Turnover oil leakage preventing vent valve for fuel tank

A ventilation valve and anti-overturning technology, applied in the direction of fuel tank safety measures, lift valves, valve details, etc., can solve the problems of unsuitable small civil helicopter fuel systems, secondary fuel leakage, and failure to reset, so as to achieve good practical value and prevent Effects of fuel leakage and overall weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with the following examples.

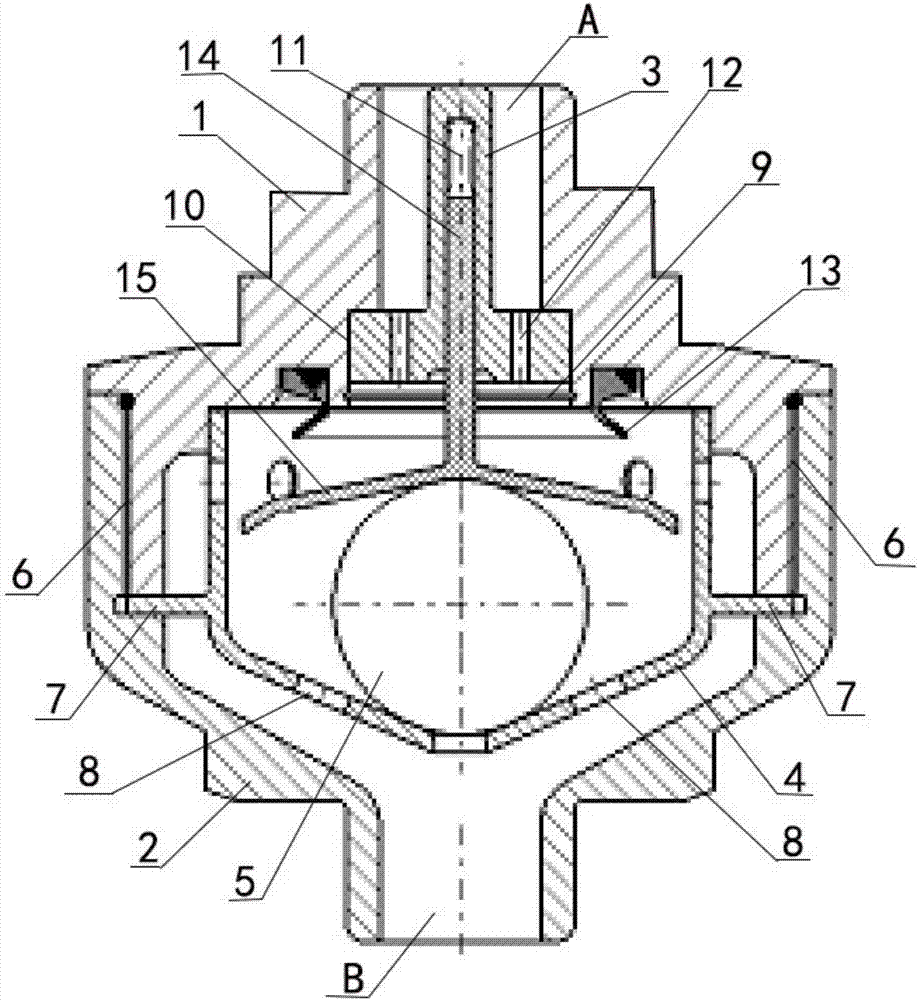

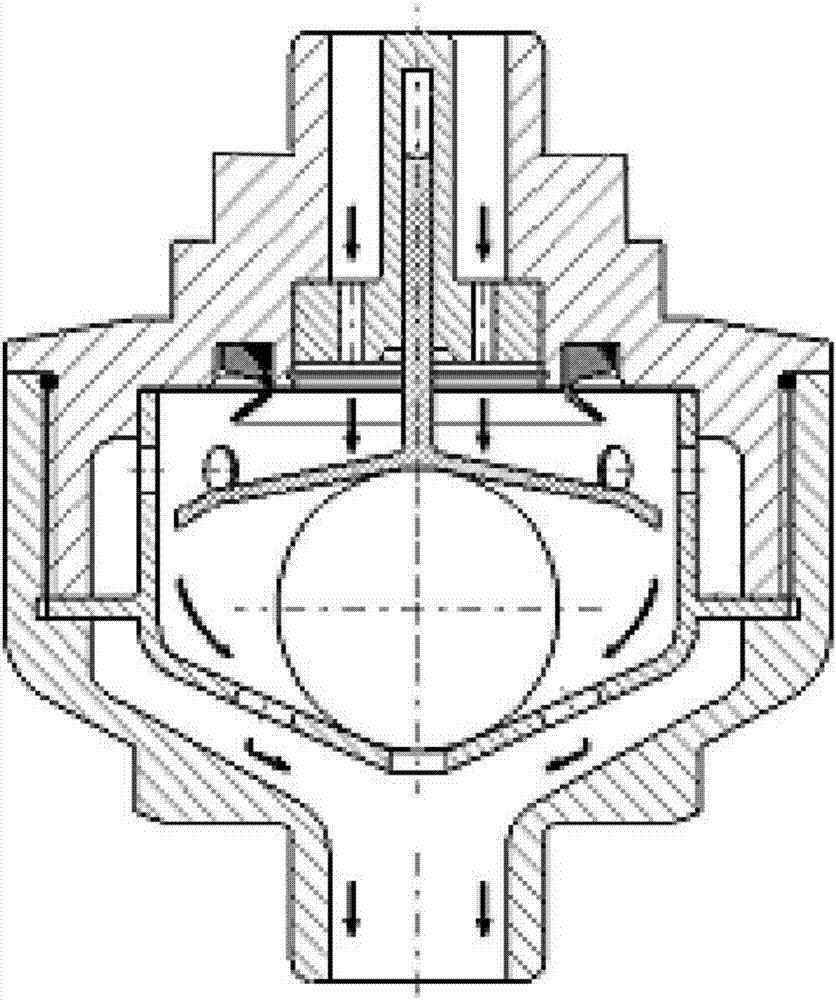

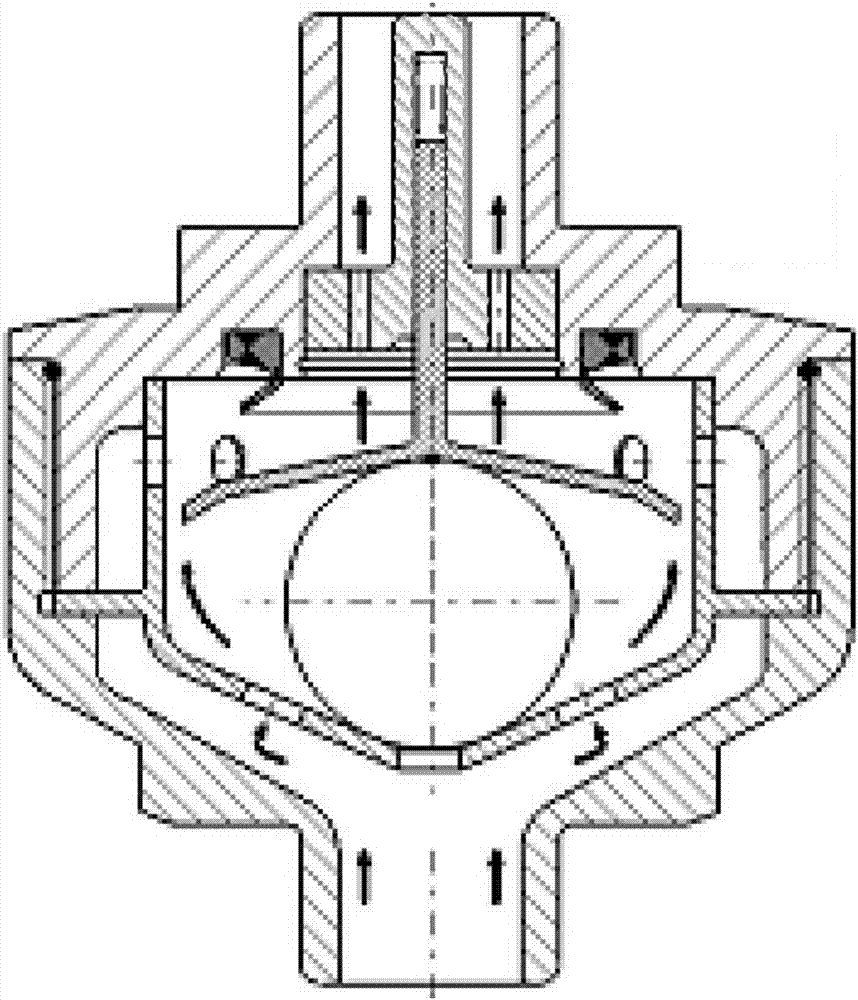

[0024] See figure 1 The shown one is used for the anti-overturning oil leakage vent valve of the fuel tank, including the intake end housing 1, the exhaust end housing 2, the guide seat 3, the cup body 4, the fork and the steel ball 5, and the The gas end housing 1 communicates with the atmosphere, and the exhaust end housing 2 communicates with the fuel tank. The intake end shell 1 and the exhaust end shell 2 are screwed together through threaded fit 6, and the cup body 4 is engaged between the intake end shell 1 and the exhaust end shell 2 through the ring plate 7, and the cup body 4 At least two first air inlet holes 8 are opened at the bottom. The guide seat 3 is fixed in the groove 10 of the intake end housing 1 through the retaining ring 9, and the guide seat 3 is provided with a guide hole 11 and a second air intake hole 12 located on both sides of the guide hole 11. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com