Surgical instrument seal assembly

a surgical instrument and seal technology, applied in the field of medical devices, can solve the problems of affecting the sealing effect of the valve, affecting the safety of the patient, and the elastomeric material of the valve seal can be damaged, and achieve the effect of simple production and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

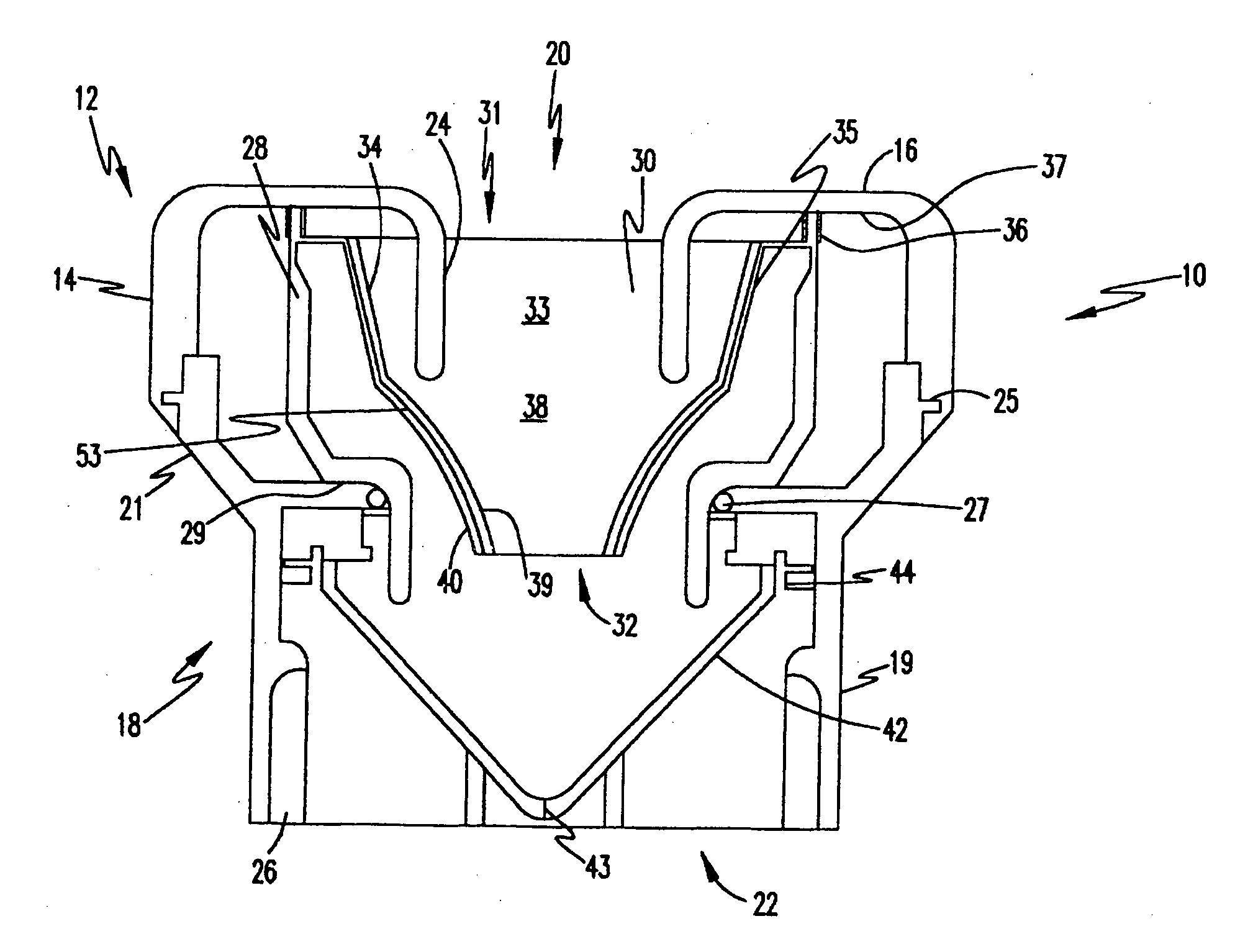

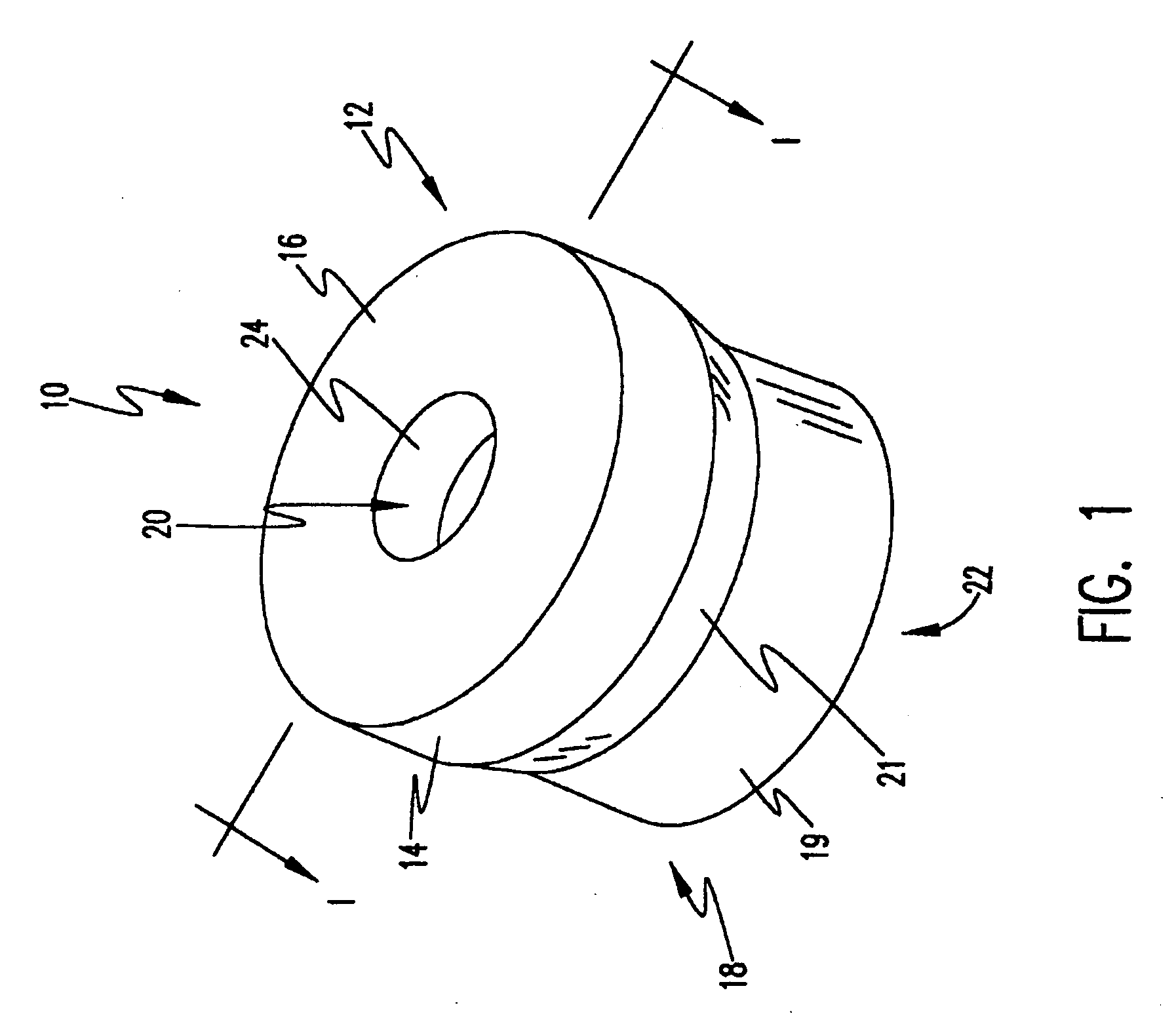

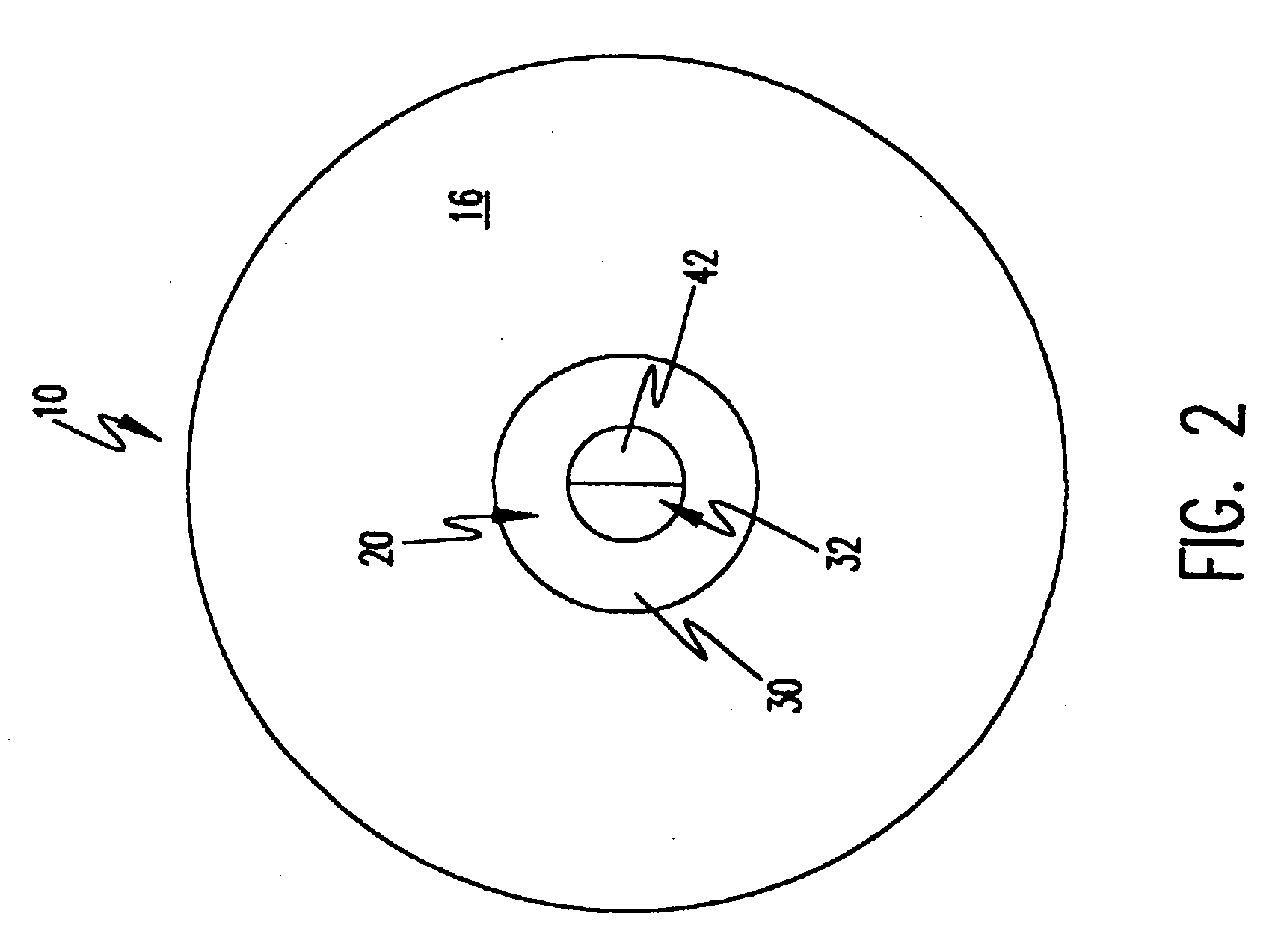

[0037] With reference to the drawings, wherein like numerals have been used to represent like features, and, more particularly to FIG. 1, a surgical instrument valve seal assembly 10 is illustrated and includes an upper body portion 12 and a lower body portion 18. The upper body portion 12 is generally cylindrical and includes a washer-shaped upper surface 16 integrally formed with a generally cylindrical sidewall 14. A throughbore 20 is provided at the center of the upper surface 16 with the throughbore 20 extending completely through the seal assembly 10. A generally cylindrical protector wall member 24 is integrally formed with upper surface 16 at the throughbore 20 to project inwardly into the interior of the upper body portion 12 to both strengthen the structure and to guide the surgical instrument into the throughbore 20.

[0038] The lower body portion 18 includes a generally cylindrical wall 19 projecting below the upper body portion 12. A tapered transition wall 21 is dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com