System and method for removing medication from packaging

a medication dispenser and packaging technology, applied in the field of medication dispenser systems, can solve problems such as reducing the usefulness of the apparatus, unable to utilize such automatic packaging devices, and arising problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

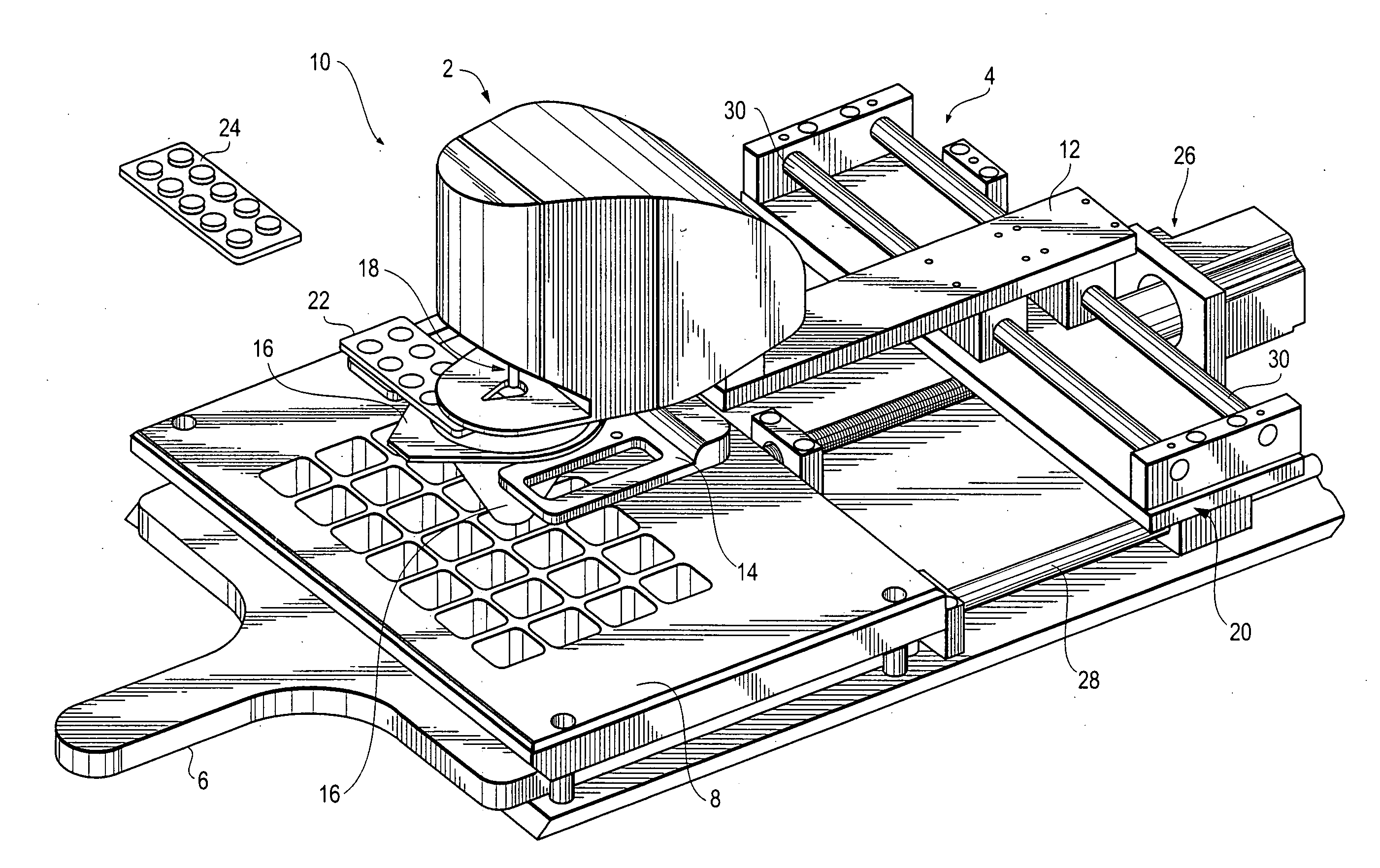

[0020]FIG. 1 illustrates a medication dispenser apparatus 10 according to the current invention. The apparatus is comprised of a de-blister apparatus 2, a positioning mechanism 4, a holding bracket 14, a cantilevered arm 12 for connecting the de-blister apparatus 2 and the bracket 14 to the positioning mechanism 4, a funnel 16 attached to the bracket 14, a sealing paddle 6 which holds a custom pharmaceutical package (not shown), and a templated structure 8 for interfacing between the funnel output and the custom pharmaceutical package. The de-blister apparatus further comprises a plunger 18 for removing individual doses of medication from a target blister-pack. The positioning mechanism includes slide rails 30 to facilitate movement in the x-direction, and slide rails 28 to facilitate movement in the y-direction. Finally, blister packs 22 and 24 are manually or mechanically fed to the de-blister apparatus 2.

[0021] For illustration purposes only, the apparatus in FIG. 1 contains a sc...

second embodiment

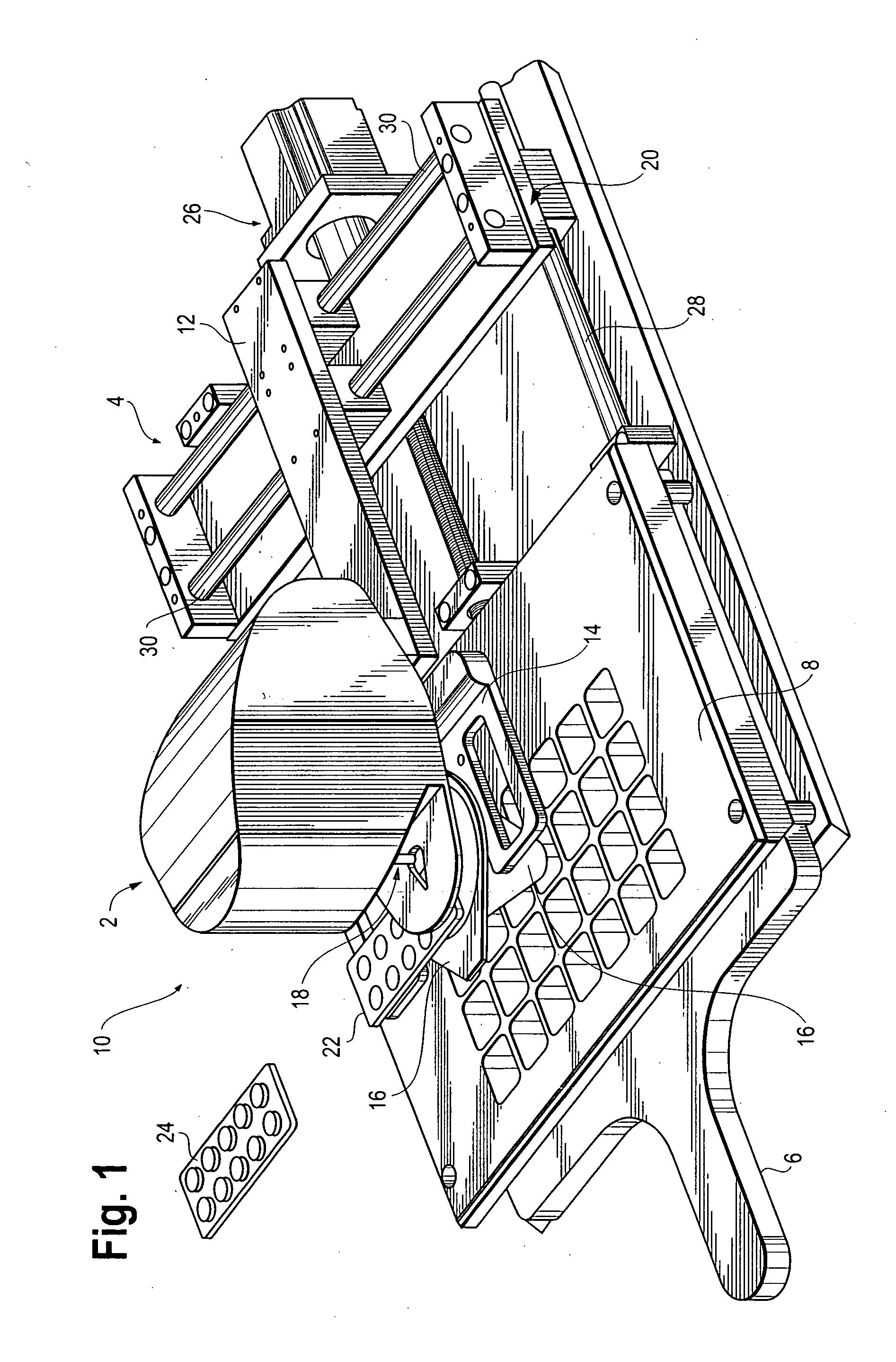

[0023]FIG. 2 shows the instant invention. Reference numbers corresponding to elements disclosed in FIG. 1 have been duplicated. In this embodiment, the pharmaceutical dispensing apparatus is under pure manual control. More specifically, there are no screw-drives in either the x or the y direction. Rather, slide rails 28 and 30 provide for free-movement of the de-blister apparatus 2 under the control of a pharmacist or other such user. In this way, there is provided a mechanism, such as a button or switch, disposed somewhere on the frame of the dispensing apparatus 10 that drives the plunger 18 (not shown in FIG. 2) downward to free a dose of medication from the blister-pack. Accordingly, there is no need to enter dosage information into a control apparatus such as a computer. Rather, the operator can simply feed the blister packs into the apparatus, position the de-blister apparatus over the desired cavity in the template 8, and manually cause the plunger to descend by depressing th...

third embodiment

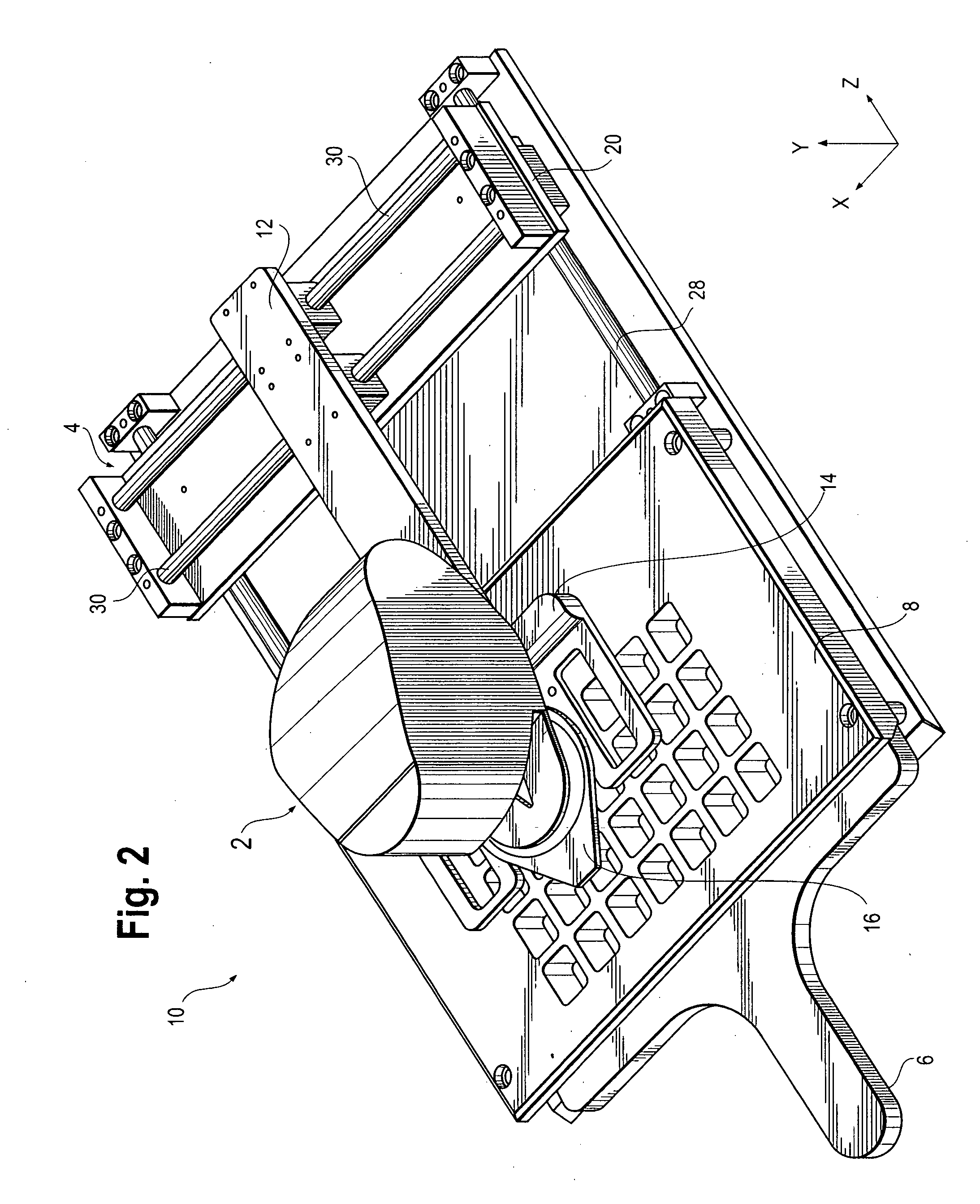

[0024] In the present invention, as shown in FIG. 3, an alternate positioning apparatus 4 is described. As in FIG. 2, reference numbers corresponding to elements disclosed in FIG. 1 have been duplicated. In this embodiment, a pivotable arm comprised of two rigid arm portions 32 and 34 and two pivots 36 and 38 allow the de-blister apparatus to be moved in the x and y directions. Additionally, though not shown, a vertical adjustment portion may be provided to allow the positioning apparatus to be adjusted in the vertical direction (the z-direction). Similar to the above two embodiments, the pivot arm may be manually adjusted by the operator, or may be placed under computer control to automatically dispose of the medication from the blister packs into the corresponding cavity of the custom pharmaceutical package. In addition, the embodiment shown in FIG. 3 is purely illustrative, and the arm may be composed of any number of segments and / or joints.

[0025] In light of the foregoing embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| movement | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com