Composite materials

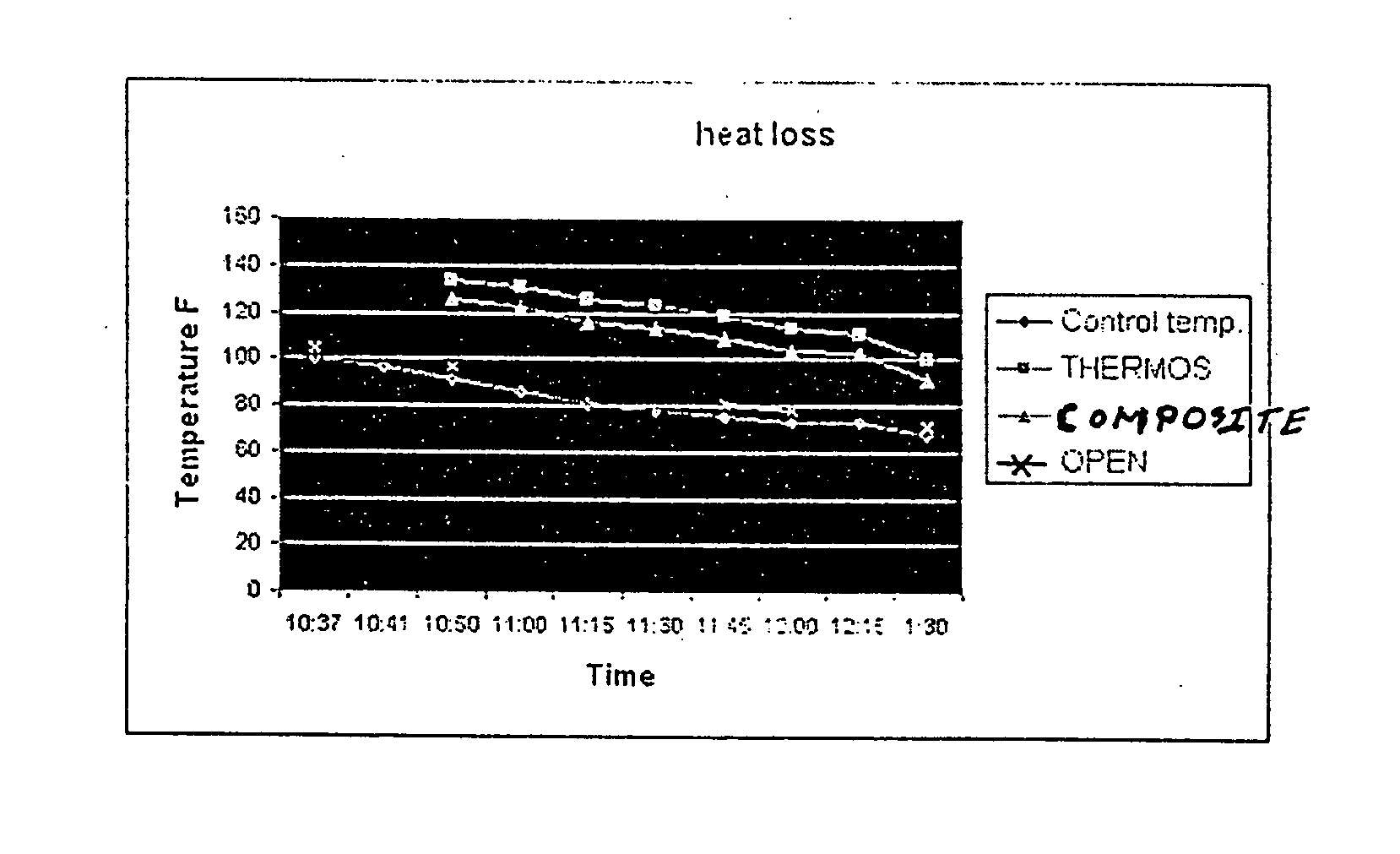

a technology of composite materials and materials, applied in the field of composite materials, can solve the problems of high manufacturing cost, high weight, and high cost of materials, and achieve the effects of improving material properties, reducing the weight of composite materials, and increasing some material properties strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

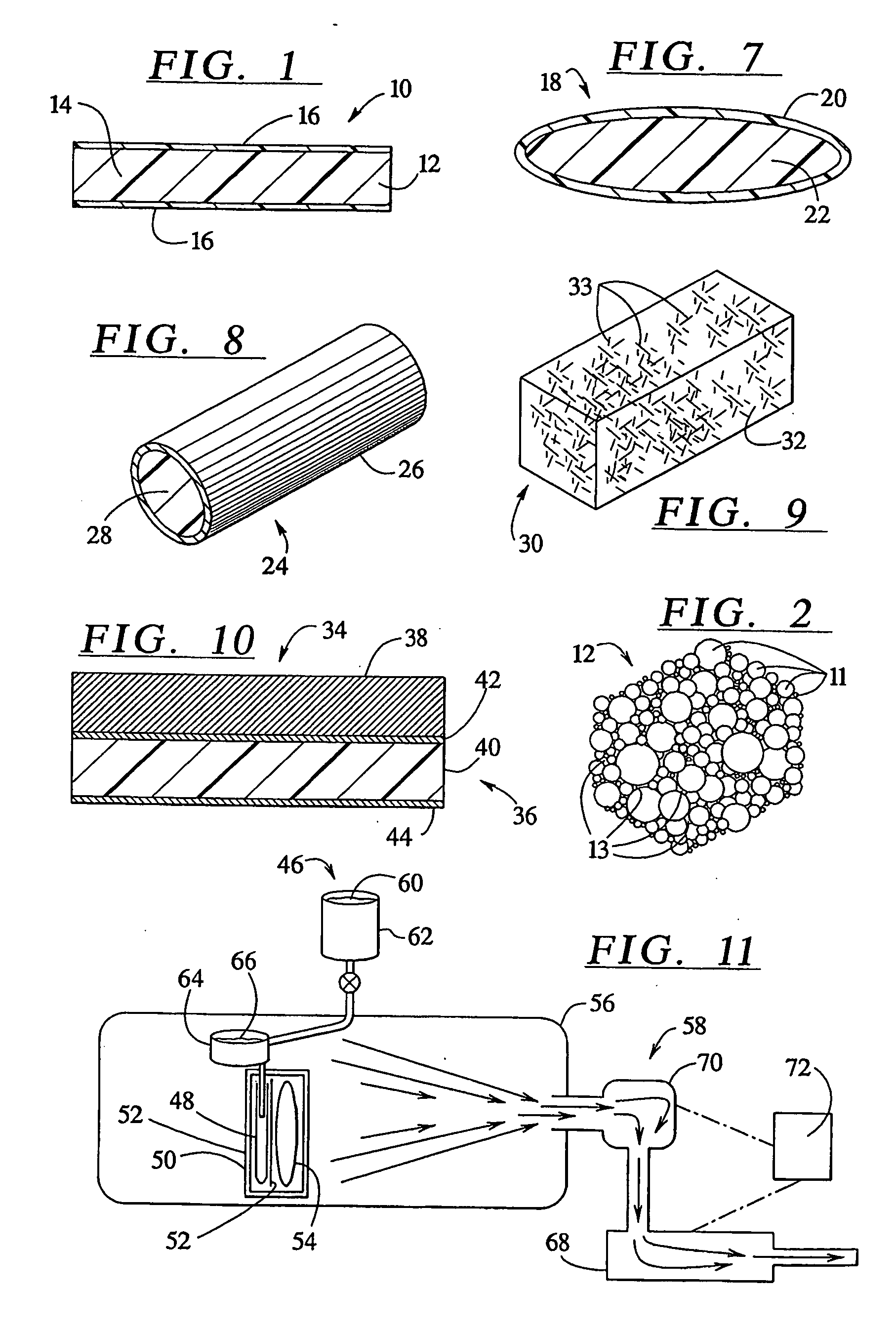

[0026] Although the present invention can be made in many different forms, the presently preferred embodiments are described in this disclosure and shown in the accompanying drawings. This disclosure exemplifies the principles of the present invention and does not limit the broad aspects of the invention only to the illustrated embodiments.

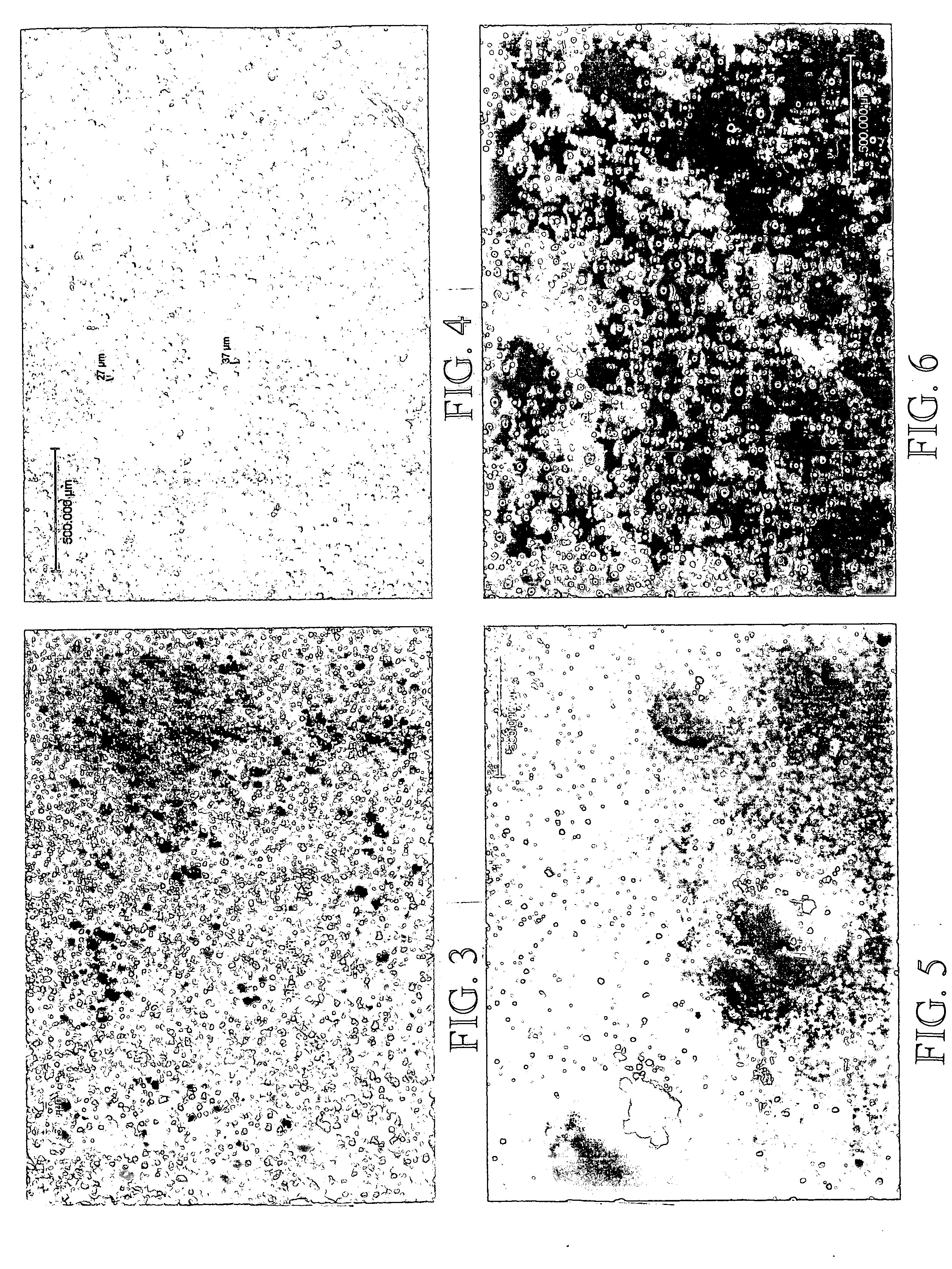

[0027] Generally, the composite materials of the present invention include a matrix material and a plurality of small particles. The matrix material contains a high density of the small particles. Because of the high density of small particles in the matrix material, the small particles are positioned very close to each other. Adjacent small particles may even be in contact with each other. Typically, the composite material includes a greater volume amount of small particles than the volume amount of matrix material. For example, one new composite material has about twice as much small particles as matrix material by volume.

[0028] A preferred em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com