Granulator for rubber master batches

A granulator and rubber technology, which is applied in the field of rubber processing, can solve the problems of insufficient internal mixing and low work efficiency, and achieve the effects of fast mixing speed, uniform mixing, and increased airflow expansion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

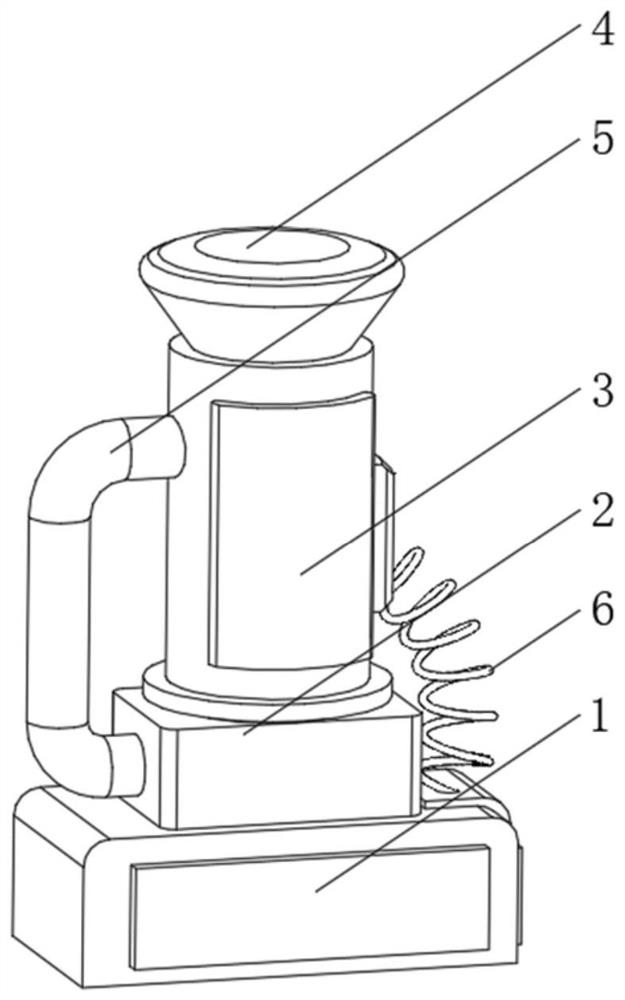

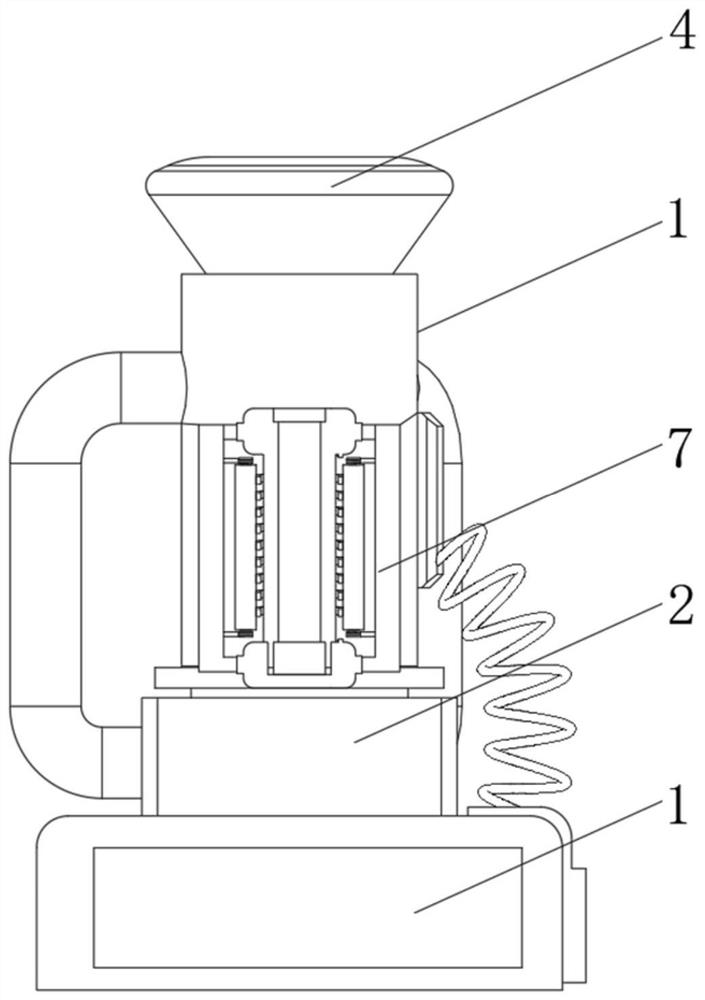

[0031] see Figure 1-4 , the present invention provides a technical solution: a rubber masterbatch granulator, including a rubber storage base 1, a granulation work box 2 and a mixing treatment tank 3, the granulation work box 2 is installed on the top of the rubber storage base 1, The kneading treatment tank 3 is located above the granulation work box 2, and the hot melt addition work box 4 is installed on the top of the kneading treatment tank 3, a conduit 5 is arranged between the granulation work box 2 and the kneading treatment tank 3, and the rubber storage base 1 A side connection pipe 6 is installed between the side and the mixing treatment tank 3, and an internal mixing device 7 is installed inside the mixing treatment tank 3;

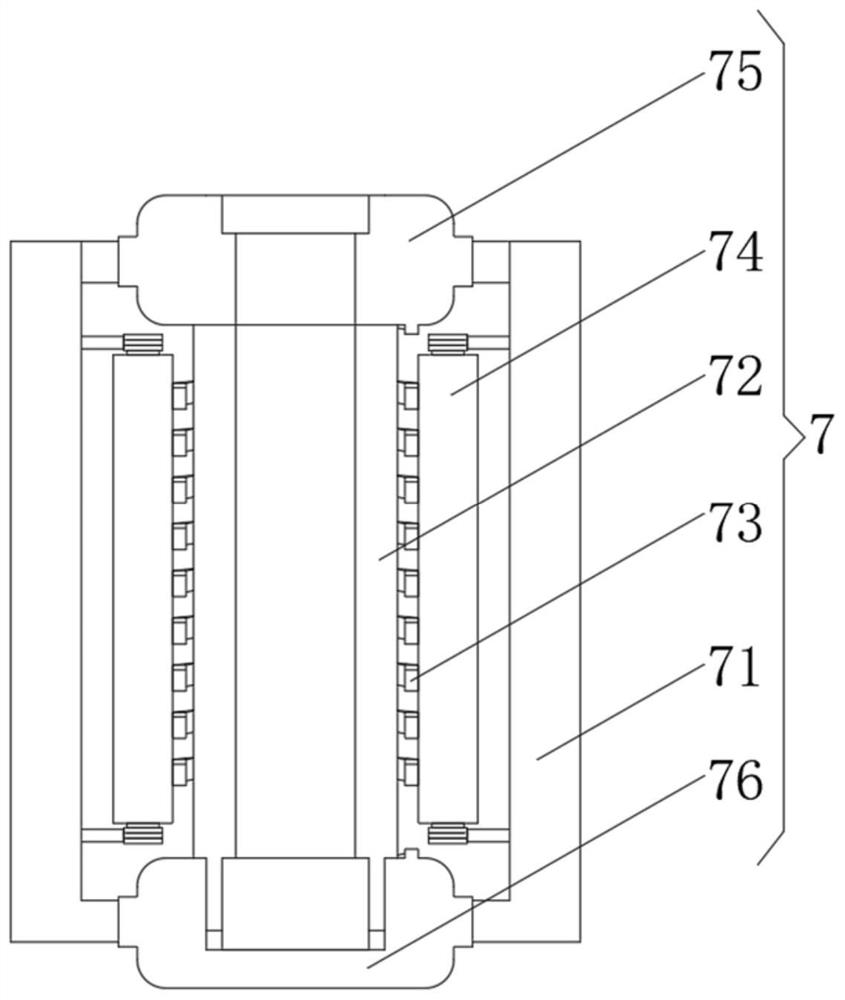

[0032] The inner mixing device 7 includes a tube body 71, a central inner tube 72 is arranged on the inner side of the tube body 71, a kneading ring 73 is arranged on the side of the central inner tube 72, an inner drum 74 is arranged on both ...

Embodiment example 2

[0035] see Figure 1-7 , on the basis of the implementation case 1, the present invention provides a technical solution: the internal mixing device q includes an arc-shaped mixing piece q1, and the top of the arc-shaped mixing piece q1 is provided with a top connecting member q2, and the arc-shaped mixing piece q1 An air duct q3 is provided on the outside, a centrifugal stripping device e is provided at the center of the arc-shaped kneading piece q1, and multiple inner kneading devices q are provided, and when the kneading ring 73 rotates at a high speed, a high-speed Centrifugal, drives the internal mixing device q to rotate, when the mixing ring 73 rotates counterclockwise, a large amount of air flow enters the upper air flow inlet q4, and the internal rubber will be taken outside by the alignment protection plate q5, flushing The incoming airflow will be discharged from the lower airflow hole e7, thereby injecting into the inside of the molten rubber.

[0036] An upper air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com