Apparatus and method for radially expanding a wellbore casing using and adaptive expansion system

a wellbore casing and adaptable expansion technology, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of increased drilling rig time, increased cost of large boreholes, and required equipment changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

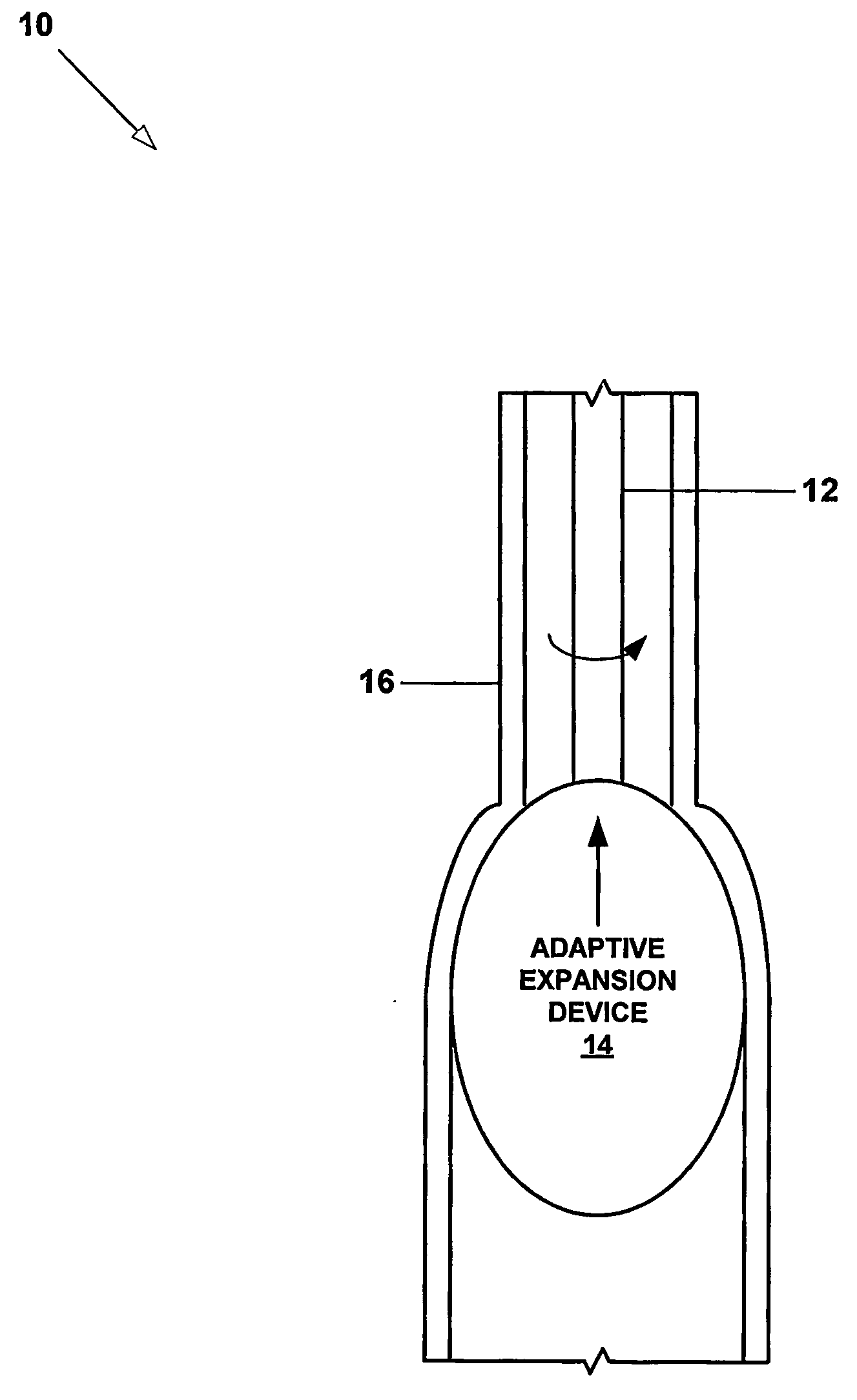

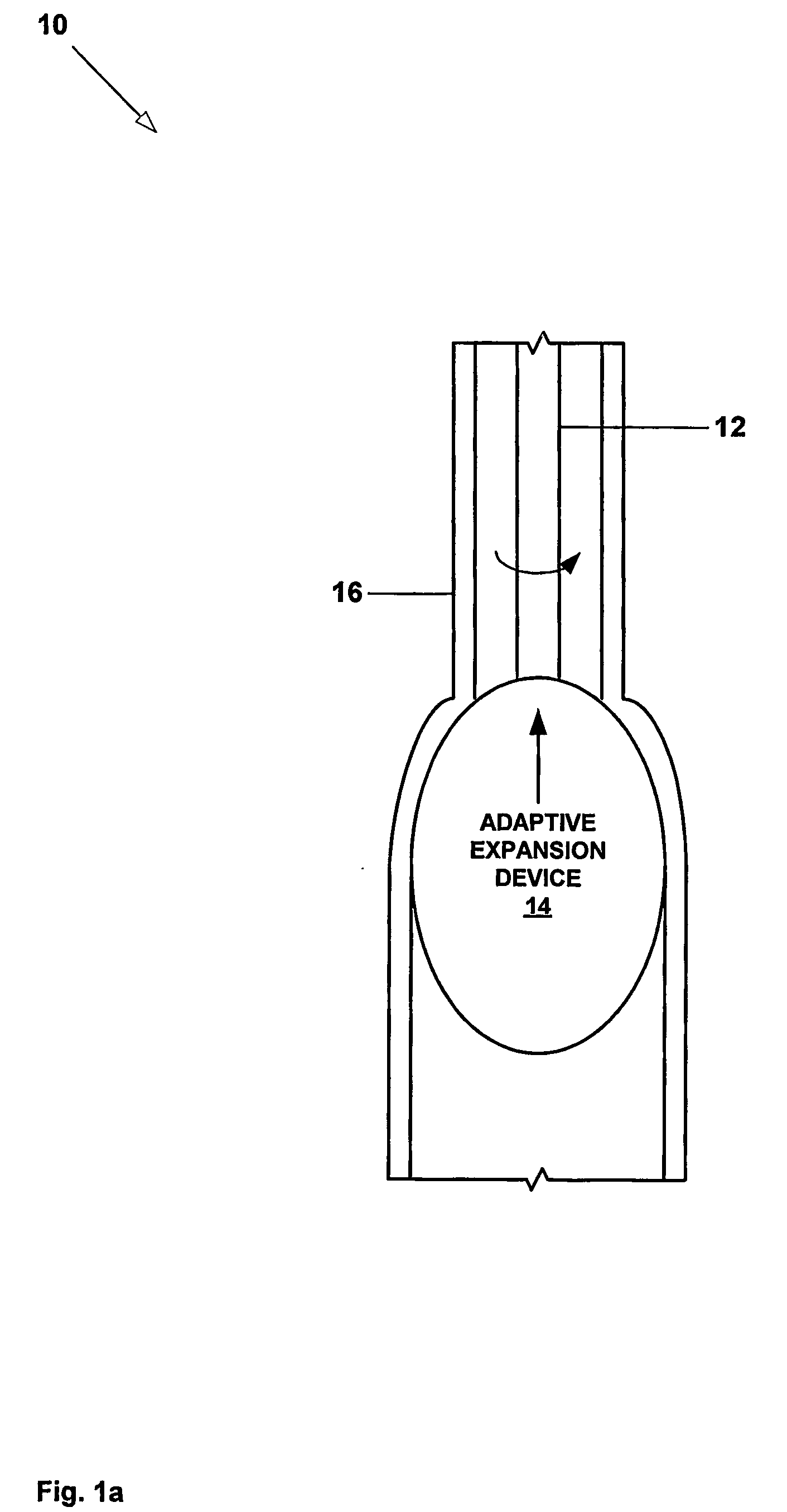

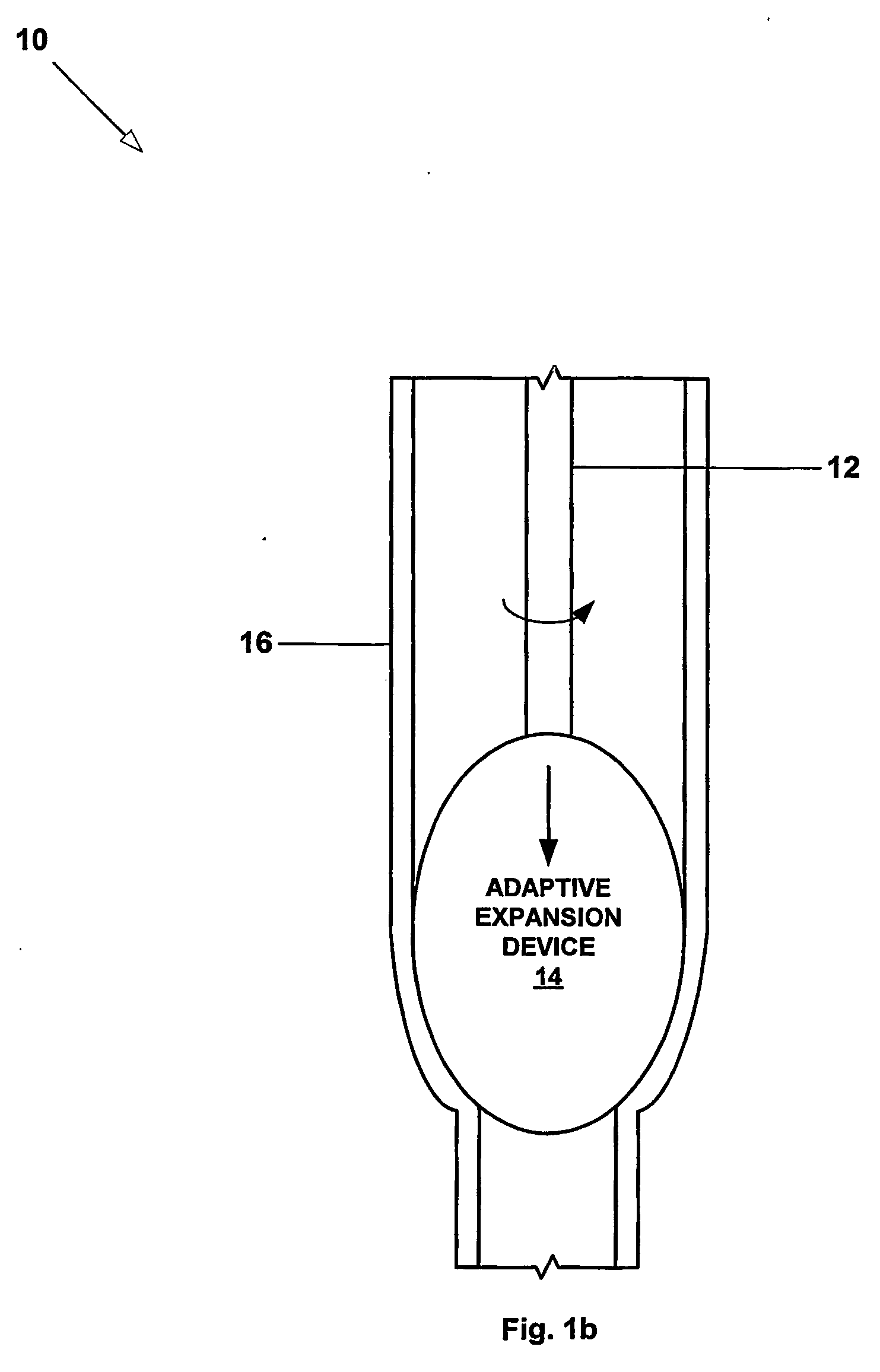

[0027] Referring to FIGS. 1a, 1b, and 2, an adaptive system 10 for radially expanding a tubular member includes a support member 12 and an adaptive expansion device 14. In several exemplary embodiments, the system 10 may be used to radially expand and plastically deform a tubular member 16 by displacing the expansion device 14 in the longitudinal direction and / or by rotating the expansion device relative to the tubular member.

[0028] In an exemplary embodiment, the adaptive expansion device 14 includes one or more expansion device segments 18 for engaging, and thereby radially expanding and plastically deforming the tubular member 16, that are coupled to an expansion device support structure 20 by one or more conventional adjustable spring elements 22 and one or more conventional adjustable damping elements 24. In several exemplary embodiments, the adjustable spring elements 22 and / or the adjustable damping elements 24 are be provided as disclosed in one or more of the following: 1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com