Section steel and wall body using the section steel

a section steel and steel beam technology, applied in the direction of girders, walls, joists, etc., can solve the problems of insufficient bonding force, difficult to reduce the thickness of the wall, etc., to reduce the effect of preventing concrete displacement, reducing shearing stress, and reducing shearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

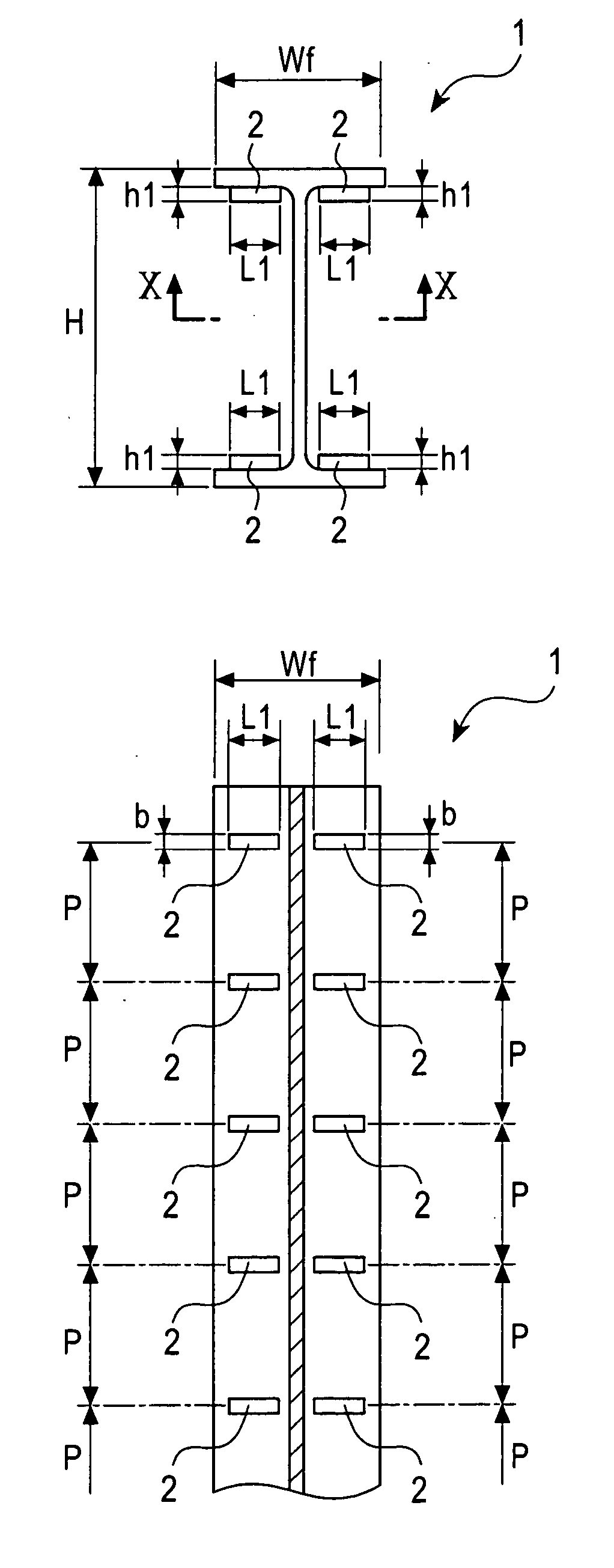

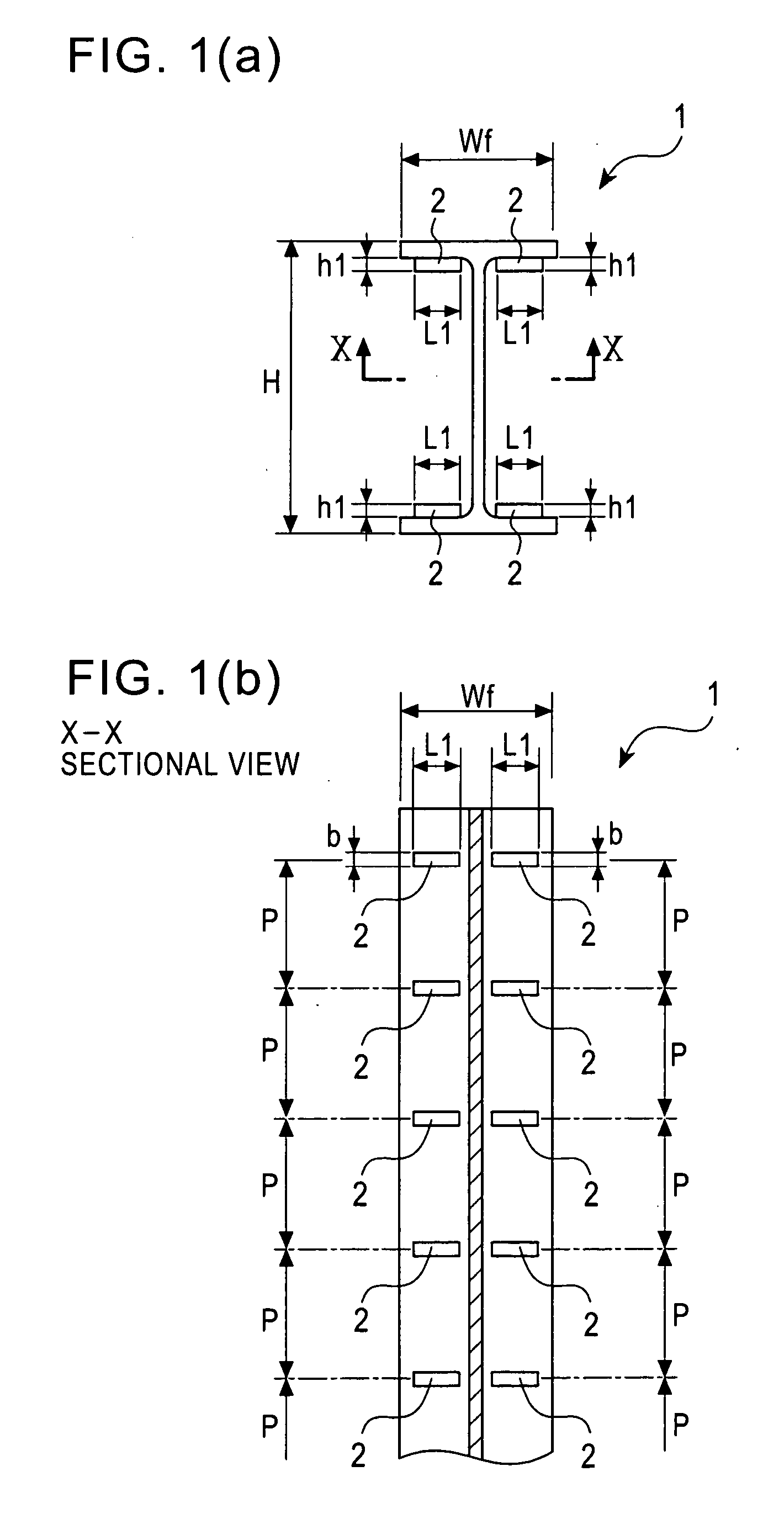

[0124] FIGS. 1(a) and 1(b) are explanatory views of an H-beam 1 with projections according to a first embodiment of the present invention. FIG. 1(a) is a schematic plan view, and FIG. 1(b) is a cross-sectional view taken along line X-X.

[0125] In the H-beam 1 with projections of the first embodiment, projections 2 of rectangular cross section are provided at a plurality of positions in the longitudinal direction of the H-beam on four inner faces of flanges so that the longitudinal direction of the projections coincides with the direction of the flange width Wf, as shown in FIGS. 1(a) and 1(b). The projections 2 on the flange inner faces have a projection height h1, a projection width b, and a projection length L1, and are not in contact with the corners defined by the flanges and a web.

[0126] Regarding the shape and arrangement of the projections, the projection pitch P is set to be within the range of 4b to 40h1, and the projection height h1 is set to be within the range of 2mm to...

second embodiment

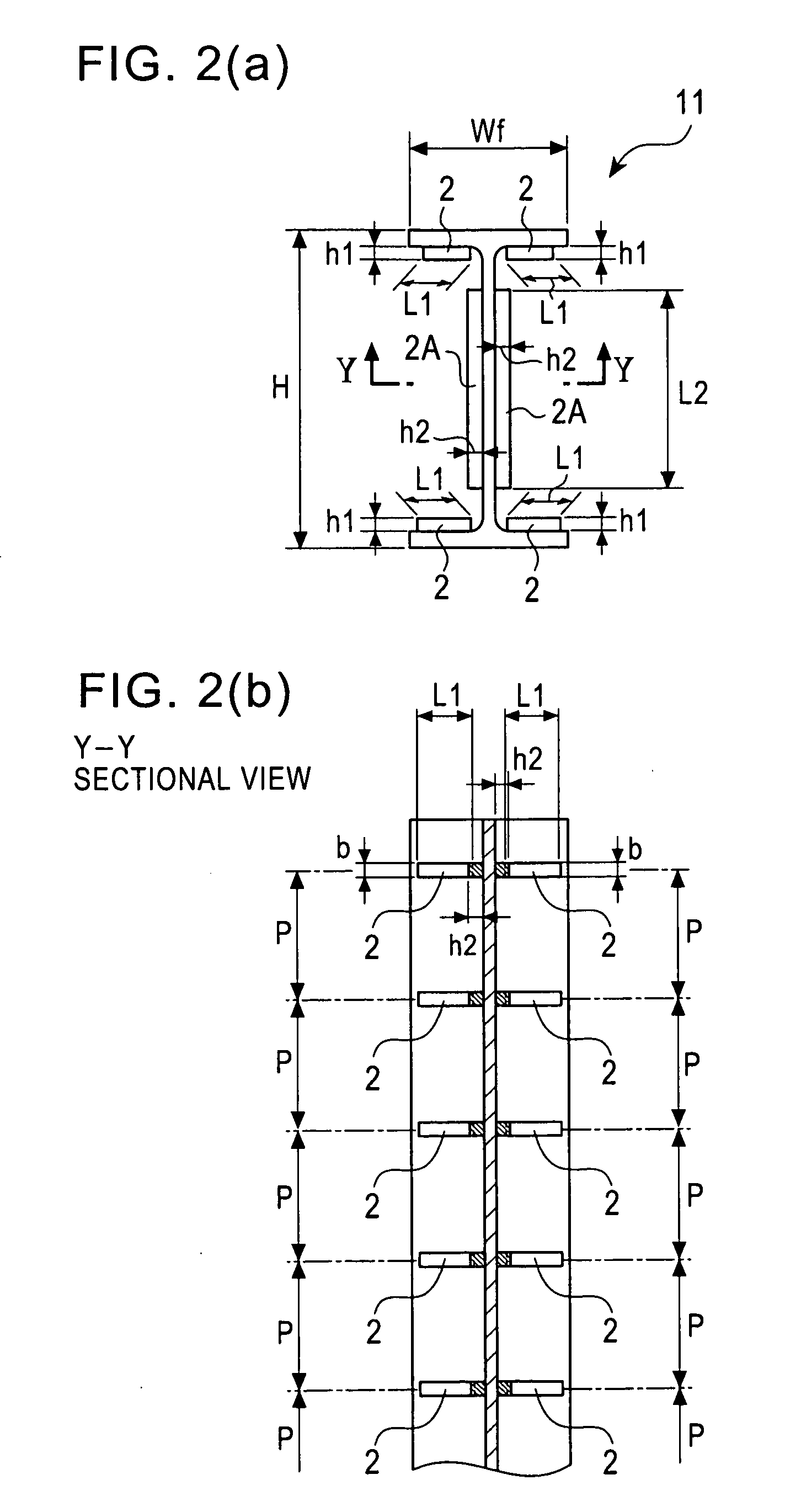

[0128] FIGS. 2(a) and 2(b) are explanatory views of an H-beam 11 with projections according to a second embodiment of the present invention, FIG. 2(a) is a schematic plan view, and FIG. 2(b) is a cross-sectional view taken along line X-X.

[0129] In the H-beam 11 with projections of the second embodiment, projections 2 of rectangular cross section are provided on four inner faces of flanges, in a manner similar to that in the projections 2 of the first embodiment, as shown in FIG. 2, and projections 2A serving as bonding-force increasing means are provided at a plurality of positions in the longitudinal direction of the H-beam on both surfaces of a web so that the longitudinal direction thereof coincides with the height direction of the web.

[0130] The projections 2A are provided on both surfaces of the web, and have a projection height h2, a projection width b, and a projection length L2. Both the projections 2 on the flange inner faces and the projections 2A on the web surfaces are...

third embodiment

[0133]FIG. 3 is an explanatory view of an H-beam 21 with projections according to a third embodiment of the present invention. In the H-beam 21 with projections of the third embodiment, projections 2 having a projection height h1, a projection width b, and a projection length L1 are provided on four inner faces of flanges, and projections 2B having a projection height h2, a projection width b, and a projection length L3 are provided on web surfaces, as shown in FIG. 3. Both the projections 2 on the flange inner faces and the projections 2B on the web surfaces are in contact with the corners defined by the flanges and the web, and the projections 2B are not provided at the centers of the web surfaces.

[0134] The above-described contact with the corners can further increase the bonding force with respect to concrete or solidification soil (composition effect). The projection length L3 of the projections 2B provided on the web surfaces of the H-beam 21 with projections in the third emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com