Aerosol can

a spray dispenser and aerosol can technology, applied in the direction of liquid dispensing, liquid/fluent solid measurement, containers, etc., can solve the problems of not meeting the requirements of convenience, the function of the spray system is only possible within a narrow temperature range, and the effect of large expansion rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

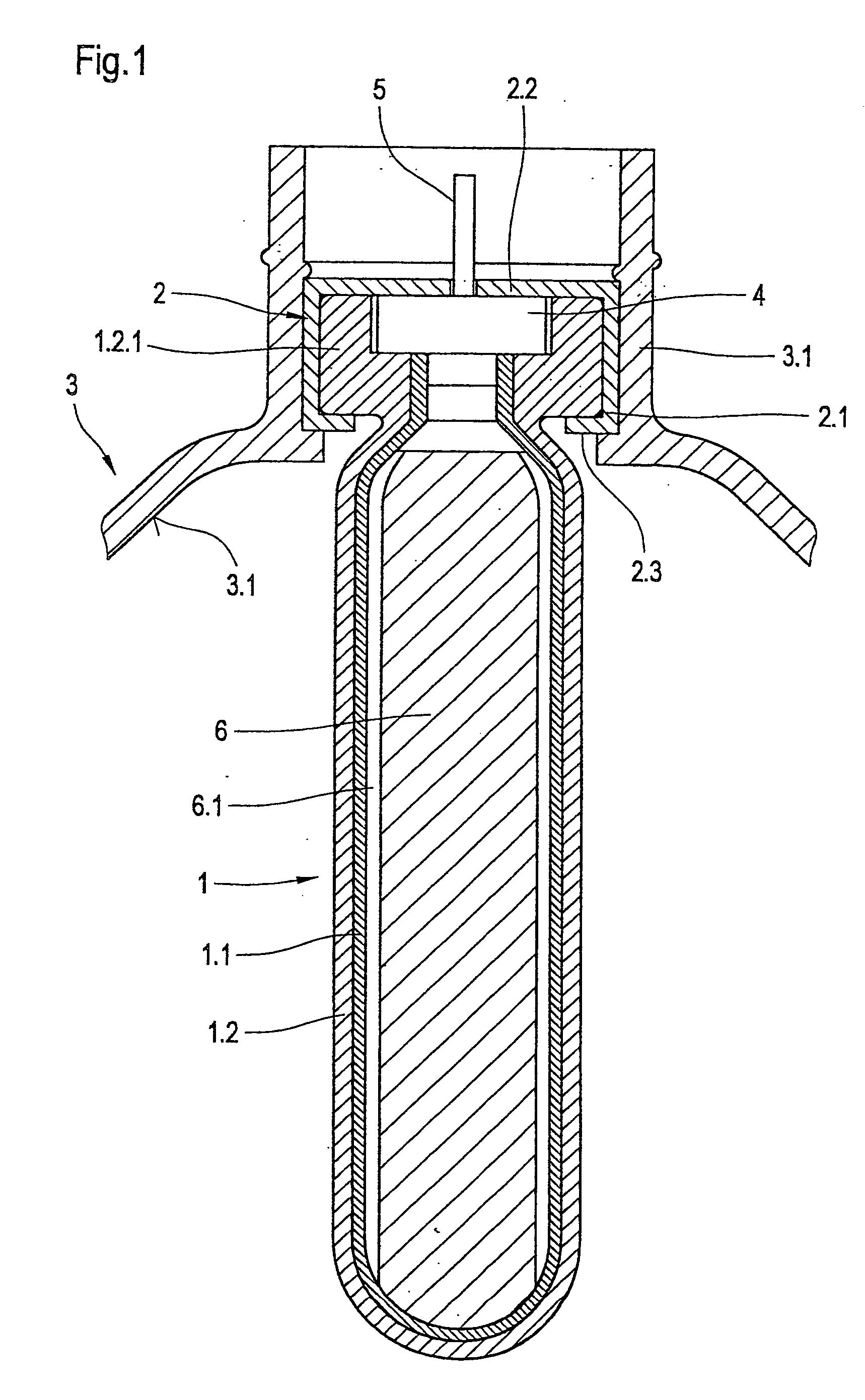

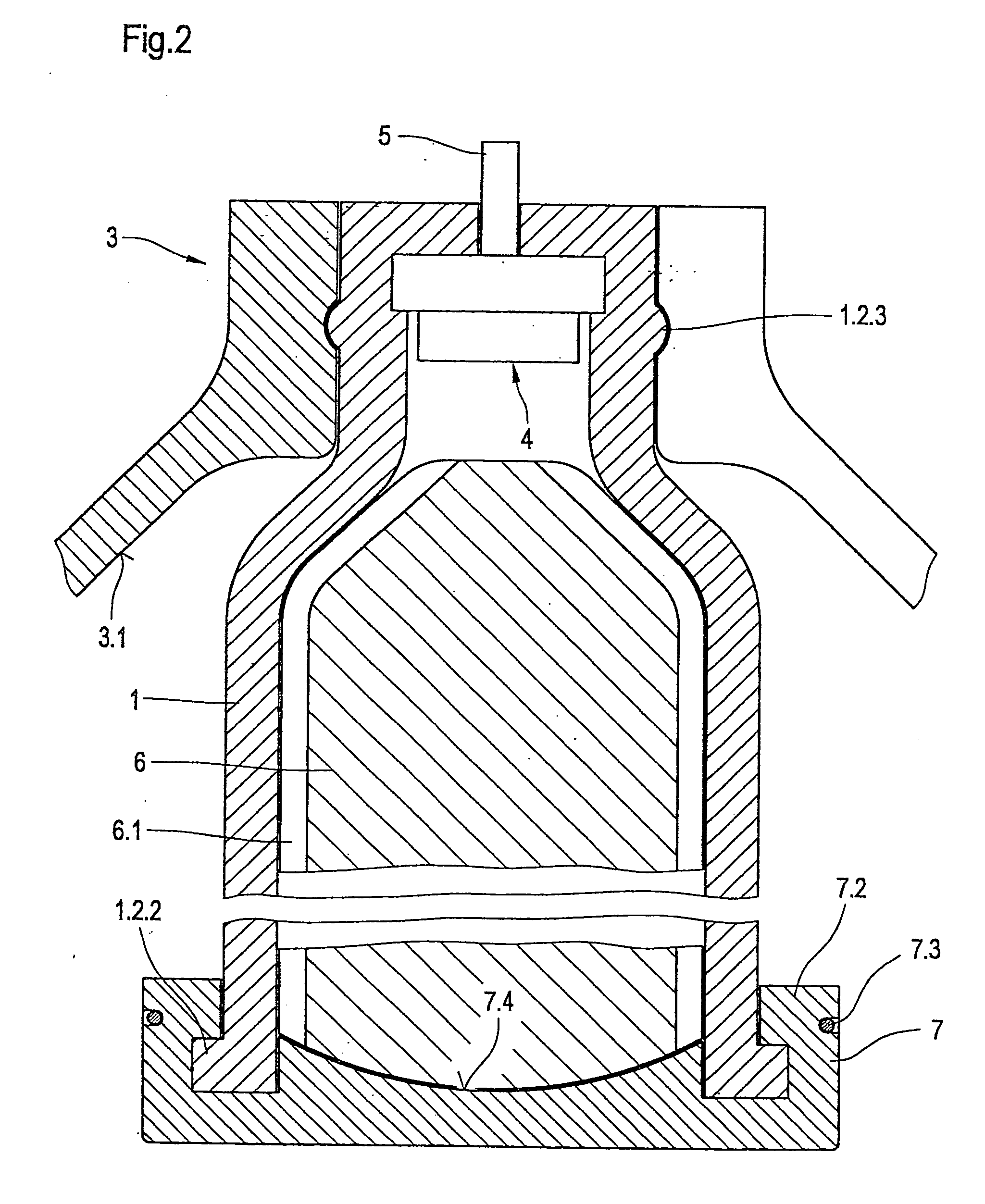

[0029] The spray dispenser shown in FIG. 1 includes a filling substance reservoir 1. In the present case this is double walled. Specifically, it consists of a combination of an external container 1.2 and an internal container 1.1. Internal container 1.1 is made from a material that is inert with respect to the filling substance in question. External container 1.2 is made from an elastic material, which forms the energy storage medium. The two containers are arranged so that their corresponding surfaces are directly adjacent one another. They retain this contact even under any operating state. The internal container thus follows movement of the external container as it expands or contracts.

[0030] External container 1.2 is enlarged in its upper area to form a flange 1.2.1. The flange is cylindrical.

[0031] A pot-shaped mounting body 2 is also shown. This tightly encloses flange 1.2.1. Mounting body 2 has a cylindrical peripheral wall 2.1, a circular plate 2.2 and a collar 2.3.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com