Tank outlet fitting with flange

a technology of outlet fittings and fittings, which is applied in the direction of pipes, pipes/joints/fittings, packaging, etc., can solve the problem of adding significant costs to this necessary means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

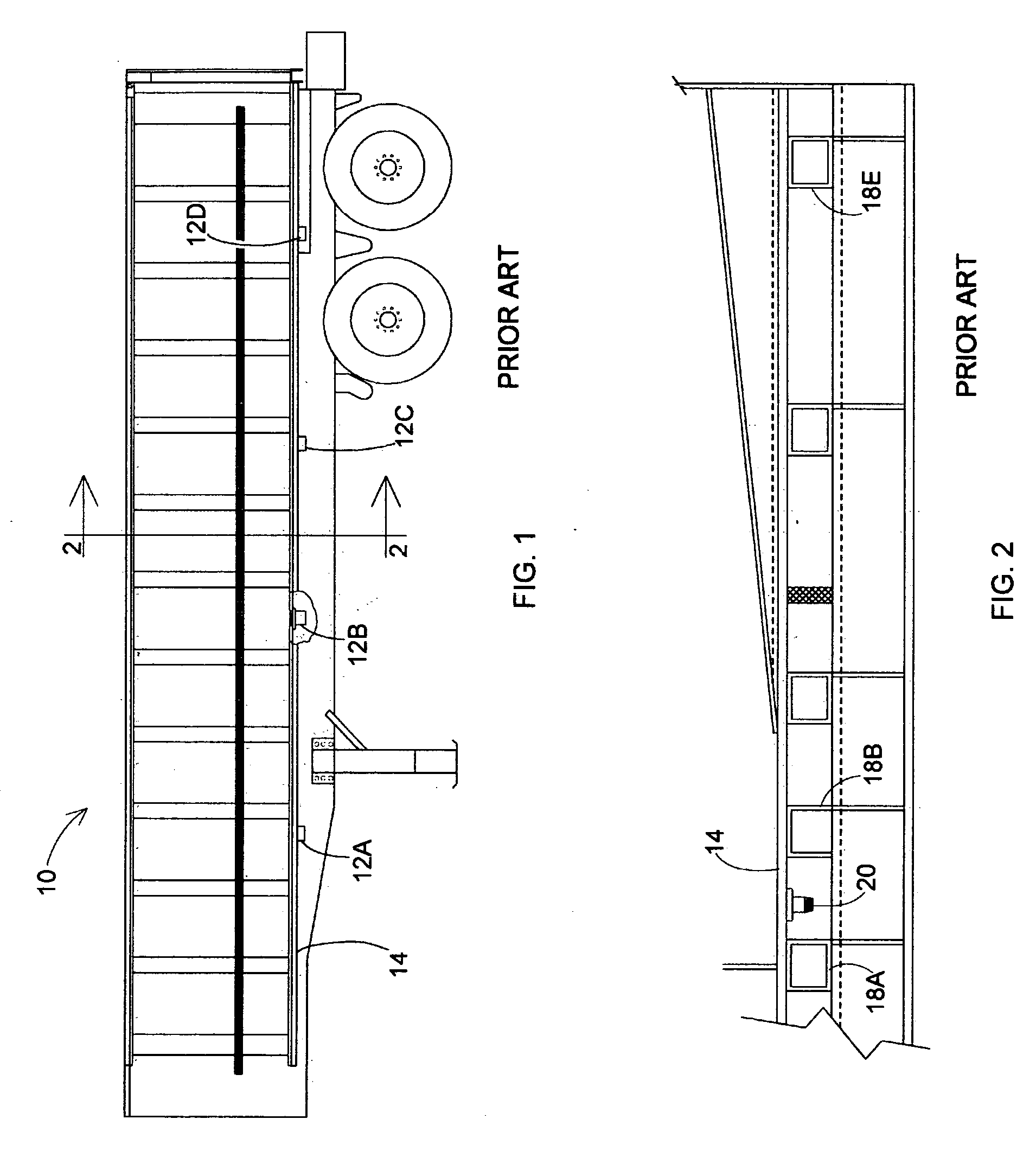

[0020] Referring now to the drawing, and to FIG. 1 in particular, there is depicted the trailer component 10 of a standard tractor trailer rig, used for over the road liquid transport. The static trailer 10, depicts three sites, along the bottom wall 14, at which such sites, outflow orifices, 12A, B, and C, are functionally positioned. It is within the skill of the art of trailer building, to provide as many such tank bottom outlets as the customer requires. The fitting is useful with any cargo of fluidized nature, which can by gravity also, dump its contents via an outlet hose connected thereto (not shown). As indicated, dependent on the capacity and cargo viscosity, there may be a number of outlet ports on the tank using the present invention.

[0021] In the broken away, vertical sectional view of FIG. 2, the bottom wall 14 of an elongate trailer is seen, also being provided with underlying, five hollow transverse beams, 18 A, B, C, D, and E, which beams bolster trailer bottom wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com