Stable Rotary Drill Bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

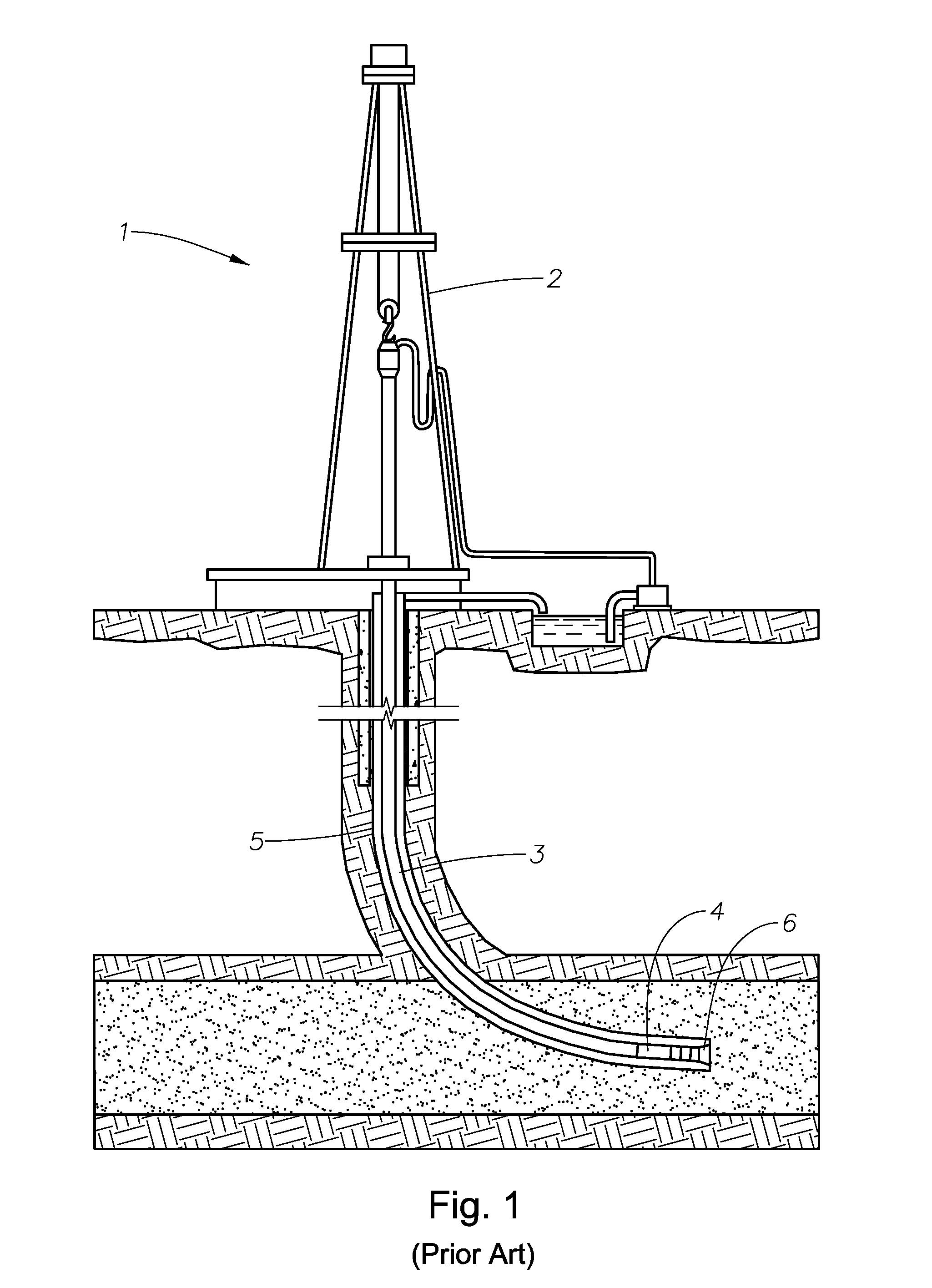

[0021] Referring first to FIG. 1, a drilling system 1, is shown and comprises a drill rig 2, with a drill string 3, and a drill bit 6, located within borehole 5. The drill bit 6 may be rotated from the surface by rotation of the drill string. Alternatively or additionally the drill bit 6, may be rotated by a downhole motor or turbine 4.

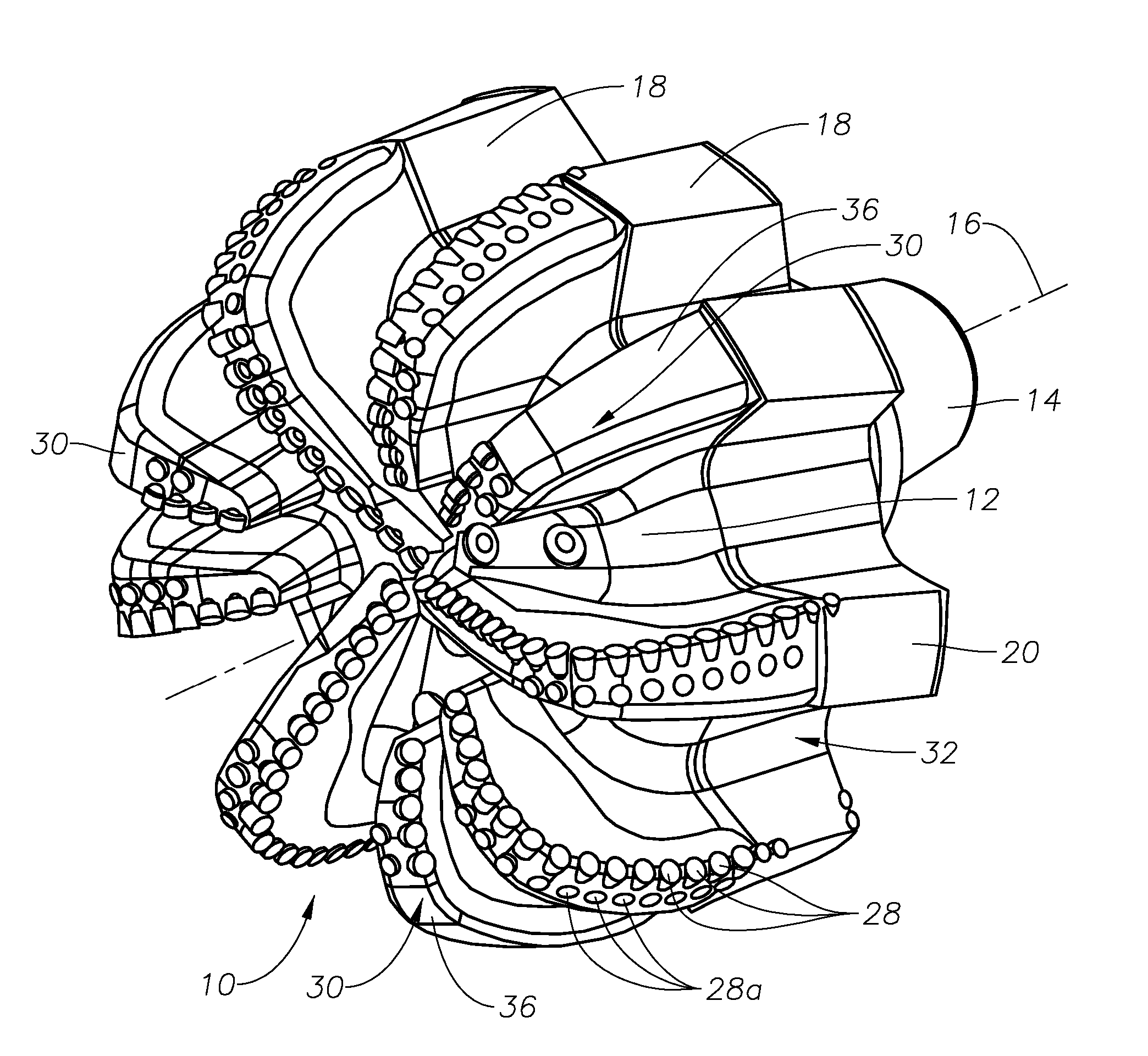

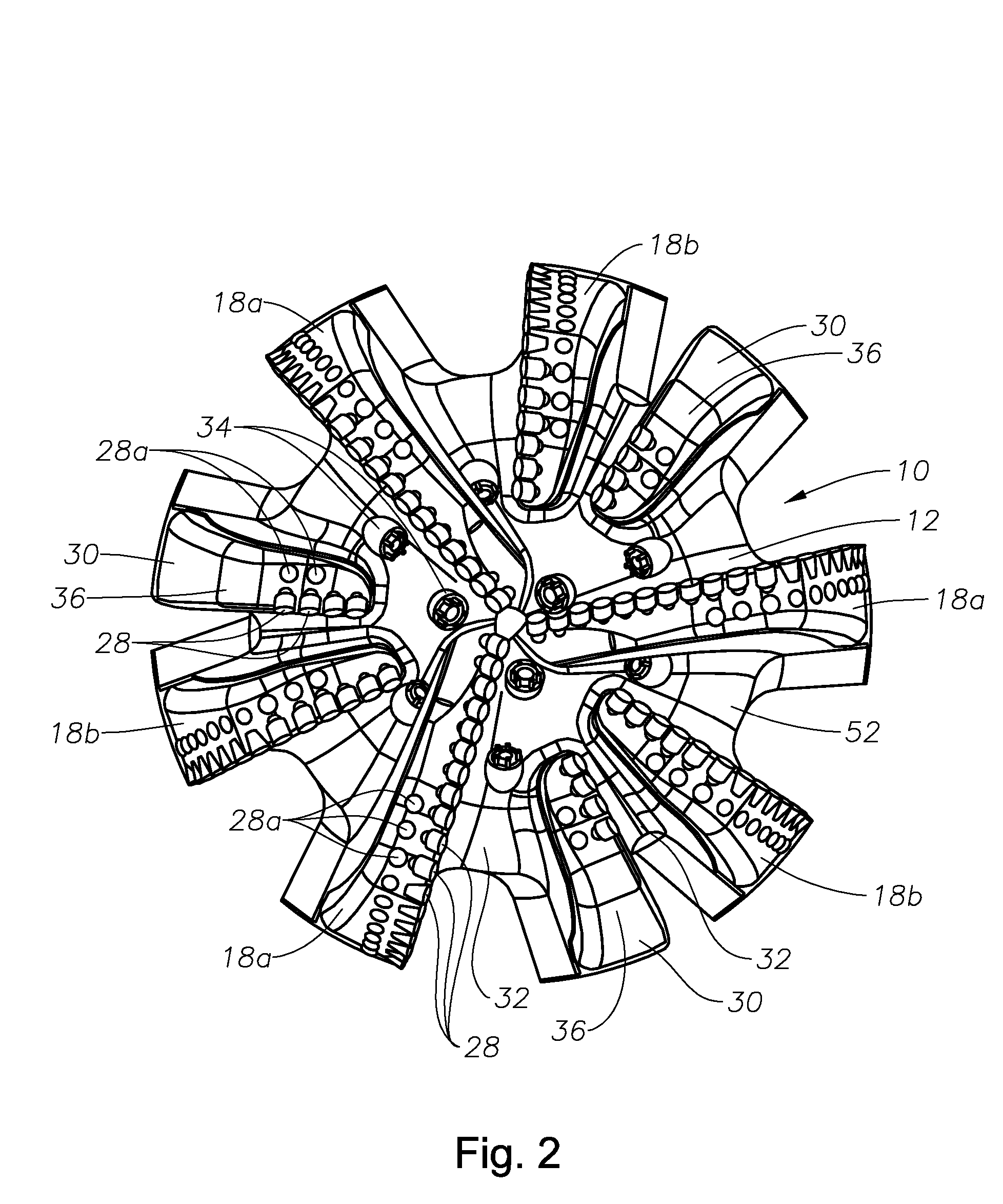

[0022] Referring to FIGS. 2 to 5 there is shown a drill bit comprising a bit body 10 having a front face 12 and a connection region 14 designed to allow the bit to be connected to other downhole components, in use, to allow the bit to be driven for rotation about its centerline 16 and to allow an axially directed load to be applied thereto.

[0023] Mounted on the bit body 10 are a number of upstanding main blades 18, the main blades 18 upstanding from the front face 12 of the bit body 10. The main blades 18 include a first plurality of blades 18a which extend from the center line 16, of the bit to the gauge region 20 thereof, and a second plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com