Adjustable support bracket for concrete reinforcing bars

a technology of reinforcement bar and support bracket, which is applied in the direction of paving reinforcements, auxiliaries of forms/shuttering/falseworks, and ways, etc., can solve the problems of weakened concrete structure lacking the ability to properly dissipate forces, requiring additional labor and some degree of skill within the form, and requiring expensive time and labor. , to achieve the effect of simple and cost-effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

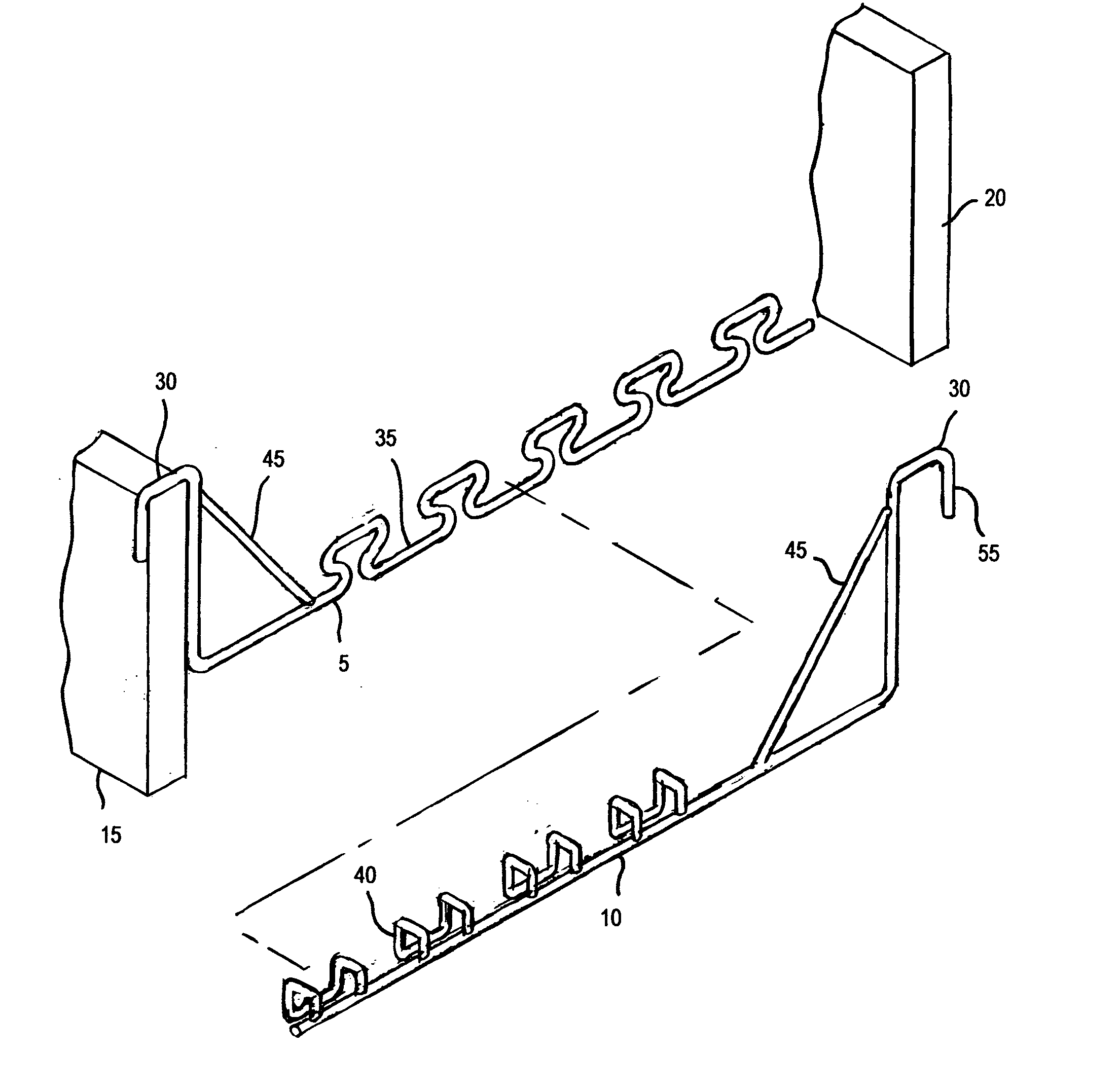

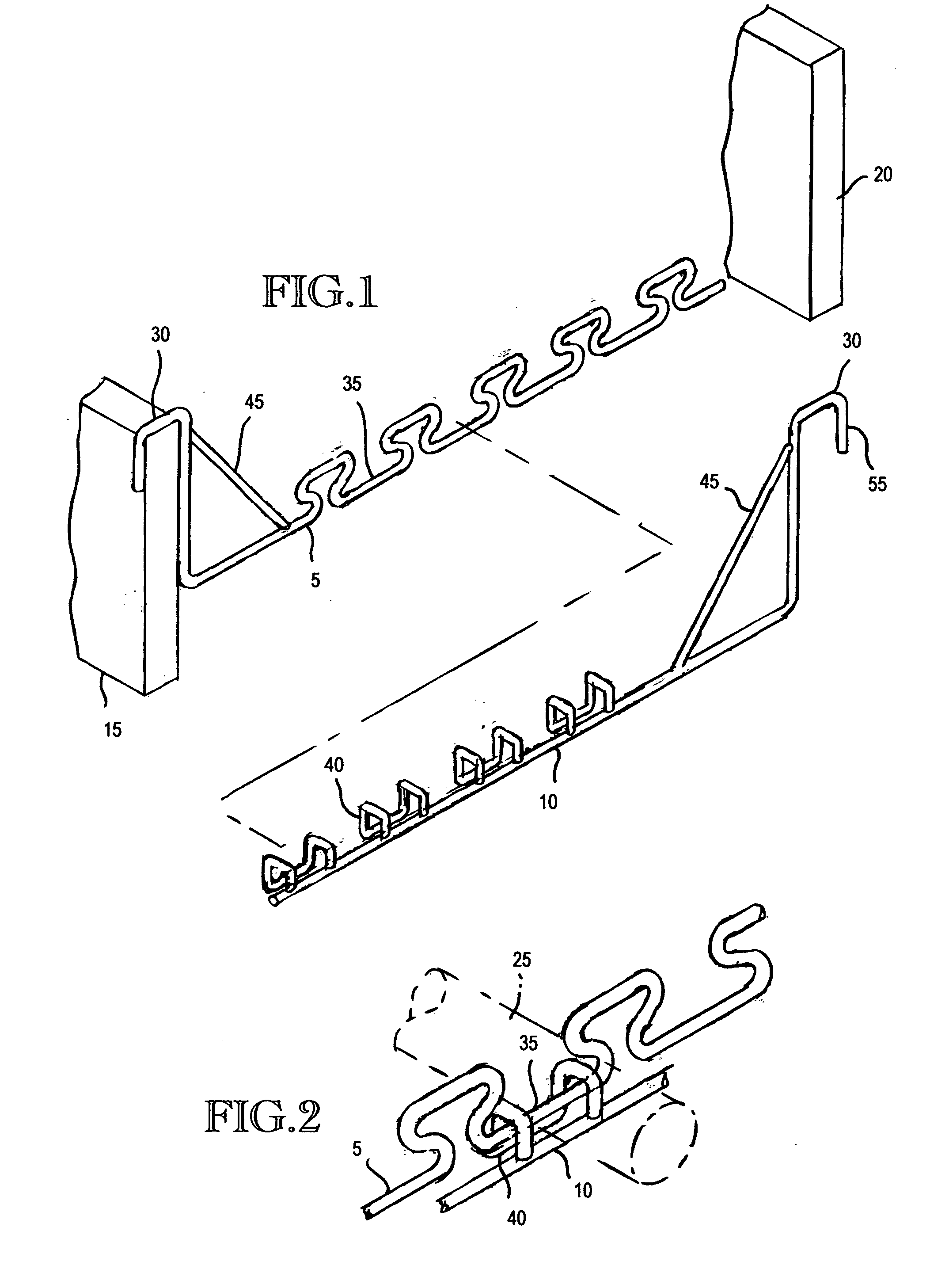

[0039] the present invention is shown in FIG. 2. In this embodiment the first member 5 and second member 10 are also formed of medium steel wire that is bent to form the recessions 35 and longitudinally disposed projections 40. The projections 40 are angled or curved toward the corresponding recessions 35 such that the first member 5 and the second member 10 can be overlapped to engage each other at any one of a plurality of locations along a common longitudinal axis. The first member 5 is further comprised of a plurality of apertures 70, and the second member 10 is further comprised of a plurality of secondary longitudinally disposed projections 75 that are angled or curved toward the corresponding apertures 70, whereby the first member 5 and the second member 10 are simply aligned on a common longitudinal axis, overlapping to form a desired length of the bracket assembly 1, and are rotated to engage and interlock the recessions 35 and projections 40, as shown in detail in FIG. 3, ...

third embodiment

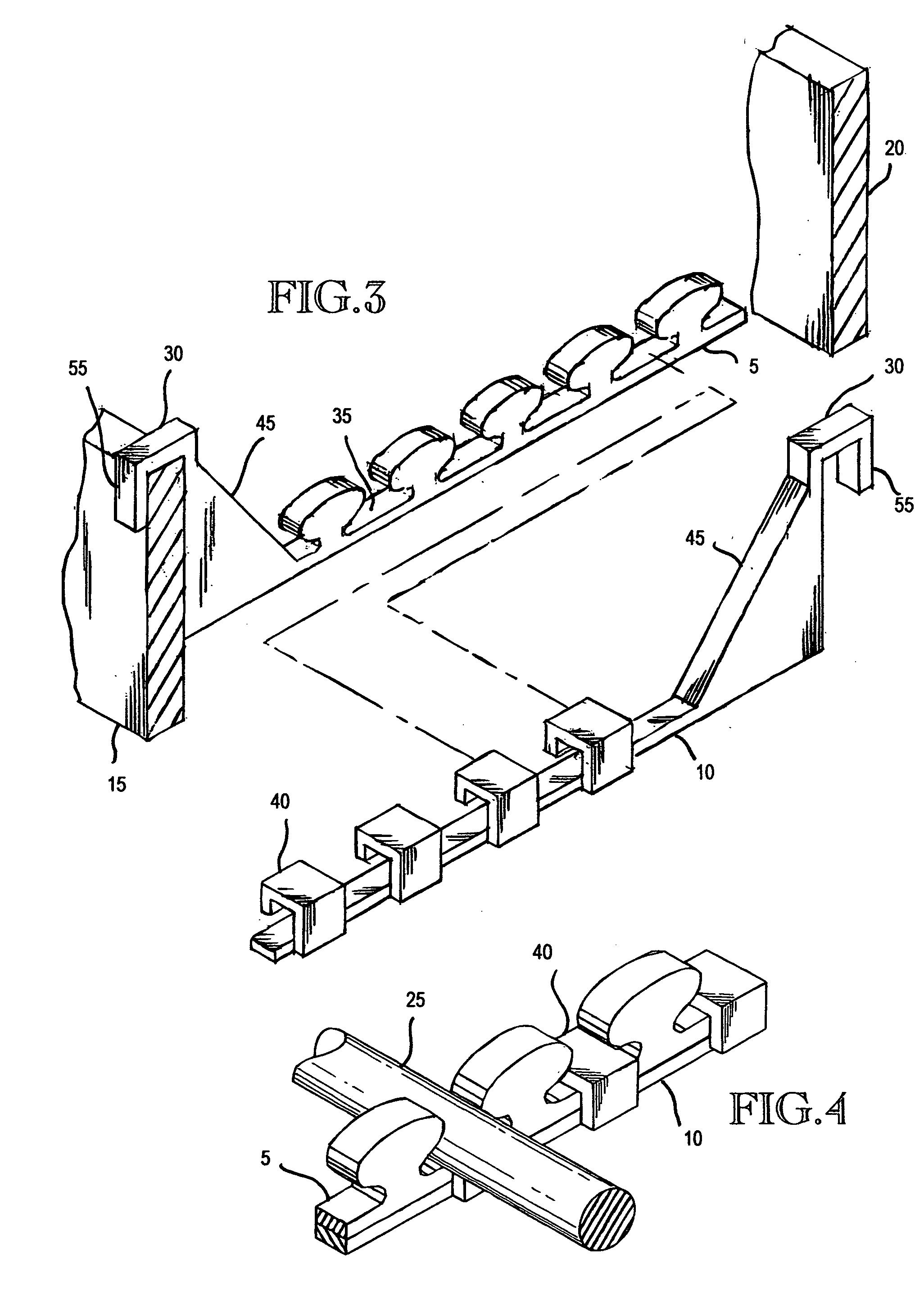

[0040] the present invention is shown in FIG. 5. Each of the first member 5 and the second member 10 is formed of a ribbon-like medium steel strip stock that is bent to form the recessions 35 and longitudinally disposed projections 40. Each member may be of a continuous length of wire or may be built up of a plurality of pieces boned or welded together. The size and shape of the second member 10 is such that the second member 10 nests within the first member 5, whereby a desired length of the adjustable bracket assembly 1 is achieved by positioning the two members to align corresponding recessions 35 and projections 40, and laterally engaging and sliding the two members together.

fourth embodiment

[0041] In a fourth embodiment as shown in FIG. 6, an adjustable bracket is comprised a first member 5 and a second member 10, each of which has a plurality of recessions 35 for receiving a plurality of reinforcement bars 25. The first member 5 is supportable from a first form wall 15 and the second member 10 is supportable by a second opposing form wall 20. A forward-facing surface on the first member 5 has a plurality of fasteners 85 such as snaps, clips or retaining tabs positioned along the length of the first member 5 as shown in FIG. 7. The second member 10 has a rearward-facing surface with a corresponding plurality of fasteners 85 positioned thereon, as seen in detail in FIG. 8, such that the length of the bracket assembly 1 is adjustable by overlapping the first member 5 with the second member 10 to achieve a desired length, aligning the recessions 35 of each member, and engaging and snapping the fasteners 85 together. This embodiment is preferably made of steel strip stock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com