Double-walled flexible dispenser sump connection system

a flexible dispenser and connection system technology, applied in the direction of functional valve types, liquid transfer devices, couplings, etc., can solve the problems of fuel leakage into the groundoil surrounding the dispenser sump and/or into the atmosphere, and the cost of retrofitting the existing sumps to bring them into compliance can be substantial, so as to prevent any fuel leakage, protect the effect of the dispenser, and reduce the cost per dispenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

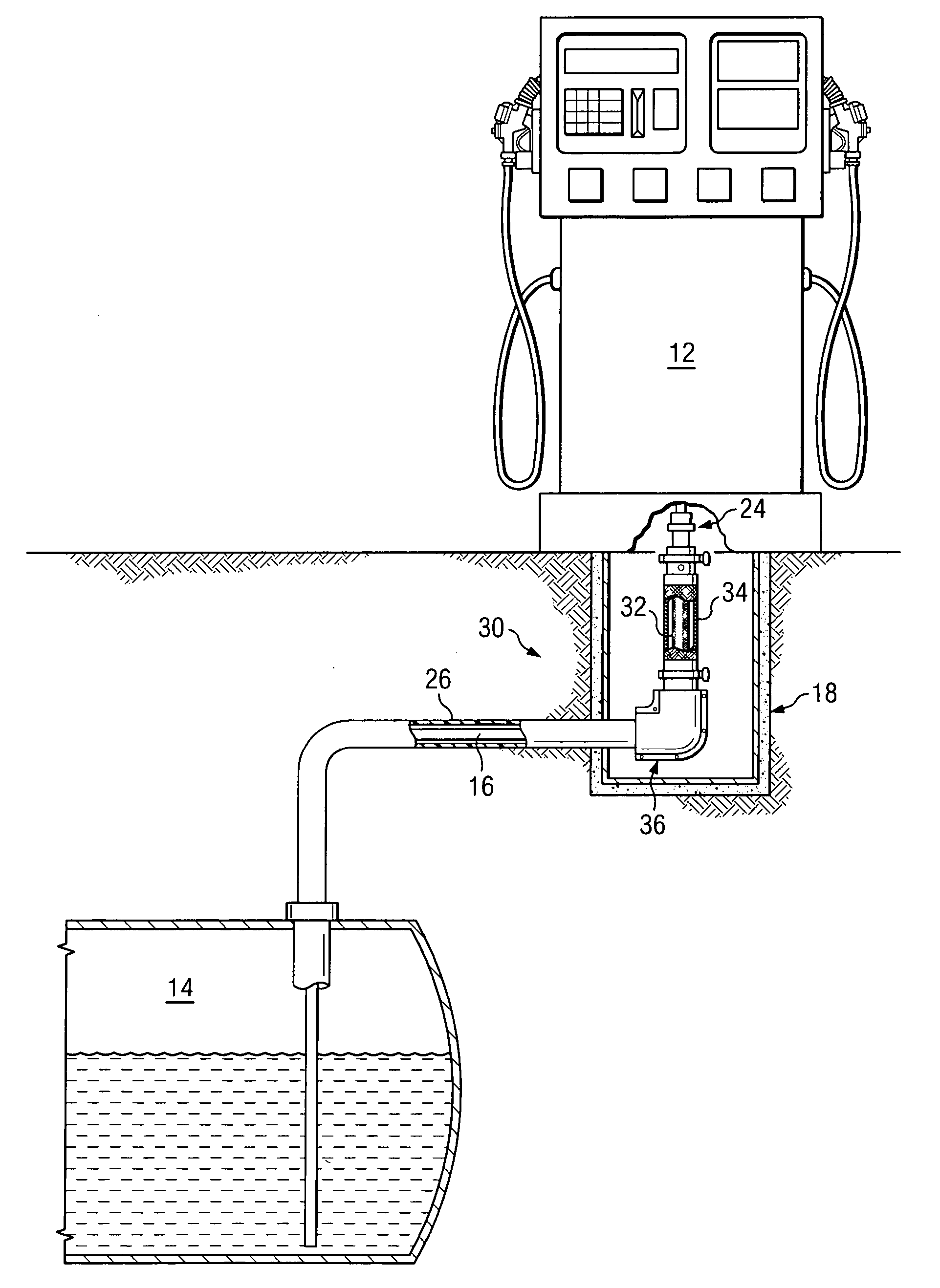

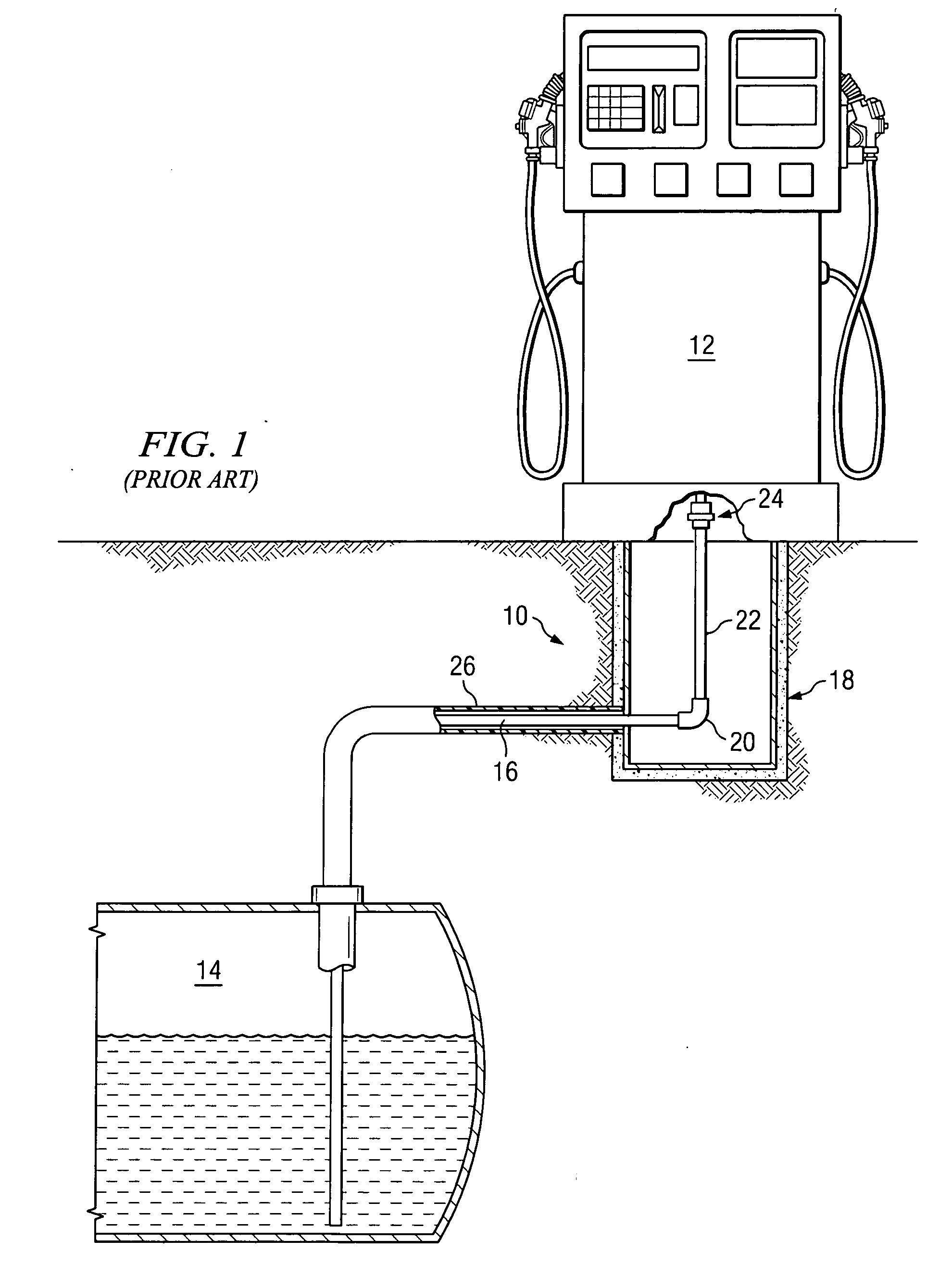

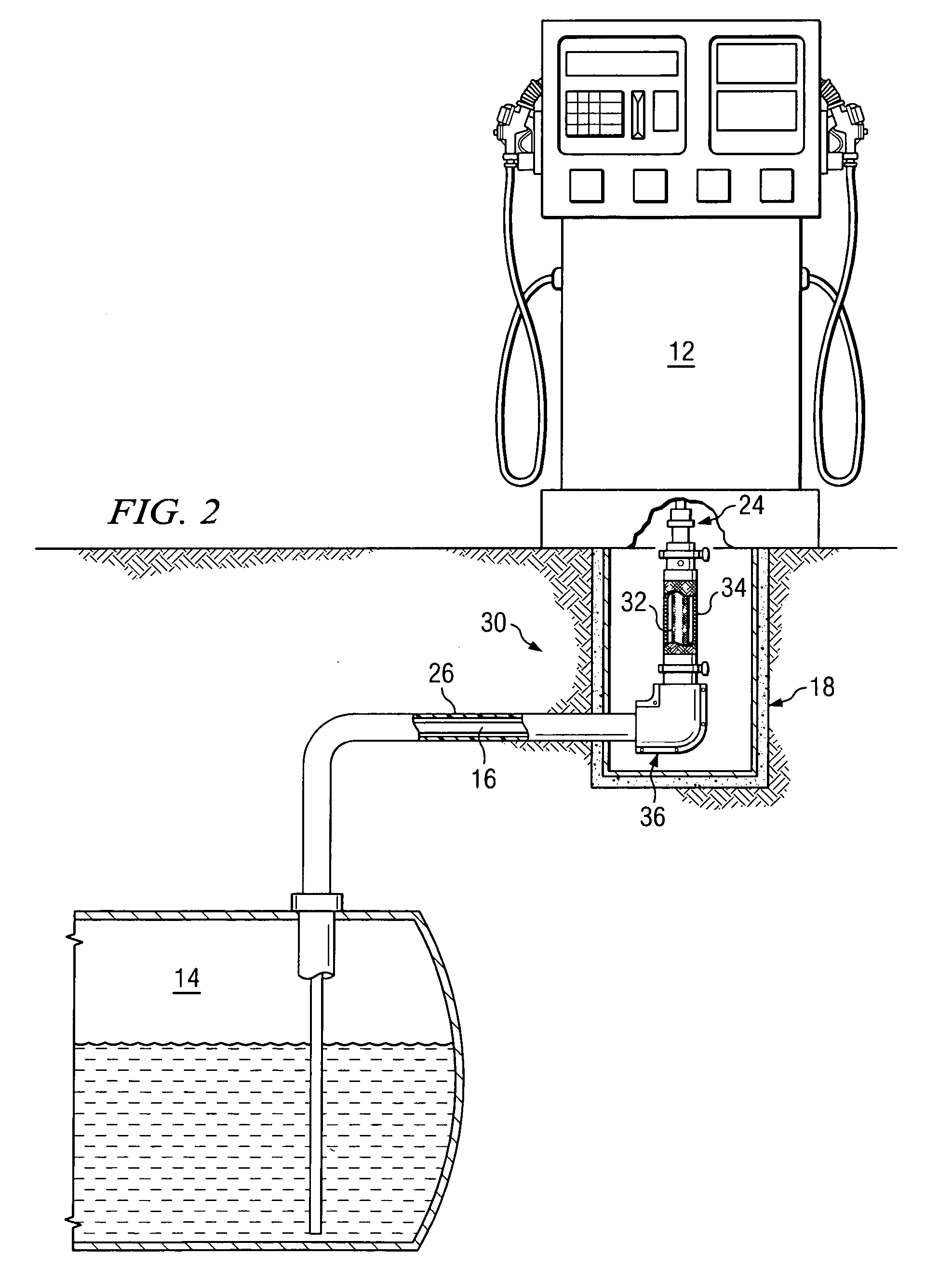

[0013] Referring now to the Drawings, and particularly to FIGS. 2, 3, and 4 thereof, there is shown the dispenser sump connection system 30 of the present invention. An inner flexible connector 32 is connected to the inner pipe 16 for completing the conveyance of fuel to the dispenser 12. An outer flexible connector 34 is installed over and completely encloses the inner flexible connector 32. The lower end of the outer flexible connector 34 is connected in fluid communication with the outer pipe 26. The upper end of the outer flexible connector 34 is connected to the shear valve 24 thereby completing the containment of any leaks from either the inner pipe 16 and the inner flexible connector 32. The interstitial space between the outer flexible connector 34 and the inner flexible connector 32 is either pressurized or vacuum sealed thereby preventing any fuel leakage into the dispenser sump 18. The flexible connectors 32 and 34 used in conjunction with the present invention are descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com