Contact terminal structure

a technology of contact terminals and terminals, which is applied in the field of contact terminals, can solve the problems of not giving a correct electrical fluctuation, and not resulting in a correct contact between the base and the motherboard of an integrated circuit, and achieves the effect of easy bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

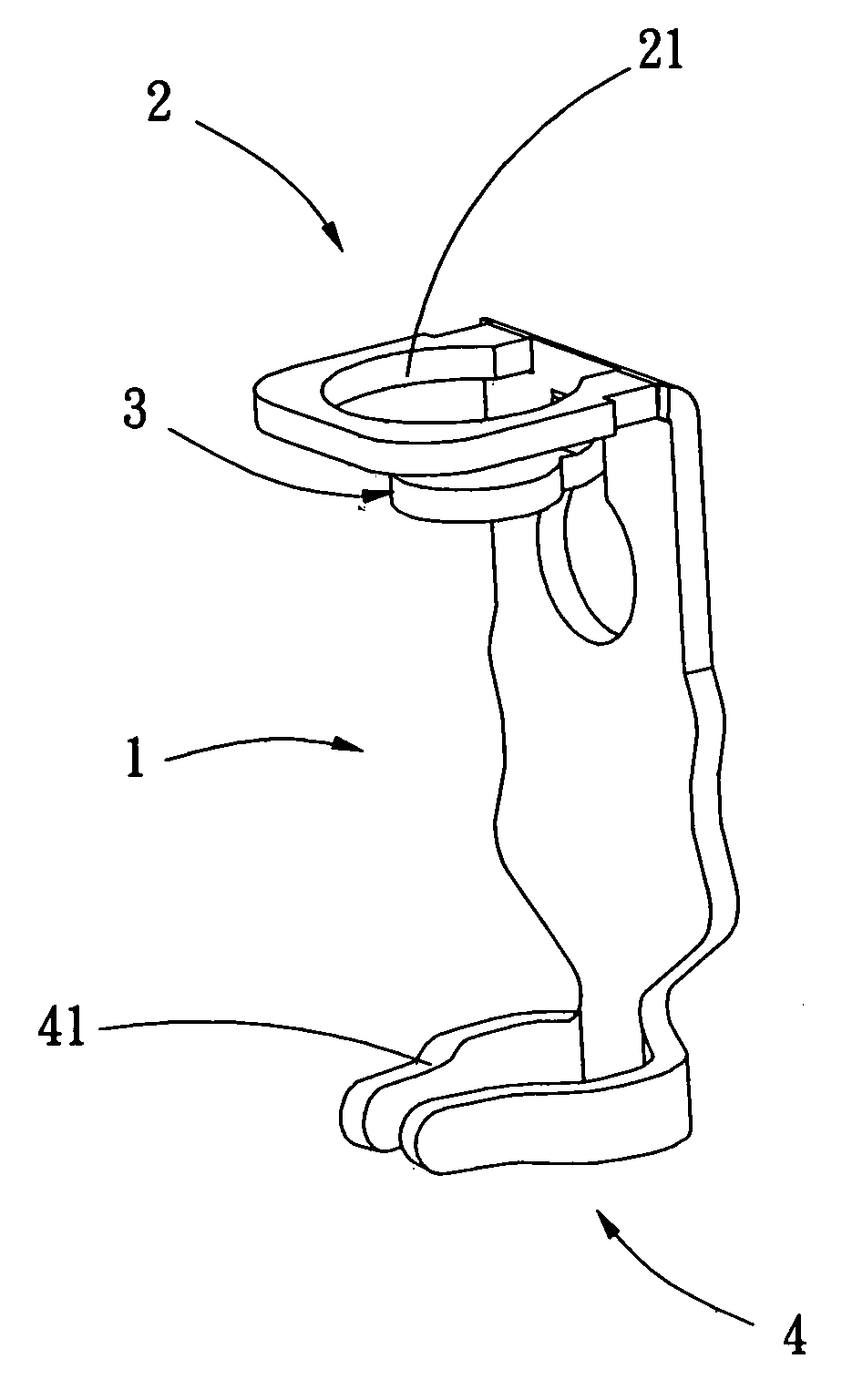

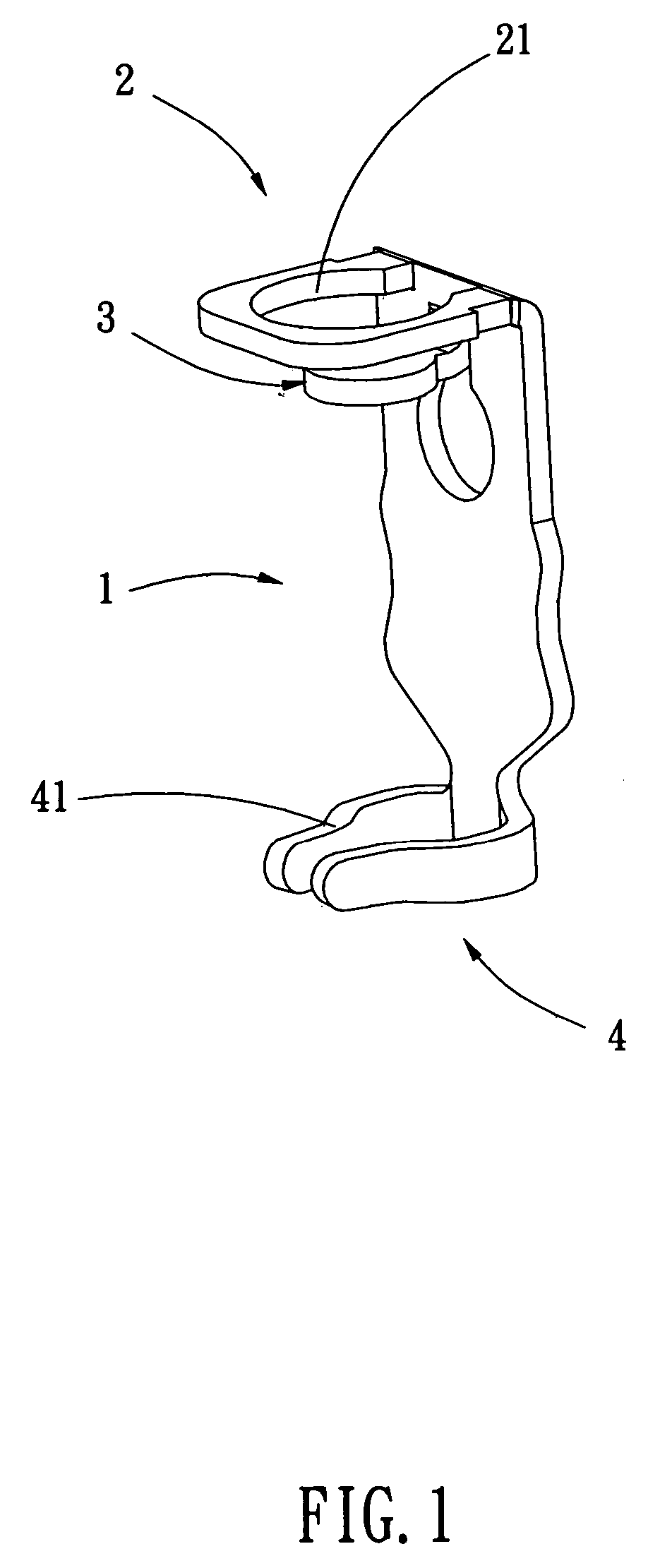

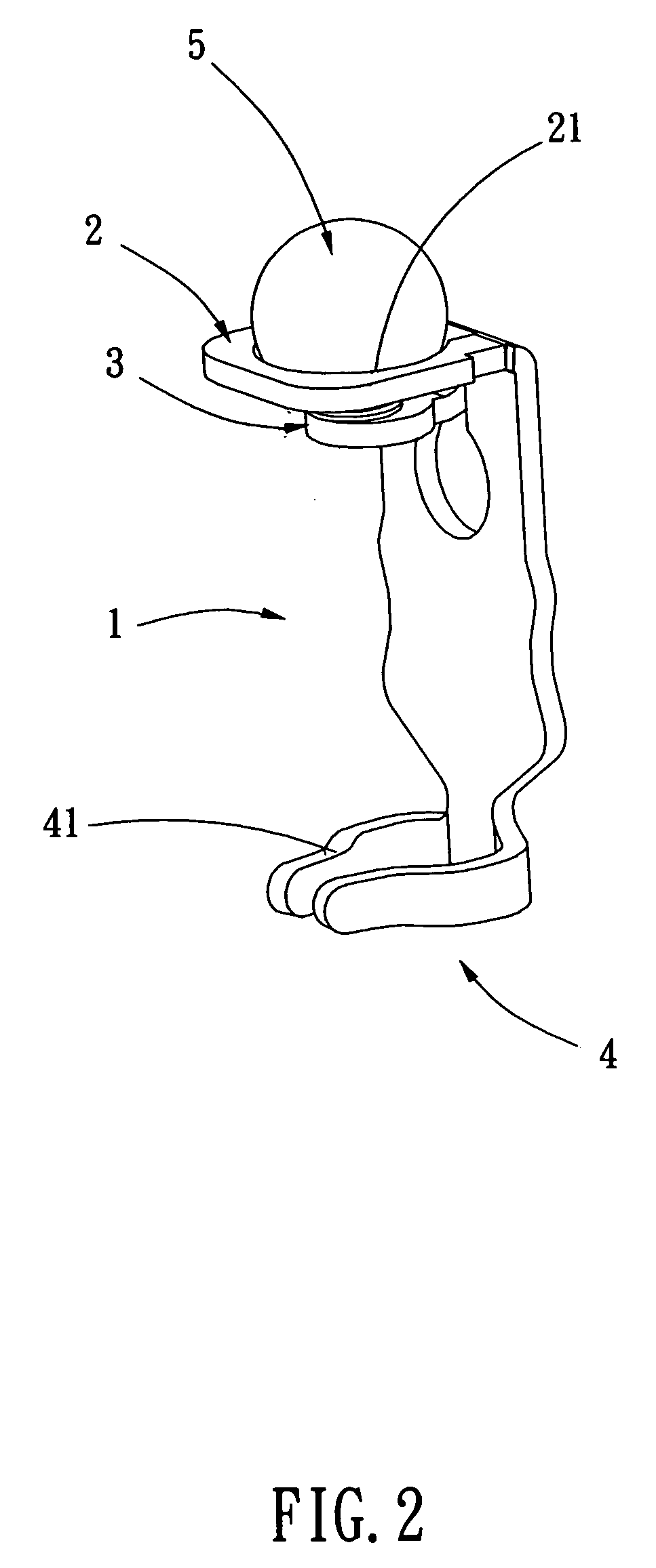

[0015] Referring to FIGS. 1 and 2, showing schematically the perspective view and the practice of an embodiment of a contact terminal structure according to the invention, respectively, said contact terminal structure comprises:

[0016] a main body 1; and

[0017] a soldering end 2, extending vertically from one end of said main body 1 and providing with an aligning portion 21 of an arcuate hollow shape for placing a solder ball 5, wherein the periphery of said aligning portion 21 may be in a rounded concave form; and

[0018] a supporting portion 3, formed from said main body 1 by a stamping process, whereby, as said solder ball 5 is placed in said aligning portion 21, said solder ball 5 will be stopped at said supporting portion 3 in a manner such that the placing depth of said solder ball 5 can be controlled, wherein said supporting portion 3 is provided adjacent to the inner side of said soldering portion 2; and

[0019] a contact end 4, extending from another end of said main body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com