Detector detecting transmission performance of optical composite cable

a technology of optical composite cable and detection device, which is applied in the direction of transmission monitoring, instruments, television systems, etc., can solve the problems of increasing transmission loss, disconnection of optical fiber and electric lines, and persisting problems, and achieve the effect of detecting transmission lines, optical composite cables, and quick knowledg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will next be described based on concrete examples. The scope of the present invention, however, is not limited to the embodiment described below.

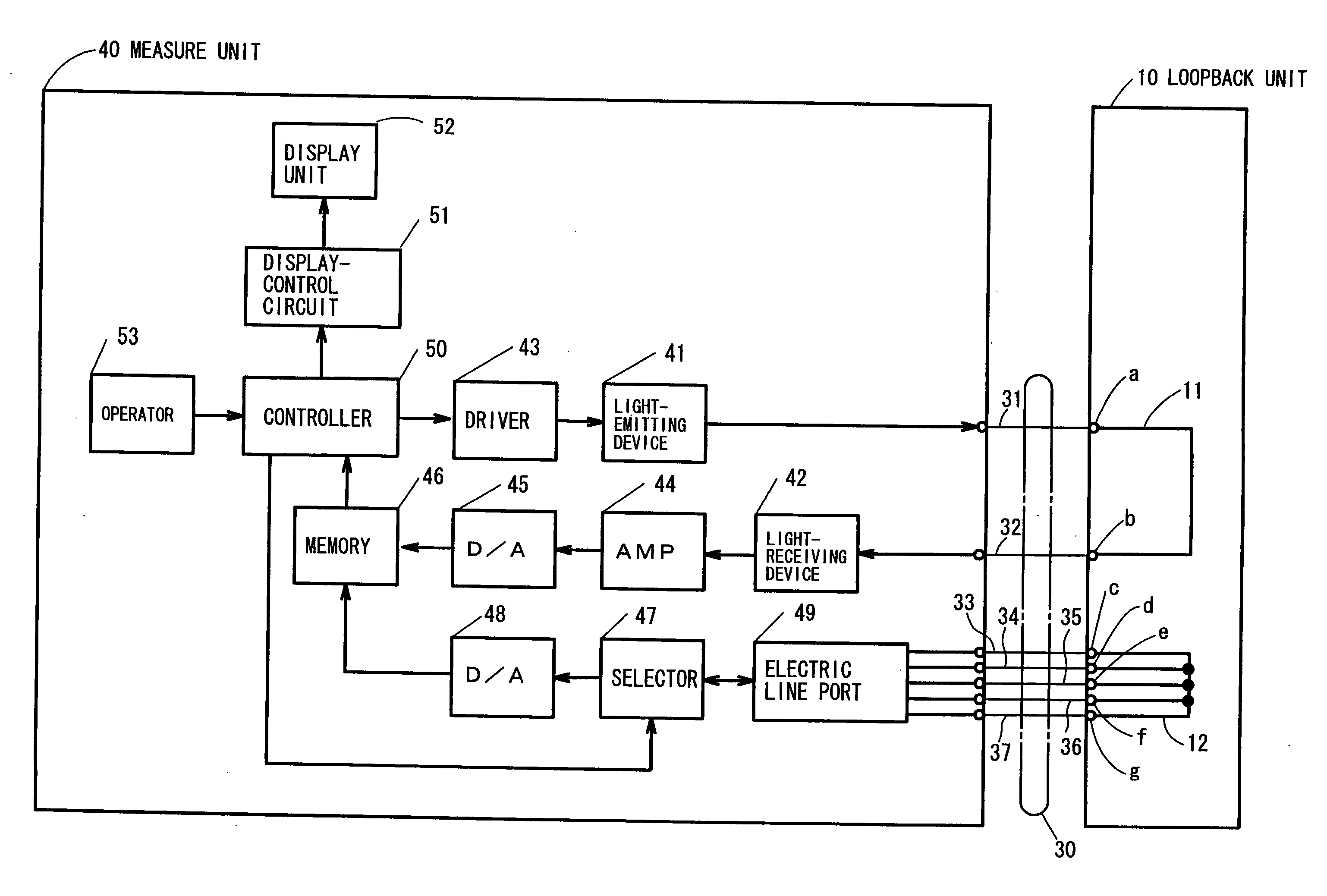

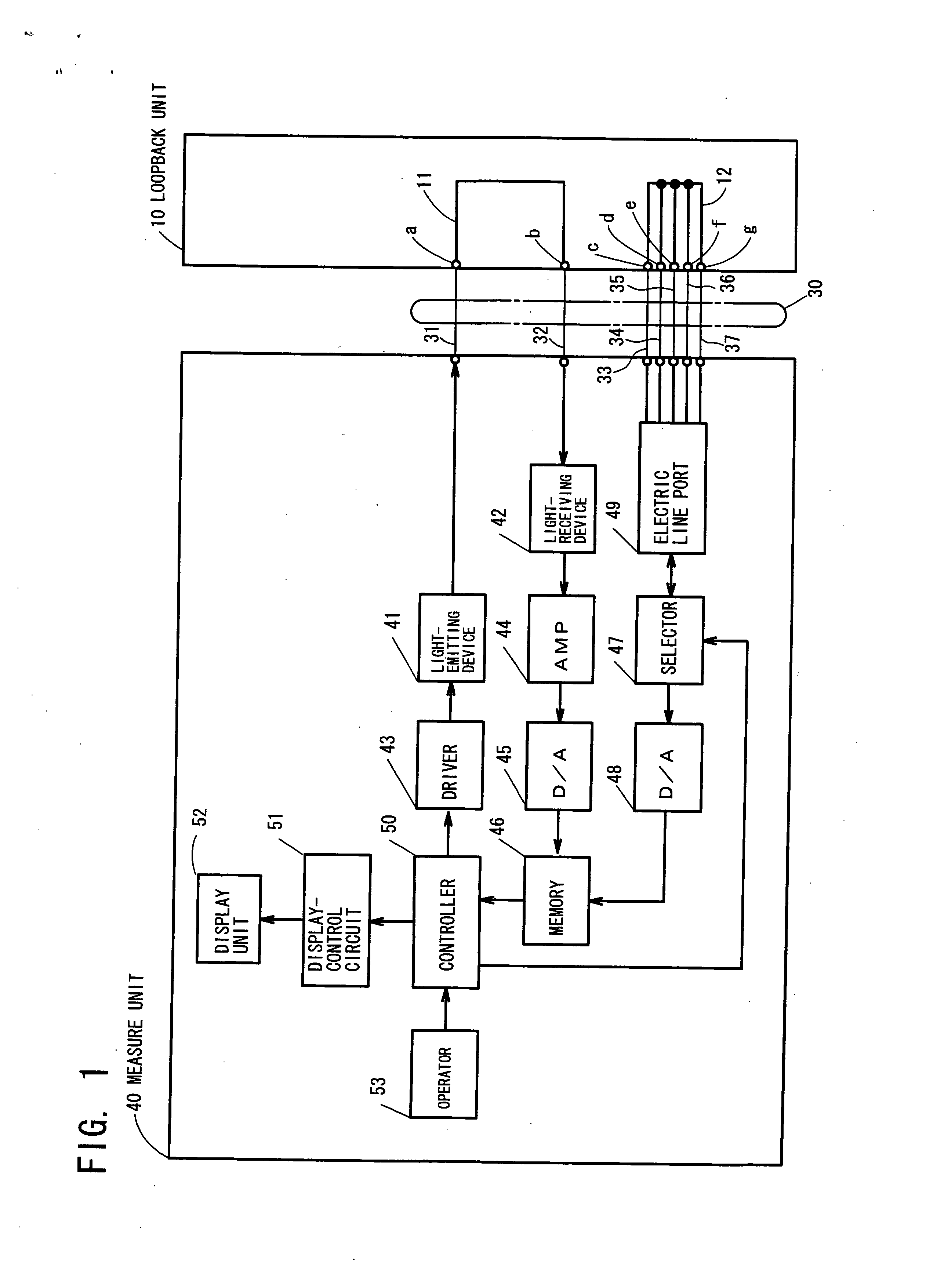

[0024] A detector detecting transmission performance of optical composite cable comprises a loopback unit 10 as a first unit and a measure unit 40 as a second unit. The loopback unit 10 comprises an optical loop part, or a loop fiber 11 which connects an end ‘a’ of a first optical fiber 31 and an end ‘b’ of a second optical fiber 32. The loopback unit 10 comprises a short-circuit part, or a short-circuit wiring 12, which short-circuits the ends c and d of a pair of signal lines 33 and 34, the ends e and f of a pair of signal lines 35 and 36, and the end g of a shield line 37.

[0025] An optical composite cable 30 comprises the first optical fiber 31, the second optical fiber 32, the pair of signal lines 33 and 34, the pair of signal lines 35 and 36, and the shield line 37.

[0026] The measure unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com