Cooling plate module

a technology of cooling plate and module, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of reducing the space utilization rate of cooling plate modules, affecting the compact trend of computers, and the bulky i>a /i> formed, etc., and achieves the effect of reducing space and minimizing the layout of cooling plate modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

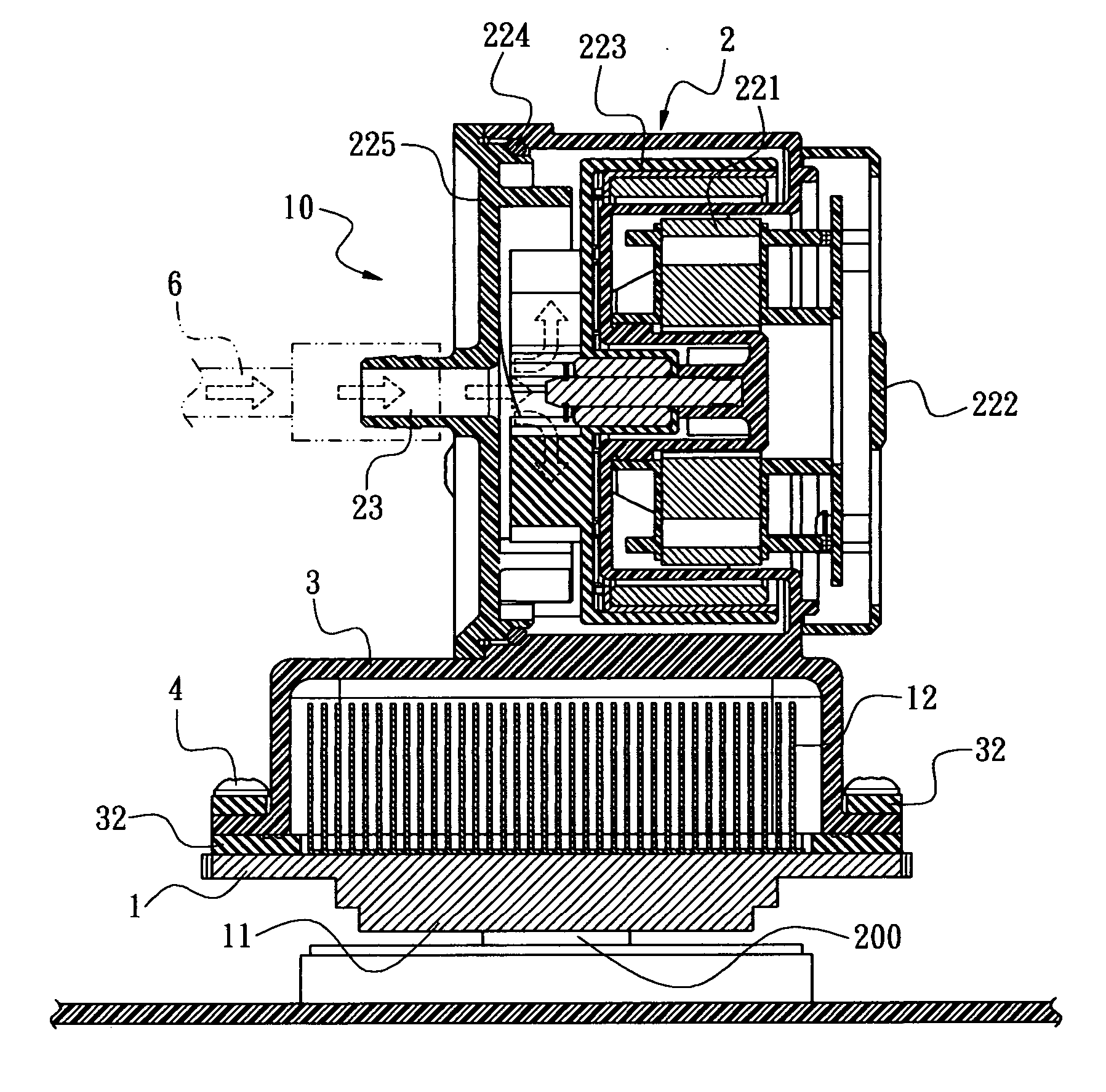

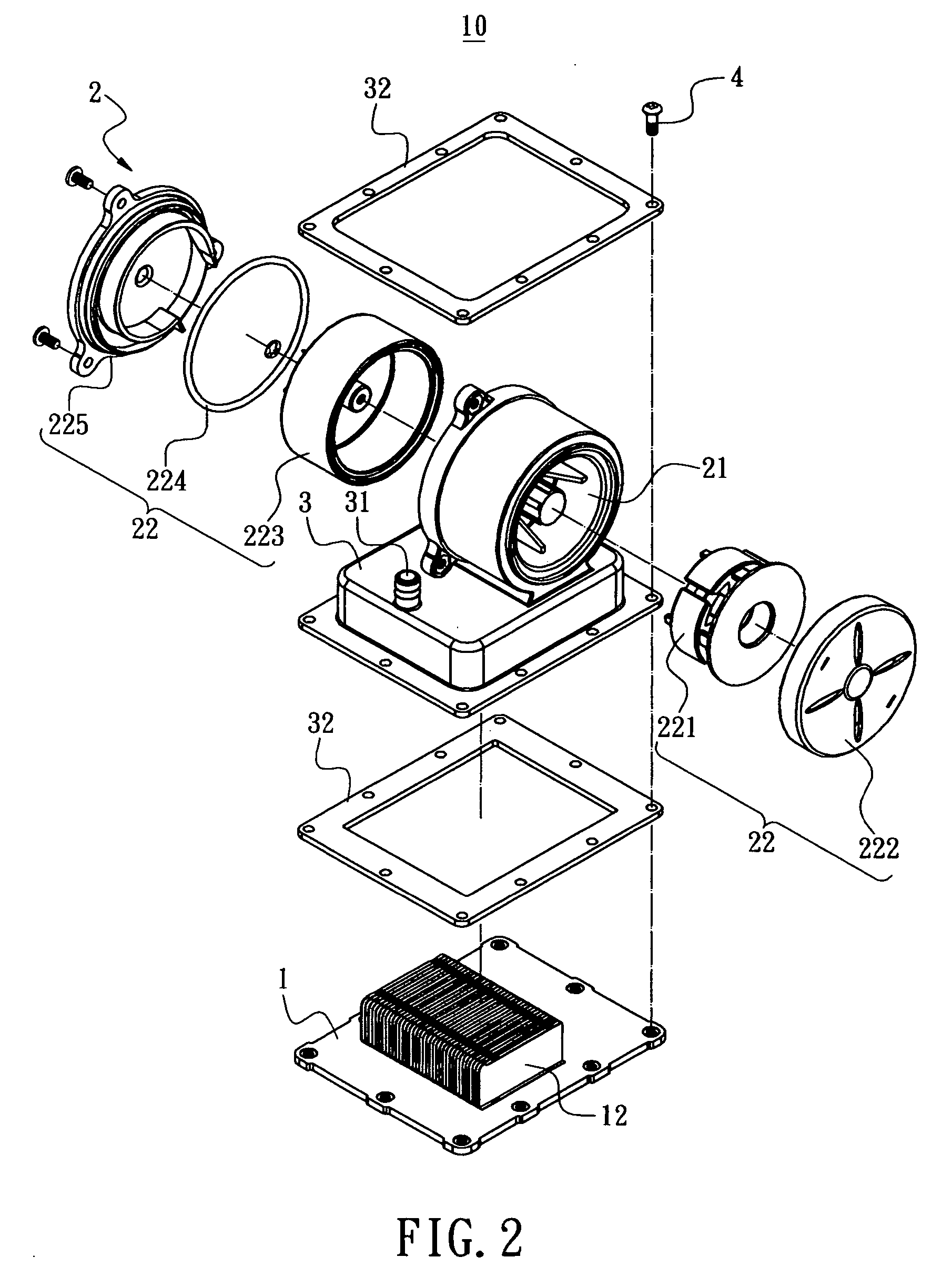

[0022] With reference to FIGS. 2 and 6, the cooling plate module 10 according to the present invention is applied to a liquid cooling cyclic mechanism 100, which is used for the heat dissipation of a CPU 200 and composed of the cooling plate module 10 and a water tank module 20 connected with the cooling plate module 10 through ducts. The cooling plate module 10 comprises a cooling plate 1 and a liquid driving module 2. The cooling plate 1 comprises a heat absorbing face 11 on bottom thereof and being in contact with a heat source. A plurality of heat-dissipating plates 12 are formed on top face of the cooling plate 1 and can be arranged in longitudinal or transverse manner. A runner is defined between the plurality of heat-dissipating plates 12 and forms a closed loop.

[0023] With reference to FIGS. 2, 3 and 4, the liquid driving module 2 comprises an accommodation chamber 21 and a liquid driving unit 22 located in the accommodation chamber 21 and used to driving the cool liquid. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com