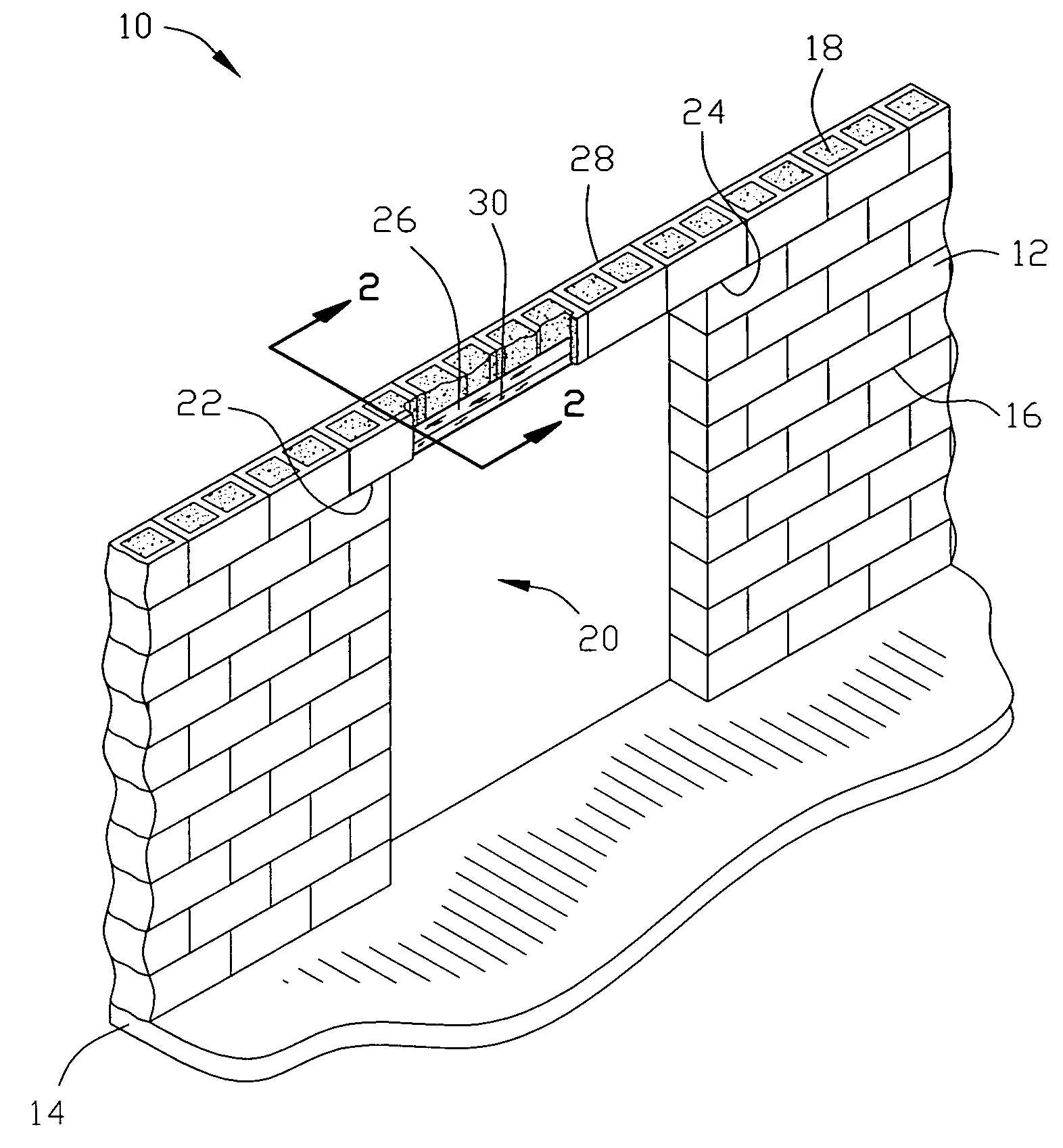

Lintel

a technology of lintel and lintel body, which is applied in the field of lintel, can solve the problems of inconvenient transportation of concrete lintels over large distances, limited length of lintel, and inability to meet the needs of construction, so as to increase the bonding strength, and increase the load capacity of lintel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

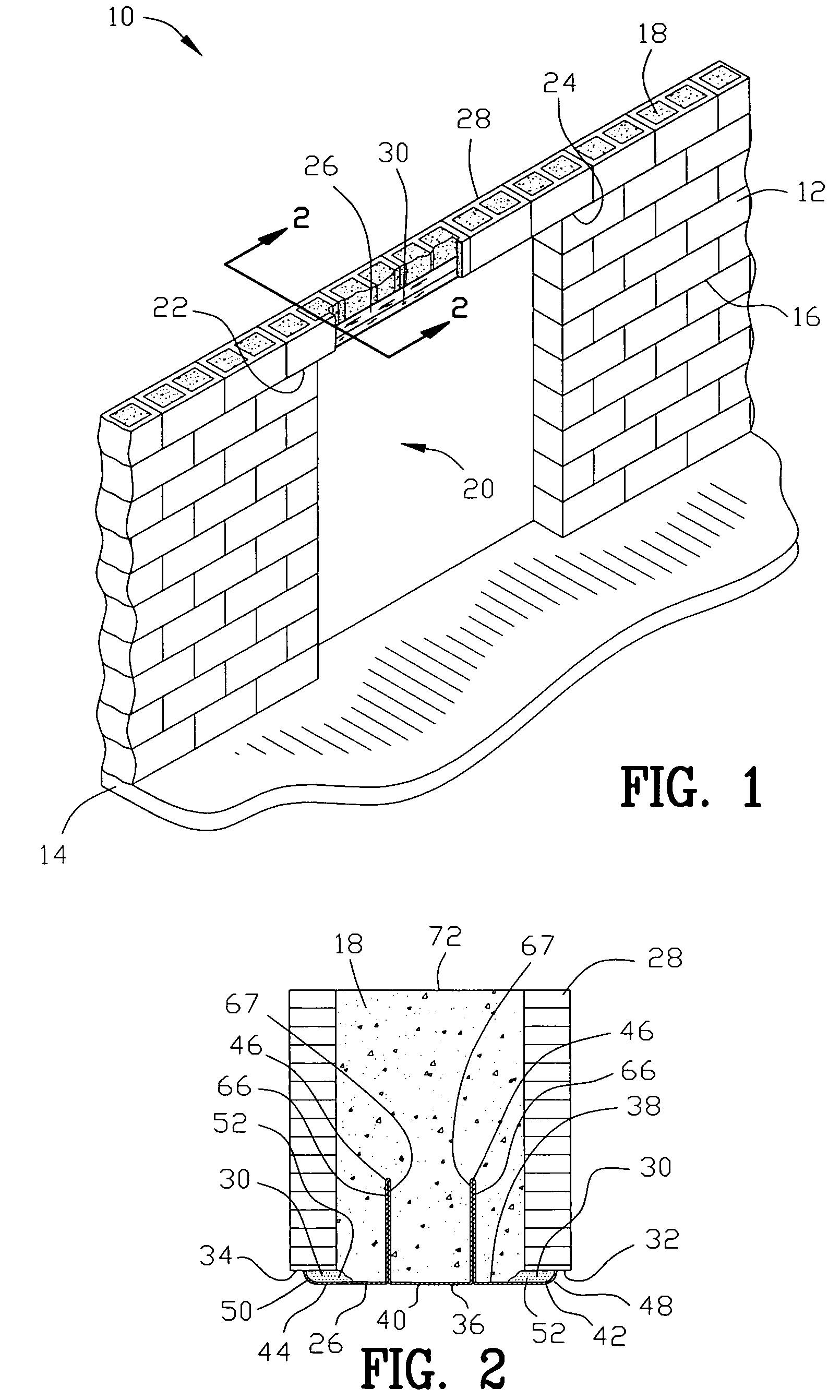

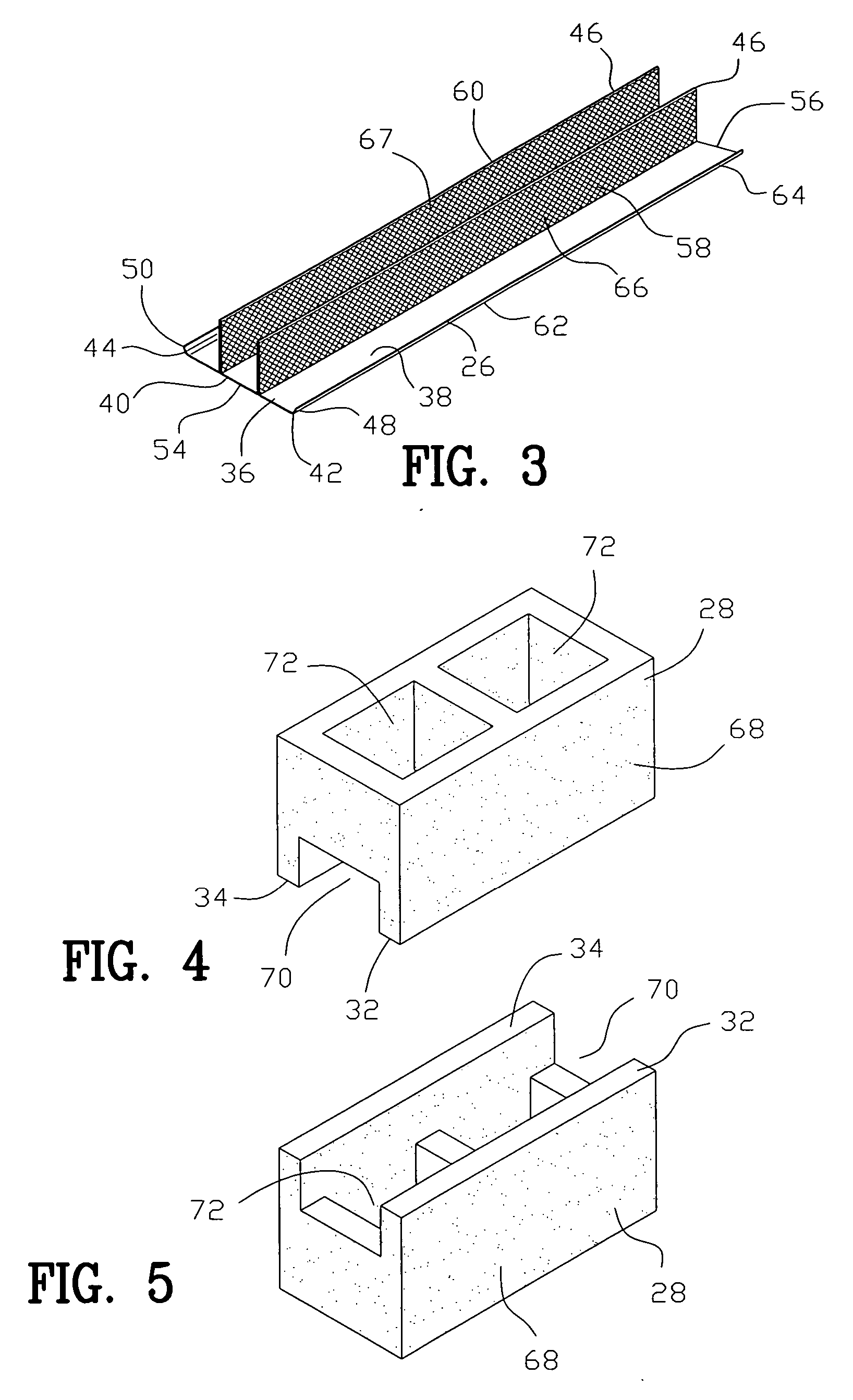

[0063]FIGS. 6-11 illustrate a second embodiment for the improved invention 10. The riser has a proximal end 74 and a distal end 76. The proximal end 74 is secured to the top portion 38 of the elongated base 36. The distal end includes an enlarged flange 78 for increasing the load capacity of the lintel 26. Upon placement of the course of blocks 28 on the lintel 26, the elongated base 36 and first and second dam 48 and 50 will be in tension. The riser have a portion in tension and a portion under compression. The enlarged flange 78 is in compression. The enlarged flange 78 may contain the texture surface 66 including a series of grooves 67. The grooves 67 provide additional surface area for the grout 18 to bond to the lintel 26.

[0064] The cells 72 are filled with grout 18 to encase the lintel 26 and enlarged flange 78. After the grout has cured and a load is placed upon the lintel 26, the enlarged flange 78 is placed under a tensile force. The grooves 67 prevent movement of the enlar...

third embodiment

[0071]FIGS. 12-14 illustrate a third embodiment for the improved invention 10. A first guide riser 104 and a second guide riser 106 extend from the top portion 38 of the elongated base 36. The first and second guide risers 104 and 106 are disposed in a spaced apart parallel relationship between the first and second dams 48 and 50 for aligning the course of blocks 28 on the lintel 26. The first and second guide risers 104 and 106 are centered in relation to the width of the elongated base 26. The distance between the first and second guide risers 104 and 106 is commensurate with the width of the cell 72 such that upon placing the course of blocks 28 upon the lintel 26, the first and second guide risers 104 and 106 extend into the cell 72 to prevent horizontal movement of the course of blocks 28 relative to the lintel 26.

[0072]FIG. 12 is a sectional view of one of the course of blocks 28 and the lintel 26. In FIG. 12 the first and second guide risers 104 and 106 are disposed with a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com