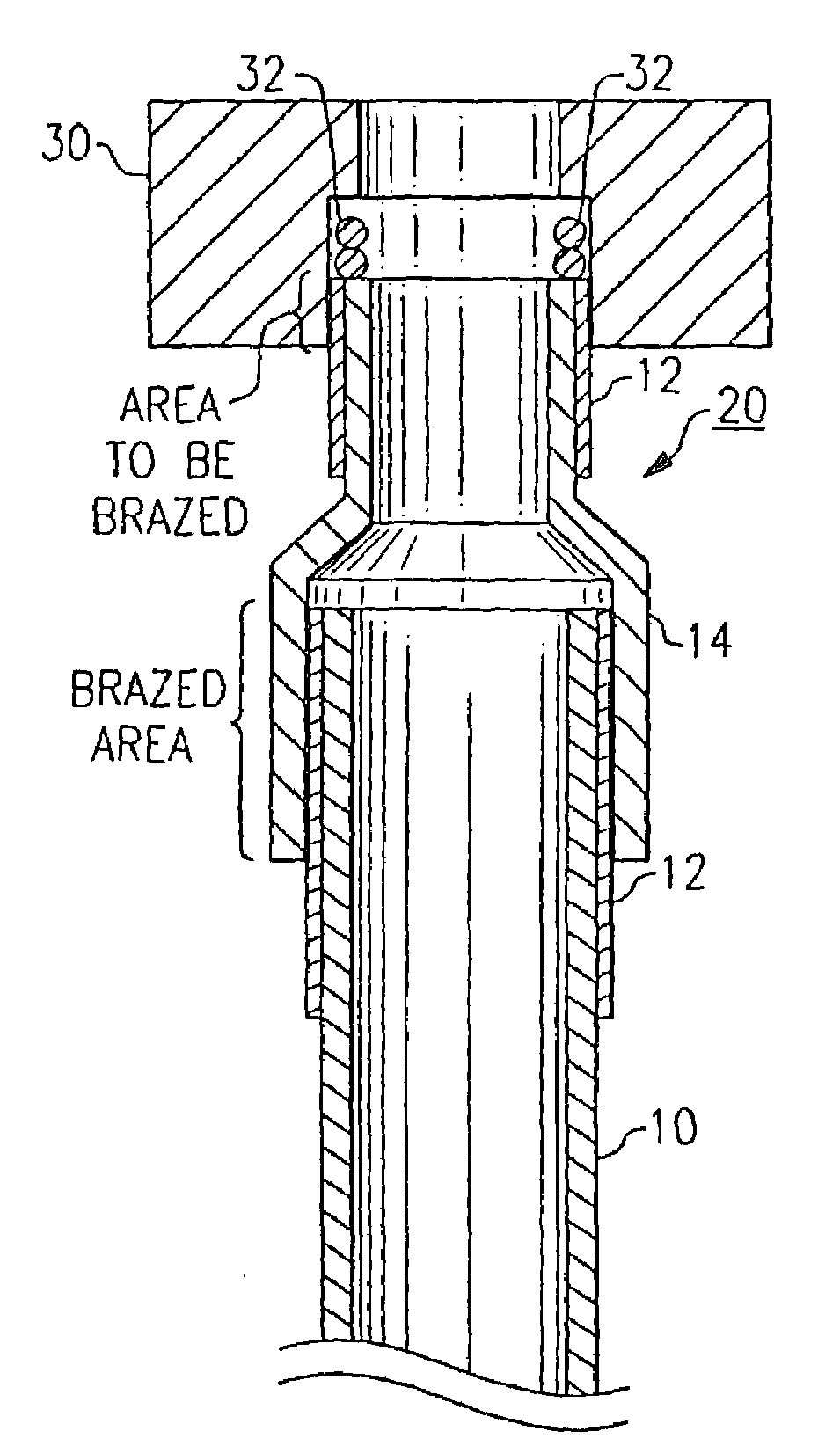

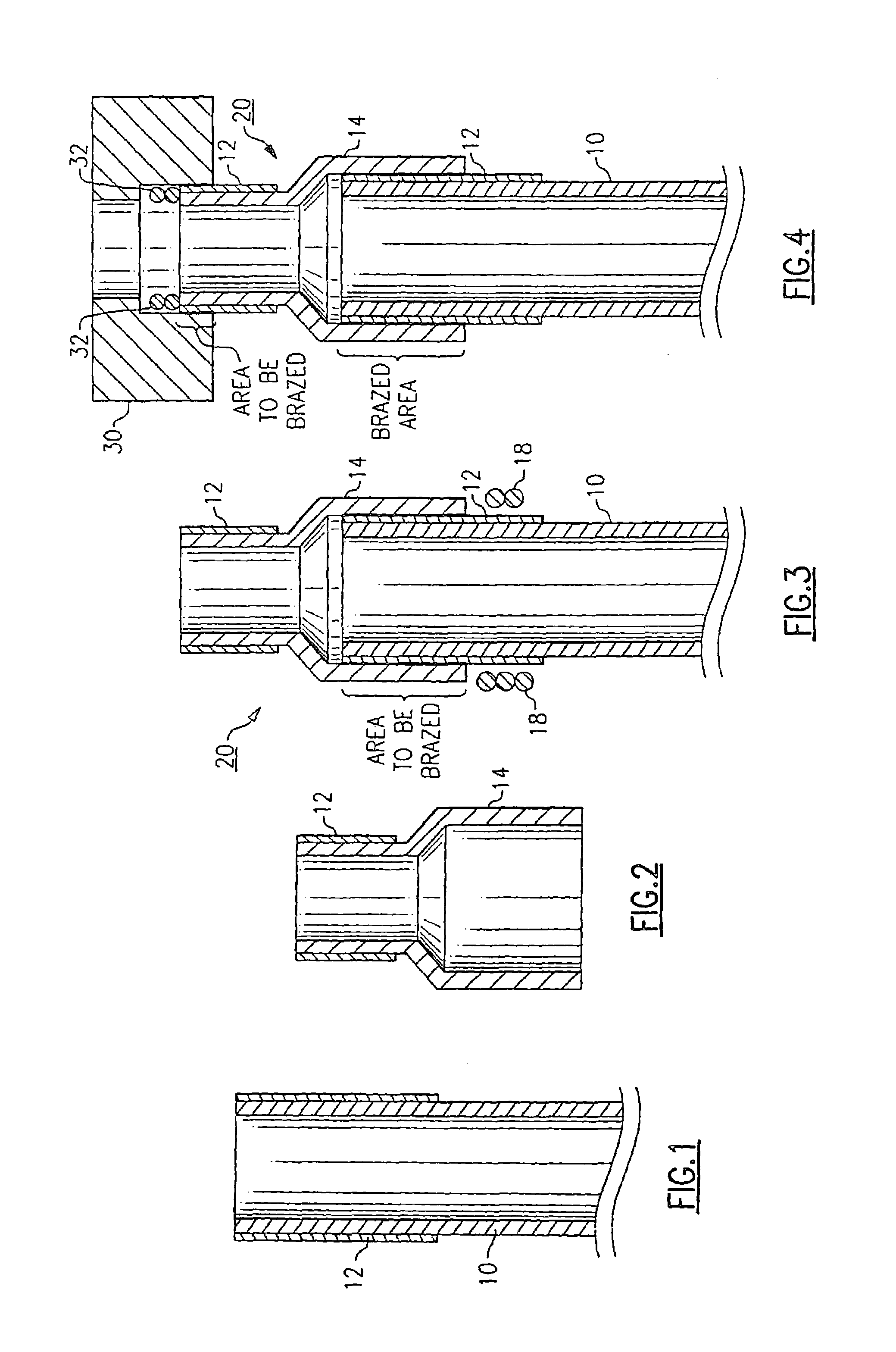

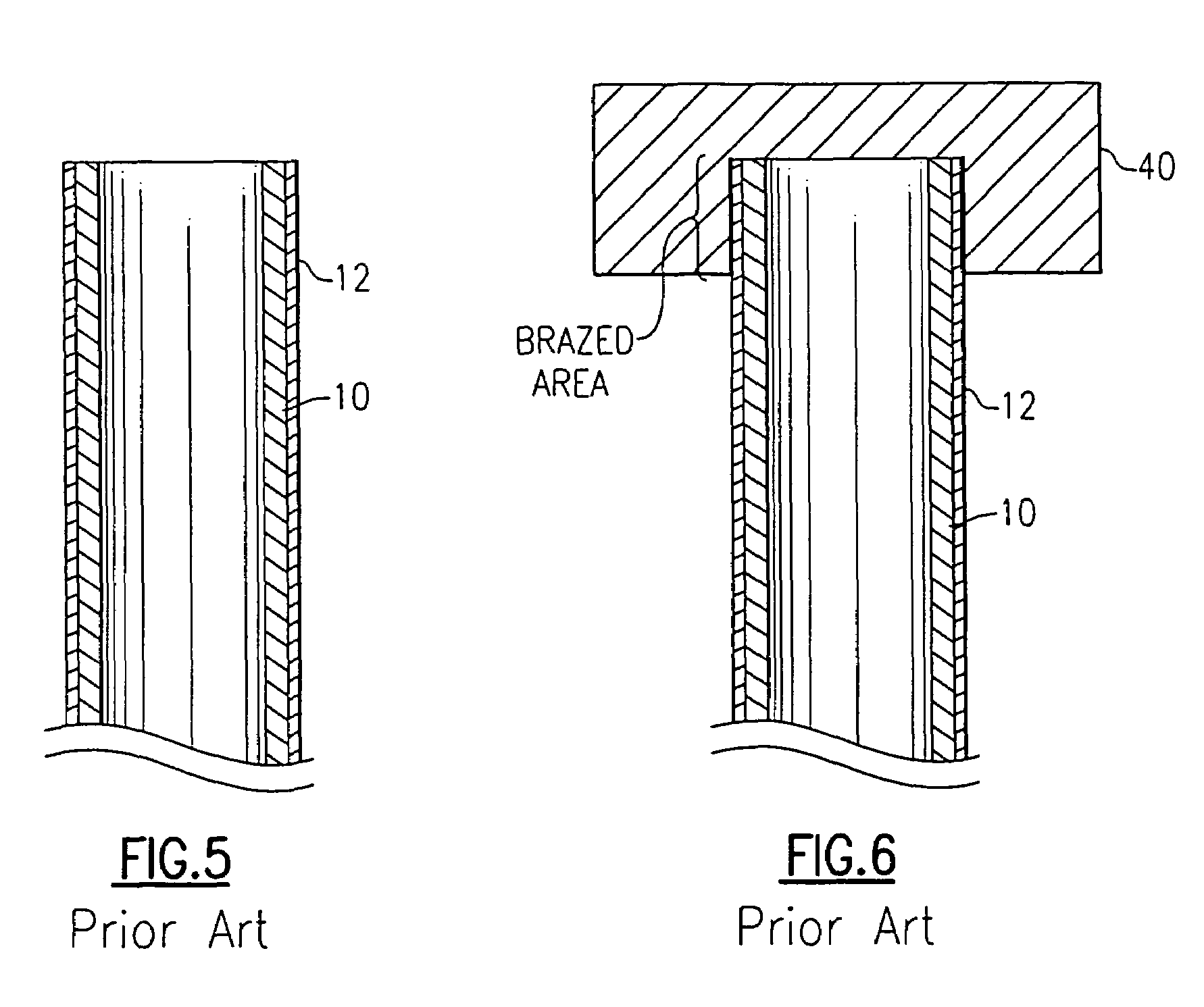

Two tier brazing for joining copper tubes to manifolds

InactiveUS20050218196A1Efficiently joinedEasy to joinHigh frequency current welding apparatusWelding/cutting media/materialsElectroplatingMelting temperature

A brazing process for joining copper and copper alloy tubes to a fitting which includes first forming a layer of a high melting temperature noble metal on one end of a copper or copper alloy tube. The plated end is then brazed to a metal ferrule to form a copper alloy-ferrule assembly. The assembly is then furnace brazed to a metal fitting.

Owner:UNITED TECH CORP

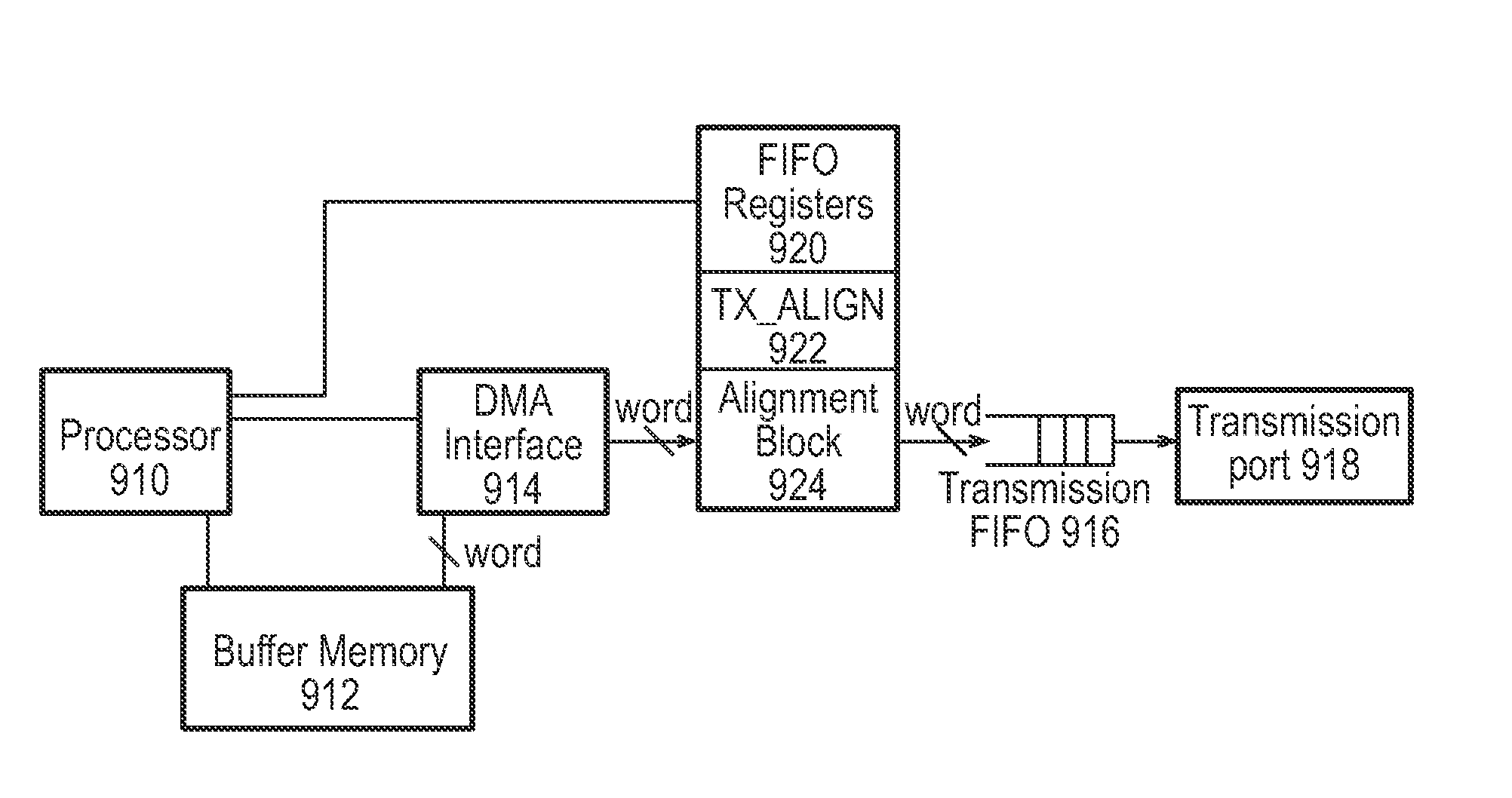

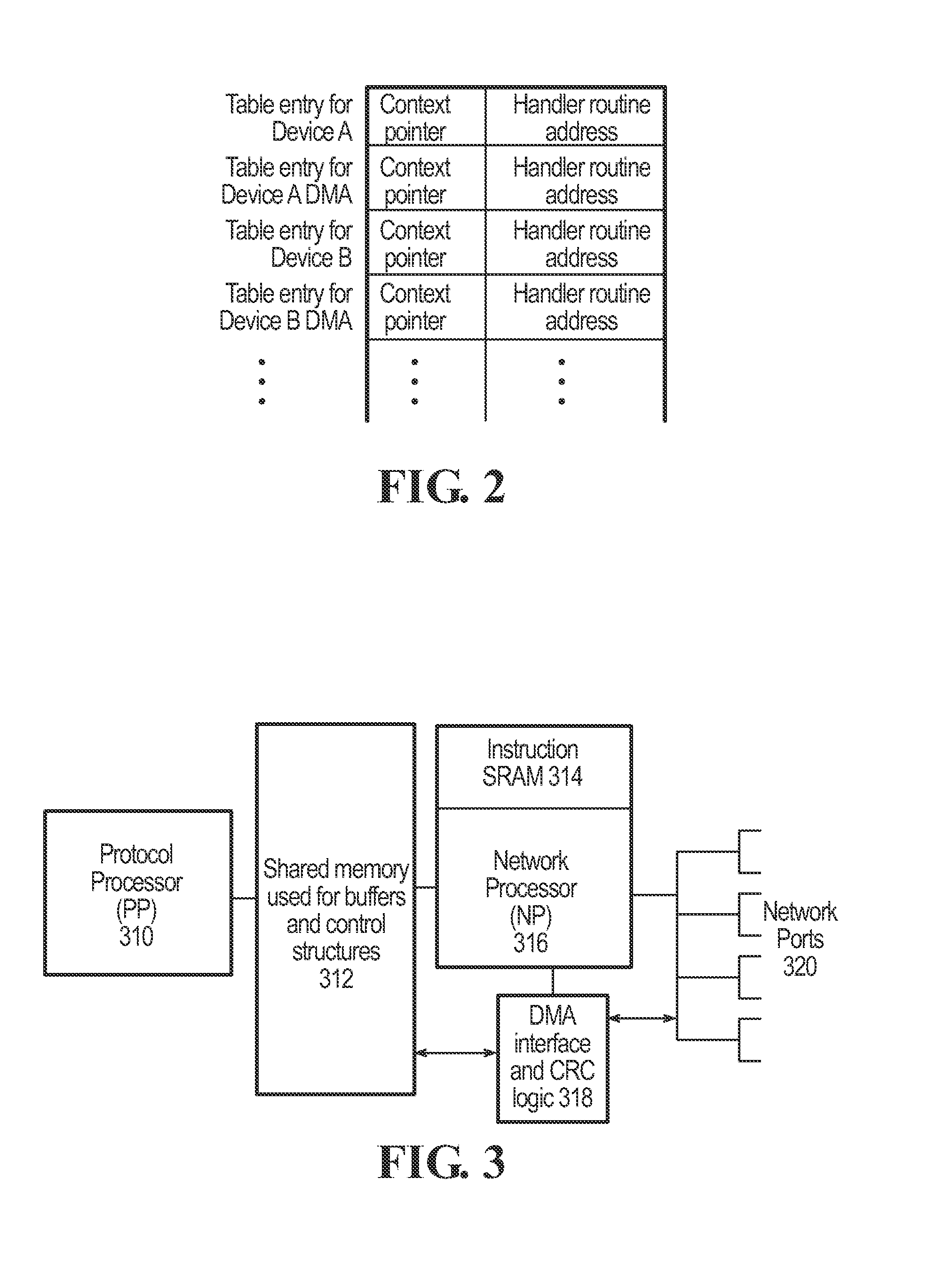

System and method for packet transmission from fragmented buffer

ActiveUS7733878B2Efficiently joinedData switching by path configurationStore-and-forward switching systemsMemory systemsSoftware

Owner:SYNAPTICS INC

Inflatable body with independent chambers and methods for making the same

Owner:CASCADE DESIGNS INC

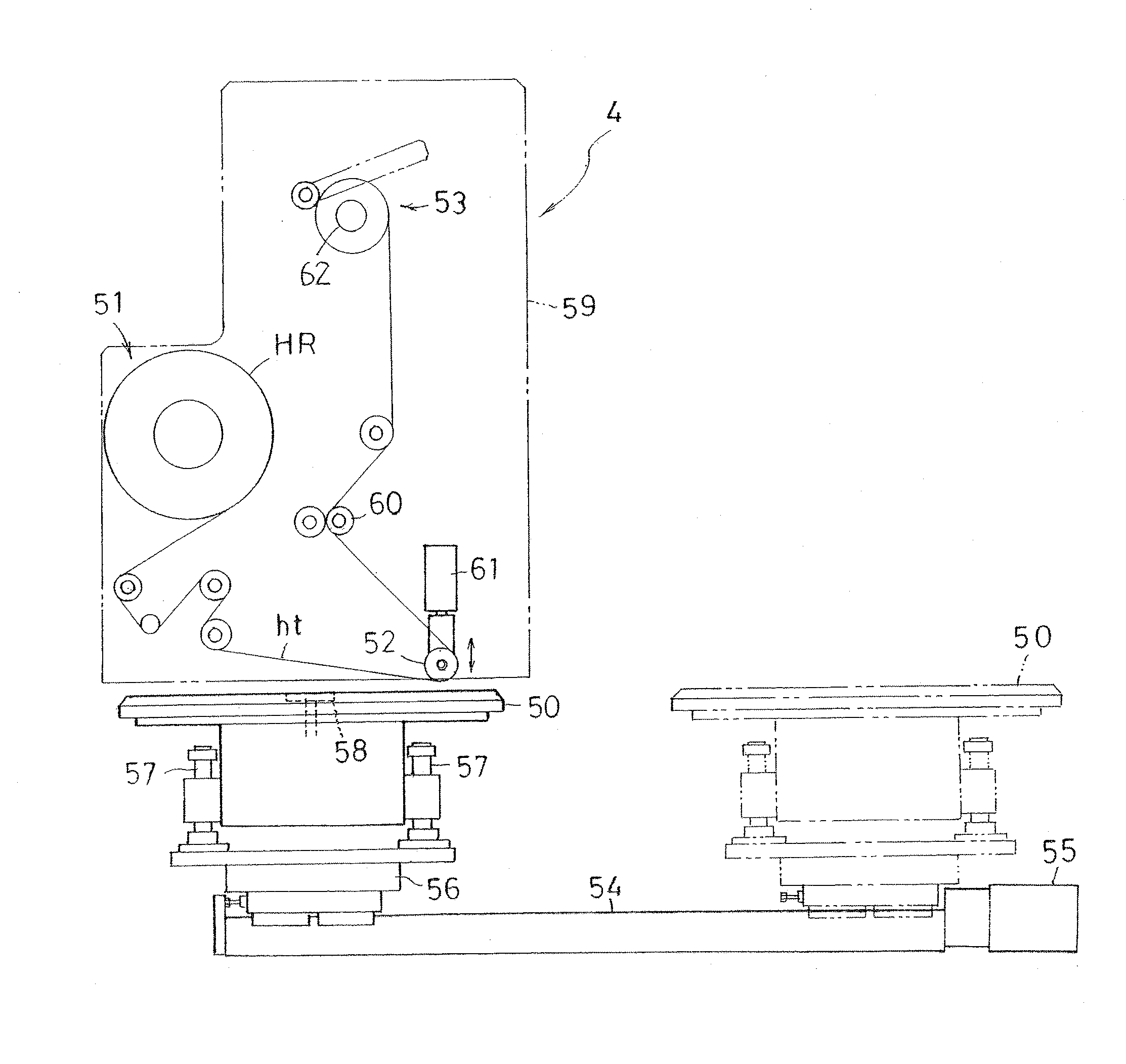

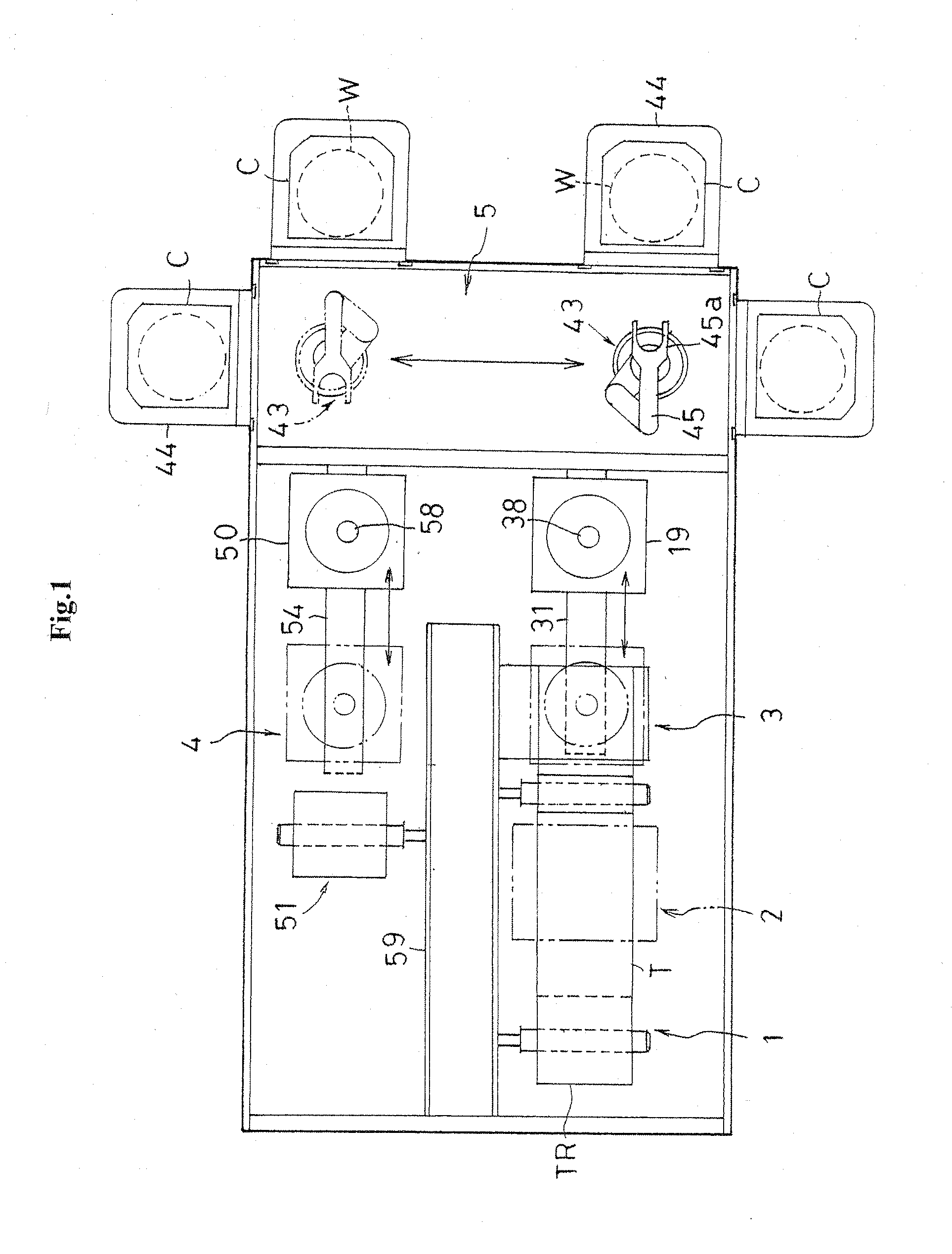

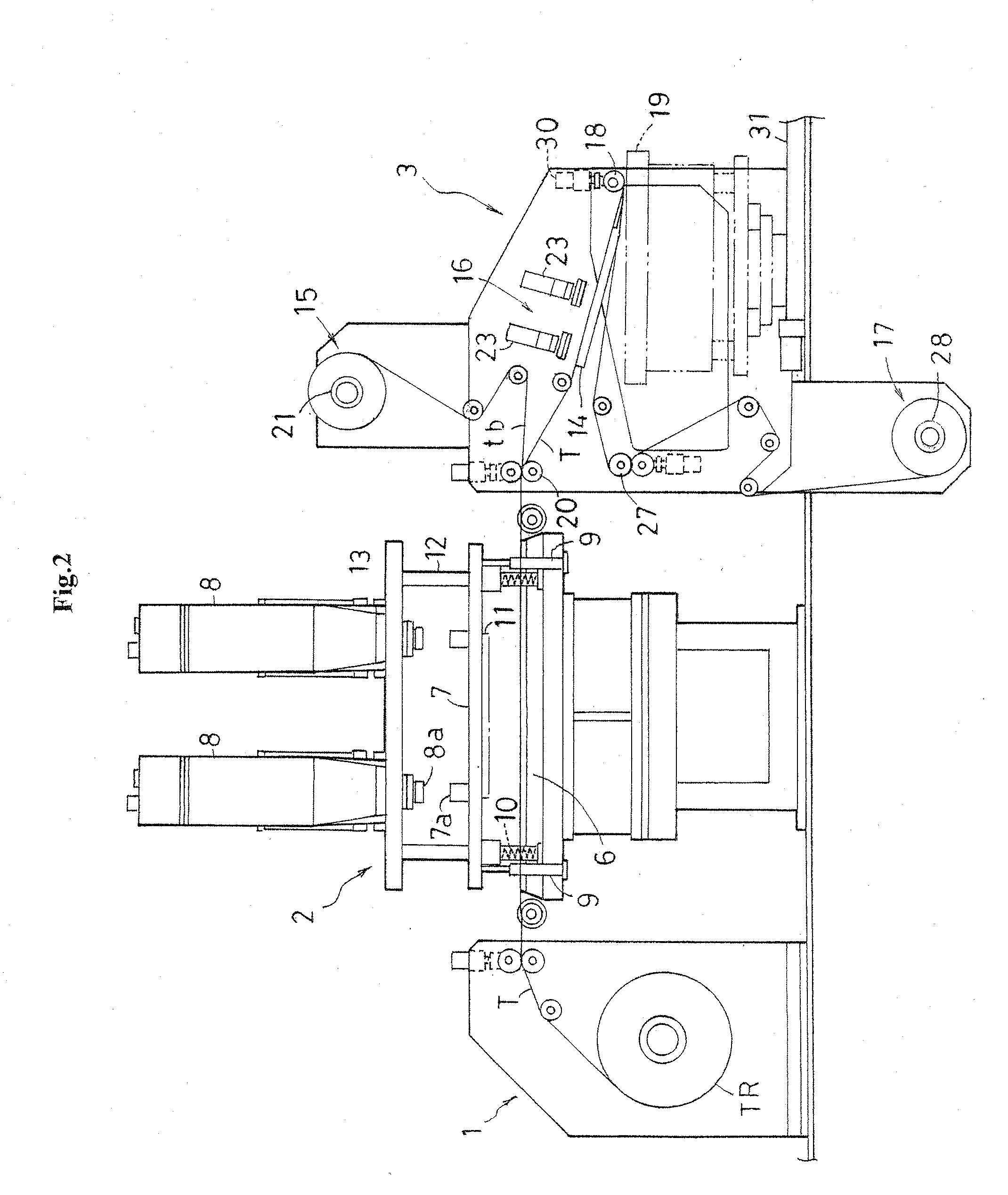

Double-faced adhesive tape joining method and double-faced adhesive tape joining apparatus

InactiveUS20120085488A1Efficiently joinedUniform thicknessAdhesive processesLamination ancillary operationsEngineeringMechanical engineering

An original master tape having a long carrier tape and a long double-faced adhesive tape joined thereto is guided to a knife edge to be folded back. The double-faced adhesive tape is half-cut on the carrier tape in front of the knife edge with a Thomson blade having a corresponding shape to a substrate. The original master tape is folded back at the knife edge. Accordingly, a piece of the double-faced adhesive tape cut into the substrate shape is separated from the carrier tape to be joined to the substrate traveling relatively at a speed synchronized to a separation speed.

Owner:NITTO DENKO CORP

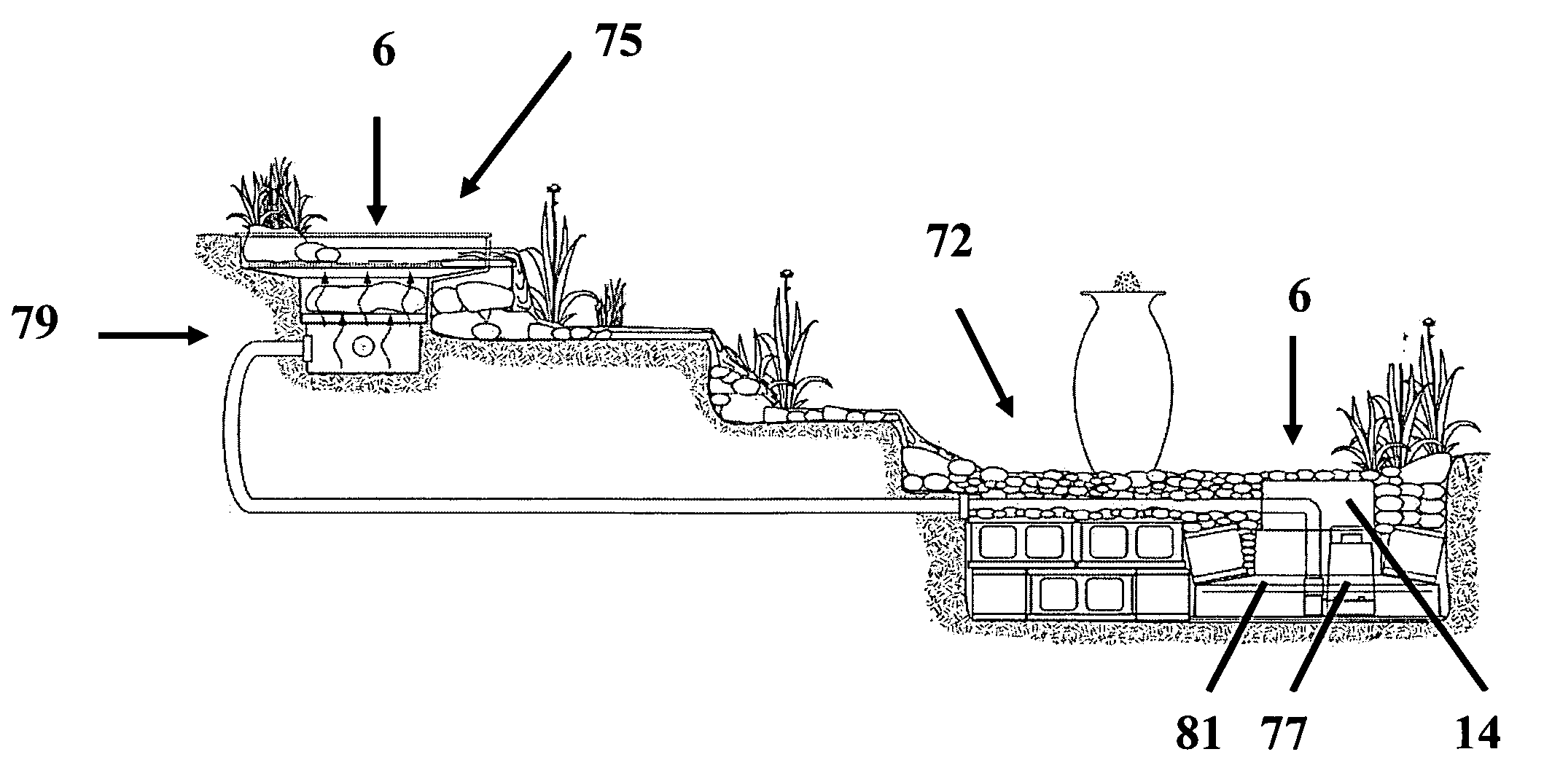

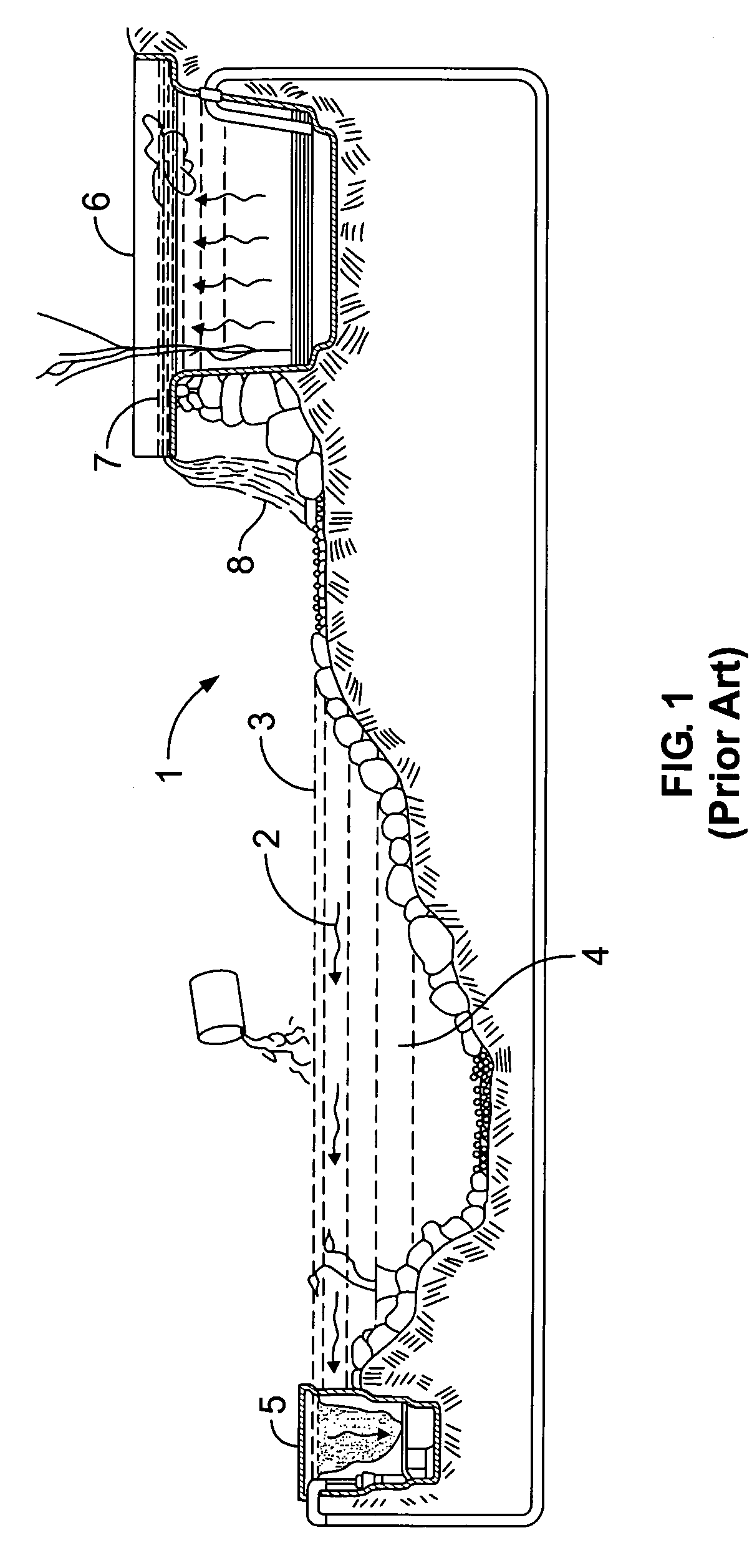

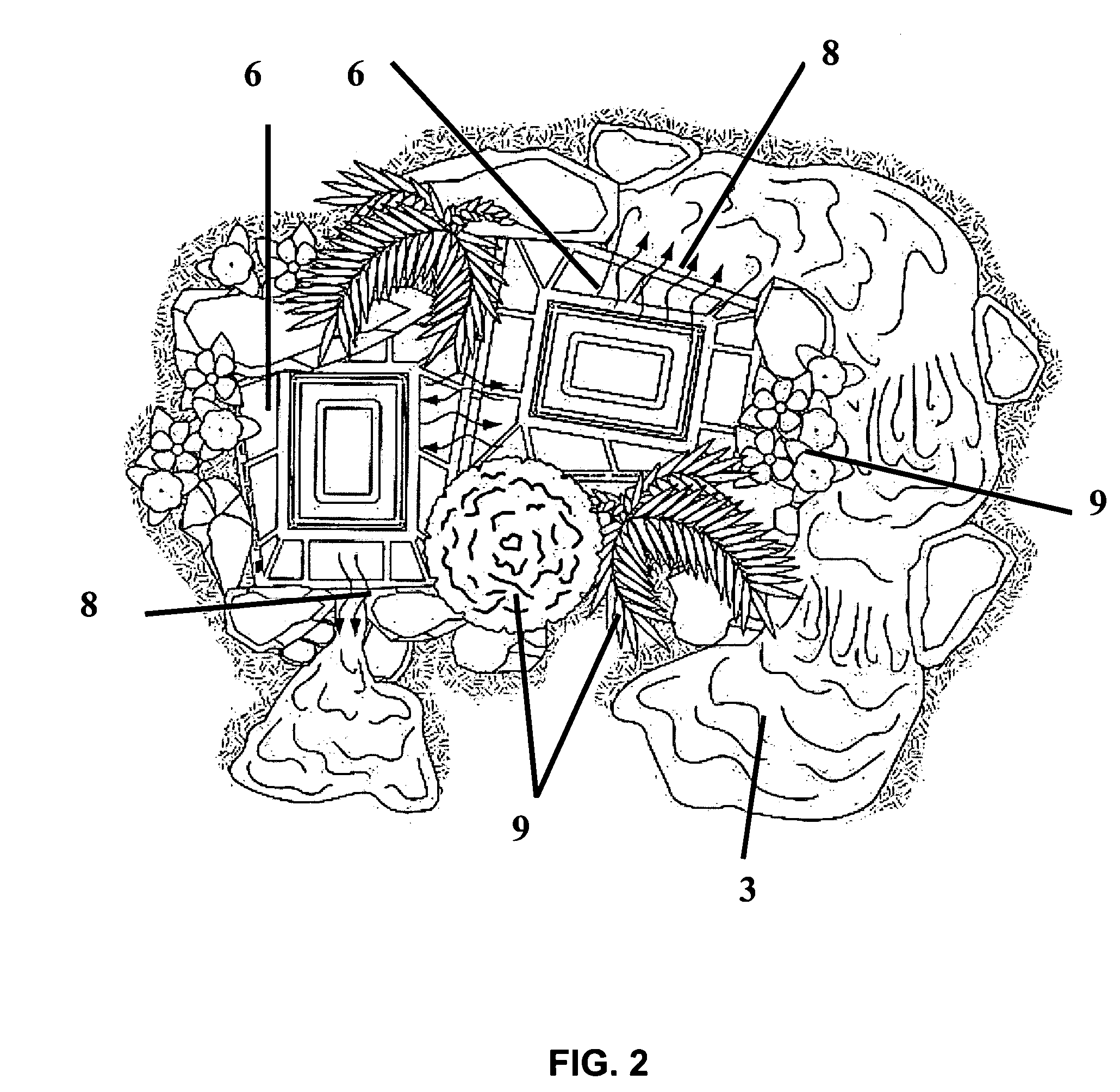

Landscaping pond system and method with variable opening falls and tesserae geometry

InactiveUS20070107664A1Efficiently joinedPisciculture and aquariaCultivating equipmentsVegetationFiltration

The present invention relates generally to an improved falls box as part of a filtration and water circulation system for artificial ponds and other bodies of water and, more particularly, to an improved falls box of a design and method of use that allows for vertical stacking during storage, the vertical use of a multitude of support grids to fill the cavity, the use of support ribs in an intermediary section to support aesthetic additions, an upper surface that can be opened to orient the horizontal flow across the box and create one or a plurality of artificial falls, the capacity of connecting a plurality of falls boxes in series to create a filtration cross-flow through falls boxes, the use of the falls box in a plurality of ways as a pump vault box in a disappearing water recuperation system either in connection with a falls box, by itself, upside down, in order to create an underground vegetation system, a disappearing falls system, a small pond, or a disappearing falls filter, and a tessellated upper geometry that allows connecting edges between boxes to be joined in a plurality of methods to create complex water surfaces.

Owner:AQUSPE DESIGNS

Plating of ceramic matrix composite parts as joining method in gas turbine hardware

InactiveUS20120210718A1Efficiently joinedMinimize thermal expansionPropellersReaction enginesGas turbinesElectroplating

Owner:GENERAL ELECTRIC CO

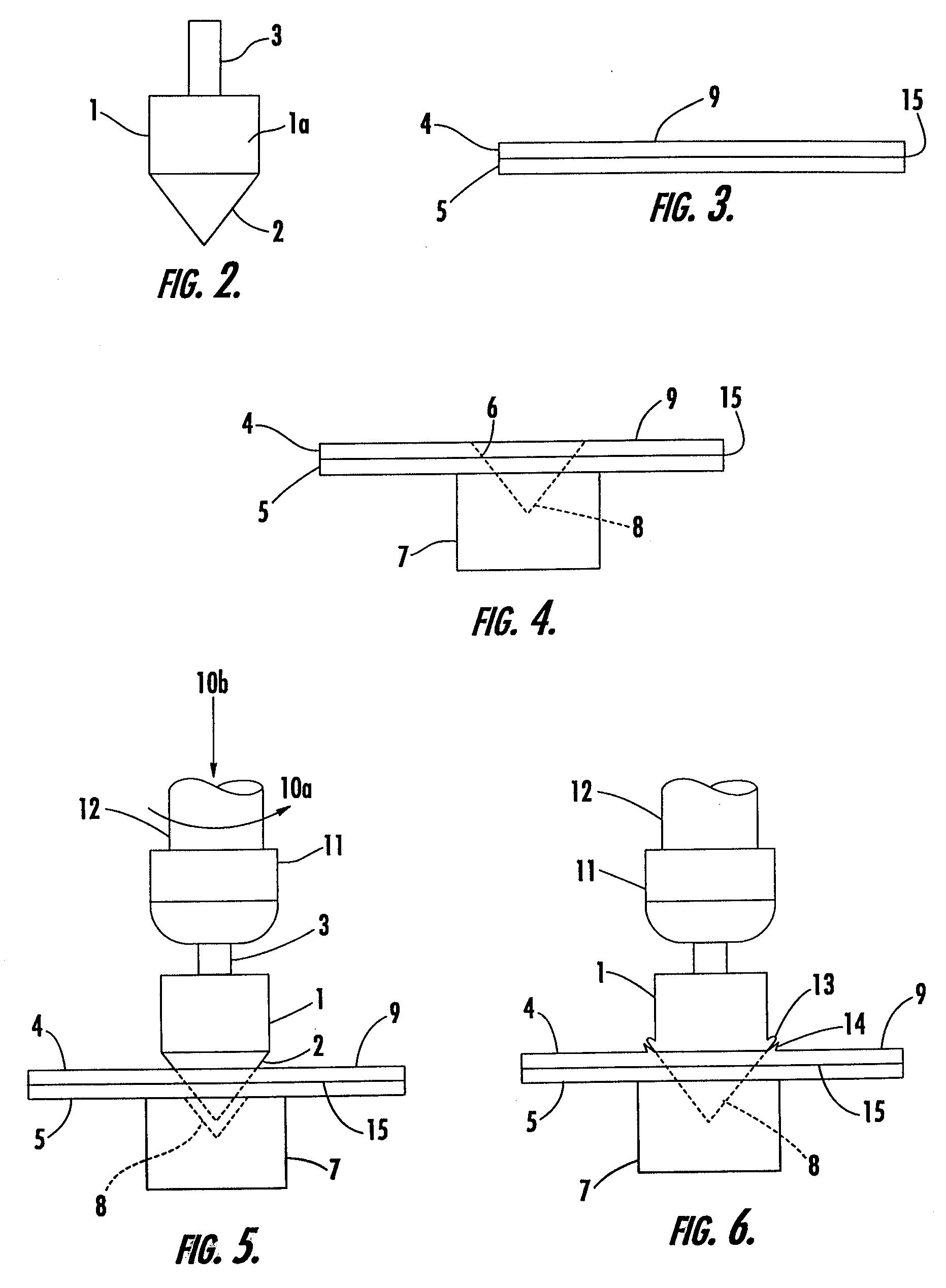

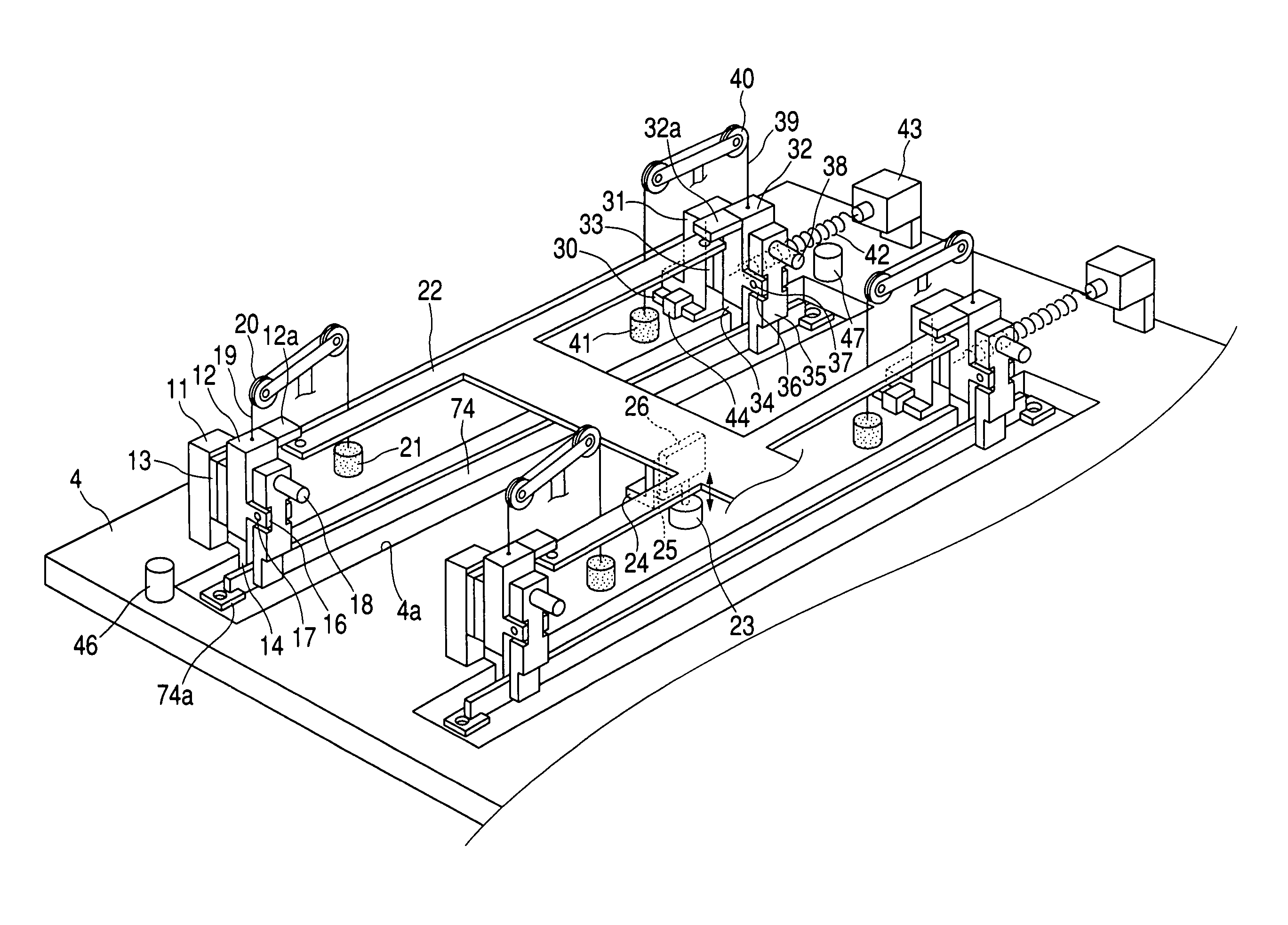

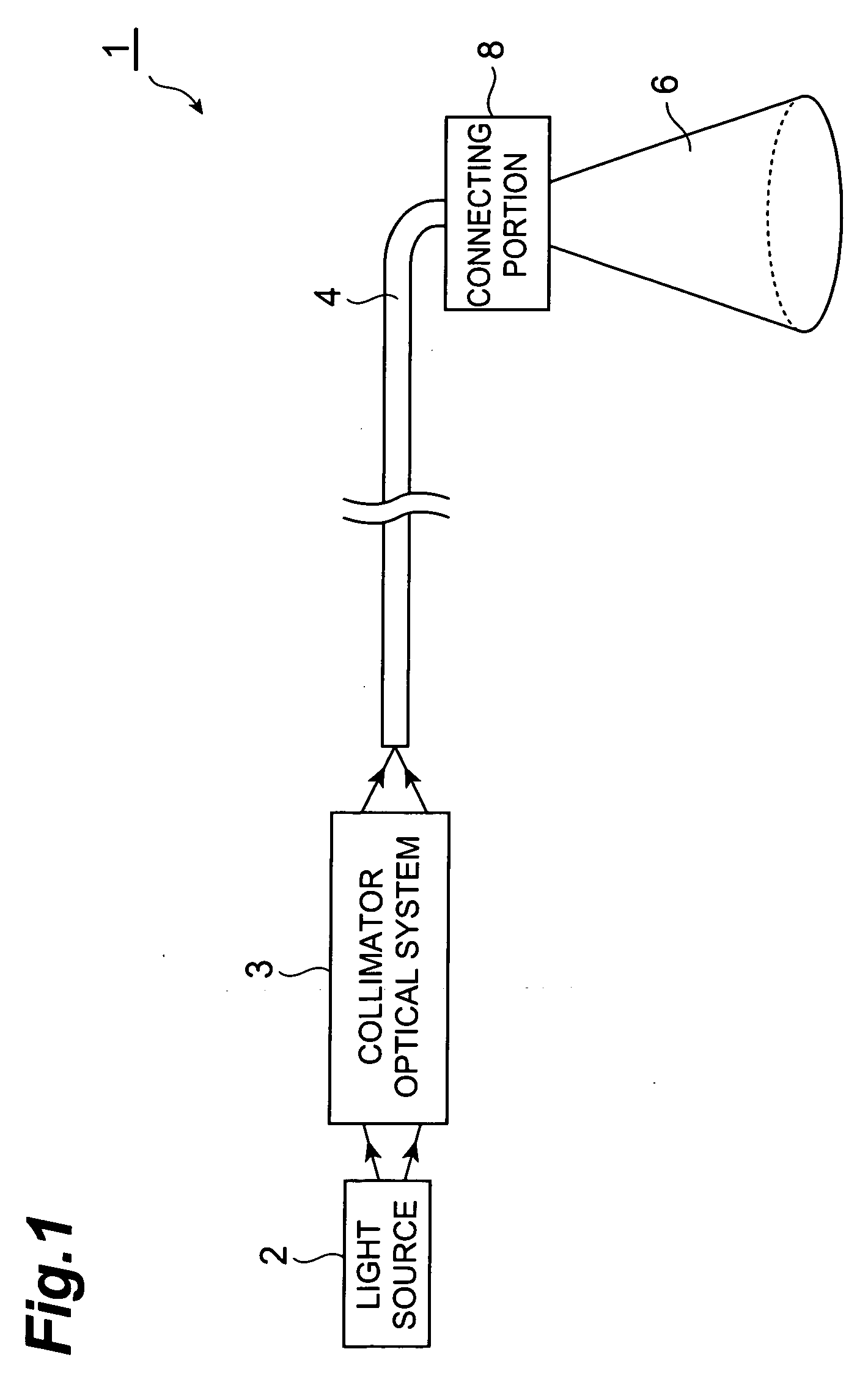

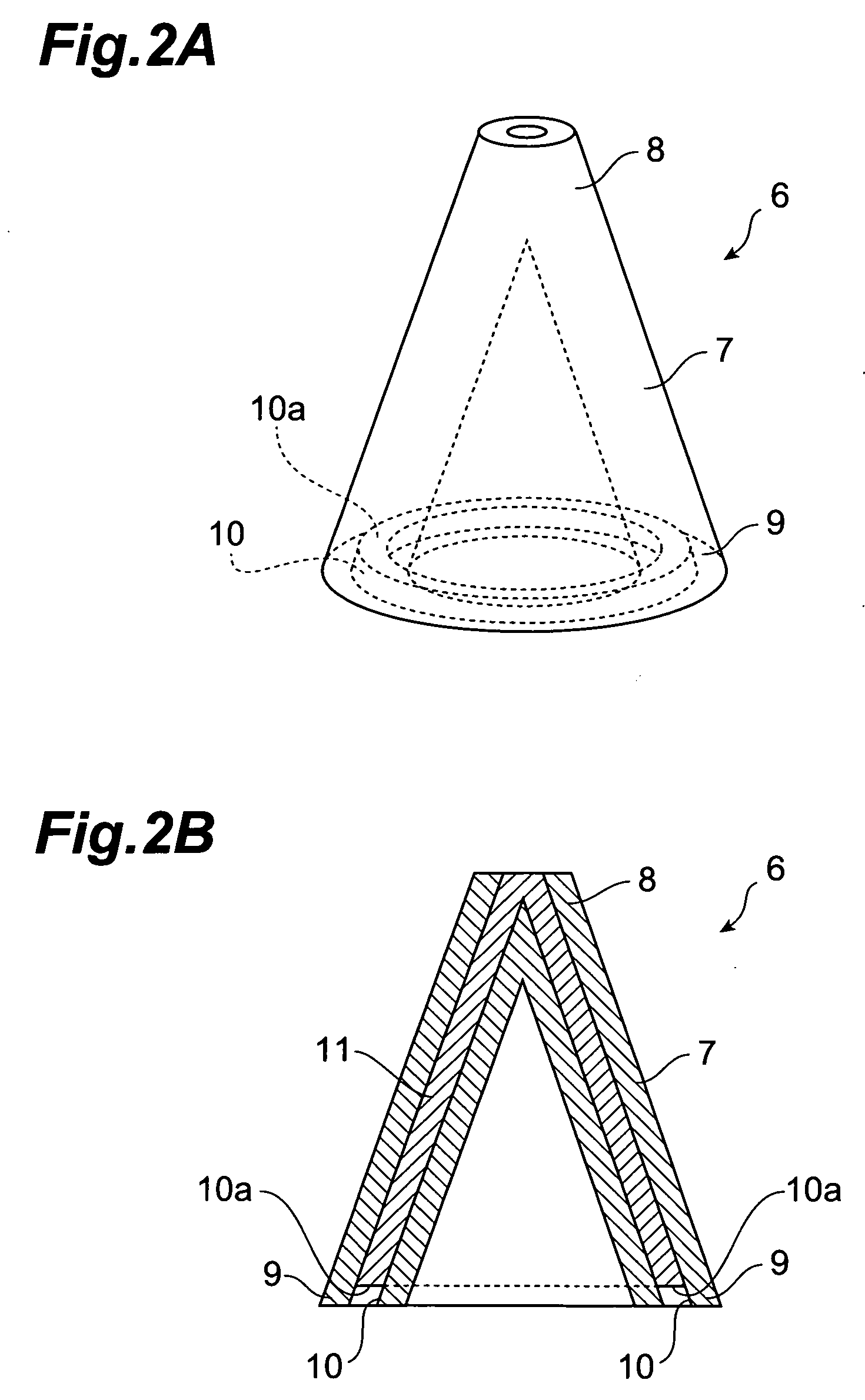

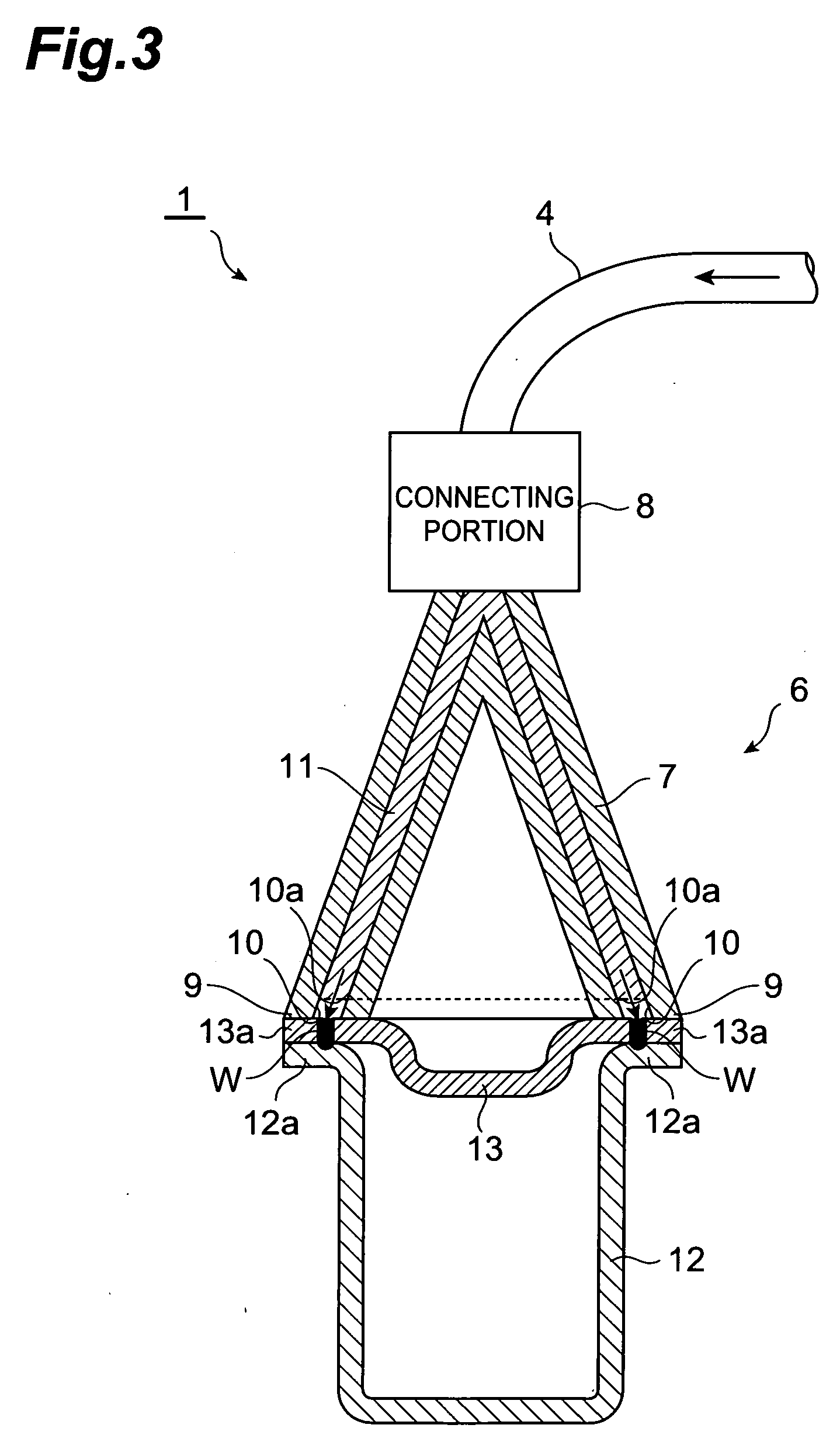

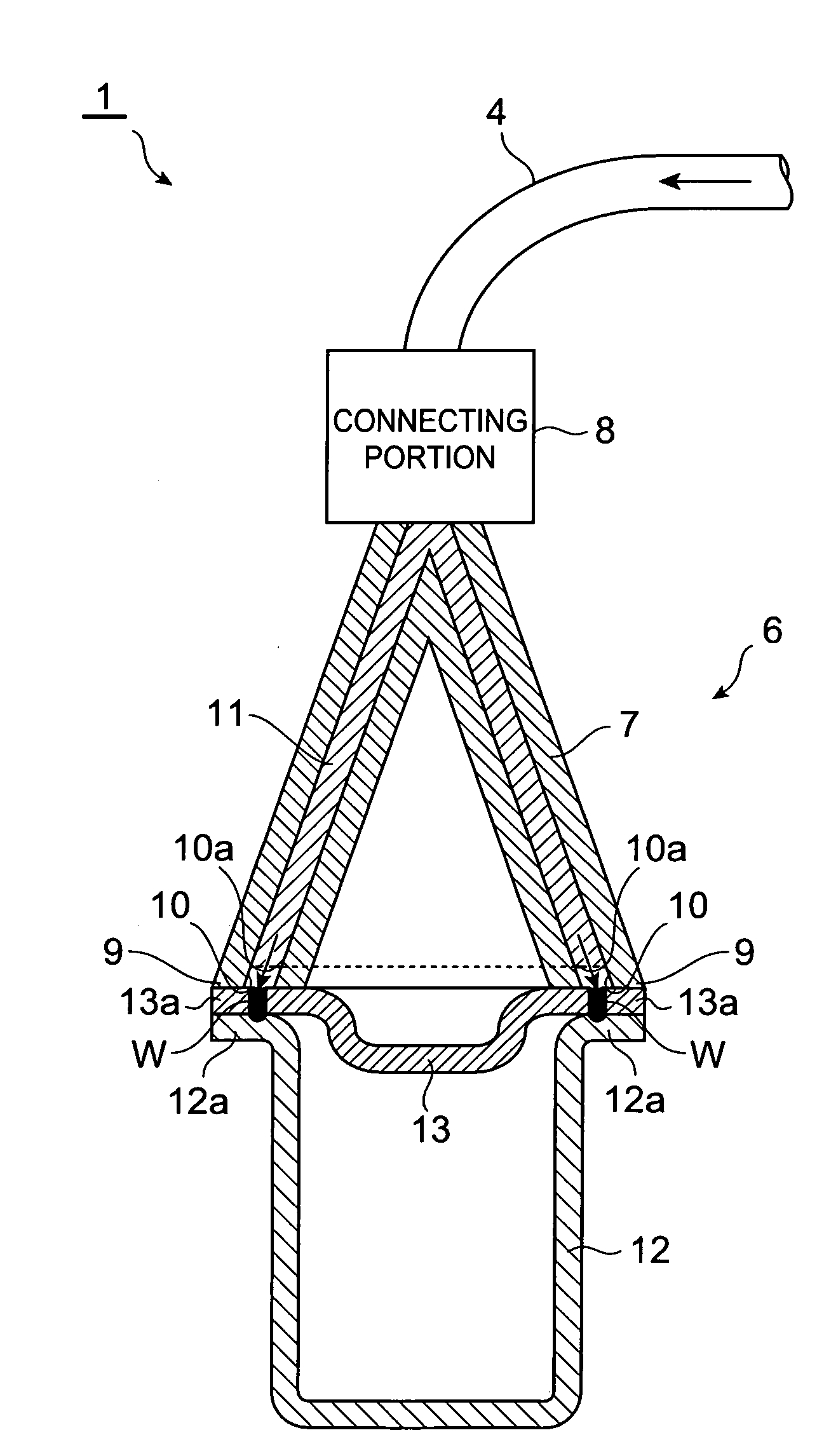

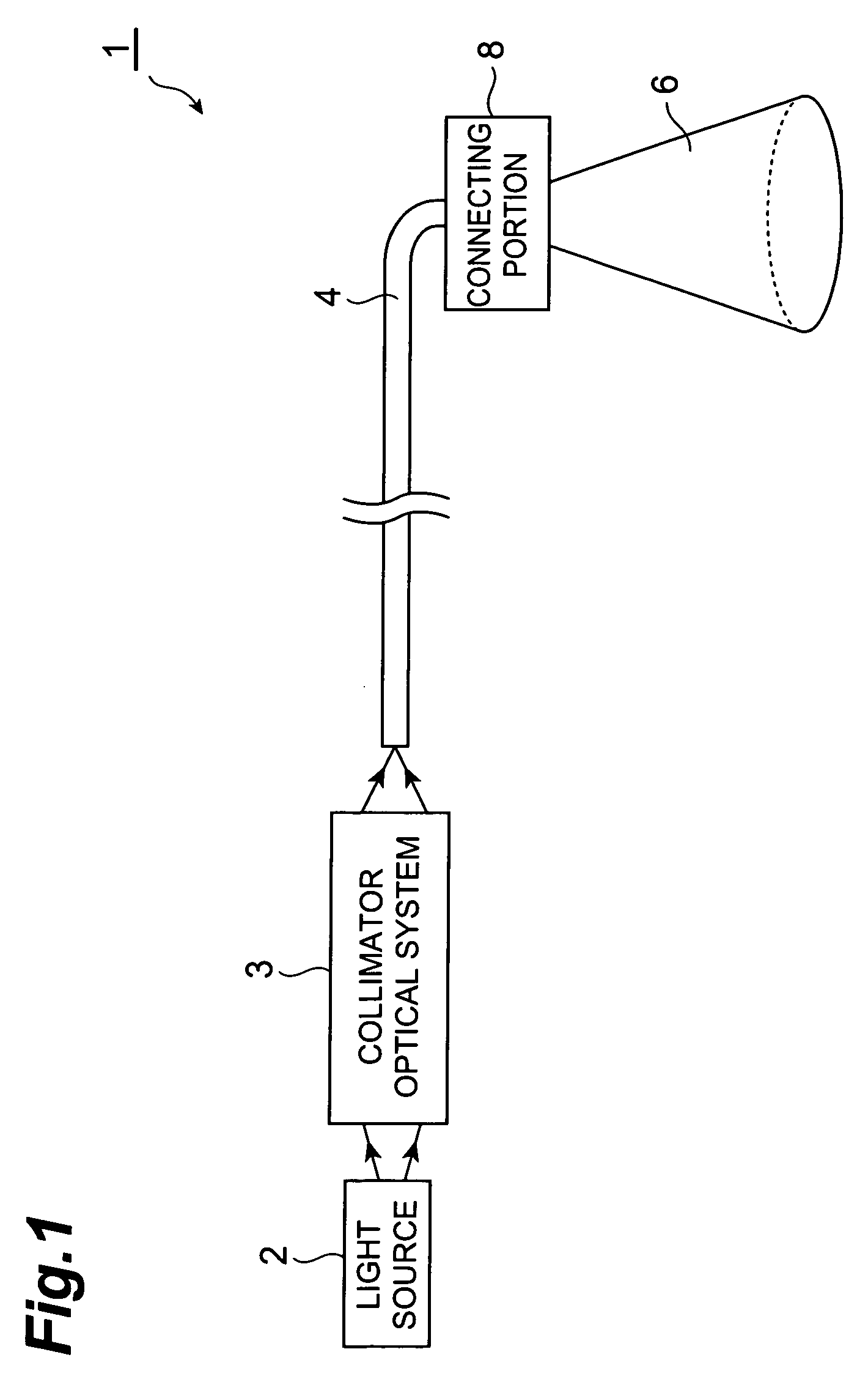

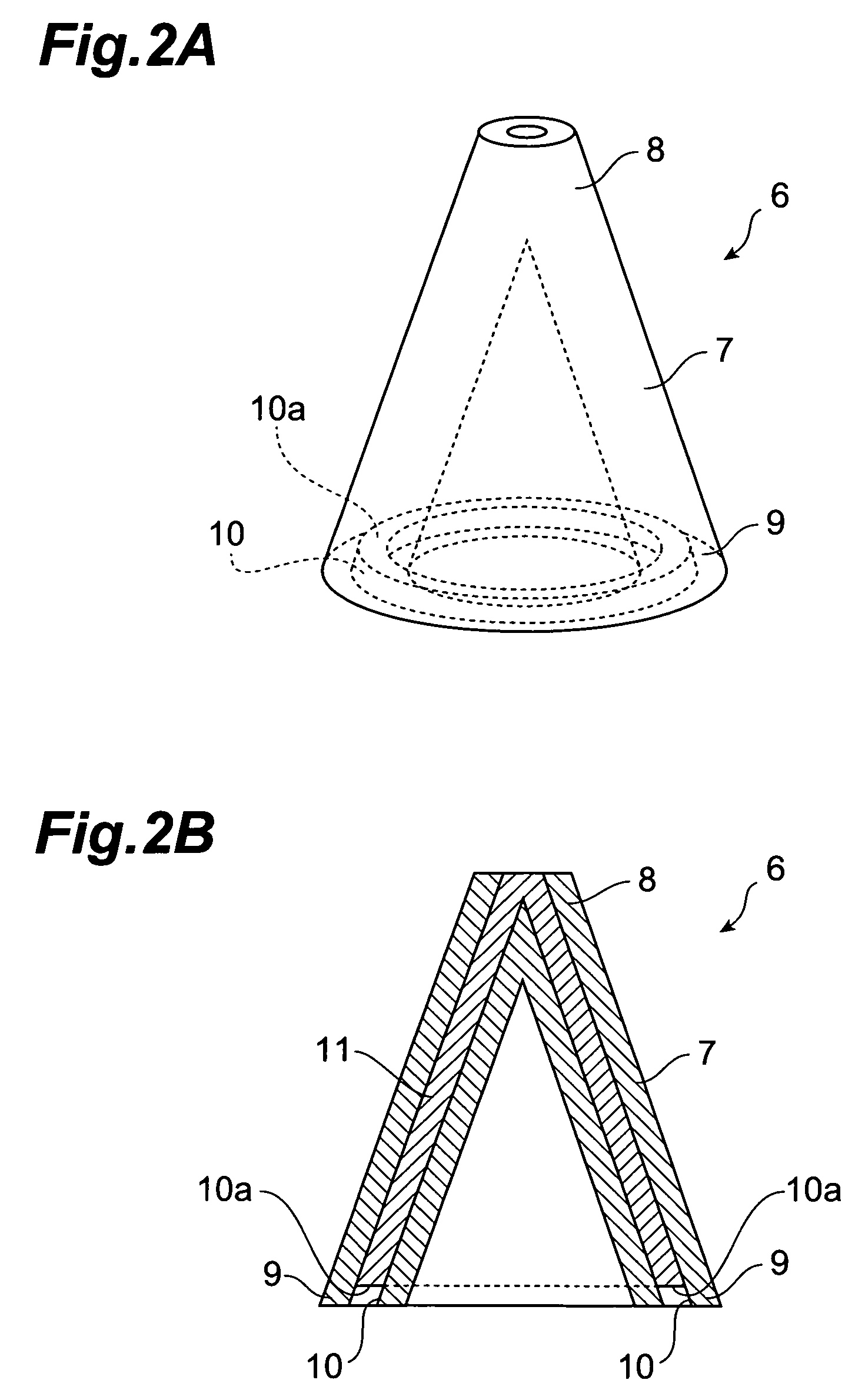

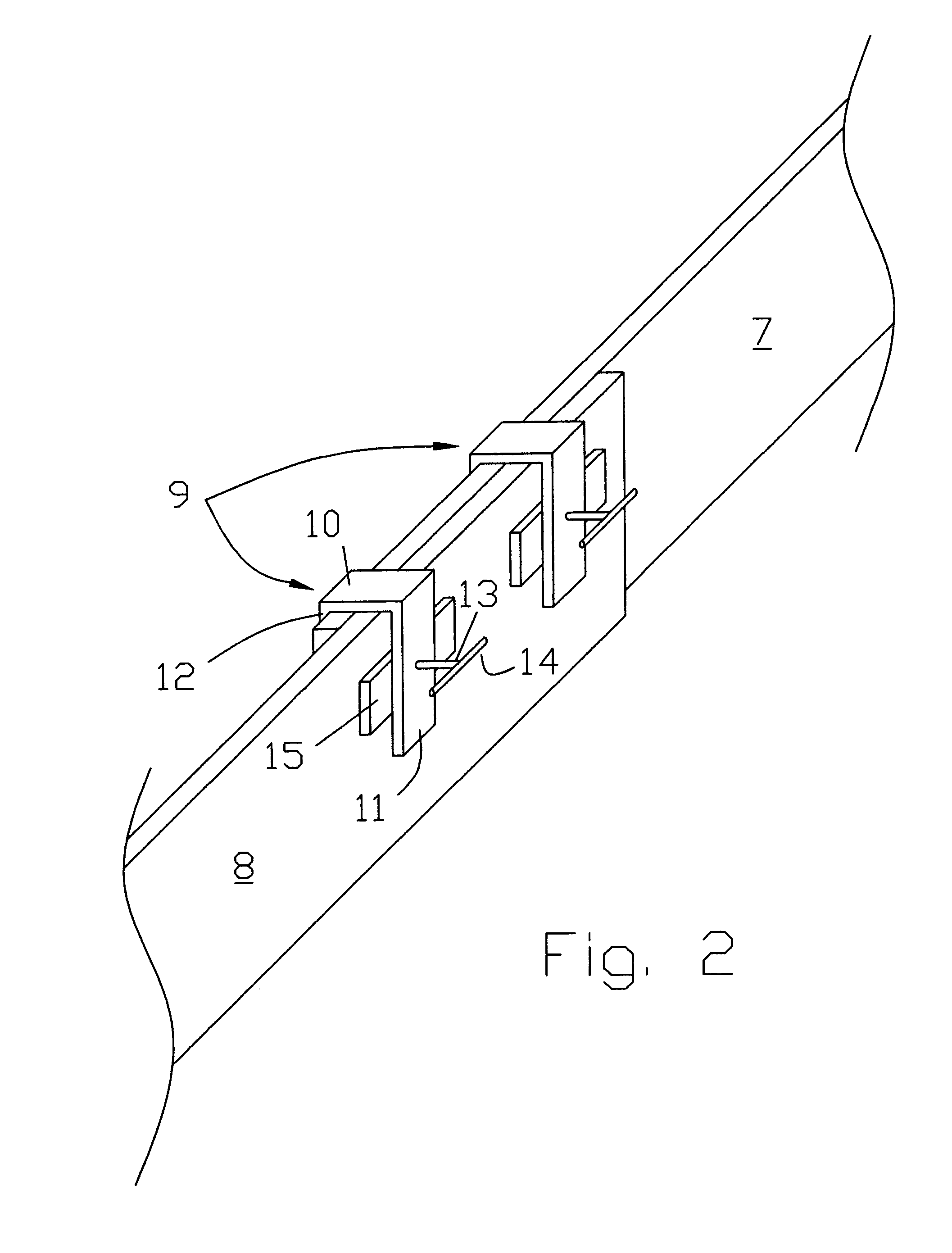

Laser beam machine

InactiveUS20060186095A1Convenience to workImprove production yieldLaser beam welding apparatusLaser beamsOptical fiber

In this laser beam machine 1, while a pressing portion 9 of an optical guide member 6 presses a lid 13 against a body 12 of a container, the optical guide member 6 annularly guides a laser beam propagated through an optical fiber 4 and outputs it from the pressing portion 9. Thereby, an annular processing region of the body 12 and the lid 13 is entirely irradiated with the laser beam at one time and the lid 13 can be joined to the body 12, whereby improving the working efficiency. Such improvement in working efficiency shortens the processing time and improves the production yield. Furthermore, this laser beam machine 1 does not need to be separately provided with a rotating mechanism for laser beam scanning and a pressurizing mechanism for the body 12 and the lid 13, so that construction of the machine can be significantly simplified.

Owner:HAMAMATSU PHOTONICS KK

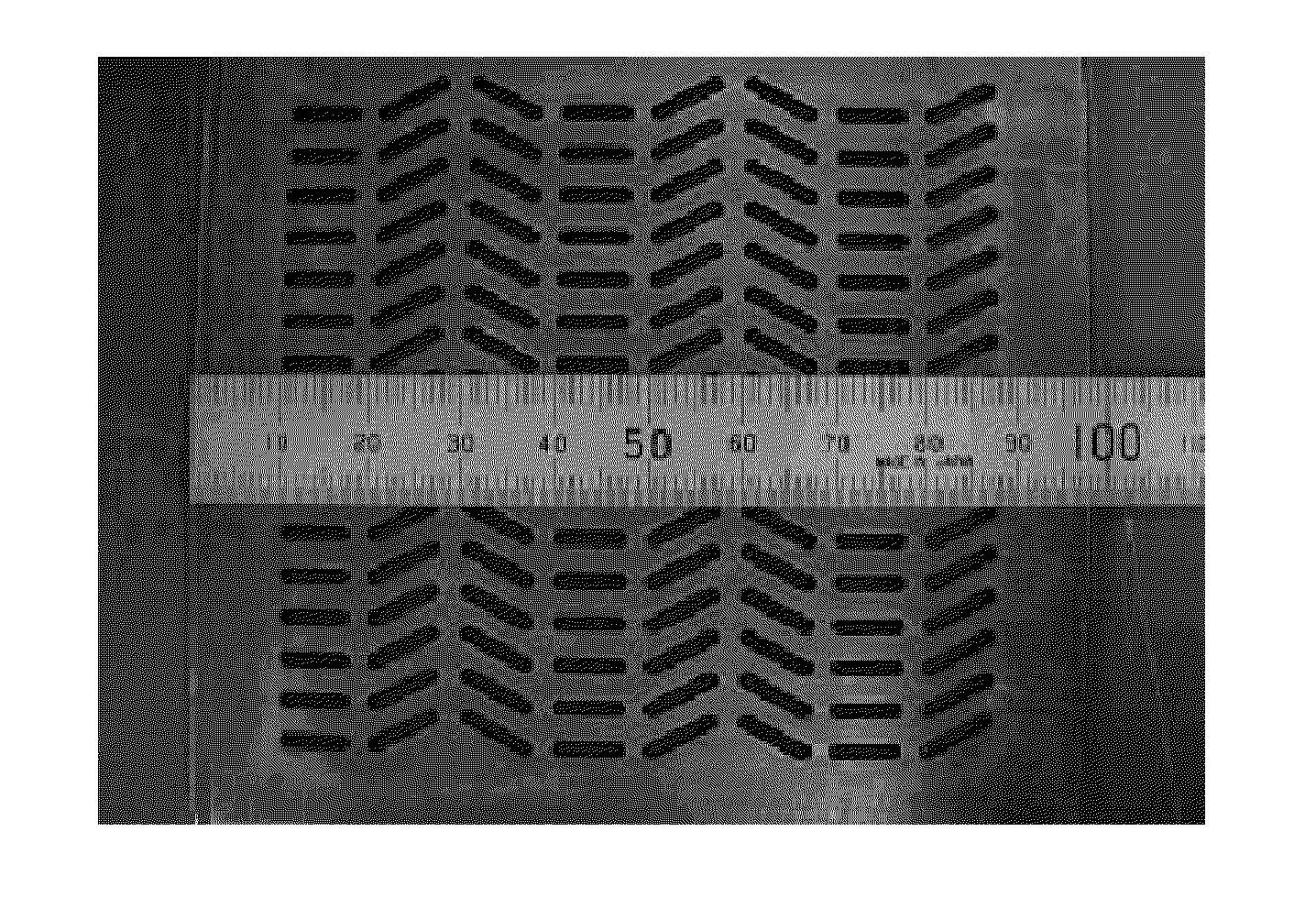

Method of manufacturing image display device

InactiveUS7258588B2Improve accuracyLevel of tensionImage/pattern display tubesVessels or leading-in conductors manufactureAdhesiveDisplay device

A method of manufacturing an image display device, having a plurality of spacers for keeping a gap between a pair of substrates, includes the steps gripping each of the spacers at both ends in a longitudinal direction of each spacer, installing the plural spacers on one of the pair of substrates while exerting a tensile force to the gripped plural spacers, and applying an adhesive to the plural spacers installed on the one substrate, to tentatively fix by the adhesive the plural spacers to the one substrate. The adhesive is heated so that the plural spacers tentatively fixed to the one substrate are finally fixed to the one substrate.

Owner:CANON KK

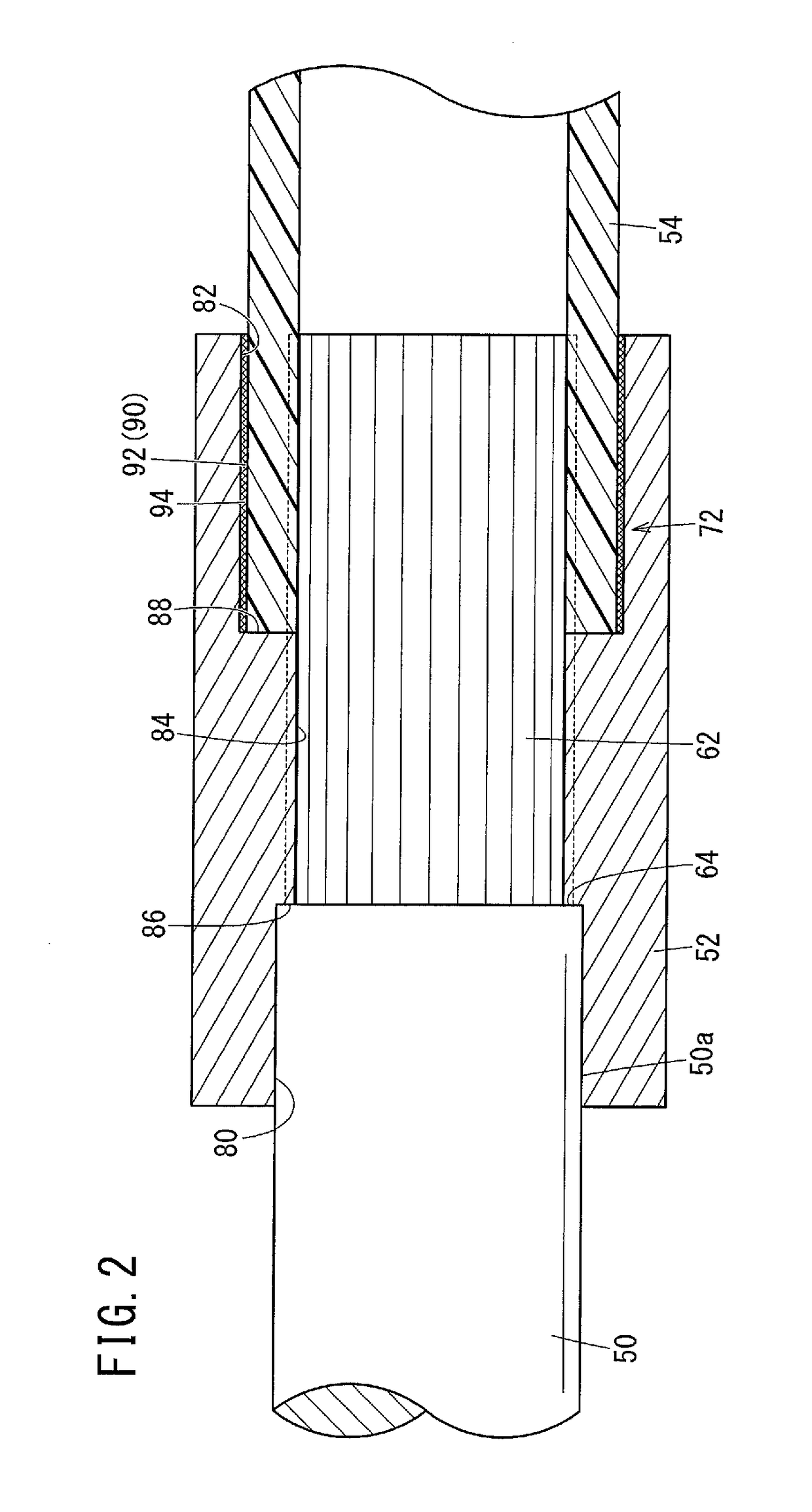

Drive shaft and manufacturing method therefor

ActiveUS20170227059A1Reduce weightThickness of adhesive layer can be adjustedYielding couplingBearing assemblyAdhesiveDrive shaft

A drive shaft includes a first shaft member made of metal, a tubular member made of CFRP, and a first exterior sleeve. The first shaft member is capable of being attached on one end side thereof to a first constant velocity joint, and has a first serrated part on which serrations are formed on another end side thereof. The tubular member is formed with a first fitting part fitted externally over the first serrated part. The first exterior sleeve covers the first fitting part by being disposed to extend over outer circumferential surfaces of the first shaft member and the tubular member. A film provided with a bonding assistance region and an adhesive are interposed between the outer circumferential surface of the tubular member and the inner circumferential surface of the first exterior sleeve.

Owner:HONDA MOTOR CO LTD

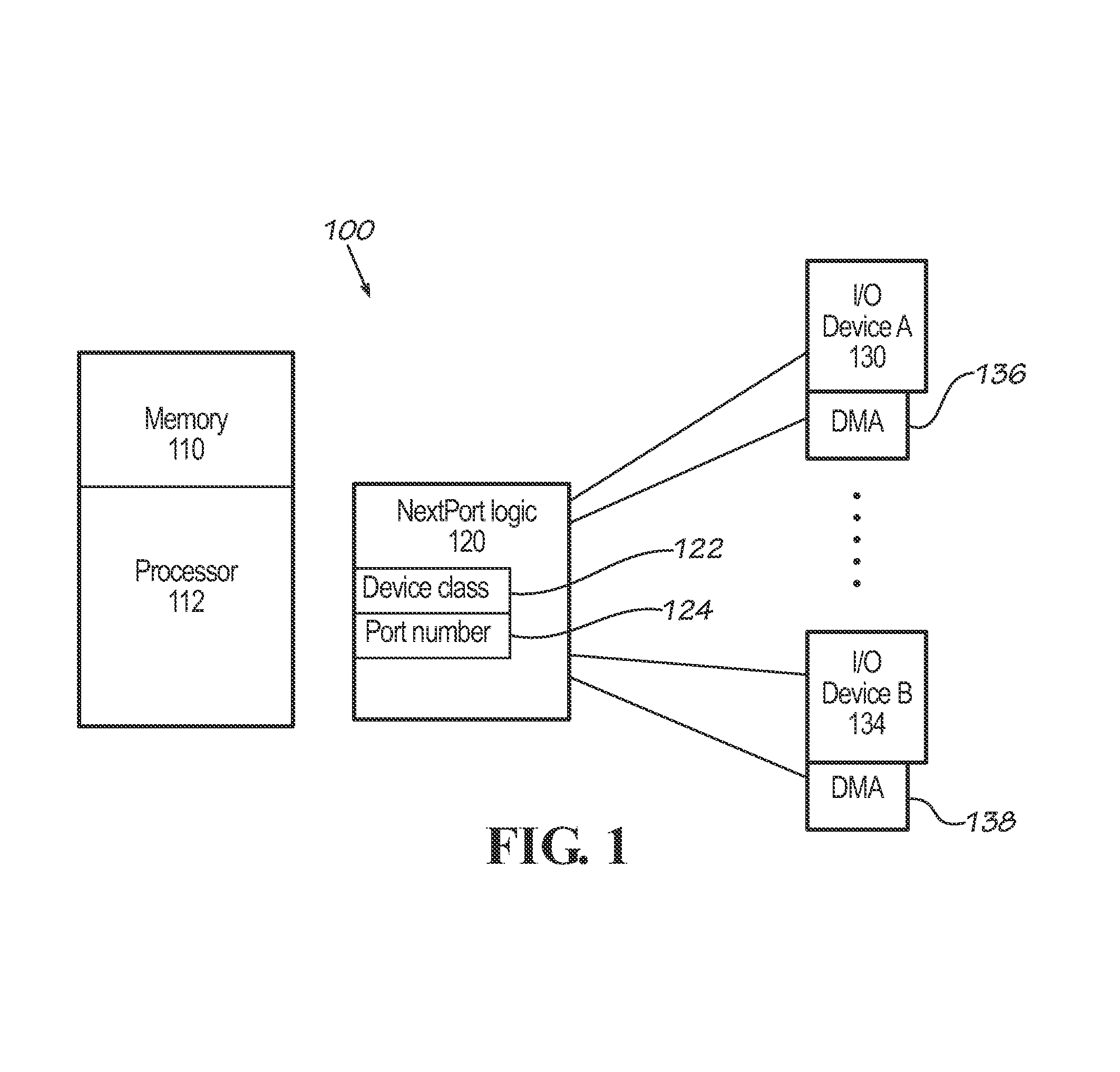

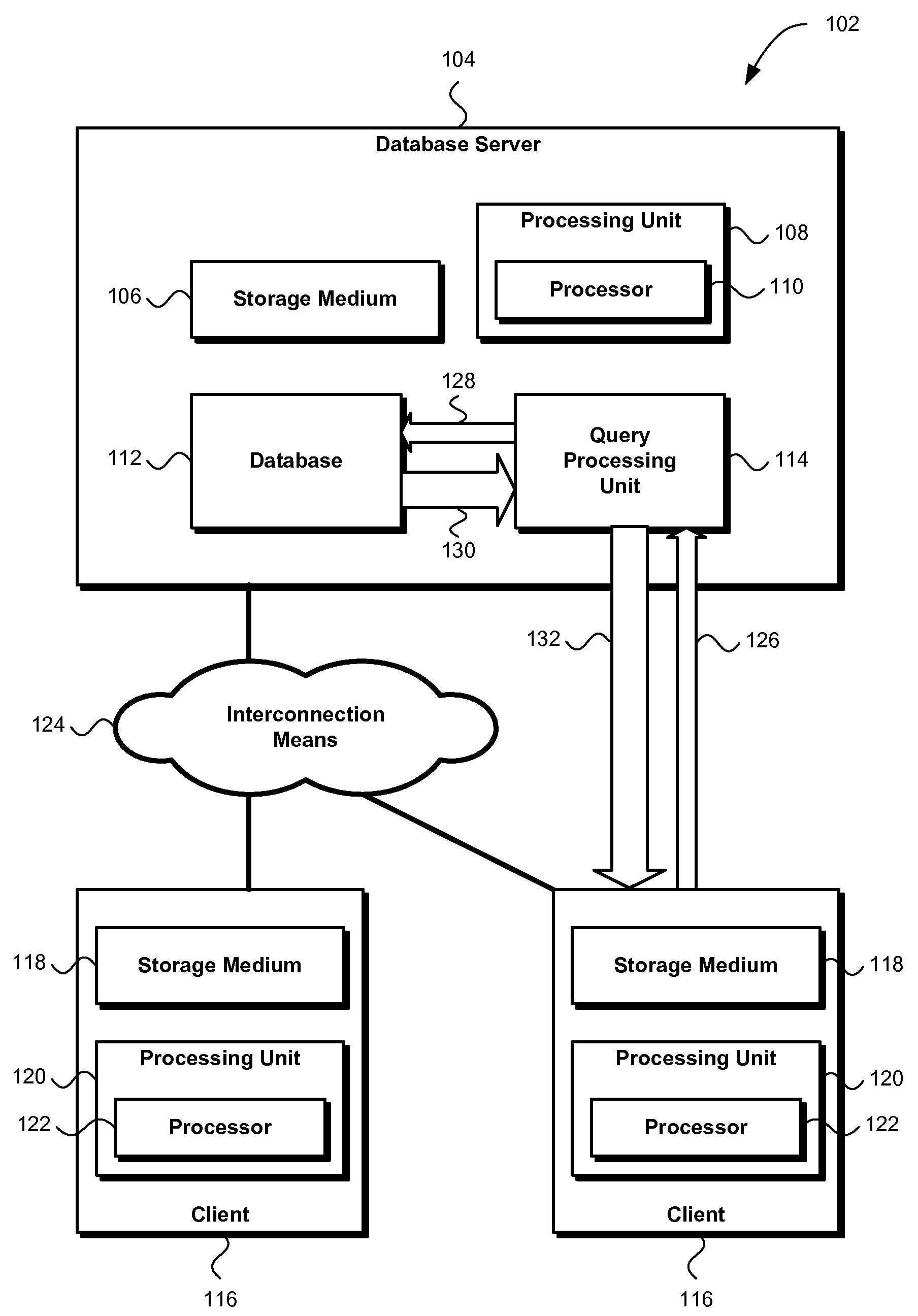

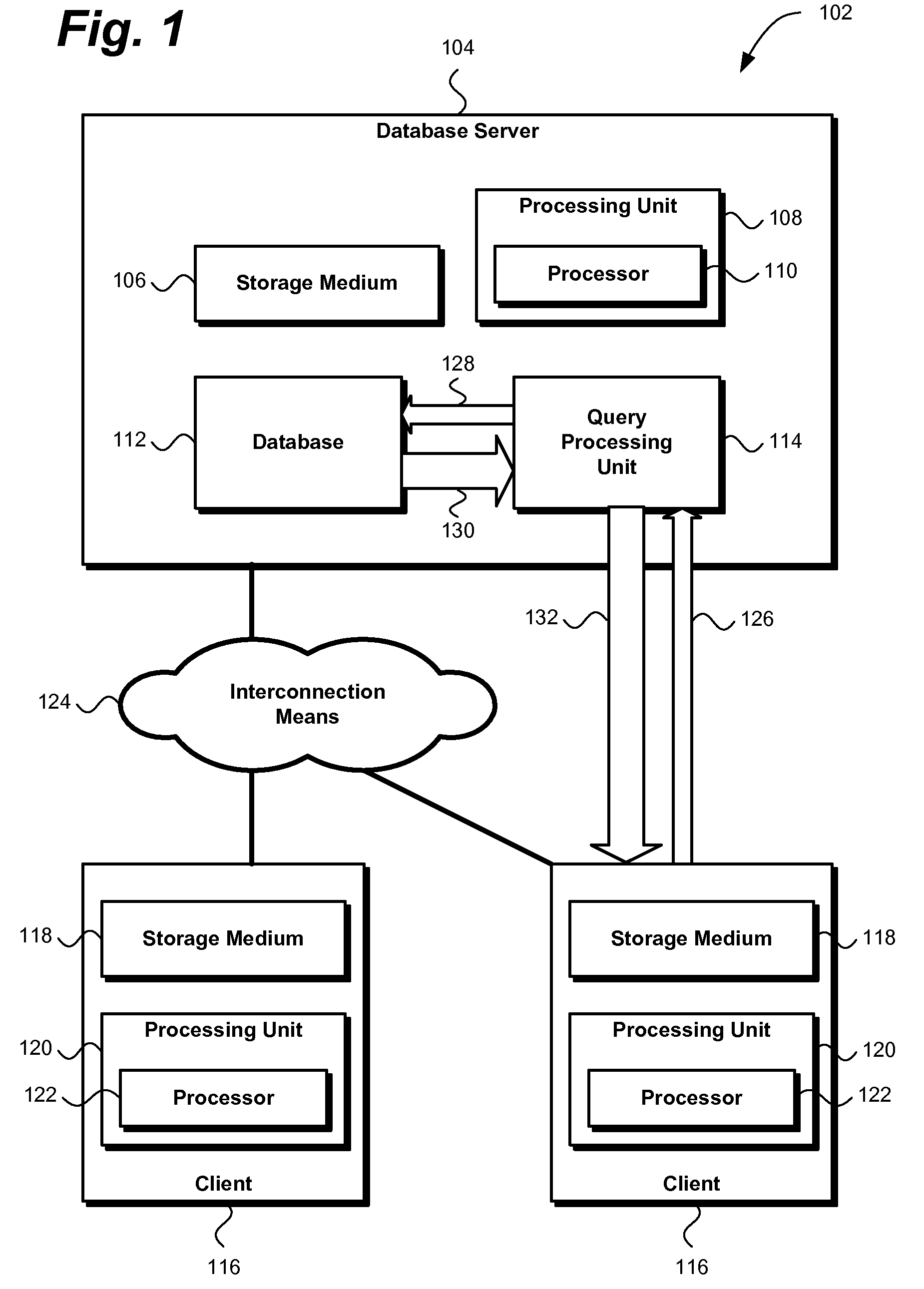

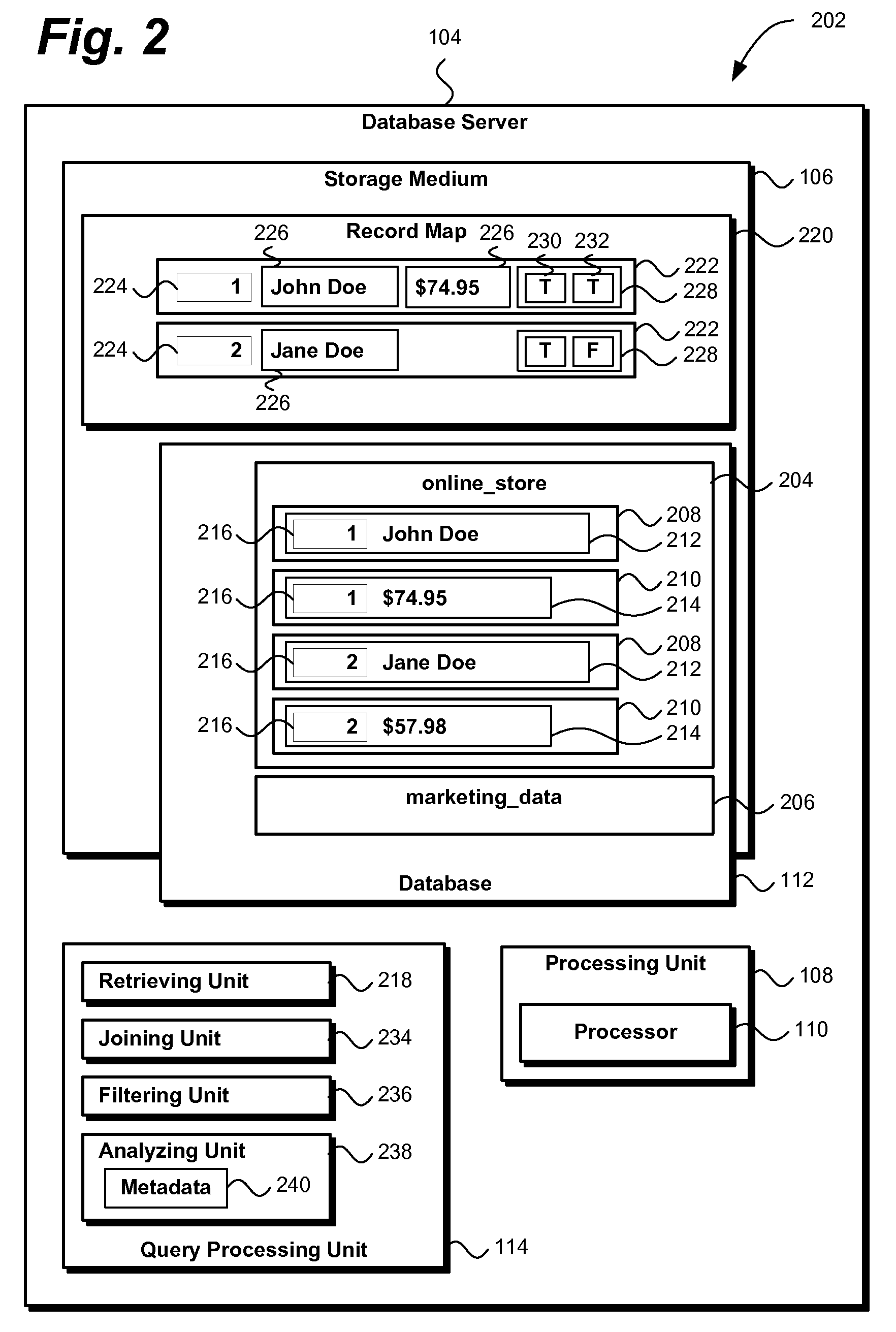

Performing an efficient implicit join of multiple mixed-type records

InactiveUS20100169307A1Efficiently joinReduce processingData processing applicationsDigital data processing detailsUnique identifierMixed type

A method, system, method and computer program product for retrieving data. Records are retrieved from a hierarchical database. The records are categorized into a plurality of record types. Each record comprises a unique identifier field. A record map contains zero or more entries. Each entry comprises an identifying value, data from at least one record and a set of Boolean flags. Each flag corresponds to a record type. A computer iterates over the retrieved records. Data from each record is stored at an entry in the record map having an identifying value equal to the value included in the unique identifier field of the record. Moreover, the flag in this entry which corresponds to the record type of the record is set. Inner joins and outer joins are then performed using the contents of the record map.

Owner:IBM CORP

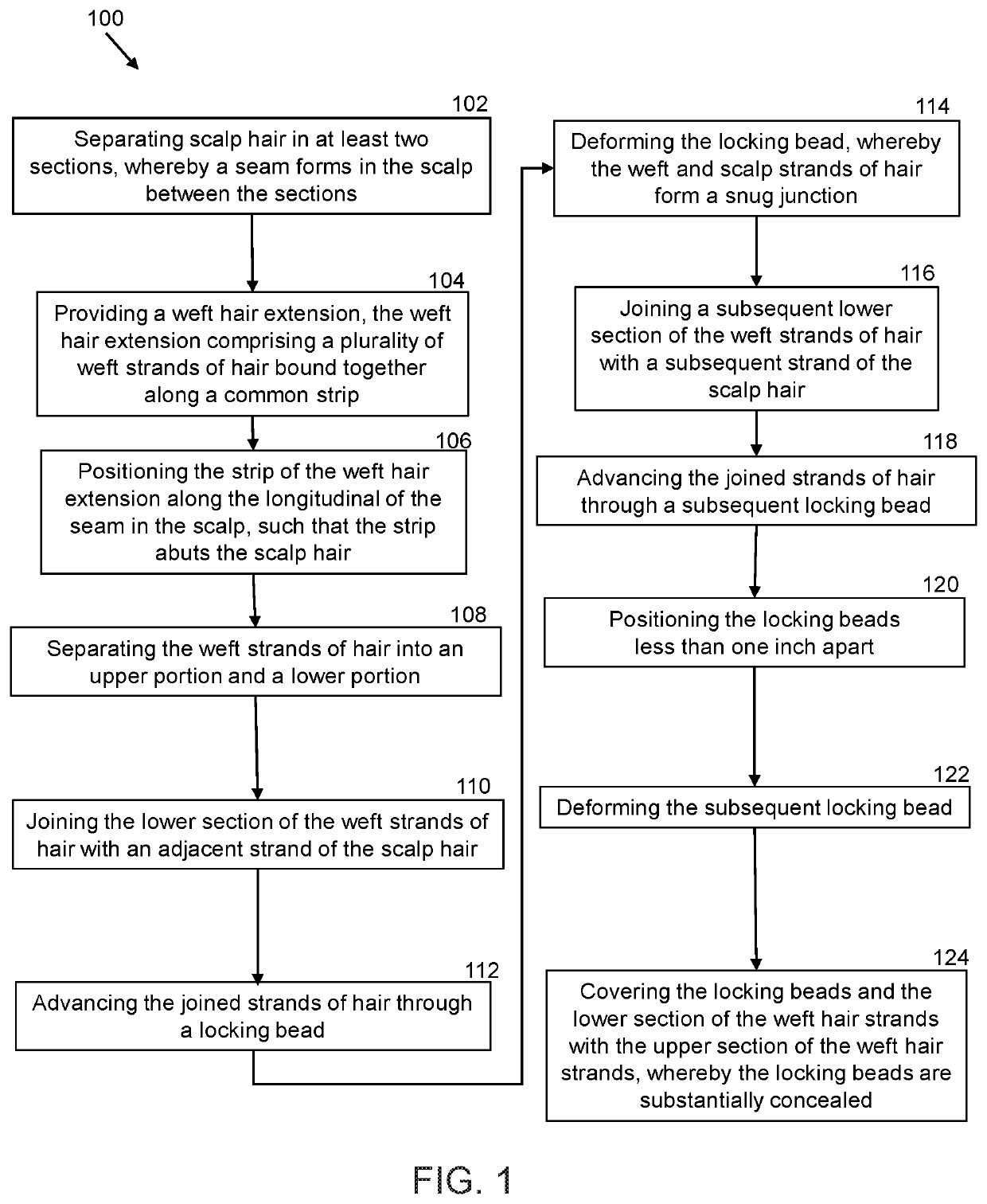

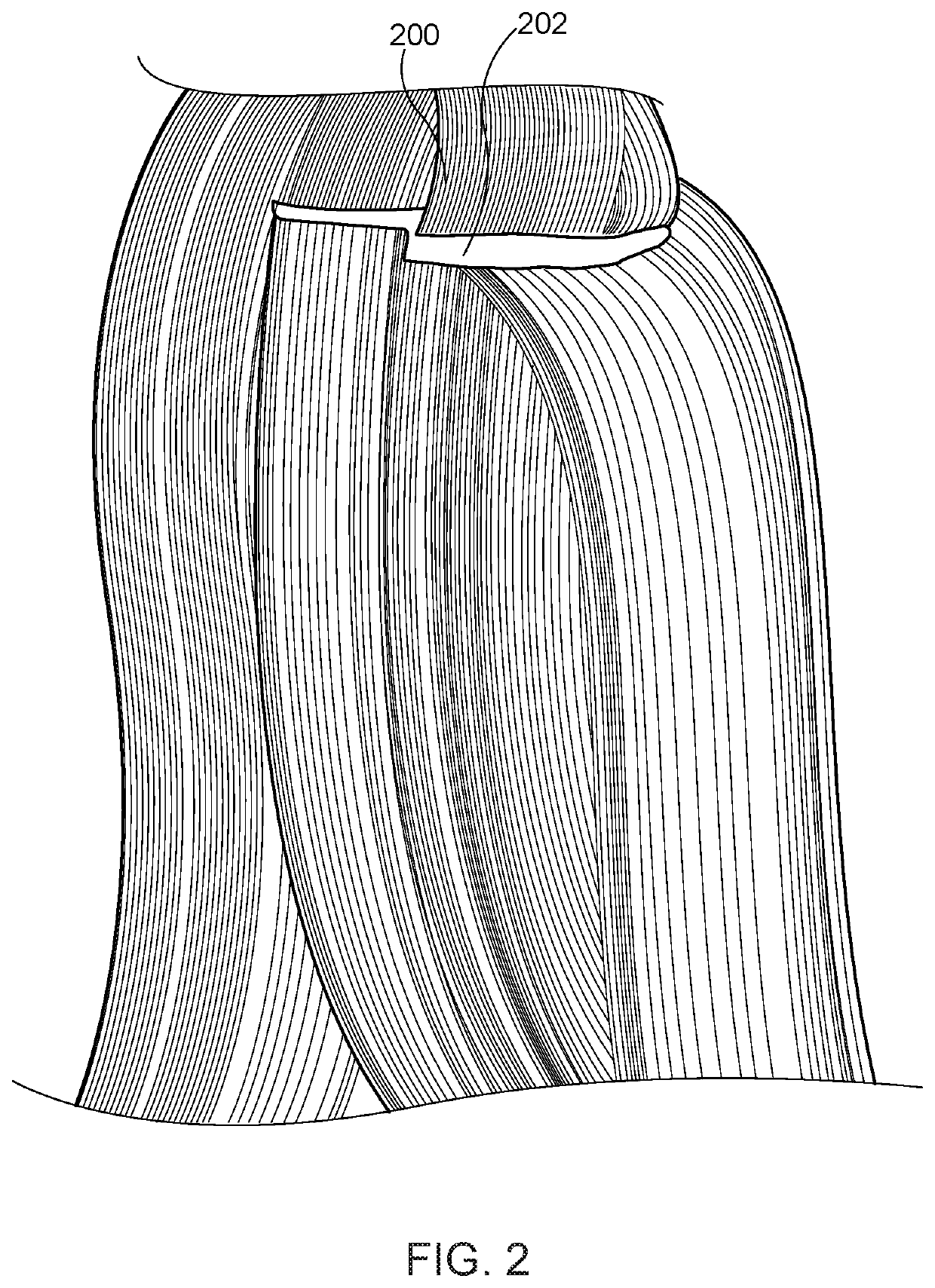

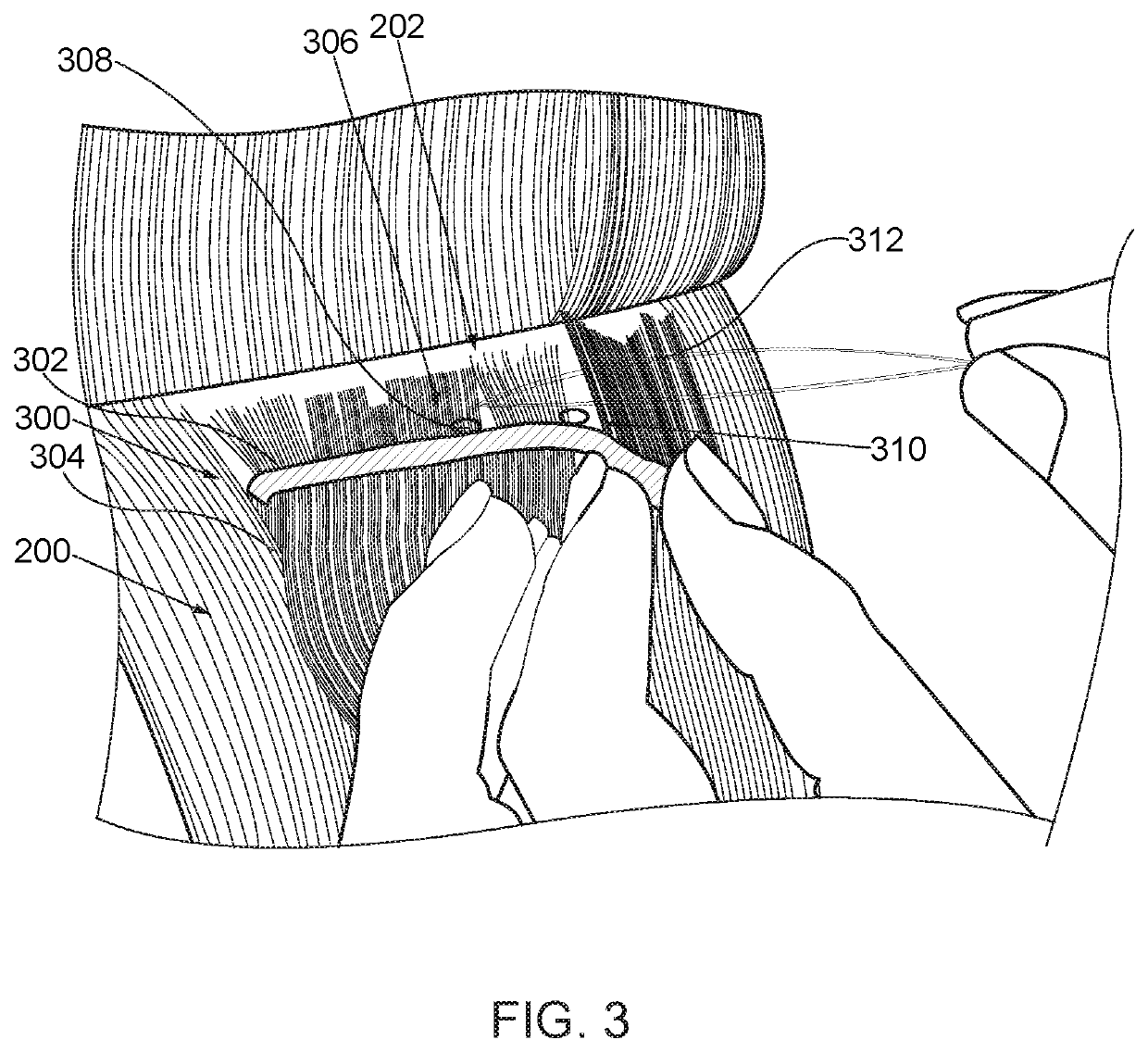

Method for applying a weft hair extension with concealed beads

InactiveUS20210227910A1Improves Structural IntegrityEfficiently joinedHair accessoriesToupeesScalp skinWeft yarn

A method for applying a weft hair extension with concealed beads utilizes a fresh set of silicone locking beads with weft hair extensions to maintain structural integrity, and then covers the locking beads with an upper section of the same weft hair extension to conceal the locking beads. The method: applies the weft hair strands along a seam in parted scalp hair; divides the weft hair strands between an upper and lower portion; weaves the lower portion of weft hair with a portion of adjacent scalp hair; pulls the combined weft and scalp hair strands through the locking bead; clamps the locking bead to secure the weft and scalp hair strands; spaces subsequent locking beads less than one inch apart; and covers the locking beads and the lower section of weft hair strands with the upper section of weft hair strands, such that the locking beads are substantially concealed.

Owner:SAWYER MICHELLE

Two tier brazing for joining copper tubes to manifolds

InactiveUS7293689B2Efficiently joinedEasy to joinHigh frequency current welding apparatusWelding/cutting media/materialsMelting temperatureElectroplating

Owner:UNITED TECH CORP

Optical device manufacturing method

ActiveUS20090233419A1Efficient preparationEfficiently joinedPolycrystalline material growthAfter-treatment detailsEngineeringHeat spreader

An optical device manufacturing method including the steps of: forming a groove with a depth corresponding to a finish thickness of the heat sink in a heat sink material at a position corresponding to an associated one of the streets sectioning the plurality of optical devices; joining the optical device layer of the optical device wafer to the heat sink material via a joining metal layer; cutting and dividing the optical device wafer along the streets into individual optical devices; sticking a protection member to the rear surface of the substrate of the optical device wafer; and grinding the rear surface of the heat sink material to expose the grooves to the rear surface to thereby divide the heat sink material into heat sinks corresponding to associated individual optical devices.

Owner:DISCO CORP

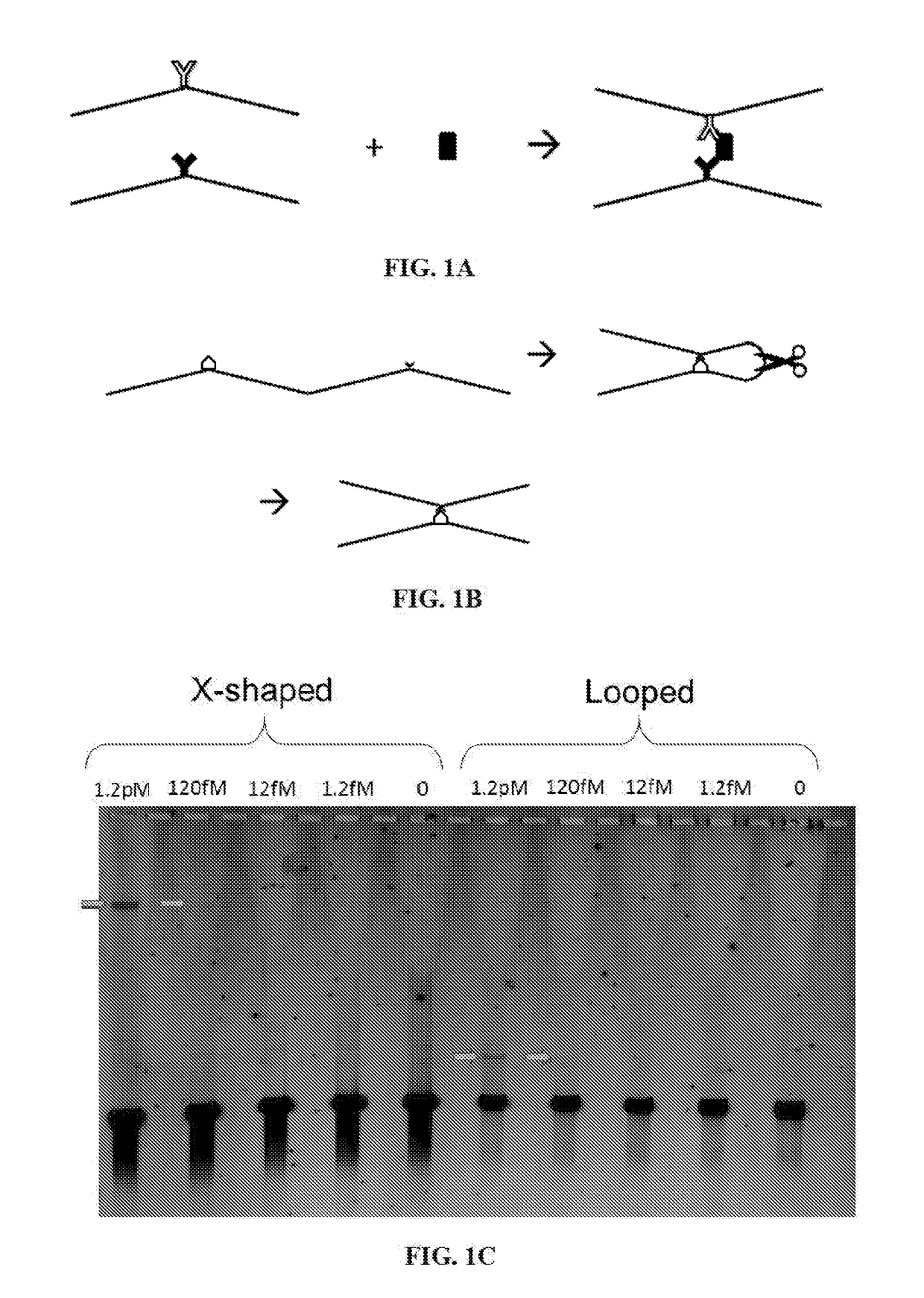

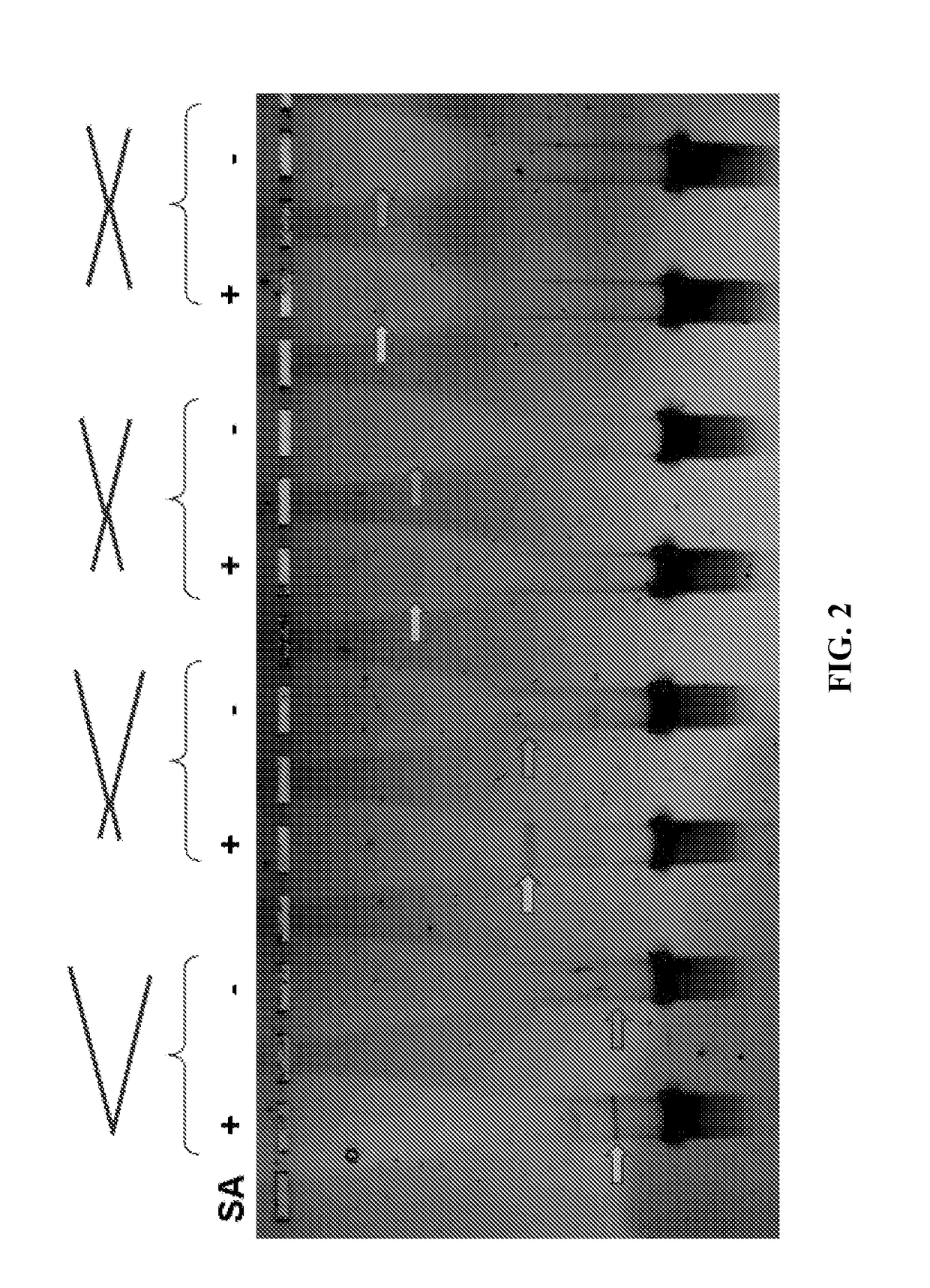

Method for detection of analytes via polymer complexes

PendingUS20190048409A1Readily detectLower noiseMicrobiological testing/measurementBiological testingEnvironmental chemistryPolymer

Provided herein are products and methods for detecting analytes using polymers that bind to such analytes and thereby undergo a conformational change or contribute to a newly formed complex.

Owner:CHILDRENS MEDICAL CENT CORP

Joint fitting between members and joint structure and joining method of upper and lower floor vertical frame members

A joint fitting 1 between members comprising a single bolt 4 having a length enabling it to be arranged vertically oriented bridging an upper floor vertical frame member and a lower floor vertical frame member at intervals along the axial direction. Joint hardware 7 is fastened to vertical frame members of the floors arranged at the upper floor side and lower floor side. Side opening grooves in the joint hardware 7 detachable receive the bolt. The attached joint hardware 7 is able to be fastened positioned along the longitudinal direction of the bolt 4. The joint hardware 7 is arranged at the upper and lower floors with the joint hardware being butted against vertical side surfaces of the vertical frame members 11 of the floors and fastened by drill screws 24 or other fasteners.

Owner:NIPPON STEEL CORP

Laser beam machine

InactiveUS7622694B2Efficiently joinedEasy constructionLaser beam welding apparatusLaser beamsOptical fiber

In this laser beam machine 1, while a pressing portion 9 of an optical guide member 6 presses a lid 13 against a body 12 of a container, the optical guide member 6 annularly guides a laser beam propagated through an optical fiber 4 and outputs it from the pressing portion 9. Thereby, an annular processing region of the body 12 and the lid 13 is entirely irradiated with the laser beam at one time and the lid 13 can be joined to the body 12, whereby improving the working efficiency. Such improvement in working efficiency shortens the processing time and improves the production yield. Furthermore, this laser beam machine 1 does not need to be separately provided with a rotating mechanism for laser beam scanning and a pressurizing mechanism for the body 12 and the lid 13, so that construction of the machine can be significantly simplified.

Owner:HAMAMATSU PHOTONICS KK

Semiconductor device having a primary chip with bumps in joined registration with bumps of a plurality of secondary chips

InactiveUS6838312B2Increase productivityEfficiently joinedSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

A semiconductor device having a plurality of semiconductor chips respectively joined to predetermined positions on a surface of a solid, and a frame holding the plurality of semiconductor chips in a relative positional relationship corresponding to joint positions on the surface of the solid. The solid may be another semiconductor chip or a wiring board. The plurality of semiconductor chips may be bonded to a surface, opposite to the surface, of the solid, of the frame. The plurality of semiconductor chips may be respectively fitted in through holes formed in the frame.

Owner:ACHLYS TECH INC

Connectors for concrete footer frames

InactiveUS20060163444A1Low production costEasy to useMouldsForms/shuttering/falseworksEngineeringElectrical and Electronics engineering

A stamped, sheet metal, form connector connects two concrete form boards together in end-to-end abutting relationship in one embodiment. In another embodiment, the connector connects two form boards in overlapping relationship. In a third and fourth embodiment, the connector connects two form boards at an inside and outside corner, respectively. Double headed nails fasten the connector to the form boards, allowing for easy removal without damage to the forms. The connector is inexpensive to manufacture, and is simple and convenient to use.

Owner:ALBANO ROCCHINO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com